Exploring Tesla Megapack Integration with Transformer Solutions

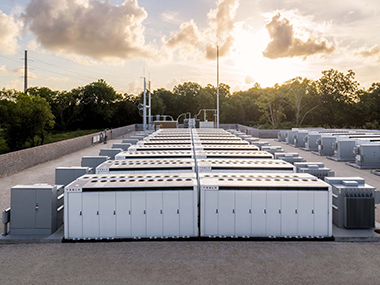

The Megapack, launched by Tesla in 2019, represents a third-generation fixed energy storage product tailored for deployment in battery energy storage power stations. Targeting large enterprises and public institutions, it stands as a highly integrated solution for large-scale energy storage needs. Offering high energy density, rapid charging capabilities, and flexible deployment options, the Megapack seamlessly interfaces with pad-mounted transformers and substation transformers. By harnessing stored excess solar or wind energy, it aids in balancing grid loads, providing supplementary power, and ensuring grid stability. Widely adopted in renewable energy sectors across North America, Europe, Australia, and other regions, the Megapack continues to revolutionize energy storage practices worldwide.

Transformer Manufactuer for Tesla Megapack

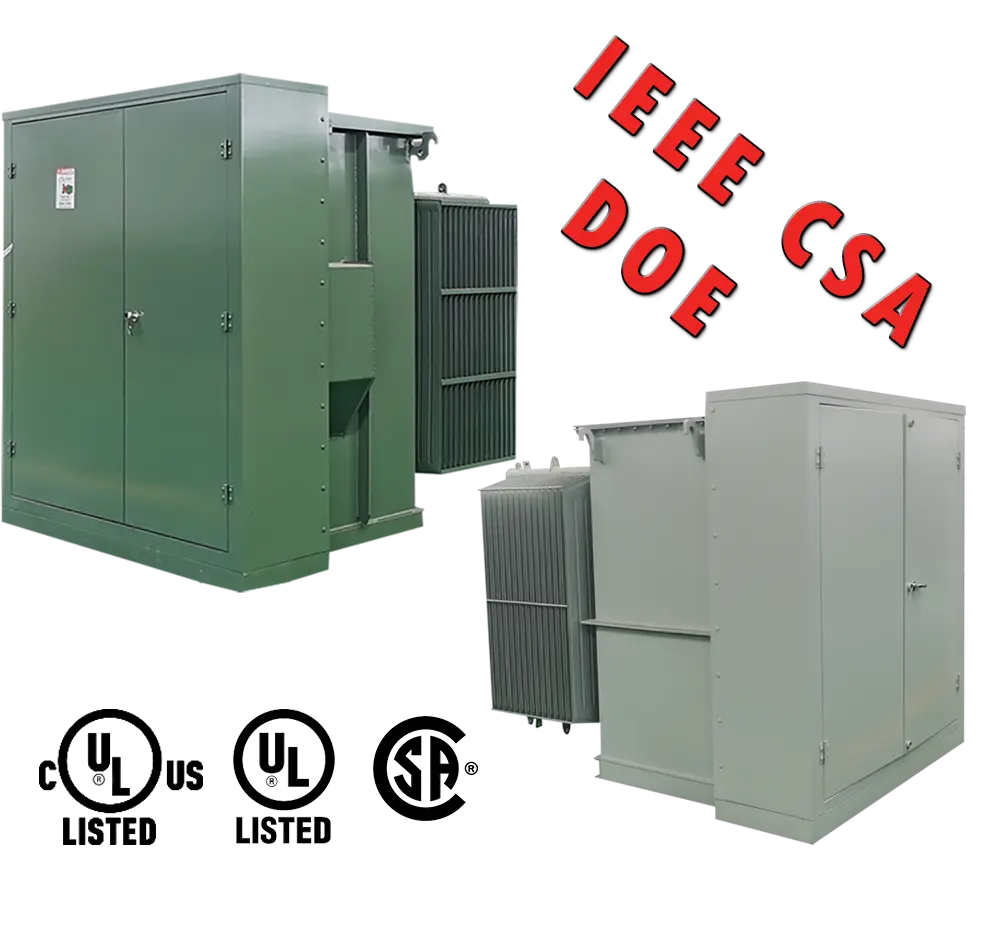

Daelim Transformer is a professional transformer manufacturer, holding full range UL, cUL, and CE certifications. Meet various international design and production standards, such as ANSI, IEEE, CSA, DOE, AS, NZS, IEC, EN, NEMA, etc. Daelim Transformer ensures the highest quality and reliability in their offerings.

