The Impact of Operating Environment on Transformer Design

Electric Transformers are the fundamental part of our electricity distribution system. Each of these Electrical Transformers is specifically designed and developed to satisfy a specific need of electricity and they are never designed in a manner that one size fits all.

When we talk about the Electrical Transformer design most people only think that the voltage Input and voltage output are the main concern of the Electrical Transformer design. However, the electrical voltage input and output is One factor of the operating environment among the several factors that control the Transformer design.

Our article will explain how the operating environment and operating conditions of different applications influence the Transformer design. To make things clear to you we will be discussing how an electrical transformer is designed based on the operating environment of different applications like for renewable energy plants, data centers and more.

Contact Daelim TransformerRenewable Energy Projects (Solar and Wind Farms)

If we can see there the renewable energy projects where Megawatts of electricity is produced using solar panels and wind turbines. Then these renewable energy projects need a dedicated electrical transformer to regulate and provide the electricity produced at the plant to either the local grid or directly to the consumers.

One of the biggest challenges that the Electrical Transformer faces in Renewable Energy projects is that the renewable energy resources like solar panels and wind turbines produce variable output power. So the Electrical Transformer is designed in order to compensate for that variable Input and regulate the electrical voltage to deliver a reliable and stable output voltage.

To design an Electrical Transformer that can deal with the variable output power of an renewable energy resource the transformer is designed with an amorphous core.

You may enjoy: Key Principles of High Voltage Transformer Design

Another challenge of the Electrical Transformer designer phase is the remote location of these renewable energy projects. Almost all of the renewable energy projects are constructed or established far away from urban areas and in open and watch fields.

So an Electrical Transformer might face a very wide temperature fluctuation in different weather conditions. The Transformer also faces a higher UV exposure due to being in an open field and may also face a lot of sand and dust storms.

So to design an Electrical Transformer that can resist these challenging operating environments of renewable energy projects. The designer needs to design an Electrical Transformer enclosure keeping in mind the outdoor rated design.

The designer needs to ensure that the material used for the manufacturing has high resistance. The designer has to design and the manufacturer has to manufacture the Transformer tank or the Transformer enclosure with IP55 rating. The IP55 rating shows that it is waterproof and sand and dust cannot be ingressed.

Other than the IP55 ratings the designer needs to ensure that the Transformer has a special UV resistant paint and all of the fittings or made from Stainless Steel material to resist the harsh outside environment. The technical Transformer designer also needs to ensure that special gaskets between the matting parts sp that extreme temperature cannot produce leakage.

The Electrical Transformer used in the renewable energy project will be installed in an open outdoor environment where temperature can reach extreme temperatures during summer. So the cooling method also needs to be as per the operating condition of the Electrical Transformer.

In regions where summer temperature is not of extreme level oil natural air natural cooling systems can be used because of their simplicity and minimal maintenance. However in regions where the summer temperature is high enough to be considered extreme it is highly recommended to use oil natural air forced cooling method to increase the cooling effect on the electrical transformer.

Get free: Daelim Transformers Solution For Renewable Power Plant

Transformer Design For Operating Condition of Data Center

In the age of artificial intelligence data is everything. This is the reason we are observing large data centres being developed and their related infrastructure being built in every big city and developed country of the world. These data centres for Artificial Intelligence use Gigawatts electricity for their day to day operations.

The first requirement of these data centers is of Huge electricity supply and the second requirement is the reliability and quality of that supplied electricity. This is because the machines and computers used in these data centers consume a huge amount of electricity and these devices are very sensitive to any type of fluctuating electricity.

Due to the operational sensitivity of these data centers, they cannot take any down time from the Electrical Transformer because it will cause billions of dollars in just a matter of minutes. Other than this these data centres need proper cyber security and smart grid integration to ensure the safety and reliability of the electrical infrastructure especially of Electrical Transformer.

The other requirements for the Transformer design for operating conditions of data centres include the Indoor installation that may require a compact design and very efficient thermal management system from the electrical transformer. To the indoor installation and that installation is using the side of a building that might be surrounded by several residential buildings so there is a strict extremely low noise requirement.

The designer of the Electrical Transformer for data centers focuses on the quality of the Electrical Transformer performance by using high quality material for the Transformer Core and the Transformer winding. Design should be compact and highly efficient to meet the energy demand of data centers. Due to indoor application excellent thermal management is required and for that K class insulating liquid natural air natural KNAN cooling system.

