Transformer PCBs: Understanding Their Role, Risks, and Modern Alternatives

The Polychlorinated Biphenyls that are also known as the transformer PCB was once the most widely used chemical in the electrical transformer industry. These PCBs were used in electrical transformers only due to their superior chemical properties as compared to any other chemical of the same category.

However with the world adopting more environment friendly solutions and international standards forcing the electrical transformer Industry to adopt more sustainable and environmentally friendly solutions. The transformer industry has to adopt solutions other than the transformer PCBs.

This article is for you to understand all about transformer PCBs, what was transformer oil pcb, what were its benefits, what are pcb transformer oil regulations and why is this transformer oil toxic.

Contact Daelim TransformerWhat Are Transformer PCBs?

The Polychlorinated Biphenyls PCBs in terms of electrical transformer oil refer to as a man made chemical that is organic in nature. In simple words it’s a transformer oil that contains Polychlorinated Biphenyls. It contains elements like carbon, hydrogen, and chlorine.

Reason why this man made chemical was developed in the first place and why it was so extensively used in the electrical transformer industry is that it has excellent chemical stability and is non flammable even under very high temperature. This chemical stability and non flammability make them an excellent choice in high voltage applications like electrical transformers.

In electrical transformers these PCBs were specifically used due to their insulation and cooling properties and they act as dielectric medium in electrical transformers.

Use Of PCBs In Transformer Oil

The transformer PCBs as the transformer oil are not being widely used today. Historically, the PCBs were very extensively used as transformer oil during the 20th century all around the globe. They were the most reliable and cost effective solution for insulation and cooling in high temperature electrical applications like transformers.

However, the same properties that made PCBs ideal for industrial use also make them persistent in the environment and hazardous to health. So it was in the late 1970s that the world got the awareness about these transformer oil toxic nature.

These Polychlorinated Biphenyls PCBs were very stable in nature and they did not decompose easily in nature. Thus once they are disposed of openly in nature, they remain a source of pollution and soil contamination for a very long time.

Other than this, these chemicals can bioaccumulate in our food chain and studies have shown a very strong link between these chemicals and potential development of cancer in humans and animals. After that international standards like ISO and other work to regulate transformer oil and most international standards start banning these transformer PCBs used as transformer oil.

Learn more about Transformer Oil

Why Were PCBs Used in Electrical Transformers?

It was not that the Polychlorinated Biphenyls transformer PCBs were the only solution available back then. There were several other chemical and natural solutions available for transformer cooling and insulation but Polychlorinated Biphenyls PCBs were prioritized due to following reasons.

Cooling Properties

The Polychlorinated Biphenyls aka transformer PCBs were initially used in transformers due to their superior cooling properties. We all know that electrical transformers produce a lot of waste heat during their operation. This waste heat needs to be removed to keep the transformer operation reliable, safe, and efficient.

To remove this waste heat, transformer oil with excellent waste heat removing abilities should be used. This is where transformers PCBs work effectively. When used in transformer oil, they tend to increase the cooling effect many fold as compared to any other available transformer oil at that time.

You may enjoy: What is Transformer Cooling and How is it done?

Insulation Properties

The Polychlorinated Biphenyls also has excellent electrical properties meaning its an excellent dielectric and does not allow any current to pass through it.