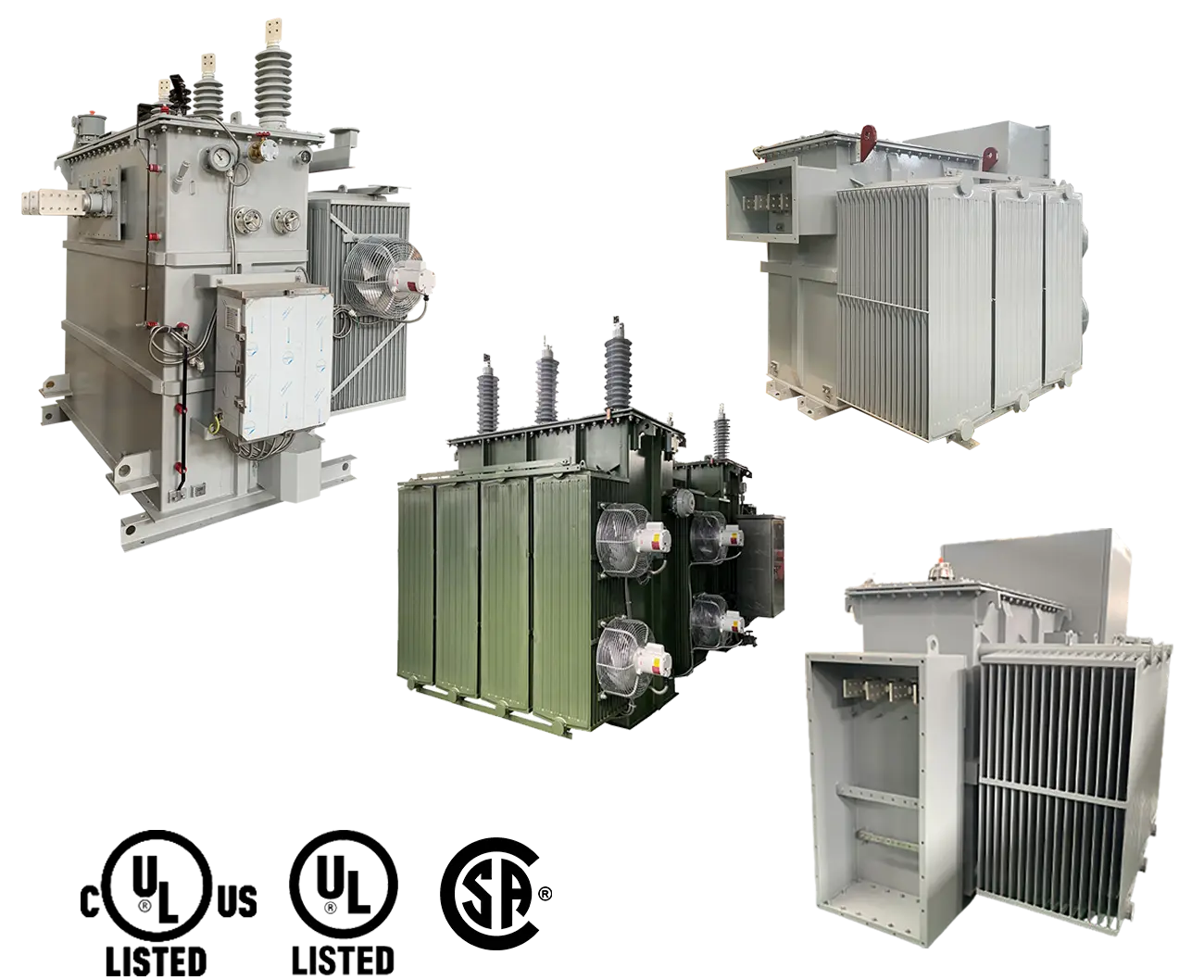

For your Tesla Megapack project, Daelim Transformer provides tailored transformer solutions designed to meet the specific requirements of Battery Energy Storage Systems (BESS). Whether you need pad-mounted transformers, substation transformers, or ecodesign transformers, Daelim Transformer offers the expertise and products to optimize the performance and efficiency of your Megapack system.

Contact Daelim Transformer today to discover how their transformer solutions can enhance the reliability and performance of your Tesla Megapack project.

Contact Daelim TransformerWhat is Megapack?