A dry type Electrical Transformer is highly recommended for indoor estimations with all types of fire safety protections. In cases where an oil type transformer is needed it is highly recommended to use non toxic fluid like natural esters to ensure and enhance the indoor safety of Electrical Transformer.

Keep reading: Empower Your Data Center with Daelim Transforme

Battery Energy Storage Systems (BESS)

Battery energy storage systems work with various energy generating resources like renewable energy. It works to store the energy in large batteries when there is an abundance of electricity produced by the electric source. Then later use that electricity When the source is unable to meet the demand.

Due to the nature of the work, this application requires a transformer that can handle frequent load cycling as the nature of the work of the battery energy storage system relies on that frequent loading cycle. Other requirements include a compact design because these battery energy storage systems are usually temporary systems that might move between one site to another.

Other than this the battery energy story system itself and the Electrical Transformer produces a lot of waste heat. So an excellent thermal stress management and waste removal management system is required in the Electrical Transformer design.

Learn more: Daelim Transformers Solutions For Energy Storage

The Electrical Transformer for the battery energy storage system should be designed using a forced cooling method likely to be forced air cooling method or forced oil Force air cooling method. The force cooling method ensures a high rate of waste heat removal reducing thermal stress on the system.

The Electrical Transformer design should be made keeping in mind that the Transformer Might be installed in a container with the battery energy storage system and might move from one site to another.

Dry type Transformers or highly recommended for such applications. The Transformer design should also consider thermal class upgrades like loss at insulation systems to tolerate the frequent cyclic loading condition and fast load change condition.

As the battery energy storage system is really designed to support electrical load when the electricity generating system cannot meet the demand, the Electrical Transformer for such an application should have enhanced short circuit resisting capabilities of this time. It is also required from the Electrical Transformer to deal with the highly fluctuating load profile and abilities to deliver a bi-directional power flow.

Reading on: Pad Mounted Transformer for BESS System

Transformer Design for Utility Scale Substations

Every country's national grid has multiple substations to facilitate the distribution of electricity. these substations or responsible for distributing electricity to a specific region or a part of the country. So any failure in the transformer of these utility scale substations means that the entire region will be without electricity. From this we can conclude that the reliability is the number one concern of these utility scale substations.

Based on the nature of the work we can predict the Transformer design for the substation will be installed in an open atmosphere so it will be exposed to all types of extreme weather. Other than these the Electrical Transformer design for the substation needs to satisfy the national grid code means the working mechanism, input and output parameters, number of safety devices, and all other parts of the electrical transformer should be in accordance with the national standards and the national grid requirement.

Electrical Transformer designers need to consider the national grid requirement and design the electrical transformer carefully so that it satisfies each and every requirement of the registration. Based on the outdoor installation of such a Transformer it is recommended that the traditional oil natural air natural cooling system for regions where highest temperature in summer does not reach to the extreme levels however for regions where summer temperature reaches with stream level it is recommended that oil natural Air Force cooling system should be used.

The main concern here is the tank of the Electrical Transformer. due to the outer installation the Transformer tank has to be outdoor rated if you have highest class enclosure ratings. To deliver Electrical Transformer design that ensures the Transformer life of 30 + years it is recommended to use heavy duty insulation systems in the Transformer and for oil type transformer Mineral oil or ester should be used as insulating and isolating medium.

You may enjoy: 69 kV Power Transformer for Substation in Pennsylvania

Transformer Design for Blockchain Operation

Very similar to the artificial intelligence data centres, the Blockchain operation is also a very high energy consuming operation. When designing an Electrical Transformer for blockchain the main requirement of depression is to have an Electrical Transformer that can deliver reliable and safe electricity of the required quantity.

Due to the extreme level of electricity consumption, the computers and electronics involved in blockchain operations produce a lot of waste heat. As all these electricity demand is being regulated and controlled by a single Electrical Transformer so the Electrical Transformer also produces heat at the Transformer winding. To deliver safe, reliable electricity to the blockchain operation an excellent thermal management system is required.

The blockchain operation uses machinery that is very sensitive to any fluctuation in the electricity so the Transformer design should be such that it ensures the reliability of electricity supply to the maximum. Other than this the blockchain operations usually perform in Indoor areas and Electrical Transformer also need to be installed indoors.

Due to indoor installation the Transformer design should be compact and modular. The designer needs to ensure that the Transformer efficiency remains high and it does ensure extreme low noise production during operation.

