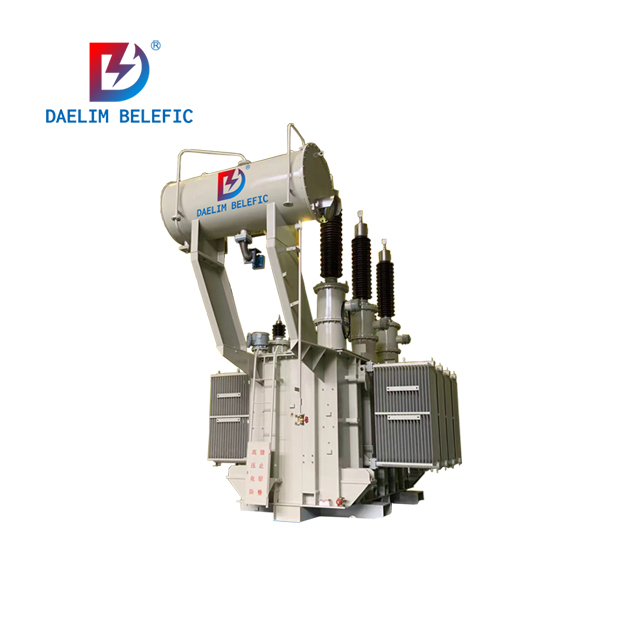

Power Transformer

DAELIM Transformer

• Prompt preparation of bids

• Optimized, consistent end-to-end project management

• Noticeably shorter production and delivery times

• Very high delivery reliability

• Fast, standardized documentation

• Just-in-time delivery

Power Transformer

Daelim’s power transforemrs are accordling to ANSI/EEE,IEC,CSA,AS as well as NEMA standards, The power ratings are up to 500 MVA and for volumes up o the highest insulation class of 1200 kV. There are a large number of project cases in North and South America, such as: 230kv power transformer in the United States, 115kv power transformer in Mexico, 66kv power transformer in Canada, 69kv, 110kv power transformer in Ecuador, etc. The local service team can provide installation, maintenance, after-sales guidance and other services for your transformer. Quick solution to your problem.

Power Transformer manufacturer

Daelim Transformer, a UL, cUL, and CSA certified power transformer manufacturer, adheres to global standards such as ANSI/IEEE/IEC/CSA/AS and NEMA. They offer transformers with ratings up to 500 MVA and voltage up to 345 kV. Daelim excels in providing innovative electrical transformer solutions, prioritizing safety and sustainability while meeting rigorous standards.

Each transformer is uniquely designed, considering factors like voltage, power rating, climate, and network topology. These solutions prioritize efficiency, eco-friendliness, high short-circuit strength, overload capacity, high-temperature operation, reliable startup during outages, and cost-effective maintenance. Their applications span renewable energy, urban substations, utilities, and industrial sectors.

Contact Daelim TransformerDaelim Transformer

At Daelim Transformer:

- Swift and efficient bid preparation

- Streamlined, end-to-end project management optimized for consistency

- Markedly reduced production and delivery lead times

- Exceptional delivery reliability

- Expedited, standardized documentation

- Punctual, just-in-time delivery

Daelim Transformer stands as a trusted partner, offering innovative and efficient power transformer solutions tailored to meet unique demands.

Send Inquiry Now

Power Transformer Desing Capability

Design Tools : SOLIDWORKS(3D) / AUTOCAD

Equipment : 3F/2F/1F Multi-winding Transformer / Autotransformer

Standard: ANSI-IEEE /CSA/EN/BS/GOST/AS, IEC

Design: Sealed-tank system /Inert-gas pressure system or conservator-tank system without diaphragm; On load or no load voltage tap changer

Cooling system: ONAN/ONAF/ODAF/OFAF/OFWF/KNAN/KNAF

Insulation: Mineral Oil Inhibited I Not Inhibited I Vegetable oil

Primary voltage: Up to 230kV, up to 900 kV BIL

Capacity: Up to 270 MVA Frequency: 50/60 HZ

Power Transformer Operating Condition

Suitable for indoor and outdoor application.