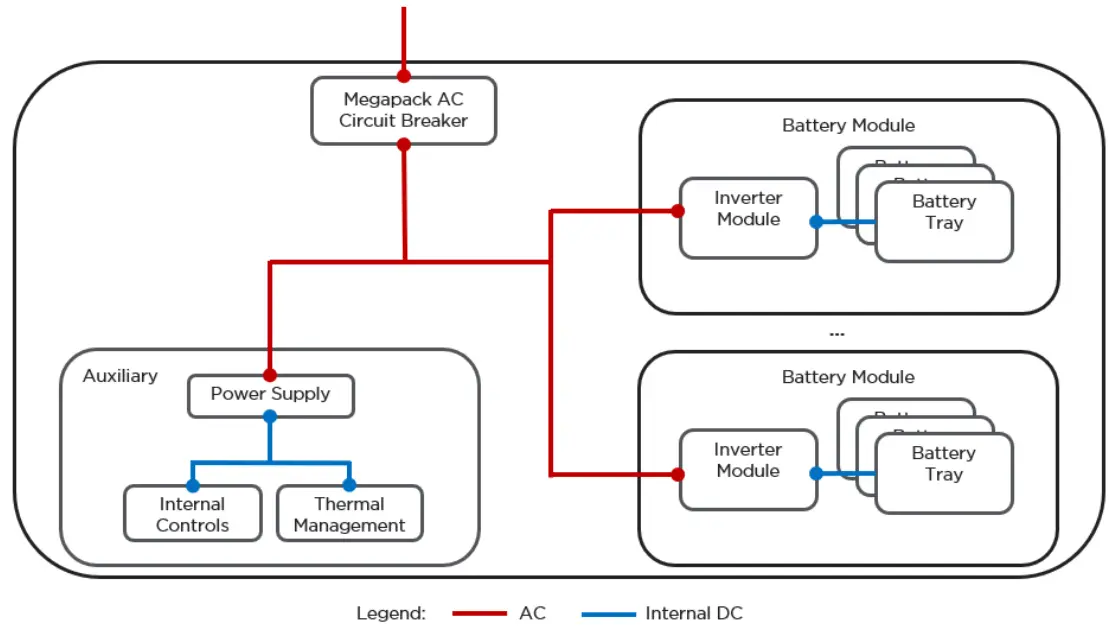

Megapack is a fully integrated battery energy storage unit with the capability to charge and discharge real power, as well as inject and absorb reactive power. It functions by converting power for storage in rechargeable lithium-ion battery modules and is engineered to support a wide range of AC power and energy requirements.

Consisting of powerful lithium batteries housed within a container-like structure, the Megapack serves as a robust storage and energy supply solution. Beyond its role as a lithium battery pack, it incorporates cables, electrical systems, and thermal management systems, among other components. These elements are seamlessly arranged within a white casing and are pre-assembled before shipping. Upon delivery to its destination, installation can be completed within a matter of hours. Primarily catering to public utility projects and large corporate customers, the Megapack represents a comprehensive and efficient energy storage solution.

What is the use of the Tesla Megapack?

The Tesla Megapack serves a crucial role as a large-scale energy storage solution in addressing the intermittent nature of electricity generation, particularly from renewable sources like solar and wind. Due to the mismatch between electricity production and demand patterns, energy storage devices act as intermediaries, storing excess electricity during periods of high production and releasing it when needed. The Megapack functions akin to a massive "power bank," facilitating the storage and deployment of electricity. It can be deployed alongside power generation facilities, at industrial sites, or integrated within the power grid infrastructure to aid in peak regulation and backup power provision. Most commonly used in BESS.

Try for free: Pad Mounted Transformer for BESS System 4.0 MVA in Riverside County, California

Tesla Megapack Applications

Utility-Scale Projects

Tailored for utility-scale projects, the Tesla Megapack offers modular inverter power stages, providing enhanced configuration flexibility. It also supports Capacity Maintenance Agreements (CMA) to ensure consistent performance. Integrating solar PV with DC coupling aligns with Tesla's forward-thinking approach, offering comprehensive solutions for renewable energy needs. Efficiency is paramount in Megapack's design, accommodating up to 24 individual battery modules and adaptable charge/discharge cycles ranging from 2 to 6+ hours. This versatility maintains superior energy density at the site level. With rapid deployment and cost-effectiveness, Megapack delivers up to a 40% reduction in EPC costs compared to Powerpack. Additionally, pre-assembly and testing at the Tesla Gigafactory eliminate the need for on-site DC connections.

Tailored for utility-scale projects, the Tesla Megapack offers modular inverter power stages, providing enhanced configuration flexibility. It also supports Capacity Maintenance Agreements (CMA) to ensure consistent performance. Integrating solar PV with DC coupling aligns with Tesla's forward-thinking approach, offering comprehensive solutions for renewable energy needs. Efficiency is paramount in Megapack's design, accommodating up to 24 individual battery modules and adaptable charge/discharge cycles ranging from 2 to 6+ hours. This versatility maintains superior energy density at the site level. With rapid deployment and cost-effectiveness, Megapack delivers up to a 40% reduction in EPC costs compared to Powerpack. Additionally, pre-assembly and testing at the Tesla Gigafactory eliminate the need for on-site DC connections.

You may enjoy: Ultimate Guide to Utility Transformer

Grid Connection Points

Megapack serves as the grid connection point for solar PV plants through integration with Tesla PV Sidecar. This innovative solution, featuring a 16-input PV combiner box with disconnects and zonal monitoring, eliminates the necessity for a separate PV inverter. By streamlining the power conversion process, Tesla's DC-integrated solution reduces system-level costs and enhances overall site-level efficiency. Megapack's architecture supports a wide range of DC/AC (solar PV) and power-energy (storage) ratios, enabling optimization for various PV plus storage use cases. Integration with a single control system ensures seamless solar PV ramp control and reliable renewable power generation.

Microgrid

Megapack enables the creation of localized grids capable of disconnecting from the main power grid. This feature offers resilience and reliability, particularly in remote or off-grid locations, ensuring uninterrupted power supply even during grid disruptions.

Power Demand Management

Megapack can discharge energy during peak demand periods to support distribution infrastructure, alleviating strain on the grid and reducing reliance on traditional fossil fuel-based power sources.

Infrastructure Support

By storing power at a single location, Megapack can postpone costly grid infrastructure upgrades, offering a cost-effective solution for enhancing grid resilience and reliability.

What is Tesla Megapack capacity?

As for its capacity, each Megapack unit boasts a storage capacity of over 3.9MWh of energy, sufficient to power approximately 3,600 households for one hour. This remarkable capacity makes it a versatile solution for a wide range of applications, from small microgrids to large-scale power projects. With its integrated system design and modular configuration, including battery modules, bidirectional high-efficiency inverters, and thermal management systems, the Megapack enhances construction efficiency and equipment reliability. It can be customized with up to 24 battery modules, offering flexibility to meet diverse project requirements.

