High Voltage Transformer:Definition,Principle,Uses and Price

High voltage transformers are not common in our daily life. It can only be seen on the outskirts of the city or near power plants. However, it plays a vital role in the development of a city and a country's livelihood/economy. Today, let's talk about the definition, working principle, uses, applications, prices, etc. of high-voltage transformers

High voltage transformer definition

Internationally, transformers are generally classified according to voltage levels: high voltage transformers typically refer to those with voltages ranging from 66 kV to 230 kV; medium voltage transformers operate within the range of 3 kV to 35 kV; and low-voltage transformers have voltages below 1 kV. Ultra-high voltage transformers exceed 330 kV but are less than 1000 kV, while transformers categorized as ultra-high voltage have voltages greater than or equal to 1000 kV.

Learn more: Why Substation Transformers Are So Important In Power Systems?

What are high voltage transformers used for?

High voltage transformers play a crucial role in the transmission of electricity over extensive distances, primarily through their functions as step up and step down transformers.

High-voltage step-up transformers

The primary function of high-voltage step-up transformers is to elevate the voltage of electricity generated by power plants before it is transmitted over long distances. Typically, electricity generated by generators operates at voltages ranging from 3 kV to 20 kV, which are relatively low. Transmitting electricity at these lower voltages results in significant power losses due to high currents. To mitigate these losses and enhance transmission efficiency, electricity passes through high-voltage step-up transformers, which increase the voltage to levels between 35 kV and 500 kV. These transformers exhibit high efficiency, typically exceeding 98%, thereby significantly reducing energy losses during transmission.

Try for free: What You Need To Know About Substation Transformer

High-voltage step-down transformers

The voltage transmitted over long distances is exceedingly high and cannot be directly utilized by industries, commercial enterprises, or residents. Consequently, high-voltage lines necessitate step-down transformers located in high-voltage substations to incrementally reduce the voltage level until it reaches below 35 kV for incorporation into the grid. At this point, the electricity is distributed to industrial, commercial, residential, and other users.

These transformers are pivotal in maintaining the efficiency and integrity of electrical transmission and distribution networks worldwide.

Try for free: How To Choose The Suitable 110KV Power Transformer?

What is the working principle of high voltage transformer?

The working principle of a high-voltage transformer is rooted in electromagnetic induction, similar to that of a generator. The primary coil of the transformer, when energized, creates a fluctuating magnetic field within the iron core. This magnetic field then induces a corresponding fluctuating electric field and electromotive force in the secondary coil of the iron core. The difference in the number of turns between the primary and secondary coils determines the disparity between the input and output voltages. More turns in the coil result in higher output voltage, while fewer turns yield lower voltage. Consequently, high-voltage transformers tend to be relatively large in size due to their construction requirements.