Ambient temperature: - 50℃-40℃

Relative humidity: ambient air relative humidity should be below 93%,

Altitude: ≤1000m

Max wind speed:≤35 m/s

Earthquake acceleration: horizontal acceleration ≤0.3g

Vertical acceleration ≤0.15g

Special conditions: customized products are available.

Get Price

Daelim Transformer Overseas Projiect Cases

66 kV 12 MVA Power Transformer

Location: British Columbia, Canada

Quantity: 3 units Standards: IEEE & CSA

Special applications: Need to step down 66kV to 12.47kV, then connect to 4 units of 3MVA pad-mounted transformers to supply power for blockchain machines.

Accessories: Some of the accessories need to be explosion-proof, and customer have special requirements for gauges and valves.

230 kV 10 MVA Power Transformer

Location: Nevada, USA

Quantity: 1 unit Standard: IEEE

The primary voltage is 230 kV, while the secondary voltage is 24.94 kV. This 230 kV transformer is capable of providing power ratings of 10 MVA, 12.5 MVA, and 15 MVA under various cooling methods.

It is designed with a KNAN/KNAF/KNAF configuration, and it utilizes vegetable oil as the insulating liquid.

66 kV 15 MVA Power Transformer

Location: Australia Application: Solar Farm

Standards: AS & IEC Power rating: 12.5 MVA/15 MVA

Primary voltage: 66 kV Secondary voltage: 33000Y/19052V

69 kV 10 MVA Power Transformer

Location: Quebec, Canada Application: 69 kV Substation

Standards: IEEE & CSA Power rating: 10000/13300kVA

Primary voltage: 69 kV Secondary voltage: 4.16 kV

138 kV 40 MVA Power Transformer

Location: Guayaquil, Ecuador Application: Substation

Standards: IEEE Power rating: 40 MVA

High Voltage: 138 kV Low voltage: 34.5 kV

115 kV 20 MVA Power Transformer

Location: NUEVO LEÓN Mexico Application: Substation

Standards: IEEE Power rating: 20 MVA

High Voltage: 115 kV Low voltage: 13.8 kV

Daelim Power Transformer

Optional Accessories

Junction Box Fiber-optic temperature measurements

Neutral Terminals Other Moving Facilities (Wheels)

