33/44/55 MVA Power Transformer

- Primary Voltage Ratings: 138kV/34.5kV; 69kV/34.5kV

- Secondary Voltage Ratings: 13.8kV

- TYPE: 3-phase,3-winding, oil-immersed construction with a conservator

- BIL: 500/200/125kV; 350/200/125kV

- Standards: IEEE/ANSI/NEMA

- Application: solar power project

- Power Rating: 33MVA, 44MVA, 55MVA

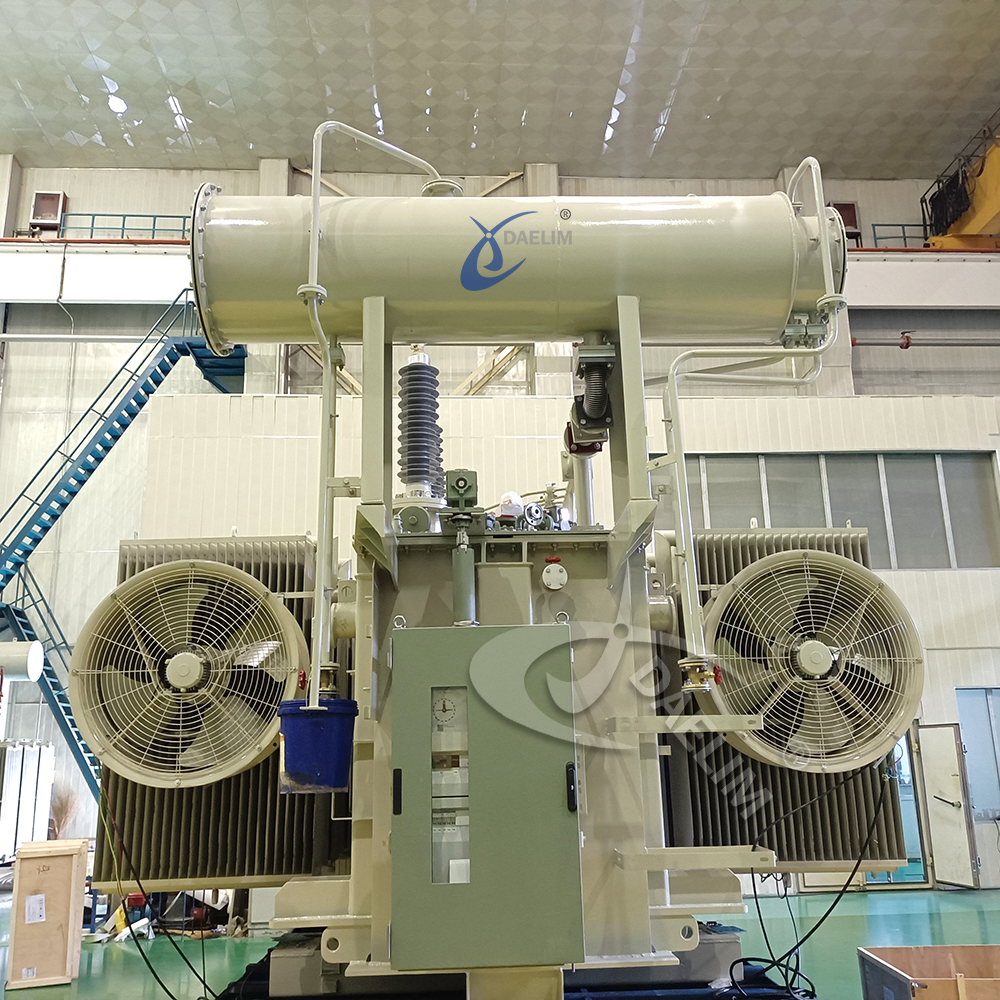

- Cooling Method: ONAN/ONAF1/ONAF2

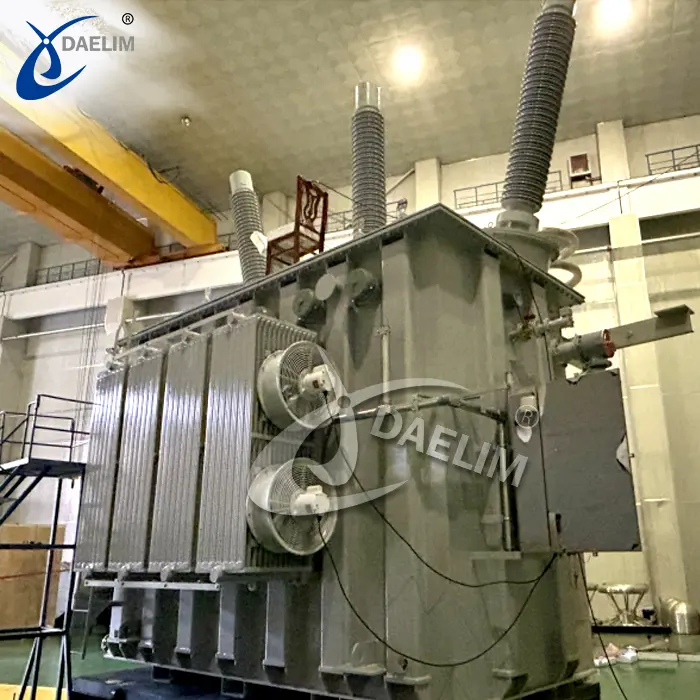

Daelim Transformer provided two 33/44/55 MVA step-up power transformers for a U.S. solar project in 2024. Each transformer features a three-phase, three-winding, oil-immersed design with a conservator. They offer capacities of 33 MVA (self-cooled), 44 MVA (Stage 1 cooling fan), and 55 MVA (Stage 2 cooling fan). Constructed with copper windings and high-quality silicon steel, they use ASTM D3487-compliant mineral oil. Equipped with various accessories and tested per IEEE standards, they come with an 24-month warranty from manufacture .