Read more: 10.5MVA-13.8/2.4kV Substation Transformer

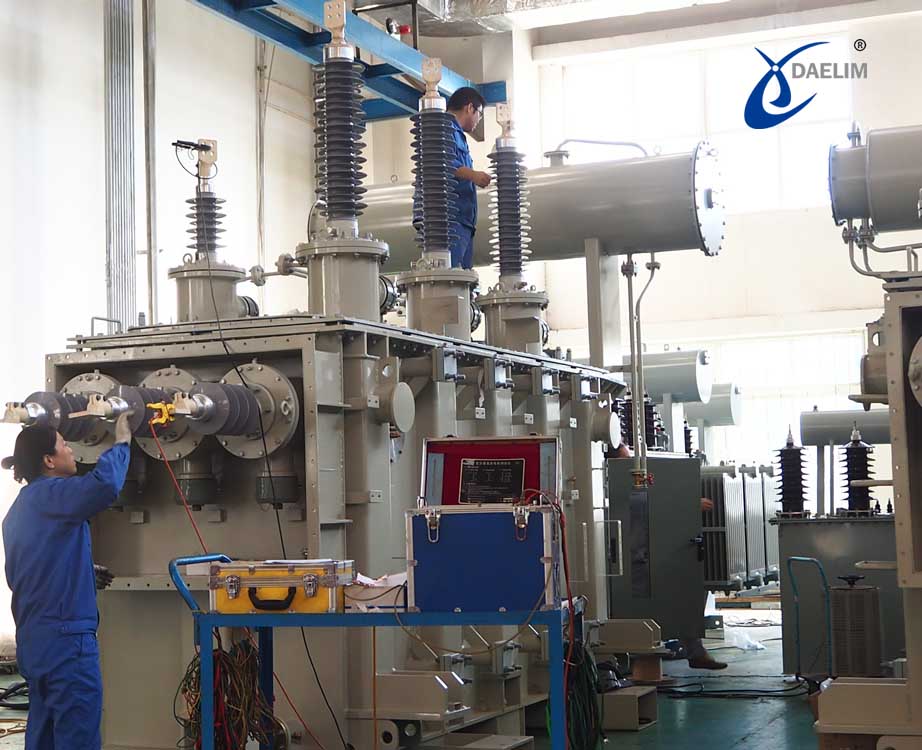

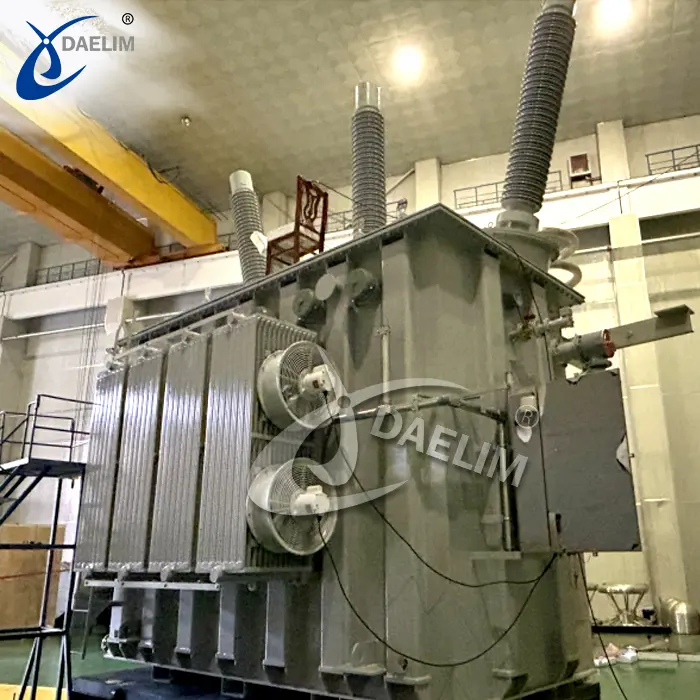

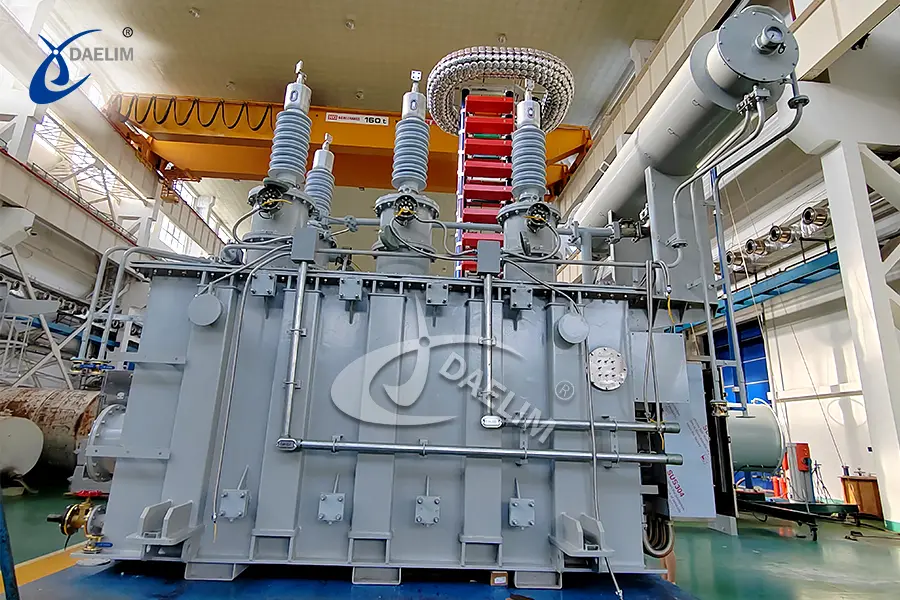

High voltage transformer manufacturers

There are far fewer high-voltage transformer manufacturers than medium and low-voltage transformers. Because high-voltage transformers have relatively high requirements and standards for technology, qualification, equipment, and environment. Daelim Transformer is a professional high-voltage transformer manufacturer in China, the voltage level can reach 345kV and 500MVA. The technical engineer team has rich experience in international transformer projects and can design and produce transformers that conform to IEEE, IEC, CSA, ANSI, AS, GOST, and other international standards.

Daelim Transformer has more than 20 years of experience in exporting transformers, high voltage transformers, and exporting to the United States, Canada, Mexico, Denmark, Ecuador, Chile, Myanmar, and other countries. High-quality transformers and efficient and professional services have won unanimous praise and long-term cooperation from customers. Famous partners include Meal, Amazon, ABB, etc.

High voltage transformer price

The high cost of high-voltage transformers stems from several factors. Firstly, their substantial size necessitates large quantities of materials. Secondly, they require meticulous design to meet stringent technical specifications and accommodate various accessories. Additionally, the need for high-quality components and specialized consumables further drives up costs.

here are several factors that significantly influence the price of high-voltage transformers. Here, we discuss five major factors:

Voltage Level and Capacity of the Transformer

The price increases with higher voltage ratings and larger capacities.

High Voltage Transformer Parts

- Tap Changer: The tap changer of a transformer regulates voltage and is crucial for adjusting voltage levels. There are two types: no-load and on-load tap changers. The on-load tap changer allows voltage adjustments without interrupting the transformer's operation, which is more convenient but costlier compared to the no-load tap changer. If you opt for the German MR voltage regulator, the cost will be significantly higher, as the price of the regulator alone can exceed $100,000.

Transformer Oil

Transformer oil, which accounts for about 20% of the transformer's total weight, varies significantly in cost depending on the type. Vegetable oils like FR3 are environmentally friendly but about three times more expensive than regular mineral oils.