Rapid Rise Relay Nitrogen gas fluid preservation system

Electrostatic shield Special / low sound level Schrader Valve

Special environment Special paint for marine ambient Gas Test Valve

Line Dissolved Gas Monitor Bushing Mounted Current Transformers

Fire Prevention System (SERGl) On-line monitoring system

High ambient designs available High elevation designs available

Optional Accessories

Insulating oil: Natural ester( FR3 Enviro Temp, RAPO etc) Fans

Cooling: ONAN/ONAF, KNAN, KNAN/KNAF Frequency: 50 Hertz

Average winding rise: 55°C or 55/65°C Future fan wiring and control

Automatic pressure relief device Galvanized or stainless-steel radiators

Accessories with additional contacts Controls Cabinet: NEMA 3R, 4, 4X

Customizable Colors Harmonic allowances up to k-20

Station Class Seismic designs: Zones 1-4

HV lightning arresters: Distribution Class, Intermediate Class

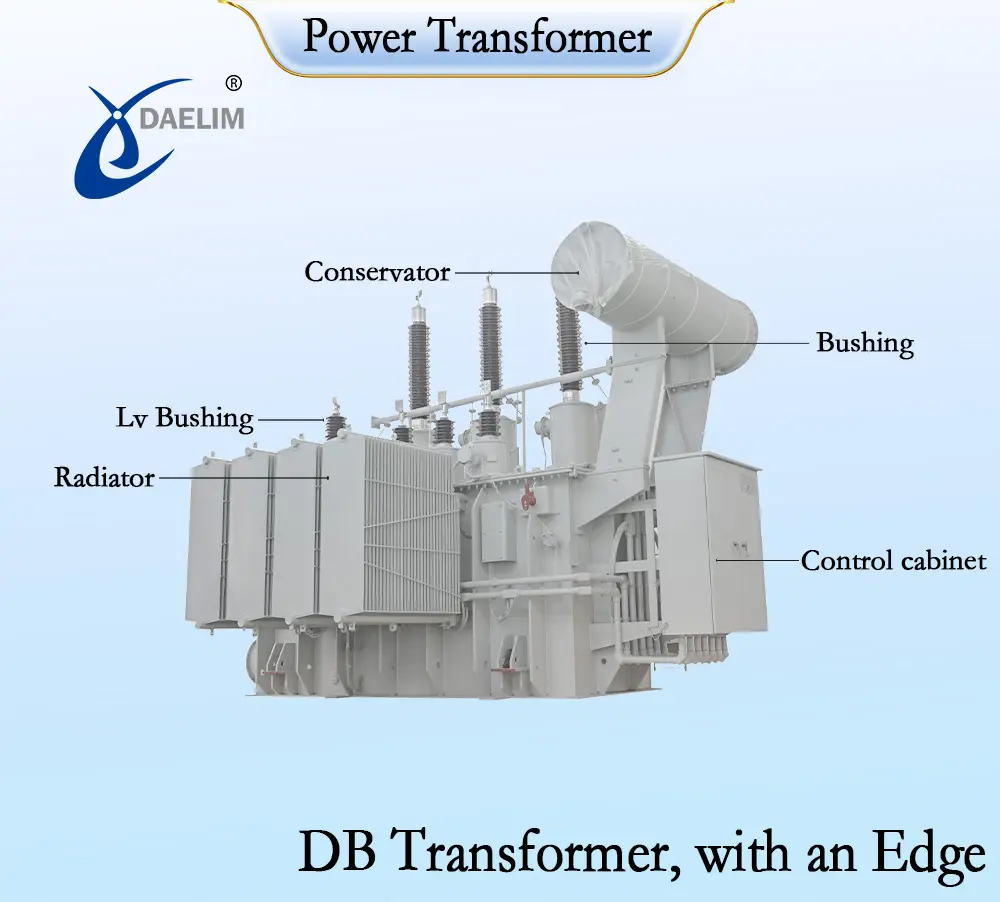

Power Transformer Standard Features

Capacity range: Through 60 MVA (ONAN), with high-voltage ratings through 230 kV (900 kV BIL)

Service Location: Outdoor Coils: Cylindrical construction;

Core: Regular grain-oriented; mitered cruciform with step-lap construction

all copper windings; custom tempered per design requirements; circular windings with rectangular or continuously-transposed conductor; helical low-voltage windings; continuous disc medium-voltage windings; shielded disc high-voltage windings Radiators: Detachable panel type with shut-off valves, mild steel

Insulating oil: Mineral oil type I & type Il Tank Cover: Welded, Bolted

Manholes: On cover or tank Tank Base: Flat bottom or Skid under base

Tank Material: Mid Steel Frequency: 60 Hertz

Winding Tem rise: 55C

HV Taps: DETC, ETC in the tank or out

- Above rated volts: 2 x 2-1/2% offload taps of full capacity

- Below rated volts: 2 x 2-1/2% offload taps of full capacity

Valve: Drain and Filter Valves, w/Sampler Lifting, Moving, and Jacking Facilities

Pressure relief valve Magnetic oi-level indicator

Dial-type oil temperature indicator Dial-type winding temperature indicator

Dial-type sudden pressure relay Pressure vacuum gauge

Paint: Exterior polyurethane enamel, ANSI 70 gray color; interior polyurethane enamel, white color

HV bushing: IEEE segment 1-4, on the top cover or in the Air Terminal Chamber.