Megapack Configuration

Megapack may be configured to meet specific site and project requirements. A fully populated Megapack has the following nominal ratings at 480 V AC.

| Megapack Standard Configurations Ratings | |||

| Megapack Configurations | Apparent Power Capability | Real Power Capability | Energy Capacity |

| 2-Hour | 2400kVA | 1927.2kW | 3854.4kWh |

| 4-Hour | 1320kVA | 979.2kW | 3916.8kWh |

The apparent power capability (kVA) of a fully populated Megapack may be factory-configured to a lower value than the above.

Megapack is capable of configurations other than the standard 2-Hour and 4-Hour configurations. To enable longer configurations, the P### option code is configured such that the power configuration is lower than the available real power from the batteries.

Tesla Megapack Specifications

Tesla offers three standard models of Megapack: Megapack, Megapack 2, and Megapack 2 XL. Below are the specifications for each model.

| Model | Unit Cost | Capacity | Power | Dimensions (W x H x D) | Weight |

| Megapack | $1.24M | 2.6 MWh | 1 MW | (7.168 m × 2.522 m × 1.659 m) | (25,400 kg) |

| Megapack 2 | $1.47M | 3.854 MWh | 1.927 MW | (7.25 m × 2.506 m × 1.637 m) | (30,500 kg) |

| Megapack 2 XL | $1.39M | 3.916 MWh | 979 kW | (8.8 m × 2.785 m × 1.65 m) | (38,100 kg) |

Megapack Standard System Specifications

| Standard System Specifications | ||

| AC Power/Energy Available per Megapack | Roundtrip System Efficiency | |

| 2 Hour Light | 1005.5 kW / 2011 kWh | 0.87 |

| 2 Hour Standard | 1257 kW / 2514 kWh | 0.87 |

| 4 Hour Light | 522 kW / 288 kWh | 0.905 |

| 4 Hour Standard | 739.5 kW / 2958 kWh | 0.905 |

| Nominal energy at 25℃ including thermal management loads | ||

Tesla Megapack 2 XL

The Tesla Megapack 2 XL, also known as Megapack, represents Tesla's latest modular, fully integrated, AC-coupled industrial battery energy storage system (BESS). This latest iteration features a capacity increase from 2.6 MWh to 3.9 MWh, marking a 50% enhancement. Correspondingly, the Megapack's physical footprint has grown by approximately 60%. The dimensions have also been scaled up, with a length increase of 27%, width increase of 3%, and height increase of 17%. Tesla employs LFP (Lithium Iron Phosphate) batteries, significantly reducing production costs.

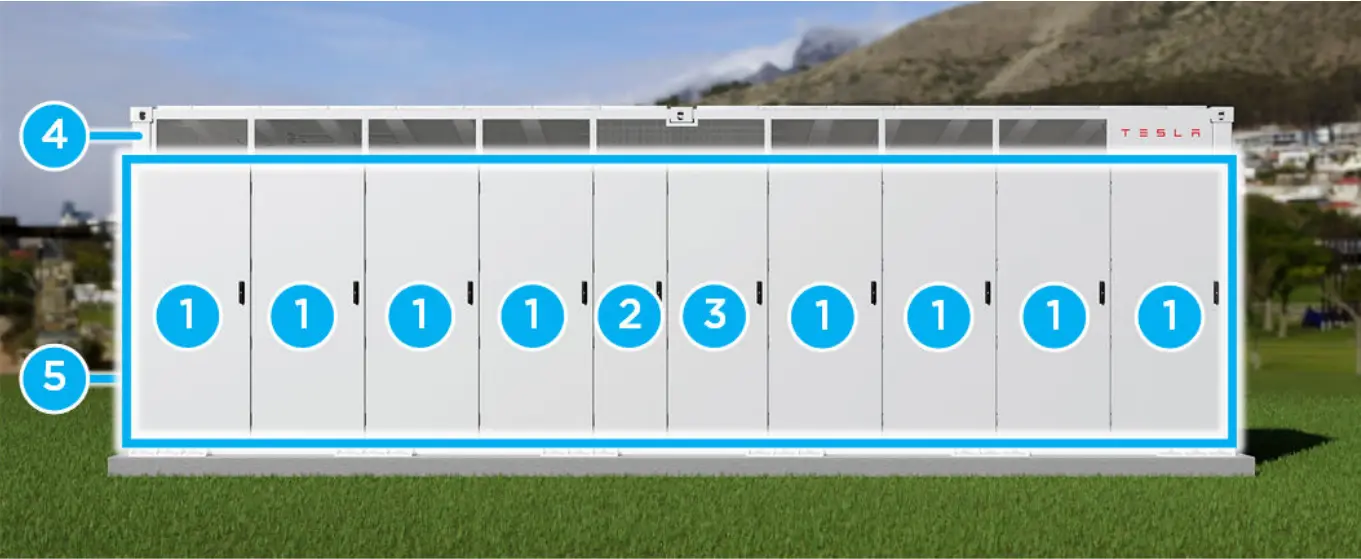

What are the key components of The Tesla Megapack unit?

