Dry Transformer: The Ultimate FAQs Guide - Daelim

The transformer industry manufactures different transformers, each with unique capabilities and features that serve different purposes. One such transformer is the dry-type transformer. Daelim's array of dry-type transformers provides many advantages, making them the preferred choice for many applications.

This Frequently Asked Questions guide will answer some common queries regarding this type of transformer to understand further what dry transformers are.

What is a Dry transformer?

A dry transformer is an electrical transformer that uses air or gas as an insulation medium instead of liquid. It is also sometimes referred to as an air-core transformer. Dry transformers are very different from their liquid or oil-filled counterparts.

For one, dry transformers are more efficient and durable than oil-filled transformers because there is no liquid to leak or catch fire. Additionally, dry transformers are easier and cheaper to maintain because there is no need to check or change the oil periodically.

Dry transformers are also smaller in size and lighter in weight for a given power rating when compared to an oil-filled transformer of the same rating. This is due to the fact that dry-type transformers use thinner wire coils which take up less space.

Learn more: Ultimate guide of cast resin dry type transformer

What is a Three-Phase Dry-Type Transformer?

A three-phase dry-type transformer is a self-cooled transformer that uses two windings and is available in a wide range of primary and secondary voltage combinations. These units are mostly used in industrial applications where there is a need for high power capacity. In addition, since it's a three-phase transformer, it works on a three-phase power supply, with both primary and secondary windings having three total sets of windings.

What is the Use of a Dry Transformer?

Dry transformers are static devices that use air as a cooling medium. When the unit heats up during the conversion from higher to lower voltage, the air and the Dupont Nomex insulation material used in the construction of the transformer, work together to dissipate the heat.

Dry transformers are typically used in indoor applications where there is no risk of the unit being exposed to water or other liquids. However, they are also used in locations where there is a high risk of fire, such as in chemical plants or oil refineries.

Dry Type Transformer Standards

The energy performance standards for dry transformers are as follows:

Single Phase KVA Rating

15kVA at 97.70 1.2 kV Class

25kVA at 98.00 1.2 kV Class

37.5kVA at 98.20 1.2 kV Class

50kVA at 98.30 1.2 kV Class

75kVA at 98.50 1.2 kV Class

100kVA at 98.60 1.2 kV Class

167kVA at 98.70 1.2 kV Class

250kVA 98.80 1.2 kV Class

333kVA, 500kVA, 667kVA, 833kVA

Three-phase KVA Rating

15kVA at 97.89 1.2 kV Class

30kVA at 98.23 1.2 kV Class

45kVA at 98.40 1.2 kV Class

75kVA at 98.60 1.2 kV Class

112.5kVA at 98.70 1.2 kV Class

150kVA at 98.83 1.2 kV Class

225kVA at 98.94 1.2 kV Class

300kVA at 99.02 1.2 kV Class

500kVA at 99.14 1.2 kV Class

750kVA at 99.23 1.2 kV Class

1,000kVA at 99.28 1.2 kV Class

1,500kVA, 2,000kVA, 2,500kVA, 3,000kVA

3,750kVA, 5,000kVA, 7,500kVA

Read more: How To Purchase A 1000kva Transformer

What is a Dry Type Distribution Transformer?

A dry type distribution transformer is a type of transformer that serves as the final stage in the electrical distribution system. It steps down the voltage from the secondary of the main power transformer to the level required by the loads.

Since it's dry-type, it uses air or gas for insulation instead of liquid or any other medium. Additionally, the unit is filled with nitrogen gas to prevent the growth of mold and mildew.

Dry-type distribution transformers can be used both indoors and outdoors. They are typically placed in a vault, on a pole, or underground. That way, they are protected from the elements and tampering.

Read my article on: How much do you know about oil-immersed distribution transformers?