Porcelain Condenser, Solid Bulk.Solid Dielectric, Quick link

LV bushing: IEEE segment 1-4, Cover mounted or in Air Terminal Chamber Porcelain Condenser, Solid Bulk. Solid Dielectric, Quick link

Diagrammatic nameplate, engraved stainless steel

Transformer lifting lugs Tank grounding pads

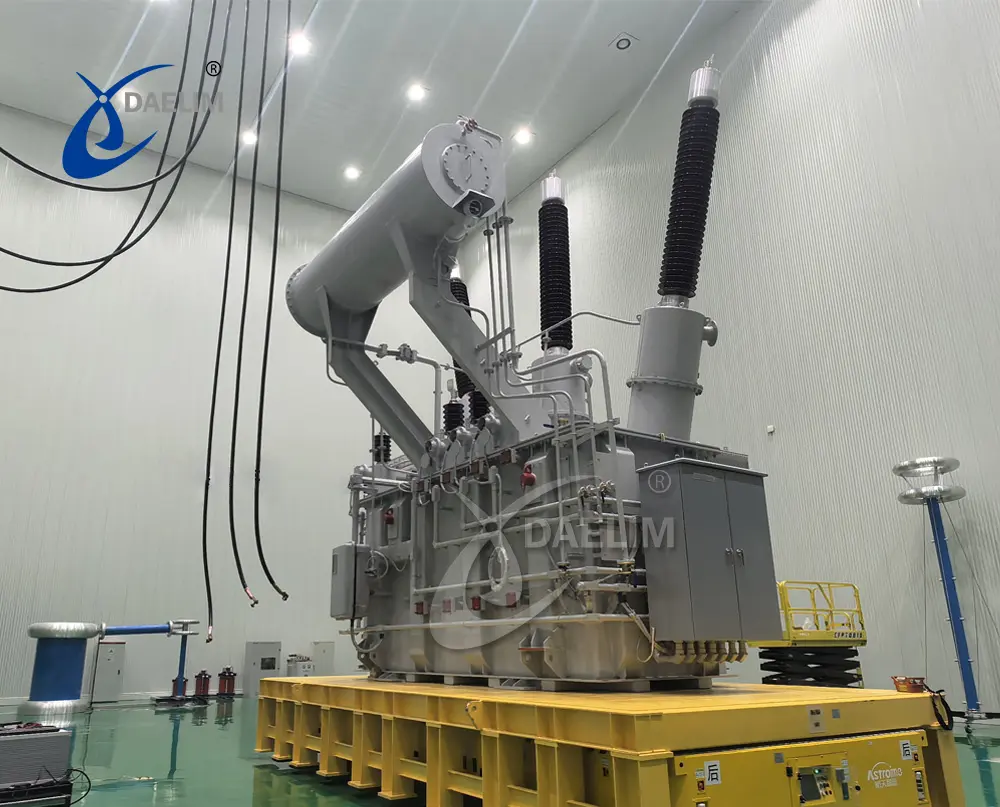

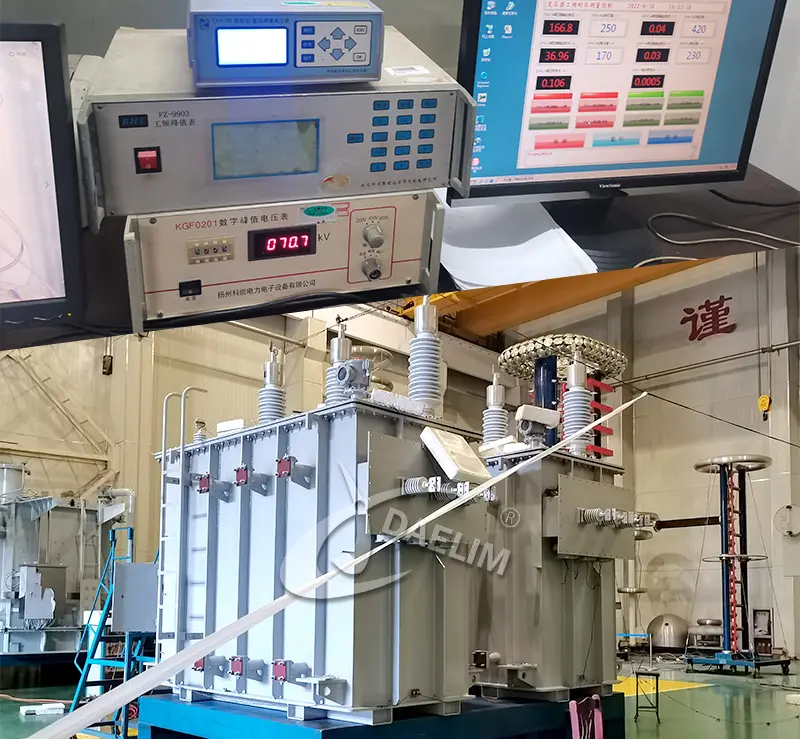

Routine Tests

Routine tests, also known as factory tests, are essential for ensuring the quality of every transformer. These tests include:

- Dielectric tests

- Measurement of Voltage Ratio and Vector Group

- Measurement of Winding Resistance

- Separate-Source Power-Frequency Voltage Withstand Test

- Measurement of Bushing Capacitance and Dielectric Dissipation Factor

- Induced Voltage Withstand Test

- Measurement of No-load Losses and No-load Current

- Measurement of Impedance Voltage and Load Losses

- Sealed Test