Quote Now

In 2024, Daelim Transformer provided two 33 MVA / 44 MVA / 55 MVA step-up power transformers for a solar power project in the United States. The design and construction of these transformers comply with IEEE standards and relevant regulations. Both transformers feature a three-phase, three-winding, oil-immersed construction with a conservator.

Transformer Specifications:

-

Transformer 1:

- High Voltage: 138 kV

- Medium Voltage: 34.5 kV

- Low Voltage: 13.8 kV

-

Transformer 2:

- High Voltage: 69 kV

- Medium Voltage: 34.5 kV

- Low Voltage: 13.8 kV

Both transformers are equipped with a two-stage forced air cooling system:

- Self-Cooling Capacity: 33 MVA

- One Fan Operating (ONAF1): 44 MVA

- Two Fans Operating (ONAF2): 55 MVA

Construction Details:

- Windings: Copper

- Core Material: High-quality, low-loss cold-rolled silicon steel

- Insulation Liquid: Mineral oil, compliant with ASTM D3487 standards

- Bushings: Top cover design, porcelain type, ANSI Segment 2 Number, ANSI 70 Gray

- Oil Preservation System: Conservator

Environmental Conditions:

- Location: Harrington, DE

- Site Elevation: 60 ft

- Ambient Temperature Range: Minimum -20°F, Maximum 110°F

- Weather/Load Criteria:

- Radial Ice Buildup: 0.5 in

- Wind Speed: 100 mph

- NESC Loading District: Heavy

- Contamination per IEEE C57.19.100: Heavy

Instrument Transformers:

- High Voltage Bushing CTs

- High Voltage Neutral Bushing CT

- Low Voltage Bushing CTs

- Low Voltage Neutral Bushing CTs

- Tertiary Winding

- ANSI Accuracy Class: C400

Arresters:

- High and low voltage stations class porcelain arresters, ANSI 70 Gray

Accessories:

- Liquid-Level Indicator

- Liquid-Temperature Indicator

- Winding-Temperature Indicator

- Pressure-Relief Device

- Rapid Pressure Rise Relay

- Buchholz Relay

- Pressure-Vacuum Gauge

- Pressure-Vacuum Bleeder

- Pressure Test and Gas Sampling Valve

- Drain and Filter Valves

- Removable Radiators and Isolation Valves

- Transformer Monitoring System

- Dry Air Fill Valve

Testing:

All routine tests as per Table 21, C57.12.00, and accompanying notes, in accordance with methods and procedures outlined in C57.12.90, including:

- Insulation Power Factor Test

- Audible Sound Level Test

- Insulation Resistance Test by Megohmmeter

- Core-Ground Resistance Test

- Temperature Rise Test

- Positive and Zero Sequence Tests

- Short-Circuit Tests

- Seismic Tests

- Sweep Frequency Response Analysis

- Dissolved Gas-in-Oil Analysis

- Front-of-Wave Impulse Tests

- Switching Impulse Tests

- Partial Discharge (PD) and Radio Influence Voltage (RIV)

Preparation for Shipment:

- Radiator cooling units are crated securely for protection, with silica gel bags installed inside each radiator to absorb moisture. Bags must be affixed securely to a ring weld inside blank-off covers.

- Heavy parts are placed on skids for handling, securely boxed, and identified by content.

- Exterior electrical receptacles are covered for protection.

- Hollow external bracings have drain holes.

- Transformers are equipped with a GPS travel recorder to register shocks in three dimensions: travel direction, vertical, and transverse side-sway.

Transformer Shipping:

- Transformers are filled with dry nitrogen.

- The shipping marker indicates pressure and temperature when sealed for shipment.

- A pressure gauge is mounted on the transformer to show tank pressure upon receipt by the buyer.

- Draw leads for HV bushings are tied to suitable clips welded to the underside of shipping covers over bushing openings.

Warranty:

- 24months from the date of manufacture .

Related Products

Related Article

Solar Photovoltaic System Solution

DB Transformer serves the world's renewable energy field. Here are solutions for some solar projects provided by Daelim for the United States, Canada, and other countries.

Daelim Transformers Solution For Renewable Power Plant

Daelim's versatile, reliable, and high-quality transformer solutions are ideal for renewable power plants. Whether it's for solar energy plants or wind farms, Daelim's expertise in transformer technology can help produce clean energy that can be efficiently and reliably delivered to the electrical grid.