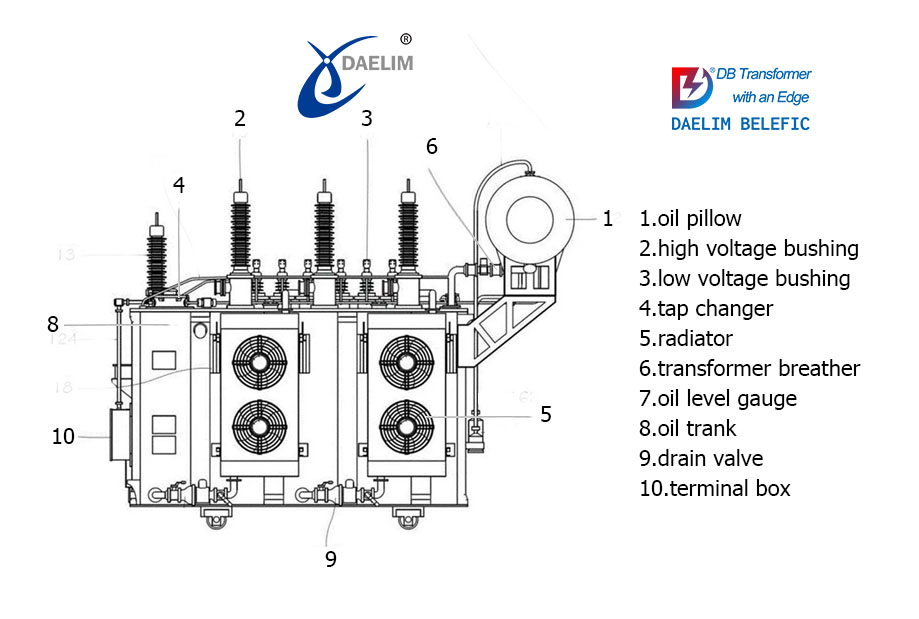

It is used in electrical transformers as insulators to insulate and isolate the electrical transformer winding, transformer core, and all other internal transformer parts from all types of electrical short circuits & leakages and environmental contaminants.

To make this happen, transformer oil containing Polychlorinated Biphenyls is used to fill the transformer tank. Tank was filled to the mark that all parts are completely submerged inside the oil.

Performance in Harsh Environment

The Polychlorinated Biphenyls are stable in all types of environmental conditions and they do not decompose or have any type of chemical breakage even under extreme operating conditions like high temperature and voltage.

Due to slow chemical degradation and no decomposition even at extreme conditions means that Polychlorinated Biphenyls will perform the same as in normal and extreme conditions and throughout its useful life.

Keep reading: Transformer Oil Uses and Requirements

Low Cost Solution

The transformer PCBs Polychlorinated Biphenyls offer the best value of money invested in transformer oil as compared to any other transformer oil. It is due to its high performance, long life, and ability to resist extreme operating conditions.

Comparison With Non PCB Oil

Although there were several type of non PCBs oil available in the market and some of them were also being used by different companies, they were not as good as the Polychlorinated Biphenyls because most of them break under extreme operating conditions or their cooling and insulation properties were not as good as of Polychlorinated Biphenyls.

Disadvantages of Using PCBs in Transformer Oil

Following are some of the disadvantages of using transformer PCBs.

- Using PCBs in transformer oil came with the drawback of its being highly toxic to humans. Any direct contact can be proven deadly.

- These chemicals are labeled as persistence as they can remain stable in the environment for a very long time and result in contamination of soil and water.

- Using PCBs in transformer oil will result in extra regulatory burden on the company that can either reduce production or add extra cost of the final product.

- Using PCBs in transformer oil also came with the additional duty of safe disposal of the PCBs which has reached its end of useful life. Adopting proper disposal techniques will result in additional cost associated with the product.

PCB Levels in Transformer Oil

Polychlorinated Biphenyls PCB in the transformer oil is measured in parts per million. It is not like that the entire transformer oil is made from these PCBs rather a fixed quantity of the Polychlorinated Biphenyls is added into the transformer oil to make it Polychlorinated Biphenyls transformer oil.

As per regulation any transformer oil that contains more than 50 parts per million of Polychlorinated Biphenyls, it is categorized as Polychlorinated Biphenyls contains transformer oil. Nowadays transformer oils that are labeled as Polychlorinated Biphenyls containing transformer oils are subjected to very strict regulations globally.

Hazards and Toxic Effects of Transformer PCBs

There were several reasons why these highly effective and efficient transformer PCBs were banned or face very strict regulations that limit their use. Following is a detailed discussion on the reason why these PCBs are not being used in the transformer industry.

Health Related Issue

The transformer PCBs are highly toxic and dangerous to all types of life on earth. They are so dangerous that their direct exposure to even the lowest level can be proven life threatening to humans, animals and especially to fresh water creatures.

These transformer PCBs can move into living organisms through inhalation, ingestion, and skin contact and they are known to cause life ending diseases like cancer, immune system suppression, neurological disorder and development disorder.