Battery Module Bays: These bays house the lithium-ion battery modules, which are responsible for storing and releasing electrical energy.

Battery Module Bays: These bays house the lithium-ion battery modules, which are responsible for storing and releasing electrical energy.- Thermal Cabinet: The thermal cabinet contains systems for managing and regulating the temperature within the Megapack unit, ensuring optimal performance and longevity of the batteries.

- Customer Interface Bay: This bay serves as the interface between the Megapack unit and the customer, facilitating monitoring, control, and communication functionalities.

- Thermal Roof: The thermal roof is an integral part of the Megapack's thermal management system, assisting in dissipating heat generated during operation.

- IP66 Enclosure: The Megapack unit is enclosed in an IP66-rated enclosure, providing protection against dust and water ingress, thus ensuring durability and reliability in various environmental conditions.

System Components

A Megapack System consists of the following components:

- One or more Megapacks: Megapack 2 XL – Part number 1848844-XX-Y1

- System Controller: Standard System Controller Enclosure (for sites up to 18 MW) – Part number 1471208-XX-Y1

What components does the Megapack site include?

In addition to the Tesla System Components above, a Megapack site may require other equipment. Typical components include:

- Meters (battery meter required, other meters optional)

- MV Transformers

- Line reactors

- Customer communications networking

- SCADA components

- Water supply

- Maintenance infrastructure

- Switchgear

Get it now: Guide to MV Transformers for Tesla Megapack (North American)

What are the requirements for transformer design for Megapack?

To ensure seamless operation and integration with Megapack, transformers employed at Megapack sites must adhere to precise design standards. These transformers may encompass step-up/step-down transformers, grounding transformers, or isolation transformers. Additionally, they will be utilized at larger Megapack sites to accommodate auxiliary transformers with a capacity of less than 500 kVA.

Here are the key considerations:

Voltage Classification

Megapack sites typically utilize MV (medium voltage) transformers, with voltage classifications ranging from 2 to 35 kV.

Low Voltage Configuration

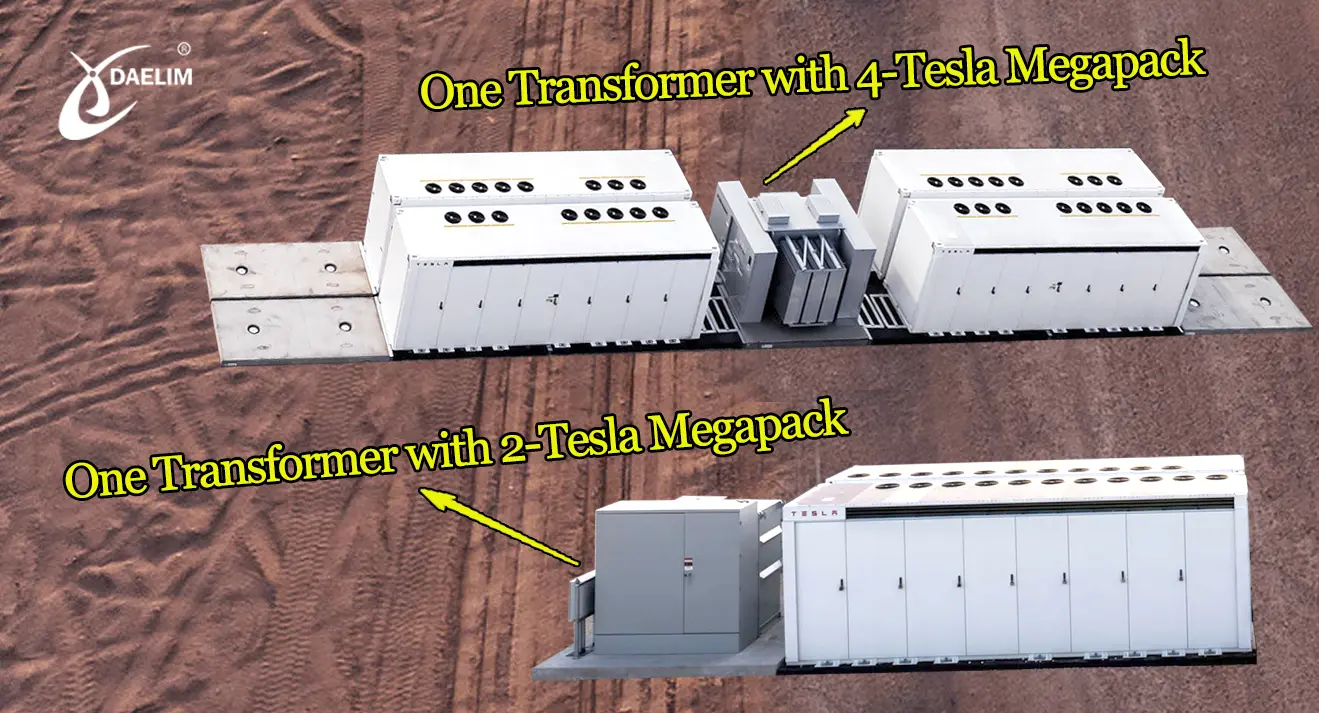

In the 2-hour system, a low voltage is required on one side of the transformer, which can be connected to two Tesla Megapack units. In the 4-hour system, two low voltages are required on both sides of the transformer, resulting in a dual low-voltage design. This design can be connected to four Tesla Megapack units.