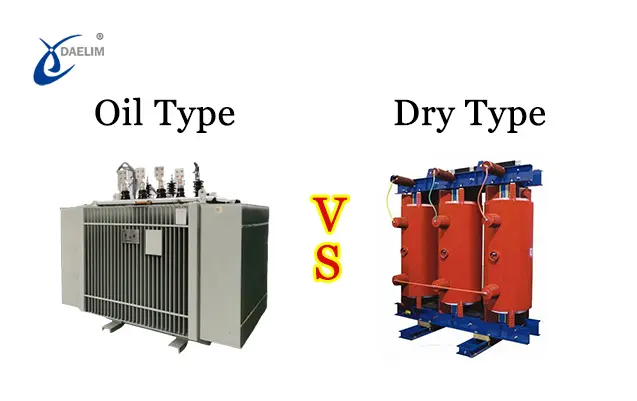

Dry Type VS Oil Type Transformers

When selecting transformers, it's essential to understand the differences between dry-type and oil-type transformers. Both types perform similar functions but differ primarily in their insulation and cooling methods.

Dry-Type Transformers

Insulation and Cooling:

Dry-type transformers utilize air or a gas medium for insulation and cooling. They can be either self-cooled or forced-air cooled. The absence of oil means these transformers are often more expensive due to the advanced cooling methods required. Additionally, dry-type transformers eliminate the risks associated with oil leakage and flammability.

Maintenance:

Dry-type transformers generally require less maintenance compared to oil-type transformers. They do not necessitate regular oil changes and are chemically resistant, thus eliminating the need for chemical contamination testing and management.

Reading more about Transformer Maintenance

Operational Costs:

Although dry type transformers incur a higher initial cost, their operational costs are typically higher in the long run. They are less efficient and have a shorter operational lifespan compared to oil-type transformers. Their larger size and lower voltage ratings can lead to overheating issues during overloads, resulting in increased maintenance and potential electrical losses.

Recyclability:

The recycling process for dry type transformers can be more complex and less commonly available compared to oil-type transformers, making it more challenging to find appropriate recycling facilities.

Efficiency:

While dry-type transformers are efficient, they do not match the efficiency of oil-type transformers. Their larger size and lower voltage ratings contribute to higher maintenance costs and potential inefficiencies due to overheating.

The energy efficiency of dry-type transformers is available in 35% nominal load and 50% nominal load. The efficiency of a transformer at 35% nominal load is typically 99.5%. The efficiency of a transformer at 50% nominal load is typically 99%.

Reading more about Transformer Efficiency

Installation Environment:

Dry transformers are best suited for challenging environments, such as outdoor or dusty locations, due to their robust construction. Conversely, oil-type transformers perform optimally in clean, dry indoor environments where their efficiency and durability are advantageous.

Oil Transformers

Insulation and Cooling:

Oil-type transformers use mineral oil as both an insulation and cooling medium. This method facilitates effective heat dissipation and typically results in lower initial costs. The use of oil also introduces potential risks related to leakage and flammability.

Maintenance:

Oil-type transformers require more frequent maintenance, including periodic oil changes and testing for chemical contamination. Despite these requirements, they are known for their durability and can offer a longer lifespan with proper care.

Operational Costs:

Oil-type transformers generally have lower operational costs due to their higher efficiency and longer service life. Although maintenance is required, their conventional energy efficiency makes them a cost-effective option over the long term.

Recyclability:

Oil-type transformers benefit from a more straightforward and established recycling process compared to dry-type transformers. The recycling infrastructure for oil-type units is well-developed.

Efficiency:

Oil-type transformers are more efficient than their dry-type counterparts. They are designed to handle higher voltage ratings and feature better cooling capabilities, reducing the risk of overheating and minimizing electrical losses.

Installation Environment:

Oil-type transformers are ideally suited for indoor environments where cleanliness and dryness are maintained. They offer superior efficiency and longevity compared to dry-type transformers, making them a preferable choice for controlled environments.

Get it now: The ultimate guide to ONAN transformers

What are the Advantages of a Dry Transformer?

Better Overload Capacity

Dry transformers can handle overloads better than oil transformers. That's because the windings in a dry-type transformer are cooled by the surrounding air, preventing them from overheating.

