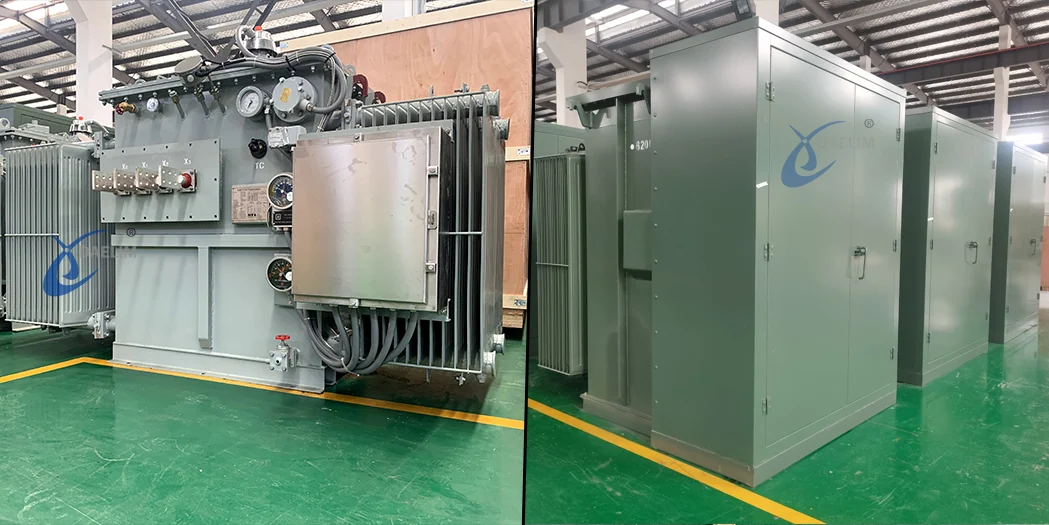

Overview of Oil-Immersed Distribution Transformers

Oil immersed distribution transformers are essential components in distribution networks, widely utilized across various applications including rural towns, oil fields, and domestic electricity supply. These transformers are designed to handle low load rates and fluctuating loads efficiently, offering a robust solution for areas with significant shock loads and load variations.

Features and Applications

Several key features characterize oil immersed distribution transformers:

-

Reliability: High operational reliability ensures continuous performance under varying load conditions.

-

Efficiency: Low loss and low noise operation contribute to energy conservation and minimal environmental impact.

-

Adaptability: Suitable for environments with large shock loads and frequent load changes, ensuring stable power supply even in challenging conditions.

These transformers are available in a wide range of power ratings from 30kVA to 2500kVA, catering to diverse power distribution needs. They are particularly suitable for locations experiencing seasonal electricity consumption, concentrated electricity demand, and low average load rates.

Structural and Design Features

Environmental Conditions

Designed to operate in ambient temperatures ranging from -40℃ to +40℃, with provisions for high humidity and wind speed conditions.

Design Considerations

-

Utilization of high-temperature resistant insulating materials and oils to withstand high overload conditions.

-

Efficient heat dissipation structures to manage temperature rise during operation.

-

Double sealing structures for components to enhance reliability and prevent oil leakage.

Reading more: The Impact of Impedance on Transformer Design

Performance Characteristics

-

Capability to handle overloads up to 2 times the rated capacity for specified durations without compromising service life.

-

Longevity ensured through vacuum oil injection processes that eliminate moisture and prevent degradation of insulation materials over a potential service life of 20 years.

Specialized Variants

High Overload Transformers

Engineered with materials and designs capable of withstanding severe overload conditions up to 2 times the rated capacity, ensuring stable power supply during peak demand periods.

Environmental Impact

Incorporation of vegetable oils and other environmentally friendly materials in newer models to enhance energy efficiency and safety while reducing ecological footprint.

Technological Advancements

Recent advancements include the development of:

Automatic Capacity and Voltage Regulation

Transformers equipped with intelligent controllers for automatic adjustment of capacity and voltage levels based on load requirements, optimizing energy efficiency and operational safety.

Digital Monitoring and Control

Integration of sensing technologies for real-time monitoring and control of key operational parameters, enabling proactive maintenance and fault management.

Conclusion

Oil immersed distribution transformers represent a critical link in modern power distribution networks, offering high reliability, efficiency, and adaptability to varying load conditions. With continuous technological advancements, these transformers are poised to further enhance energy efficiency, environmental sustainability, and operational safety in the power sector.

Related Products

Related Article

Advantages of Transformer Yyn0 Vector Group

The Yyn0 vector group transformer offers distinct advantages in suppressing high-order harmonic currents and managing low-voltage single-phase ground short-circuit faults. However, it does have limitations regarding the handling of single-phase unbalanced loads, where the Dyn11 connection demonstrates superior performance. These characteristics should be carefully considered when selecting the appropriate transformer connection for specific applications to optimize performance and reliability.

Impact of Operating Temperature on Transformers

Maintaining an optimal operating temperature is crucial for the longevity and reliability of transformers. Excessive temperatures accelerate the aging process of the winding insulation, leading to a significant reduction in service life. Ensuring that the hottest point temperature remains within safe limits can help in maximizing the operational lifespan of transformers and maintaining their performance. For long-term efficiency and reliability, it is essential to monitor and control the operating temperature of transformers.

Transformer Drying Methods and Procedures

The article outlines transformer drying methods: oil tank iron loss, zero-sequence current, and vacuum dehumidification, emphasizing controlled heating and moisture removal for enhanced insulation reliability.

Transformer Oil Aging, Regeneration, and Purification

Effective management of transformer oil ensures prolonged equipment lifespan and reliable performance in electrical applications.

Technical Requirements for Transformer Installation

The article outlines critical technical requirements for transformer installation, covering support, grounding, cable management, safety measures, and fan operation to ensure safe and efficient electrical system performance.

Basic Knowledge of Transformer Transportation

Transformer transportation varies by size. Below 80 tons, use oil with dry air above oil level. Above 80 tons, use dry gas, monitor pressure, and conduct tests. Ensure sealed integrity and monitor regularly during storage.