Insulating liquid

Transformers need to use degradable vegetable oil with a flash point greater than 300° as the insulating liquid. The cooling system is KNAN.

Color Consistency

Transformers installed at Megapack sites are often painted in colors that match the Megapack's exterior paint color code, which is RAL 9016 Traffic White. This ensures a uniform and visually appealing installation.

Grounding

A solidly grounded circuit is required to ensure that the line-to-ground nominal voltage does not exceed 300 V AC during steady-state conditions. Megapack terminals should be connected to the wye side of the transformer.

Parallel Operation

Customers can parallel multiple Megapacks on a single secondary (low voltage side) winding. One transformer grouped with several Megapacks is called a “transformer block.”

Galvanic Isolation

Megapacks do not require galvanic isolation from each other. Therefore, a standard single winding primary single winding secondary transformer is sufficient for connecting multiple Megapacks. Additional transformer features such as K-factor or shielding are not required.

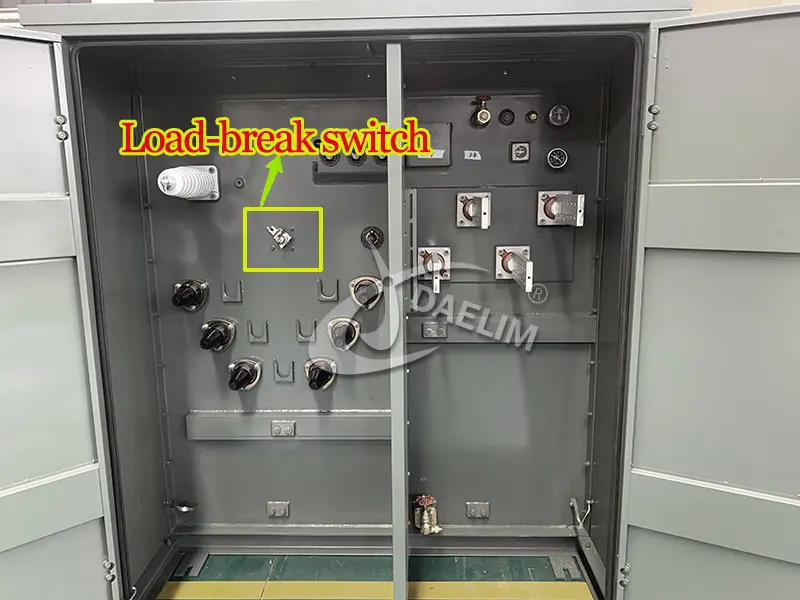

Operations and Maintenance

To enable the isolation and locking of the line-side busbars and cables within the Megapack for maintenance or safety purposes, a load break switch must be installed on either the primary or secondary side of the transformer. This load break switch allows for the disconnection of power flow to the Megapack, ensuring that maintenance can be performed safely.

Load Break Switch

By incorporating a load break switch into the transformer configuration, personnel can visually verify that the Megapack is disconnected from the power source before conducting any work on the system. This enhances safety protocols and facilitates efficient maintenance procedures, contributing to the overall reliability and longevity of the Megapack installation.

Transformer Impedance

The transformer impedance should be at least 5.75% to ensure proper performance.

Learn more: The Impact of Impedance on Transformer Design

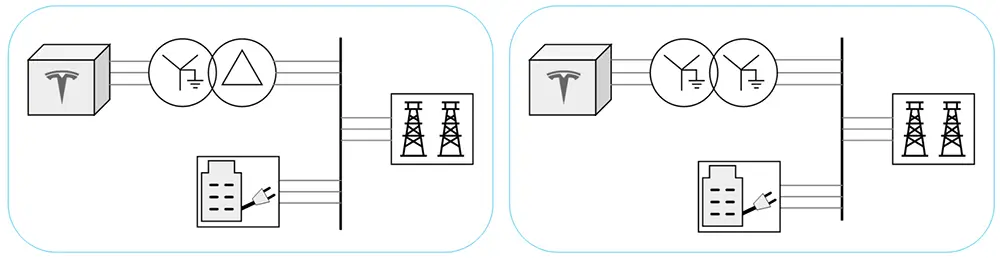

On-Grid and Off-Grid Configurations

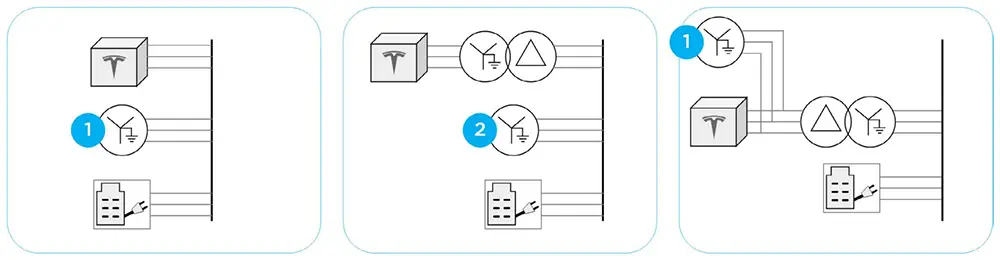

Depending on whether the application is on-grid (grid-following) or off-grid (grid-forming), specific transformer configurations are required.

