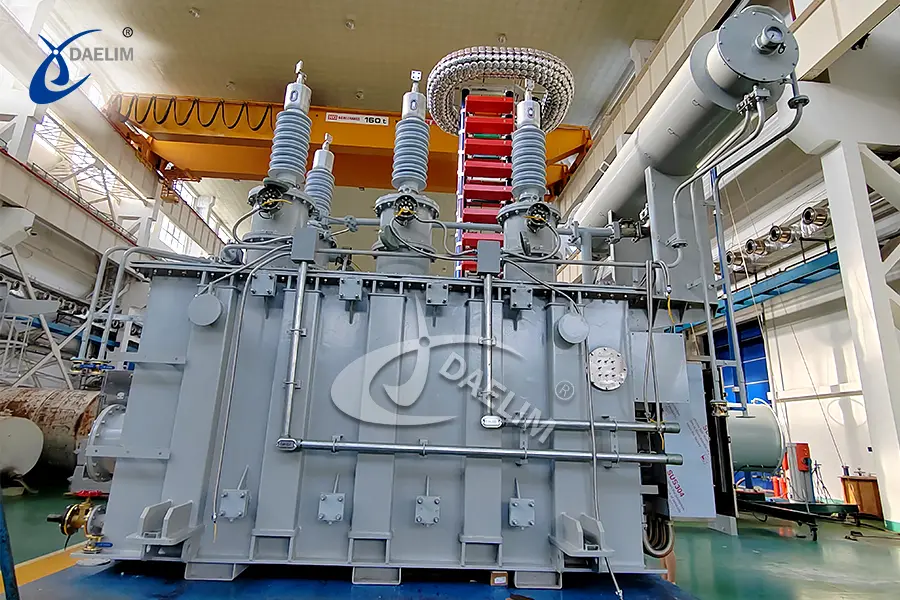

22 MVA 115 kV Oil Filled Power Transformer

- Primary Voltage Ratings: 115kV

- Secondary Voltage Ratings: 6.9kV

- H.V. TAP RANGE: 115 kV ±2×2.5%

- CONNECTION TYPE: YNd1

- BIL: 550/95kV

- Standards: CSA

- Application: Canadian Hydropower Plant

- Power Rating: 22 MVA

- Cooling Method: ONAN/ONAF1/ONAF2

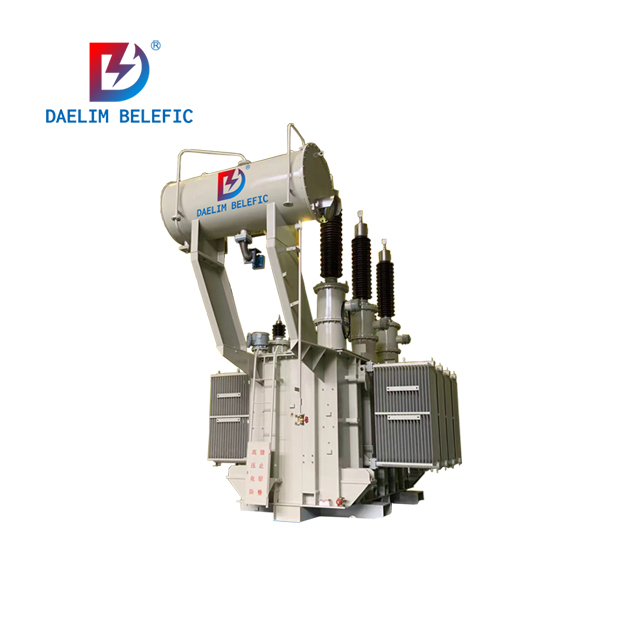

This is a heavy duty 3 phase power transformer designed and developed by Daelim Transformers for a hydropower plant in Canada. It's an oil immersed type power transformer that has been designed and developed for reliable performance in challenging operating environments of Canada. This Power Transformer is featured with high surge withstand capabilities, multiple cooling systems, wide tap range, and compliance with CAN/CSA C88 and other related international and national standards as per Canadian laws. Energy efficiency design and robust manufacturing make it an ideal transformer for applications like the Canada national grid station.

Quote Now

Power Rating

This three phase power transformer offers three different power rating operations. This is specially needed when the transformer is being designed for an application like power generation setup like a hydropower plant where power generation capacity and load capacity both change.

The transformer offer power ration of

- 12.5 MVA

- 16.5 MVA

- 22 MVA

Three different power ratings has one specific voltage value for all but three different current values (one for each rated power rating). The power rating of 12.5 MVA works here as the base line.