It is recommended that a drive Electrical Transformer should be used for blockchain operations with the year natural or post air cooling system depending on the system requirement.

Go on with: Transformers Solution For Data Center and blockchain

Transformer Design For Oil & Gas Exploration Sites

The Transformer design for oil and gas exploration sites is nothing ordinary. This is because all of the oil and gas exploration sites are very far away from any type of industrial or residential areas and they usually have any extreme operating conditions.

As the oil and gas exploration sites you really operate very heavy machinery And these exploration sites have their own small electricity generating setup that utilise diesel generators to generate electricity. So this application of the electrical transformer is similar to what we called a temporary power solution where a small electricity generation and distribution sector is temporarily called on a site.

It is also important to note here that the oil and gas exploration sites are considered very dangerous and operating conditions or considered as explosive in nature. So it is required from the electrical transformer design that the transformer is designed to be explosion proof.

The Transformer tank or Transformer enclosure should be designed and developed as a hazardous area rated enclosure (ATEX/IECEx compliant) with considerations to show that the transformer design is flame proof.

All parts of the Electrical Transformer that are exposed to the atmosphere should have an anti corrosion coating and to be made from the Stainless Steel material. The cooling system of the transformer design for the oil and gas exploration sites depends on the size and capacity of the transformer.

Small size Transformer can be a dry type Electrical Transformer with natural air or forced air cooling systems but a large size Electrical Transformer has to be an oil type electrical Transformer with a forced oil forced air cooling system.

Reading more: Transformers Solution For Oil and Gas Plant

Transformer Design for Industrial Application

Any type of large industry needs to have its own Electrical Transformer to support the electricity needs of its heavy machinery and equipment. One of the most challenging parts of the transformer design for industrial application is the environment or operating conditions under which the Transformer has to operate.

Any type of large industry needs to have its own Electrical Transformer to support the electricity needs of its heavy machinery and equipment. One of the most challenging parts of the transformer design for industrial application is the environment or operating conditions under which the Transformer has to operate.

In all Industries dust moisture heavy vibrations and very heavy duty frequent cycles is a normal thing. So the Electrical Transformer designer needs to consider all these factors during the designing and manufacturing stage of the Electrical Transformer.

Electrical Transformer enclosure should be designed with at least NEMA 4X or IP66 rating Protect it from all types of dust and moisture. To protect the Transformer internal components from industrial equipment vibration it is recommended that the Transformer should be provided with reinforced core clamping structures and other parts should be provided with special dumpers to resist the vibration.

As the Electrical Transformer for industrial application is most likely to be installed indoors so dry type transformers can be used depending on the industrial needs. However for oil type electrical transformers oil natural air natural cooling system is recommended for small transformers and oil natural air force cooling system is recommended for large size and Power capacity transformers.

Transformers Solutions for Industrial and Commercial Buildings

Transformer Design for Commercial Buildings

In commercial buildings where large HVAC systems are required to keep the environment comfortable, the transformer design is done to ensure that it delivers all the requirements of the commercial HVAC.

Some basic requirements of the commercial buildings are aesthetic considerations, low noise level and strict Energy Efficiency target. The commercial buildings also have space constraints, so the Transformer needs to be designed based on these limitations and requirements.

Due to lower electricity needs as compared to other applications the dry type electrical Transformers or highly recommended for commercial buildings. These Transformers are also compact in design and are much lighter in weight as compared to the oil type Transformers. In dry type transformer electrical transformers are much more silent (<50 dB) in Operation as compared to the forced air cooling system transformers.

These transformers are designed for commercial buildings so these transformers have to be designed for the maximum efficiency because in the United States Electrical Transformer design for commercial buildings should have an energy efficient design that meets the standards of DOE 2016 or EU EcoDesign standards.

Conclusion

Electrical Transformers or everywhere they are a key for our Electricity Distribution system and in respect to the application wherever there is the use of electricity there is a dedicated Electrical Transformer to regulate that electricity. Each application like data centre blockchain centres or industrial application commercial buildings each application has its own requirement and you need to design Electrical Transformer based on that needs and requirements. We have delivered you a very comprehensive understanding on how Electrical Transformer design depends on the operating condition of different applications. Each application has its only limitation and we require a dedicated Transformer for each application.

