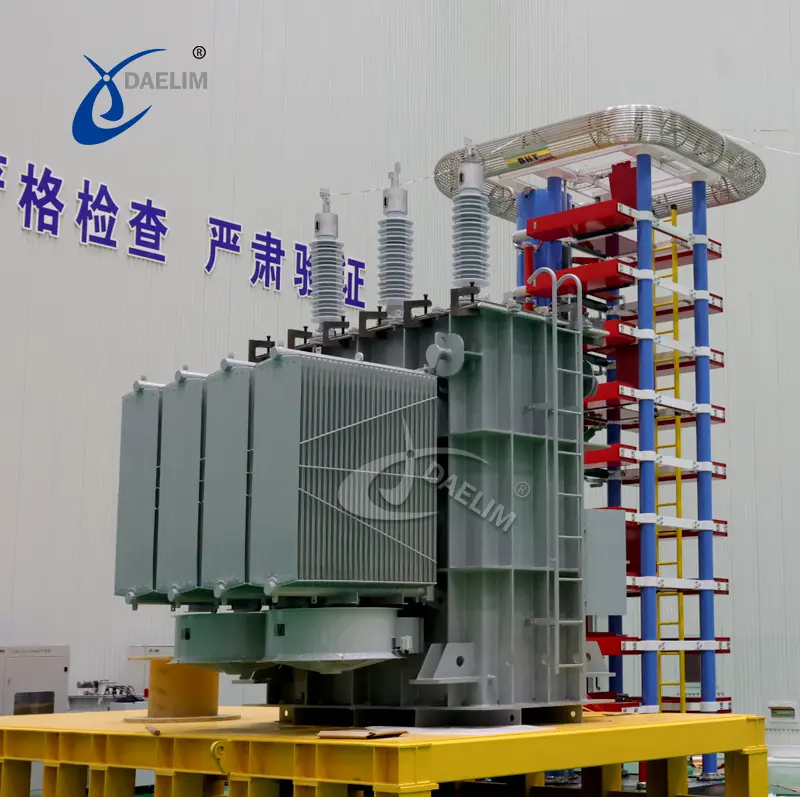

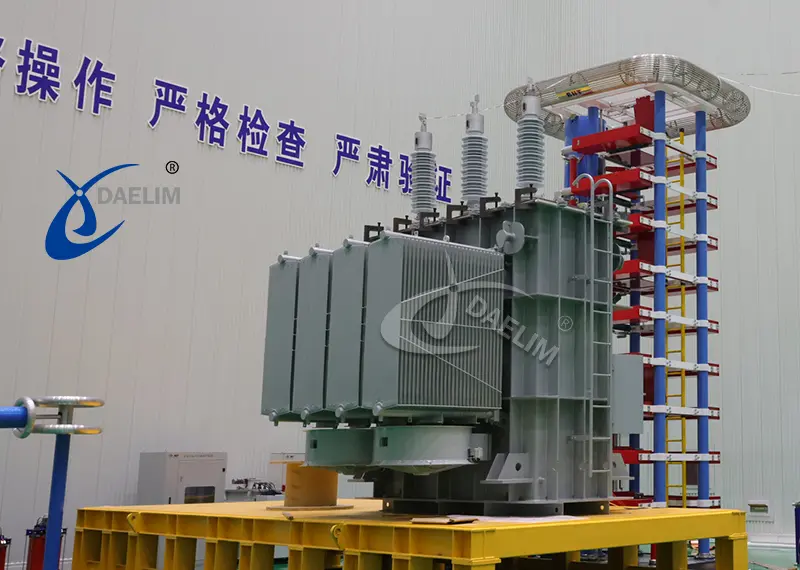

67kV 8400kVA/10500kVA Three Phase Power Transformer

- Primary Voltage Ratings: 67 kV

- Secondary Voltage Ratings: 4.16 kV

- H.V. TAP RANGE: 67kV±2x2.5%

- CONNECTION TYPE: Dyn1

- TYPE: Three phase oil transformer

- BIL: 350/75kV

- Standards: IEEE

- Application: Utility

- Power Rating: 8400 kVA/10500 kVA

- Cooling Method: ONAN/ONAF

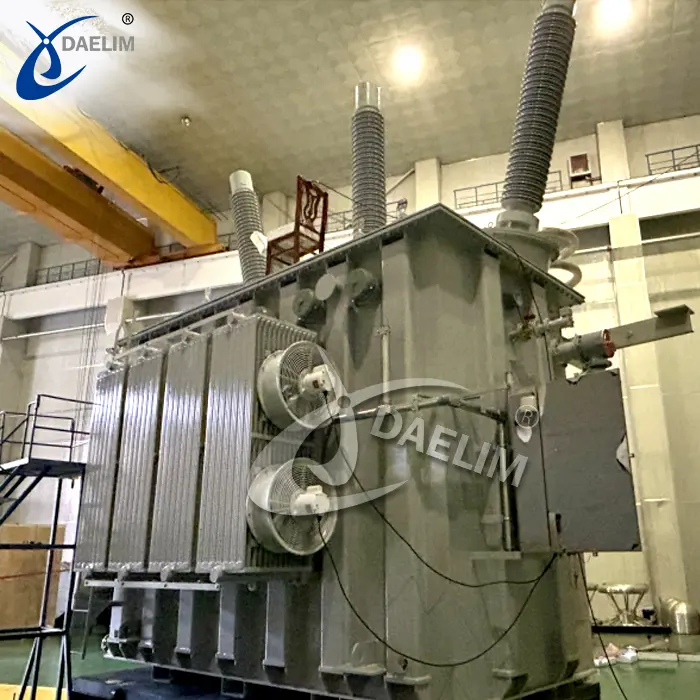

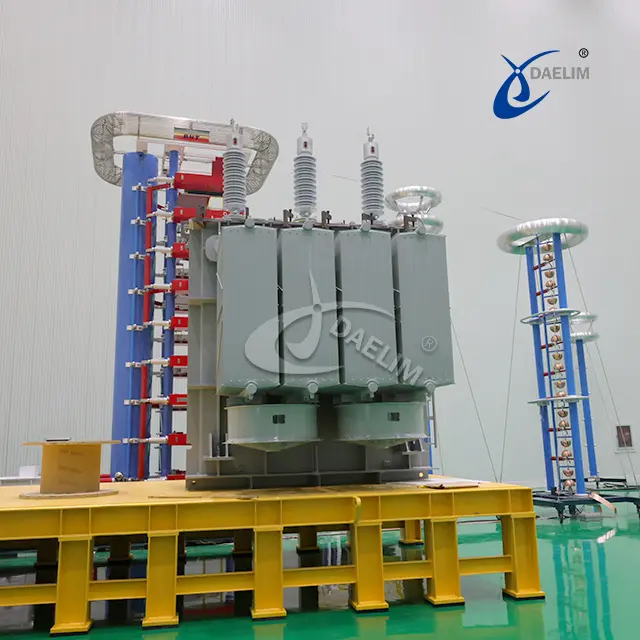

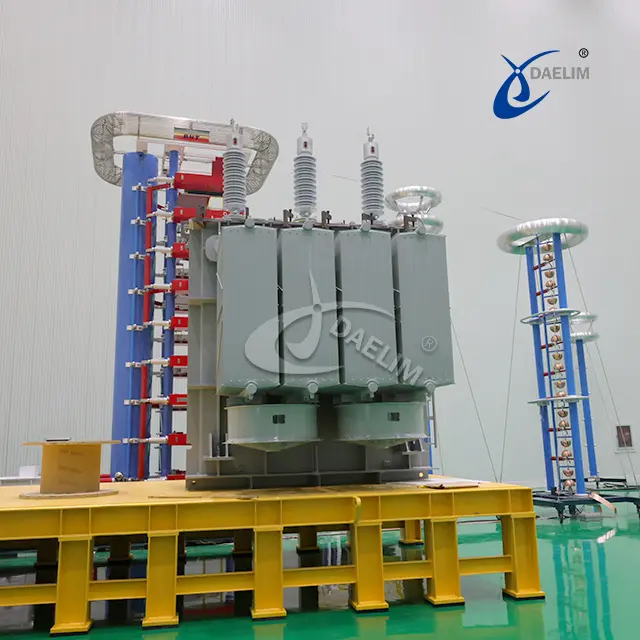

In November 2024, Daelim Transformer successfully completed and fully tested two 67kV, 8400kVA/10500kVA three-phase power transformers. These transformers have been delivered to customers in the United States for use in a utility project in Minnesota.

Quote Now

Core Features

Designed in accordance with IEEE Std. C57.12.00, ensuring safe and reliable operation.

Temperature rise is designed for 55°C/65°C, which enhances the transformer’s service life, improves safety, and reduces energy consumption and maintenance costs.

The transformers feature a two-stage air-cooled design with a fan-assisted cooling system that improves heat dissipation efficiency. This system offers low maintenance costs, high adaptability, and is suitable for high-load, medium-to-high power applications.

Equipped with remote monitoring contacts for real-time operational status tracking.

Get OfferCooling System (ONAN/ONAF)

The transformer is an oil-immersed, air-cooled type that enhances heat dissipation through a fan-driven air flow.

- Under natural air cooling (ONAN), the rated capacity is 8.4MVA

- When the fan operates (ONAF), the rated capacity increases to 10.5MVA

This cooling system efficiently handles sudden increases in load or temperature. The fan automatically activates when required, ensuring continuous operation under varying conditions.

