Cast Resin Transformer: Definition, Types, Benefits, Applications, Maintenance

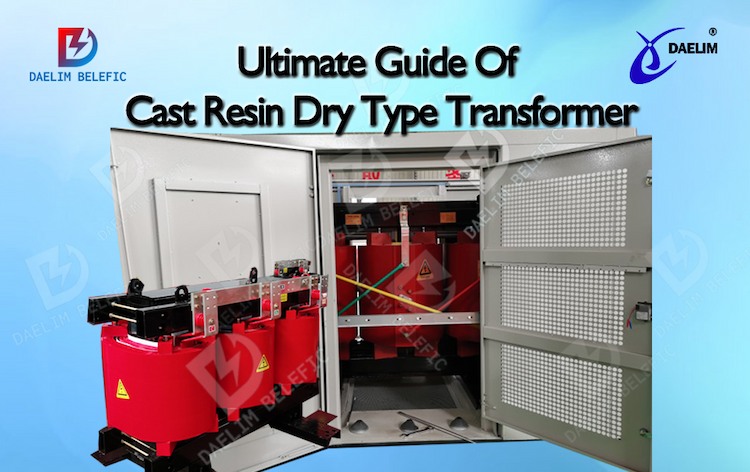

The cast resin transformer is a type of dry transformer that uses epoxy resin to encapsulate the windings and core, providing excellent insulation and environmental protection. Here are key points about cast resin dry-type transformers:

What is a Cast Resin Transformer?

A cast resin dry-type transformer, also known as an epoxy cast resin dry-type transformer, is a type of SC(B) dry transformer widely utilized due to its epoxy resin construction. Its windings are encased in high-quality protective material, ensuring robust insulation even in challenging environments such as dust and humidity. The resin casting process involves using molds and specialized equipment to cast coils under vacuum conditions. Epoxy resin, an insulating adhesive, makes it non-flammable and suitable for indoor use.

A cast resin dry-type transformer, also known as an epoxy cast resin dry-type transformer, is a type of SC(B) dry transformer widely utilized due to its epoxy resin construction. Its windings are encased in high-quality protective material, ensuring robust insulation even in challenging environments such as dust and humidity. The resin casting process involves using molds and specialized equipment to cast coils under vacuum conditions. Epoxy resin, an insulating adhesive, makes it non-flammable and suitable for indoor use.

The large heat capacity of the cast molding windings gives the epoxy cast resin dry-type transformer strong overload capacity and requires no maintenance, making it highly favored. With the global economy's growth, demand for resin dry-type transformers is expected to increase rapidly.

How Does a Cast Resin Dry Type Transformer Work?

Cast resin dry-type transformers operate on the principle of electromagnetic induction, similar to other types of transformers. When a conductive object is exposed to a varying magnetic field, it induces an electric current within the conductor.

AC voltage is applied to the primary winding at both ends of the dry-type transformer. As AC current flows through the primary winding, it generates an alternating magnetic field. This magnetic field is primarily confined within the iron or magnetic core of the transformer. Since the secondary winding is also wound around this core, the changing magnetic field induces an electromotive force (EMF) across the ends of the secondary winding. The voltage generated by the secondary winding differs from the input voltage, and its frequency and waveform mirror those of the input AC voltage.

Types of Cast Resin Dry Type Transformers

Filled Resin Casting: Includes quartz powder for improved mechanical strength and thermal conductivity.

Unfilled Resin Casting: Pure epoxy resin without fillers, simpler in construction.

Advantages and Disadvantages

Advantages:

- Safe, fire-retardant, and suitable for indoor installation without special containment.

- High electrical performance, resilient to short circuits, and requires minimal maintenance.

- Energy-efficient and environmentally friendly.

Disadvantages:

- Higher initial cost compared to oil-filled transformers.

- Limited to lower voltage levels (up to 35kV) and capacities (up to 25,000kVA).

- Requires protection if used outdoors due to resin vulnerability to UV and weather.

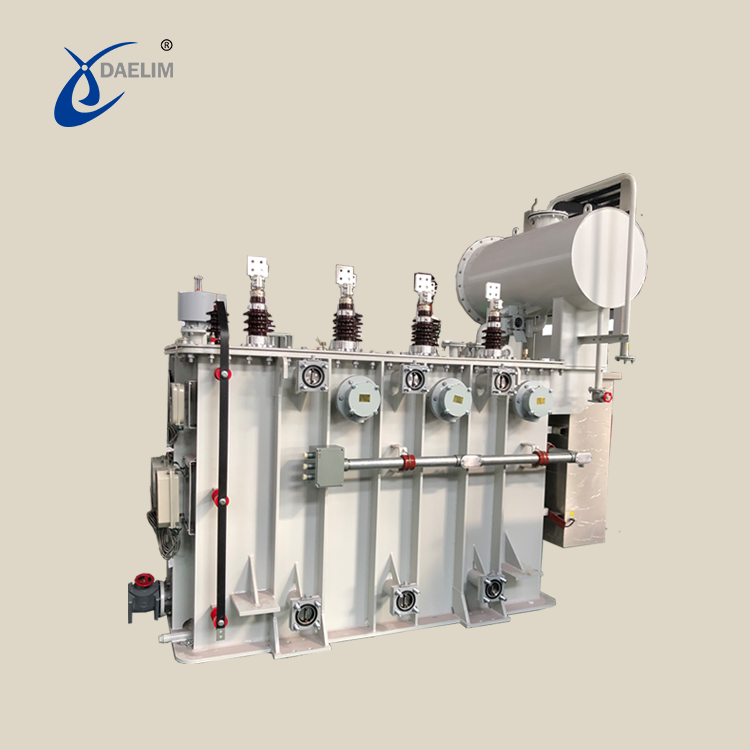

Differences from Oil-Type Transformers

Construction

Oil transformers use mineral oil for insulation and cooling, while cast resin transformers use epoxy resin.

Applications

Oil transformers are versatile for both indoor and outdoor use, while cast resin transformers are predominantly used indoors.

Application

Indoor Applications

Ideal for areas with high fire safety requirements like shopping malls, hospitals, and high-rise buildings.

Outdoor Use

Can be used outdoors with proper weatherproof casing and protection against UV degradation.

Maintenance and Testing

Maintenance and Testing

Maintenance

Generally low maintenance but requires periodic inspection for dust and insulation integrity.

Testing

Routine tests include insulation resistance, AC withstand voltage, and temperature monitoring to ensure operational safety.

Conclusion

Cast resin transformers offer significant advantages in safety, environmental friendliness, and reliability for indoor electrical distribution. Their application is crucial in modern settings where safety and environmental concerns are prioritized, despite higher initial costs compared to traditional oil-filled transformers.

Related Products

Related Article

Dry Transformer: The Ultimate FAQs Guide - Daelim

A dry transformer is an electrical transformer that uses air or gas as an insulation medium instead of liquid. It is also sometimes referred to as an air-core transformer. Dry transformers are very different from their liquid or oil-filled counterparts.

Why Does Dry-Type Transformer Make Noise?

Noise in dry-type transformers is mainly caused by poor-quality silicon steel sheets, uneven installation sites, and high grid voltage increasing the core's magnetic density.

Differences Between Dry Transformers and Oil Immersed Transformers

Dry transformers are used indoors for fire safety, have visible coils, resin insulation, and are costlier. Oil immersed transformers are outdoor units, use oil for cooling and insulation, handle higher capacities, and are more cost-effective.