Read more about Transformer Oil

Short-Circuit Impedance

This refers to impedance voltage, which varies based on international standards. Higher impedance values increase manufacturing costs and thus the price of the transformer.

High-Voltage Transformers at High Altitudes

Transformers used in high-altitude areas require special design considerations due to lower temperatures and harsh weather conditions, which increase costs. Factors include improved insulation, enhanced cooling systems, and special UV-resistant coatings.

Learn more: Surplus 15000 kva transformer for sale!

High-voltage transformers are key components in power transmission networks, helping to efficiently transmit electricity over long distances. These transformers are available in voltage levels from 66 kV to over 1000 kV. Key factors that affect their price include voltage capacity, transformer accessories, type of transformer oil used, short-circuit impedance, and special requirements.

When sourcing high-voltage transformers, you must be careful and work with experienced and capable suppliers. Manufacturers such as Daelim Transformer can be your best partner in meeting global standards and providing high-quality solutions suitable for the international market.

Related Products

Related Article

230 kV Three Phase Power Transformer For USA Market

In 2023, Daelim Transformer designed and manufactured a cutting-edge 230 kV three-phase power transformer for a client in Nevada, USA. The client recently shared installation and operational photos, showcasing the successful deployment of this remarkable transformer. Let's delve into the specifics of this transformer project!

Canadian 69 kV Substation Transformer Project

Today, we are excited to present a case study on a 69 kV substation transformer project by Daelim Transformer. Our Canadian client required a step-down transformer for their substation to connect with the hydroelectric grid in Quebec.

20MVA Power Transformer for the United States

This project involves the development of a 20 MVA three-phase power transformer tailored for the United States market. The primary voltage is 24.94kV, and the secondary voltage is 4.16kV, indicating it functions as a step-down transformer. The design and production fully comply with IEEE C57.12.00 standards and have passed third-party UL team testing. All accessories also adhere to IEEE standards. FR3 vegetable oil serves as the insulating liquid for the transformers.