Send Inquiry Now

22 MVA 115 kV Oil Filled Power Transformer

Voltage and Current Rating

Voltage regulation is a key aspect of power reliability, so this transformer is designed with a 5 position tap changer on the high voltage winding side, allowing adjustment of voltage from 109 kV to 120 kV. This is highly important for applications like transmission grid and to facilitate the precise control over primary side voltage.

| Winding | Voltage | Configuration |

| HV | 120/117/115/112/109 kV | Wye (grounded) |

| LV | 6.9 kV | Delta |

Tap positions are as follows.

| Tap Position | Voltage (V) | Current @ 12.5 MVA (A) | Current @ 16.5 MVA (A) | Current @ 22 MVA (A) |

| 1 | 120,750 | 59.8 | 78.9 | 105.2 A |

| 2 | 117,875 | 51.2 | 80.8 | 107.8 A |

| 3 | 115,000 | 62.8 | 82.8 | 110.4 A |

| 4 | 112,125 | 64.4 | 85.8 | 113.3 A |

| 5 | 109,250 | 66.1 | 87.2 | 116.3 A |

On the low voltage winding side, the transformer delivers 6.9 KV of voltage for all three power ratings with different current ratings. This ensures that the required output is delivered reliably under all operating scenarios.

| Voltage (V) | Current @ 12.5 MVA | @ 16.5 MVA | @ 22 MVA |

| 6900 | 1045.9 A | 1380.6 A | 1882.7 A |

Internal Current Transformers

The transformer is also designed with a built-in current transformer for accurate monitoring, protection, and metering. Multiple ratios offer flexibility in current sensing across both the high and low voltage sections. These CT conform to C100 and C200 accuracy classes that ensure precision in protection replat operations and systems.

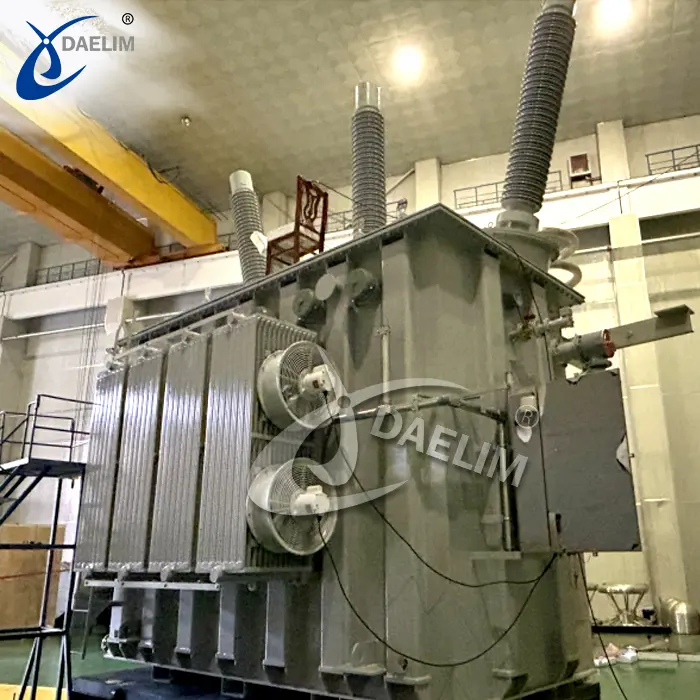

Cooling System

The transformer is designed in a manner that it can utilize three different cooling mechanisms based on the power rating and load requirement. The transformer has one ONAN cooling system designed with fins on the transformer tank and two ONAF systems. One ONAF system is for when power rating is moderate and both ONAF systems are used when the transformer is operating on maximum power.

| Cooling Method | Rated Power Output |

| ONAN | 12.5 MVA |

| ONAF-1 | 16.5 MVA |

| ONAF-2 | 22 MVA |

The transformer uses about 8000 Kgs of mineral oil for the transformer cooling system. Sealed inside the transformer tank and work based convection mode of heat transfer.

Weight of Transformer

Each part of the transformer is precisely designed for balance between weight and structure integrity. Weight of each part is mentioned below in kg and combined weight of the transformer when fully assembled and when transported is mentioned separately.

| Component | Weight |

| Tank & Fittings | 8,900 kg |

| Transformer oil | 8,000 kg |

| Core & Coils | 14600 kg |

| Transport Weight | 27,500 kg |

| Total Weight | 32,500 kg |

Engineering Design

This power transformer is very carefully designed for reliability, safety, and efficiency due to the nature of its application. Some common features are as follows.

- Transformer winding is made from highly quality and pure copper material ensuring that no material defect is present in copper before and after winding of the transformer is done.