For on-grid applications, the side of the transformer connected to Megapack must have a wye-grounded connection, while the other side of the transformer may have either a delta or wye connection.

For off-grid applications, the side of the transformer connected to Megapack must have a wye-grounded connection, whereas the other side of the transformer must be a delta connection.

- Grounding Transformer

- Optional Grounding Transformer: An example of a potential system ground source and neutral source for line-to-neutral loads if present. This is not required for Megapack’s proper operation in this example.

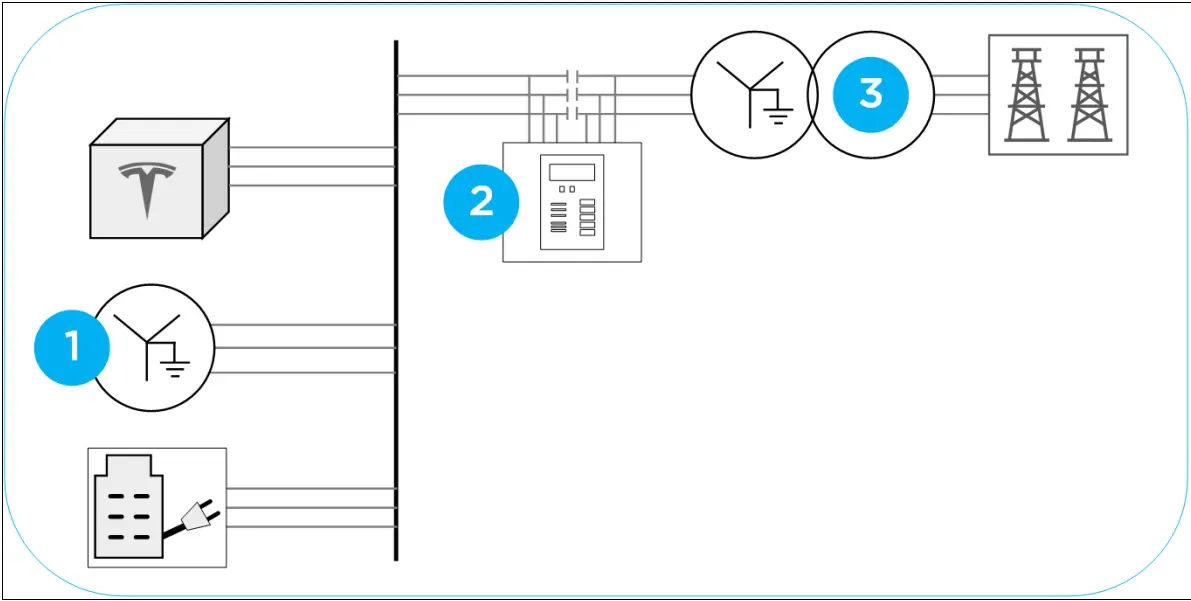

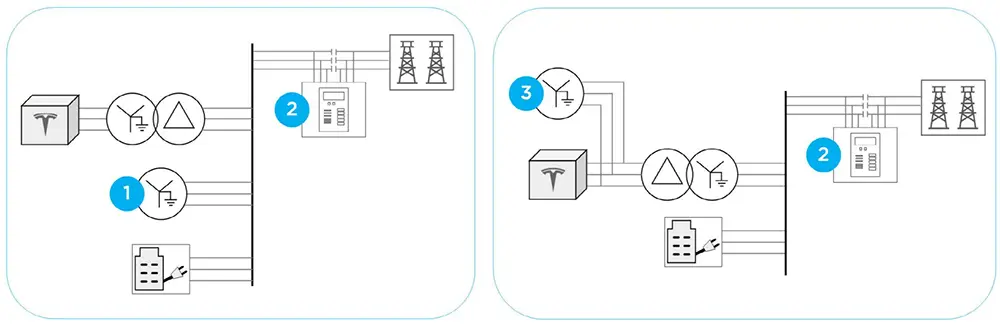

Islanding Configurations

For islanding applications, a solidly grounded circuit is necessary during both on-grid and off-grid operation. Grounding transformers may require disconnection when on-grid, depending on project requirements.

Islanding with a Utility Transformer and a Grounding Transformer

- Grounding Transformer

- Islanding Controller

- Delta or Wye

Islanding with a Step-up/Step-down Transformer

- Optional Grounding Transformer: An example of a potential system ground source and neutral source for line-to-neutral loads if present. This is not required for Megapack’s proper operation in this example.

- Islanding Controller

- Grounding Transformer

By adhering to these transformer design requirements, Megapack installations can ensure efficient and reliable operation within utility-scale projects.

How are Megapack and Transformer connected?

The megapack and the transformer are connected through low-voltage AC conductors, which are routed from the cable tray into the transformer's low-voltage cabinet. There are various methods for connecting the cable tray to the transformer's low-voltage cabinets.

To simplify the installation of low-voltage cables, the transformer may include a removable sill panel at the base of its low-voltage cabinet. This panel can be taken out during the pulling and termination of AC conductors to the transformer's low-voltage terminals, and then reinstalled once terminations are completed. The figure below illustrates an example sill panel with cutouts.