Low Partial Discharge

Partial discharge is a phenomenon that causes insulation degradation in transformers. There are tiny gaps or voids in the insulation that allow for a small discharge of electricity.

This ultimately causes the transformer to fail. On the other hand, dry transformers are less likely to experience partial discharge because the windings are surrounded by a solid material that doesn't have any gaps or voids.

Can Be Fitted Outdoors

Another advantage of dry transformers is that they can be fitted outdoors. That's because they don't rely on a liquid insulation medium, so they are not at risk of leaking. For that reason, you can fit dry transformers outdoors inside an IP-45 enclosure without any issue.

Zero Risk to Fire Hazard

Since it uses nonflammable air as winding insulation, a dry-type transformer doesn't pose a fire hazard. In contrast, oil-type transformers are a fire hazard because the oil used for insulation is flammable.

Non-Hygroscopic

Dry-type transformers are also non-hygroscopic. That means they don't absorb moisture from the air, which can cause corrosion. That's why dry-type transformers are ideal for outdoor applications since they can withstand the elements better than oil-type transformers.

Try for free: 1 MVA Transformer: The Ultimate FAQs Guide - Daelim

Can Dry Transformers Be Used Outside?

Yes! Dry transformers can be used both indoors and outdoors because of the following features:

It's non-flammable

It's not hygroscopic

It can be fitted inside an IP-45 enclosure

They are typically placed in a vault, on a pole, or underground. That way, they are protected from the elements and tampering.

Reading more: Different Transformer Types and Their Applications

How Are Dry Transformers Cooled?

Dry-type transformers are cooled in one of two ways: self-cooling or forced cooling.

Self-cooling is the most common cooling method, and it's used for small to medium-sized transformers. The surrounding air cools the transformer, so they are often fitted with fans to circulate the air.

Forced cooling is used for larger transformers that generate more heat. The transformer is cooled by a liquid, typically water or oil. The liquid is circulated to the transformer to remove the heat.

How Do You Protect a Dry Transformer?

Dry transformers can make use of different shells and enclosures to protect them from the environment and from tampering. However, it will depend on the environmental aspect and the transformer's size and power rating.

The IP-20 protective casing prevents the entry of foreign objects bigger than 12 millimeters in diameter. This level of protection provides solid safety for the live parts inside the dry transformer.

The most common type of enclosure is an IP-45 enclosure. This type of enclosure is made of sheet steel and fitted with a door that seals the transformer inside. The IP-45 designation means that the enclosure is dust-tight and protected against water jets.

If you're installing the dry transformer outdoors, then the IP-23 and IP-54 levels of protection are suitable since they are ideal for use in damp or wet conditions. In addition, these protective enclosures prevent water ingress which could cause damage to the transformer.

The IP-65 level of protection is the highest, and it's used in hostile environments. This type of enclosure is made of stainless steel and it's fitted with a door that seals the transformer inside. In addition, the IP-65 designation means that the enclosure is dust-tight and protected against water jets.

Reading on: Electrical Transformer Protection Knowledge Guide

Dry Type Transformer Manufacturers

Daelim is one of the best dry-type transformer manufacturers because we offer different high-quality transformers suitable for various applications and industries. We also provide a wide range of services, such as installation, maintenance, and repairs.

Daelim has been in the transformer business for years, and our experience and expertise are unrivaled. Daelim offers a wide range of dry-type transformers, such as air-cooled cast resin transformers.

Related Products

Related Article

Why Does Dry-Type Transformer Make Noise?

Noise in dry-type transformers is mainly caused by poor-quality silicon steel sheets, uneven installation sites, and high grid voltage increasing the core's magnetic density.

Differences Between Dry Transformers and Oil Immersed Transformers

Dry transformers are used indoors for fire safety, have visible coils, resin insulation, and are costlier. Oil immersed transformers are outdoor units, use oil for cooling and insulation, handle higher capacities, and are more cost-effective.

Transformer Drying Methods and Procedures

The article outlines transformer drying methods: oil tank iron loss, zero-sequence current, and vacuum dehumidification, emphasizing controlled heating and moisture removal for enhanced insulation reliability.