- Measurement of the winding frequency spectrum response curve

- Current transformer test

- On-Load Tap Changer (OLTC) tests

- Measurement

- Oil test

Type Tests & Special Tests

Type Tests

Type tests verify if a transformer meets specified standards and whether products of the same type or series meet these standards. Type test items include:

- Temperature rise test

- Lightning impulse test

Special Tests

Special tests are conducted as mutually agreed upon by the manufacturer and the user. Special test items encompass:

- Transient voltage transfer characteristics measurement

- Three-phase transformer zero-sequence impedance measurement

- Short-circuit test

- Sound level measurement

- Measurement of harmonic currents during no-load

- Measurement of power consumption by fans and oil pumps

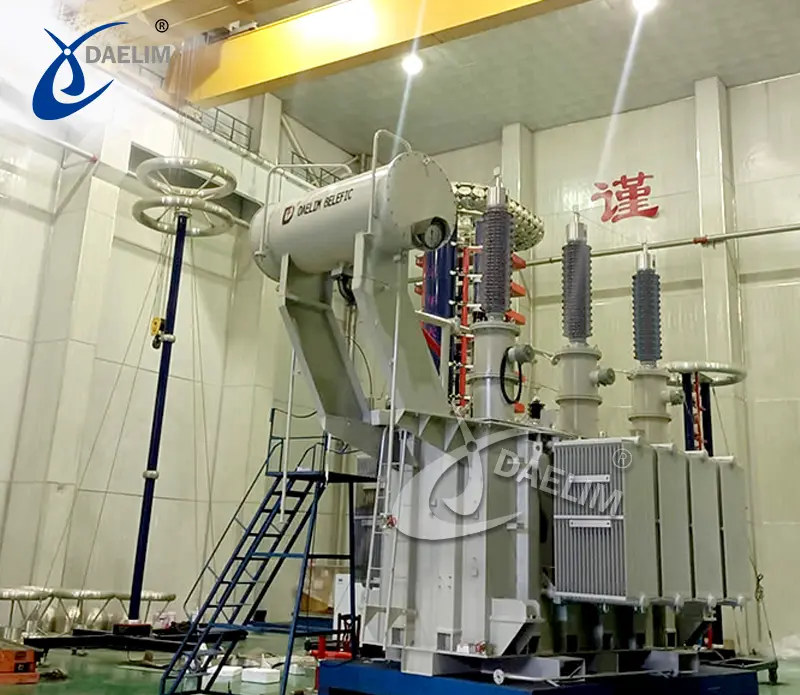

Core Assembly & Coil Winding

Core Assembly:

The iron core consists of cold-rolled, granular-oriented silicon steel sheets known for their low loss and high magnetic conductivity. These sheets are structured in multiple steps with a complete tilt to minimize both loss and noise. Fixed clamps are applied to the iron core to enhance mechanical strength and reduce leakage losses. The addition of a PET banding structure further reduces noise and ensures the core column's stability.

Coil Winding:

For the high-voltage (HV) winding, the adoption of an entanglement or inner-screened continuous design with a phase insulation structure guarantees robust insulating strength. The medium voltage (MV) and low voltage (LV) windings use high-strength conductors or conductor transposition and incorporate forced cooling to reduce temperature rise and enhance short-circuit resilience. The specific winding construction—whether interleaved, shielded disc, helical, disc, or layer—is selected based on voltage and impulse ratings.

Contact Daelim TransformerActive Parts Assembly & Oil Tank

Active Parts Assembly:

The assembly process for active parts involves cold pressing to ensure cleanliness and enhance the reliability of leads. Whole assembled phase insulation is utilized to expedite assembly and guarantee the precise dimension and shape of the insulation structure. High-voltage (HV) leads are fortified with specially molded insulation parts for protection, significantly improving insulating strength and reducing the risk of partial discharges.

Oil Tank:

The oil tank undergoes a three-dimensional finite element strength analysis and employs a Pro-E mold to strengthen its mechanical integrity. Welding methods incorporate automatic submerged arc welding, accompanied by ultrasonic fluorescence leakage testing to ensure a leak-free performance. Stringent quality control is maintained throughout the surface coating process.

Send Inquiry Now

Service & Support

Daelim Transformer collaborates with clients to understand their specific transformer requirements and tailors solutions accordingly. Once the exact needs are determined, the company's engineers swiftly recommend the appropriate solutions.

The engineering team has the expertise to meet various performance requirements. This includes enhancing short-circuit strength, upgrading kVA ratings, adjusting voltages, reducing losses, modernizing LTC (Load Tap Changer), reducing sound levels, and modifying the transformer tank.

For technical inquiries, Daelim Transformer's engineering team responds promptly to address questions from both clients and end-users.

Contact Daelim TransformerService & Support

Factory-to-Onsite Logistics Support:

The company provides logistical support for safe transportation, utilizing both ships and trucks. Impact recorders are employed to measure and store three-axis impact data, identifying any unusually severe impacts that could potentially damage the transformer during transportation.

On-Site Technical Assistance:

On-site technical support is available, covering assembly, oil treatment, testing, and commissioning (energization), and is conducted by an experienced engineer.

Training:

Factory specialists offer training on transformer operation and maintenance to ensure clients can effectively manage their equipment.

Repair:

Daelim Transformer's technicians are capable of performing various repairs, such as replacing gaskets, broken bushings, and accessories. They can also purify or replace the oil, conduct sanding, priming, and repainting as needed. After repairs are completed, the unit undergoes comprehensive testing to ensure proper functionality.

Package and Transportation

Power transformers are typically high-voltage transformers known for their substantial size and weight. Daelim Transformer often disassembles various components of the transformer for transportation. The primary transformer unit is typically arranged for transport within an open-top container, while the disassembled components are securely packaged in wooden crates and transported using separate 20 ft/40 ft containers.

Throughout the packaging process, Daelim Transformer pays meticulous attention to numerous details. For example, the control box on the transformer unit is individually encased in a wooden crate to safeguard against potential impacts during transit. Moreover, a protective rain and sun cover is placed above the open-top container to ensure that the transformer unit remains shielded from rain, moisture, and corrosion during transportation.

Get Price