Megapack is designed with two above-ground wireways for routing AC cabling to LV transformer termination and communications cabling. These wireways eliminate the need for on-site trenching construction. Each wireway extends from both sides of the Megapack into the AC bus bar area in the Customer Interface Bay. It's important to ensure that circuits using wireways are designed and installed in accordance with local code regulations.

- 1. Transformer

- 2. Megapack

- 3. System Controller

- 4. Meters

- 5. Customer communications

- 6. AC circuits between the Megapack and transformer

- 7. Communications circuit between Megapack and System Controller

- 8. Communications circuit from System Controller to site meter as applicable

- 9. Communications circuit from System Controller to the battery meter

- 10. Communications circuit from System Controller to customer communication interface

Reading on: The Ultimate FAQs Guide To Transformer Connection

What type of transformer is a perfect match for the Tesla Megapack?

Based on the different regions and their respective transformer preferences for Tesla Megapack, the ideal transformer types include pad-mounted transformers, substation transformers, and eco-design transformers.

In North America, where pad-mounted transformers are favored for their safety, reliability, and ease of installation, they serve as an excellent match for Tesla Megapacks. For instance, at HEA's Soldotna power generation and substation facility, a 93-megawatt-hour (MWh) Battery Energy Storage System (BESS) with 37 Tesla Megapack units is equipped with 19 units pad mounted transformers. Similarly, at the Gambit Energy Storage Park in Newton, Texas, which boasts 81 Tesla Megapacks, 41 units of Pad Mounted Transformers have been installed.

In Europe, distribution transformers meeting ecodesign standards are commonly used, providing compatibility with Megapack systems. For example, the Contego project near Burgess Hill in West Sussex, UK, with a capacity of 34 MW / 68 MWh, has installed 28 Tesla Megapacks and 14 units of 2800 kVA Ecodesign Transformer.

The largest energy storage project in the UK is located at Clay Tye in Essex, boasting an energy storage capacity of 198MWh. The site is equipped with 52 Tesla Megapacks with a 2-hour system. Additionally, the site utilizes 26 units of 4.2 MVA 33kV/480V tier 2 transformers and two 150 kVA 33/415V auxiliary transformers.

In Australia, the preference for MV substation transformers aligns well with the requirements of Tesla Megapack installations. For instance, the Riverina BESS in New South Wales, with a capacity of 150 MW/300 MWh, has installed 212 Tesla Megapacks along with 53 units of Substation Transformer.

Therefore, pad-mounted transformers, substation transformers, and eco-design transformers are considered perfect matches for the Tesla Megapack, depending on the region and its specific transformer preferences.

Related Products

Related Article

2600 kVA Pad Mounted Transformer For Crypto Mine In Kansas

This morning, I received the on-site photos of the pad-mounted transformers from the customer, and I was overwhelmed with excitement and joy. These pad-mounted transformers are installed at a 20MW crypto mining site in Kansas, USA. A total of 5 sets of 2600 kVA pad-mounted transformers, all UL-listed, are being deployed at this site. Currently, 3 sets have already been installed onsite and are scheduled to be powered on imminently.

Guide to MV Transformers for Tesla Megapack ( North American)

As the demand for sustainable energy solutions grows, the Tesla Megapack has emerged as a leading choice for large-scale energy storage projects. Key to the seamless integration of the Megapack is the Medium Voltage (MV) transformer, which plays a critical role in ensuring efficient energy transfer and distribution. This guide aims to provide comprehensive insights into selecting and deploying MV transformers for Tesla Megapack installations in the North American market.

4000 kVA Three Phase Power Transformer For Canada

A Canadian customer has shared photos with us, showcasing the installation and operation of two 4000kVA transformers designed and produced by Daelim Transformer. The transformers have received highly positive feedback from the customers, who found them to be efficient and expressed satisfaction with the collaborative experience working with the Daelim Transformer team. We look forward to further expanding our cooperation with Daelim Transformer in the future.

Pad Mounted Transformer for BESS System 4.0 MVA in Riverside County, California

Today, Daelim Transformer is proud to introduce a pad-mounted transformer for a 4.0 MVA Battery Energy Storage System (BESS) project located in Riverside County, California. The transformer is meticulously crafted to comply with the specifications outlined in the California Electrical Code Article 450.

Three Phase Power Transformers for Bitcoin Mining Facility in Texas!

Daelim Transformer thrilled to share details of our project - the supply of 90 units of three-phase power transformers for a large-scale Bitcoin mining operation in Odessa, Texas. Each transformer is rated at 2500(3000)KVA with a primary voltage of 34.5kV Delta and a secondary voltage of 480GrdY/277. With strict UL certification requirements and a focus on high-quality accessories from reputable brands, this project demanded precision, efficiency, and reliability.

20MVA Power Transformer for the United States

This project involves the development of a 20 MVA three-phase power transformer tailored for the United States market. The primary voltage is 24.94kV, and the secondary voltage is 4.16kV, indicating it functions as a step-down transformer. The design and production fully comply with IEEE C57.12.00 standards and have passed third-party UL team testing. All accessories also adhere to IEEE standards. FR3 vegetable oil serves as the insulating liquid for the transformers.