Environmental Impact

As we have mentioned, these pcb transformer oil are hazardous for human life and due to its high chemical stability, pcb transformer oil disposal without proper technique in the environment is also very dangerous for the environment. These PCBs do not decompose in the environment and they remain present in soil, water, and in air for a very long time.

Once they are disposed of in water bodies like rivers or channels, they can travel hundreds of thousands of miles, thus affecting a far greater area. They can even become part of growing plants and thus make a permanent mark in the food chain.

You may enjoy: The Impact of Operating Environment on Transformer Design

Long Term Dangers

Explained above how these transformer PCBs are dangerous for human and animal life and how they can become part of the environment if disposed of without due care. Once they became part of water or plant based food, they chemical became part of human or other living organisms by accumulating in their fatty tissues. By this they can transfer from one organism to another and remain in the environment for a long term causing even more damage to each and every living organism they touch.

Risk in case of spills or leak

It does not matter how strictly you follow the procedures or how good you are in following the international laws or International standards there is always a chance of an accident that can result in spill or leakage of this harmful chemical in the environment.

As these electrical transformers or almost everywhere in all residential areas in industrial areas and even in areas where other facilities are not available. So in any case where these full transformer oil chemicals are spilled or leaked into the environment. Then this can cause permanent or very long lasting damage to the environment and all living organisms in that area.

Get it free: How to Spot and Repair Transformer Oil Leaks

Regulations Related to PCB Transformer Oil

Stockholm Convention on Persistent Organic Pollutants (POPs)

It is an international organization that is working to develop rules and regulations and all the related laws about the use of chemicals and all the associated products that can in any manner damage involvement or can cause harmful events. Organization studies the chemical properties and the life of the chemical and how that chemical will affect the environment elements throughout its useful life.

This Stockholm Convention on Persistent Organic Pollutants (POPs) organization has classified transformer PCBs as extremely dangerous for the environment in every manner and has listed them as global elimination. Means they are working to completely eliminate it from all types of industrial application thus ensuring it no longer exists in our world.

Global and National Standards

There are several international and national standards that work to control and eliminate the use of transformer PCBs. Each region and country has its own standards and rules regarding use of transformer PCBs like United States EPA’s TSCA regulations.

The rules and regulations developed by these International and national standards are also followed in all the regions of the world where the products associated with these chemicals or the similar products are used that are being made by manufacturers located in the United States of America. The national standards of the United States of America have completely banned the use of these transformer PCBs in any products specially in electrical transformers. While the national standards of the EU restricted the use of these chemicals.