Send Inquiry Now

Instruments and Monitoring

The 67 kV transformers are equipped with a variety of advanced instruments, including remote monitoring capabilities, to ensure optimal performance and safety:

The 67 kV transformers are equipped with a variety of advanced instruments, including remote monitoring capabilities, to ensure optimal performance and safety:

-

Oil Level Indicator: Equipped with two alarm contacts to signal when the oil level inside the tank is too high or too low.

-

Oil Temperature Indicator: With alarm/trip contacts to trigger an alarm or trip the system if the oil temperature exceeds 65°C/90°C.

-

Winding Temperature Indicator: Featuring four contacts, this indicator allows users to set alarm thresholds at 60°C or 75°C, and trip settings at 105°C or 125°C, cutting off power to protect the transformer and associated equipment.

-

Vacuum Pressure Gauge: Includes two alarm contacts to monitor internal pressure changes. It activates an alarm when pressure reaches a critical threshold.

-

Pressure Relief Device: Equipped with alarm/trip contacts to trigger an alert and automatically release excess pressure if the internal pressure exceeds safety limits. If the pressure continues to rise or the valve fails to function, the system will trip, disconnecting the transformer to prevent equipment damage.

These gauges ensuring reliability and effective monitoring of transformer health, enabling timely detection of potential issues to prevent equipment failure and safety hazards. The vacuum pressure gauge and pressure relief device are sourced from the renowned brand Qualitrol.

Insulation

-

High-voltage side: 67kV, with a BIL rating of 350kV, designed to withstand transient overvoltage shocks up to 350kV without insulation failure.

-

Low-voltage side: 4.16kV, with a BIL rating of 75kV, capable of withstanding transient overvoltage shocks up to 75kV without insulation failure.

Control Box

The transformer is fitted with a NEMA 3R standard stainless steel control box, which is suitable for outdoor use. The enclosure is waterproof, dustproof, and corrosion-resistant, ensuring durability and reliable performance under harsh environmental conditions.

All instruments, meters, fan contacts, and related circuits are integrated into this NEMA 3R control box, providing a centralized location for monitoring and control.

Daelim Transformer’s Global Expertise

Daelim Transformer has extensive experience in delivering high-quality transformers for utility projects worldwide. We offer tailored solutions to meet the specific needs of your projects. Contact us today to discuss your requirements and explore how we can support your energy infrastructure.

Related Products

Related Article

13.8 kV 10.5 MVA Substation Transformer for Ecuador

A customer from Ecuador contacted Daelim Transformer for a 10.5MVA substation transformer (13.8kV high voltage, 2.4kV low voltage). Daelim Transformer provided a customized solution, conducted virtual factory tours, ensured rigorous quality control via video inspections, and offered post-delivery online training and ongoing support, fostering a successful partnership.

20MVA Power Transformer for the United States

This project involves the development of a 20 MVA three-phase power transformer tailored for the United States market. The primary voltage is 24.94kV, and the secondary voltage is 4.16kV, indicating it functions as a step-down transformer. The design and production fully comply with IEEE C57.12.00 standards and have passed third-party UL team testing. All accessories also adhere to IEEE standards. FR3 vegetable oil serves as the insulating liquid for the transformers.

69 kV Power Transformer for Substation in Pennsylvania

Daelim recently completed the design, supply, and installation of a custom 69 kV transformer for a substation in Pennsylvania. This high-efficiency, three-phase transformer is engineered for reliability, scalability, and long-term performance, ensuring a stable power supply to the substation. Key features include low load losses, minimal maintenance, high insulation levels, and flexible cooling options. The solution enhances grid stability, supports future expansion, and minimizes energy consumption, reinforcing Daelim’s commitment to quality and innovation in power systems.

Single Phase Pad Mounted Transformer For USA Utility

Introducing a utility transformer project tailored for the USA, located in Virginia. This utility initiative requires 215 units of single-phase pad-mounted transformers, all UL listed, including 175 units of 25 kVA and 40 units of 50 kVA. The end user's project timeline is 90 days. Adherence to IEEE standards is imperative for single-phase transformers. Additionally, the design of transformer components and markings must be customized to meet project specifications.

2000 kVA Pad Mounted Transformers for Canadian Utility

Daelim Transformer is pleased to announce its contribution to a utility project in Toronto, Canada, involving the supply of two units 2000 kVA pad mounted transformers. These transformers are integral to enhancing the power infrastructure in the region. The project demands adherence to CSA standards, with a stringent delivery deadline of 10 weeks to meet the urgent needs of the client.

2 MVA Pad Mounted Transformer for Utility

Behold the backbone of Canada's utility infrastructure—the 2MVA pad mounted transformer. With a primary voltage of 4160Grdy/2400V and a secondary voltage of 800GrdY/461V, this transformer stands as a testament to efficiency and reliability in power distribution. Crafted in strict accordance with CSA standards and CAN/CSA802.1 energy efficiency guidelines, it embodies the pinnacle of engineering excellence.