Follow Up

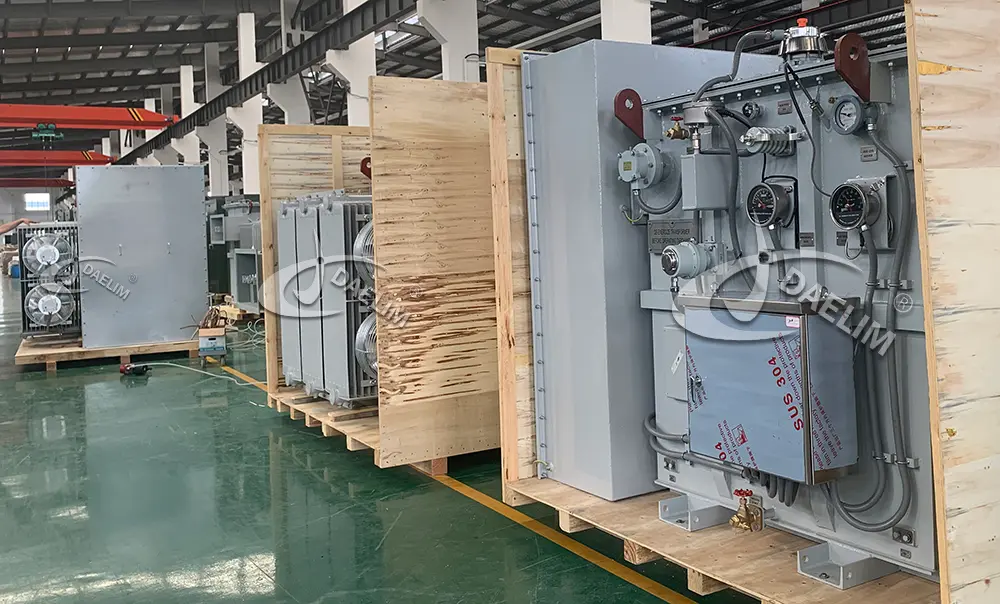

It is highly important for you to select and have a properly designed Electrical Transformer against your unique needs and operating environment. We at Daelim Transformer design and develop transformers for all types of applications including data centers, renewable energy plants like solar power plants and wind turbine power plants, and for other industrial applications or commercial buildings. Each of our products is designed and developed as per international standards and can meet all regional regulations related to safety and environmental protection.

If you have any special requirement for transformer design, Contact Us and we will talk you through the process.

Related Products

Related Article

Manufacturing of Large Power Transformer

Large power transformers are vital for electricity distribution, requiring precise design, manufacturing, and testing. Key parts include the core, windings, and tank, all built with high-quality materials and strict processes. Challenges include size, cost, skilled labor shortage, and environmental concerns. Precision equipment and expert handling are essential for high performance and reliability.

What are Different Types of Transformer Repair & Field Service

This article explains the importance of transformer repair and field services for maintaining continuous, safe electricity distribution. It covers when repairs are needed, common transformer issues, types of repair and maintenance services, diagnostic tests, emergency services, retrofits, and factors to consider when choosing a service provider to ensure reliable operation.

Addressing the Iberian Blackout: A Wake Up Call

A major blackout in Spain and Portugal exposed critical grid vulnerabilities, especially with renewable integration, transformer infrastructure, and reactive power control. Daelim offers fast-delivery, high-quality, custom transformers—ideal for modernizing outdated systems and supporting renewable energy projects. Contact Daelim for reliable, future-ready transformer solutions.

How To Calculate Transformer Load Capacity?

This article explains how to calculate transformer load capacity, detailing key concepts, step-by-step methods, and factors like efficiency, temperature, and load type. It highlights the importance of accurate calculations for safety and performance. Software tools like ETAP and SKM Power Tools are recommended. Daelim Transformer offers expert support and high-quality transformers for global clients.

Distributed Energy and Temporary Power

Daelim Transformer provides reliable, efficient solutions for the growing demands of distributed energy and temporary power systems, including solar, wind, and data center applications. With deep expertise and proven performance, Daelim ensures safe and sustainable electricity delivery while addressing the unique challenges of today’s evolving energy landscape.

How To Do Transformer Coil Winding Calculation

Transformer winding calculation involves determining turn ratio, core area, turns per volt, total turns, and wire cross-section. Based on input voltage, current, and frequency, you can design step-up or step-down transformers accurately. Proper wire gauge selection ensures safe and efficient operation. Daelim Transformer offers customized transformer design services to meet specific requirements.