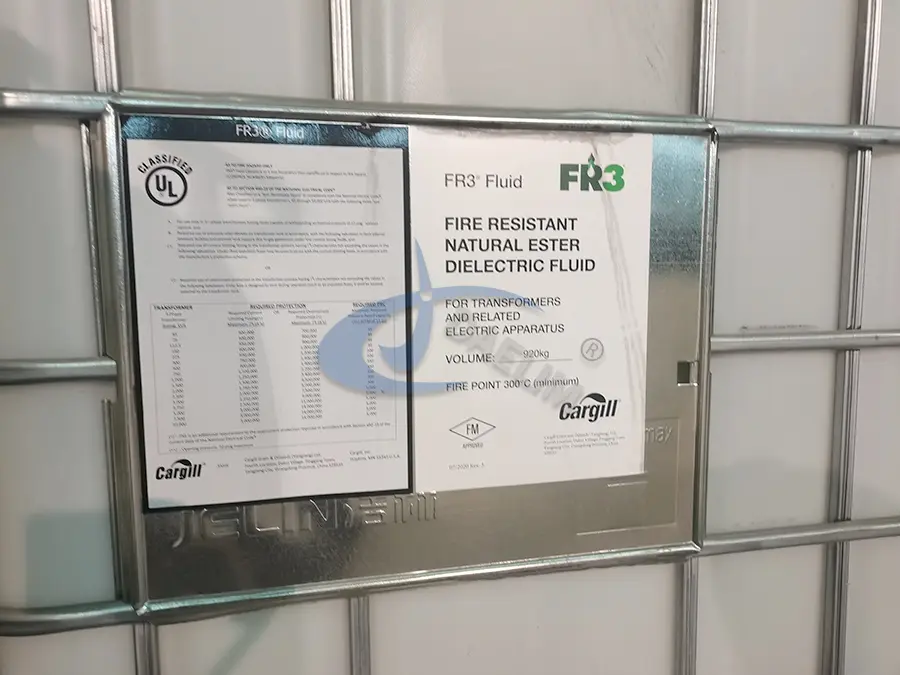

Reading on: Exploring the Benefits of FR3 Oil vs Mineral Oil Transformer

Disposal of PCB Containing Transformer Oil

Safe Handling and Disposal

As we have explained, transformer PCBs are toxic in nature and anyone who is responsible for safe handling and disposal of these transformer PCBs need special education training and years of experience to do the task safely and properly. The safe handling and disposal of these transformer PCBs need dedicated personal protective equipment to limit any damage that can happen due to any accident. There are several regulatory bodies that issue documentation and guidance on how to safely handle and dispose of these transformer PCBs after their useful life.

Approved Disposal Methods

The most common method of PCBs transformer oil disposal is by a method called high temperature incineration. In this method the PCBs filled with transformer oil are heated at a very high temperature of 1100 C. At this temperature the PCBs chemical composition starts to decompose into a less dangerous form. Other methods include disposing of PCBs transformer oil in far off landfills but it only can be done for transformer oil with very low PCBs concentrations.

Decontamination

If by any accident there is contamination of transformer PCBs, then you can do decontamination by the process called dechlorination. The process removes chlorine from the PCB thus making it a less toxic and less harmful component for the environment and living organisms.

Conclusion

Today the transformer PCB is mighty seen as fast but there was a time when these transformer PCBs were the most widely used chemical in transformer oils. One of the reasons why these chemicals were used in electrical transformer oil is that they are extremely stable in all types of environments and extreme operating conditions and they have some super chemical properties that enable them to offer cooling and insulation at the same time. Why these chemicals were banned is mainly due to the toxic nature of these chemicals and these chemicals are very stable in all types of environment and contaminate the environment for a very long time if they are disposed of safely in the environment.

Follow Up

Electrical transformers are everywhere they are a key part of our electricity distribution system and thus they are installed in all residential areas. As they are such a key part of our electricity distribution system these transformers need to be made on very strict International standards to protect the environment. Daelim Transformer designs and manufacturers a wide variety of electrical transformers with NON-PCB insulation, ensuring both high performance and environmental safety.

If you have any questions, contact us and we will talk you through the process.

Related Products

Related Article

The complete guide to Transformer Oil

Transformer oil: essential insulating and cooling fluid in transformers. Functions include insulation, heat dissipation, and arc extinguishing. Types include mineral oil (traditional, limited by pour points) and vegetable oil (biodegradable, safer, longer lifespan). Choosing the right oil involves balancing performance, environmental impact, and operational needs. Daelim Transformer offers customizable solutions.

How to analysis of gases and check oil level in transformer ?

The gas produced by transformer oil and fiber insulation in operation is mostly dissolved in the oil, but the rate of gas production is quite slow. When there is an initial fault inside the transformer or a new fault condition is formed, the gas production rate and gas production volume are very obvious. Therefore, a proper analysis of the gas produced by the transformer can detect the transformer fault.

What is the structure of the oil immersed transformer?

This article mainly introduces the structure of oil-immersed transformers. Important accessories and functions of oil-immersed transformers.Introduction of Daelim transformer factory.

Overview of Oil-Immersed Distribution Transformers

This article mainly describes the oil-immersed distribution transformer, including the oil transformer application, characteristics, types, and other issues of the transformer.

The Ultimate FAQs Guid To Oil Type Transformer

An oil-type transformer is a kind of transformer that uses oil as a cooling and insulating medium. The core and coils of an oil-type transformer are immersed in oil, which helps to cool the transformer and provides insulation.

Transformers Solution For Oil and Gas Plant

Transformers are crucial for oil and gas plants to maintain a stable and dependable power supply, which is necessary for safe and efficient operations. However, these transformers often face challenges due to harsh operating conditions and high electricity demand, which can result in performance issues and shorter lifespans. At Daelim Transformer Solutions, they offer advanced and innovative transformer solutions that address these challenges.