500kVA Tier 2 Oil Filled Distribution Transformer

- Standards: BS EN 60076

- Rated Power: 500kVA

- Rated Frequency: 50 Hz

- Rated High Voltage: 11kV

- HV Tapping Range: +7½, -5 %

- Tap Switch: Off circuit

- Rated Low Voltage: 415V

- Tap Steps: 5 x 2½ %

- Rated Current: 695.60 A

- Cooling Method: ONAN

- Thermal Class: A (105°C)

- Coolant: Mineral Oil

- Insulation Level : Li75.Ac28 / Ac3

- Vector Group: Dyn11

- Core Material: Aluminium

- Winding Material: CRGO

- Temperature Rise, Oil/Wdg: 60 / 65°C

- Load Loss @ 75°C: 3900 W

- No Load Loss: 459 W

- Impedance: 4.75%

Quote Now

Related Products

Related Article

2000 kVA Oil immersed Substation Transformer For Portugal Market

Today, we introduce Daelim Transformer's export of a 2000 kVA oil-immersed substation transformer to Portugal. This transformer represents our commitment to delivering high-quality electrical solutions to global markets. With meticulous design and engineering, this transformer is tailored to meet the specific needs of our customers in Portugal, ensuring reliable performance and efficiency. Daelim Transformer continues to uphold its reputation for excellence, providing innovative solutions that power progress and reliability worldwide.

500 kVA Distribution Transformer for the Greek Market

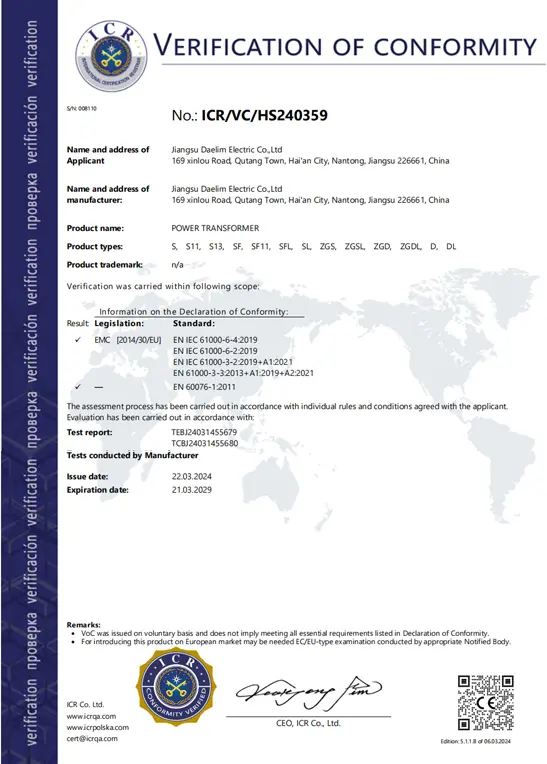

Today, we're thrilled to showcase a European transformer project tailored for the Greek market. This project involves the supply of 500 kVA distribution transformers, with an input voltage of 20 kV and an output voltage of 400V. The client has requested adherence to both IEC and TIER-II energy efficiency standards. With a total quantity of 5 units, this project marks another milestone in Daelim Transformer's commitment to delivering high-quality solutions worldwide.

4500 kVA Substation Transformers for Australian Mining Site

Today, we introduce a project by Daelim Transformer aimed at supplying transformers to a mining site in Australia. This project entails the provision of two units of 4500 kVA substation transformers tailored to fit the narrow confines of mining tunnels. Due to space constraints, the transformers need to be compact in size and mounted on mobile racks for easy maneuverability within the mine shafts. This necessitates meticulous design to meet the strict dimensional requirements set by the client.