- Similarly the core of the transformer is very carefully sized, designed, and manufactured using highest standard steel sheets to ensure quality manufacturing.

- The transformer tank design, size, and manufacture is done to ensure reliability in the extreme environmental conditions of Canada where temperature can go well below zero.

- Transformer tank surface is heat treated and coated with rust resisting materials to increase the life of the tank in outdoor applications.

- All types of safety devices like thermal sensors, surge arrestors, lightning arrestors, transformer grounding etc are installed with IoT integration for remote monitoring and control.

- Oil use in the transformer is free from PECs at the time of delivery and operationalization.

- YNd1 vector group offering delta wye transformation with a 30 degree phase shift. This is considered perfect for grid balancing and synchronization.

Compliance and Safety

The power transformer designed and developed by Daelim Transformers can satisfy all international standards as we follow each and every standard procedure during transformer design and manufacturing.

Some of the basic standards that our transformer satisfies are mentioned below.

- ANSI / IEEE C57.12.00 for general power transformer requirements

- ANSI / IEEE Std.32 standard requirements and testing procedure of transformers

- CAN/CSA C22.2 No.94 special purpose enclosures

- CAN/CSA C88 Power Transformer standards

- IEEE C62.82.1 standards for insulation coordination

- IEEE C62.11 and IEEE C62.22 standard for metal oxide surge arresters and alternating current system

Applications

Power Transformer of this specification can be used in application including

- Hydroelectric power plant

- National Grid Stations

- National grid substations

- Diesel Generator power plants

Why Choose Daelim?

Having a team of engineers that has decades of experience in designing, manufacturing, assembling, testing, transporting, installing and operationalizing electrical transformers make Daelim a prominent name in the electrical transformer world.

Our team has already completed hundreds of projects all around the globe and we offer quality services like no other. We combine

- Custom engineering and CAD based simulation to ensure efficient designing of transformer parts

- Full pre and post shipment testing as per international standards

- Complete network of expert global logistics and support for transformer supply and installation.

- Compliance with IEEE, UL, CSA, and IEC standards

Request a Quote

If you need any help related to power transformers, then contact us and we will be happy to help you in your power transformer sizing, specs, and shipment.

Related Products

Related Article

230 kV Three Phase Power Transformer For USA Market

In 2023, Daelim Transformer designed and manufactured a cutting-edge 230 kV three-phase power transformer for a client in Nevada, USA. The client recently shared installation and operational photos, showcasing the successful deployment of this remarkable transformer. Let's delve into the specifics of this transformer project!

Canadian 69 kV Substation Transformer Project

Today, we are excited to present a case study on a 69 kV substation transformer project by Daelim Transformer. Our Canadian client required a step-down transformer for their substation to connect with the hydroelectric grid in Quebec.

2000 kVA Oil immersed Substation Transformer For Portugal Market

Today, we introduce Daelim Transformer's export of a 2000 kVA oil-immersed substation transformer to Portugal. This transformer represents our commitment to delivering high-quality electrical solutions to global markets. With meticulous design and engineering, this transformer is tailored to meet the specific needs of our customers in Portugal, ensuring reliable performance and efficiency. Daelim Transformer continues to uphold its reputation for excellence, providing innovative solutions that power progress and reliability worldwide.

13.8 kV 10.5 MVA Substation Transformer for Ecuador

A customer from Ecuador contacted Daelim Transformer for a 10.5MVA substation transformer (13.8kV high voltage, 2.4kV low voltage). Daelim Transformer provided a customized solution, conducted virtual factory tours, ensured rigorous quality control via video inspections, and offered post-delivery online training and ongoing support, fostering a successful partnership.

Pad Mounted Transformer For High Voltage Substation

FWS commissioned Daelim Transformer to design and manufacture a new high voltage substation for the Richardson International Canola Crush facility expansion in Yorkton, SK. The project required two specially designed top-in pad-mounted transformers, one 2 MVA and one 5 MVA. Unable to meet the delivery deadline, local North American suppliers led FWS to choose Daelim Transformer for their capacity and quality. The transformers were successfully produced and delivered within 16 weeks and are now operating safely.

69 kV Power Transformer for Substation in Pennsylvania

Daelim recently completed the design, supply, and installation of a custom 69 kV transformer for a substation in Pennsylvania. This high-efficiency, three-phase transformer is engineered for reliability, scalability, and long-term performance, ensuring a stable power supply to the substation. Key features include low load losses, minimal maintenance, high insulation levels, and flexible cooling options. The solution enhances grid stability, supports future expansion, and minimizes energy consumption, reinforcing Daelim’s commitment to quality and innovation in power systems.