The ultimate guide to ONAN transformers

ONAN is a form of transformer cooling in which mineral oil is used inside the transformer tank to cool and cool the transformer. KNAN is another cooling method for transformers, which means that vegetable oil is used to cool the transformer inside the oil tank.

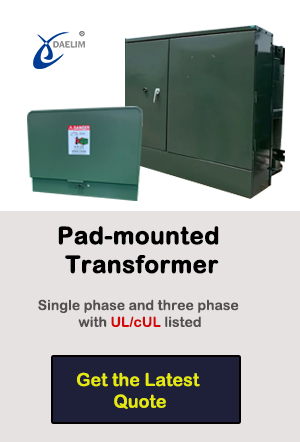

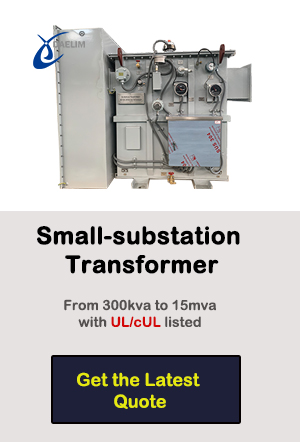

Daelim manufactures transformers with ONAN and KNAN cooling options, which allow the use of either mineral or vegetable oil according to customer requirements. Daelim-manufactured ONAN transformers are sold to the United States, Canada, Australia, and other countries, widely used in construction, utilities, industrial, power industry, etc. Welcome to consult me at any time for any ONAN transformer needs!

What does ONAN mean on a transformer?

ONAN as indicated in the transformer nameplate is a four-digit code that describes the cooling method of a transformer unit as defined by ANSI/IEEE Standard C57.12.00 wherein:

1st letter - Internal cooling medium

2nd letter - Internal cooling mechanism

3rd letter - External cooling medium

4th letter - External cooling mechanism

Based on this, ONAN in transformers can be decoded as:

O - Oil

N - Natural

A - Air

N - Natural

Read more: Basic Guide To High Voltage Power Transformers

What is an ONAN transformer?

An ONAN transformer is the least complex cooling system among oil-immersed types of transformer.

The ONAN transformer cooling system is very typical. No fancy fans or pumps are used. It is designed to cool itself naturally with mineral oil as its ultimate internal cooling medium.

Learn more: The Ultimate Guide to Dead Front Transformers

500 kVA ONAN Transformer

Primarily used among power distribution systems to convert electrical energy to usable energy. 500kVA rating is commonly used around the end-use site for industrial manufacturing and residential application. They produce low noise and are generally energy-saving.

| KVA | 208V | 240V | 480V | 600V | 2400V | 4160V |

| 500 | 1390 Amps | 1204 Amps | 602 Amps | 482 Amps | 120 Amps | 69.6 Amps

|

More resources:

500 kVA Pad Mounted Transformer

500kVA Tier 2 Oil Filled Distribution Transformer

What is the cost of a 500 kVA ONAN transformer?

The price for a 500kVA oil-immersed transformer can run between $6,000 to $10,000. Please note that the price for dry-type transformers is more expensive than the oil-immersed transformers.

What is the weight of the 500 kVA ONAN transformer?

The weight of a 500kVA oil-immersed transformer can be around 1. 87tons or 1700Kg.

What is an ONAN or ONAF transformer?

Unlike ONAN type transformer, ONAF(oil - natural - air - forced) type transformer cooling is better facilitated with the use of external fans.

These fans are strategically designed to aid faster dissipation of heat. A higher power rating can be attained with a more sophisticated cooling design.

This is a transformer designed with a base rating of natural air convection for external cooling and increases power rating when forced air is introduced using fans and pumps enhancing cooling capacity.

Reading on: 750 kVA Transformer

What is the difference between Onan and ONAF transformers?

Let's go back to the four-digit coding system, if ONAN is decoded as

O - Oil

N - Natural

A - Air

N - Natural

Then, ONAF is decoded as

O - Oil

N - Natural

A - Air

N - Forced

Notice that they only differ on the 4th letter. A single letter totally makes both transformers different.

ONAN is the most basic cooling method where all cooling mediums are introduced to the system naturally.

While for the ONAF type, the cooling medium used is forced. Cooling fans are installed to introduce more air into the system.

As a result, the system will have better circulation, and heat dissipates much faster. With a better cooling system, ONAF can further increase the transformer's power rating.

However, as an accessory is added means more maintenance and the fans can also produce more noise during the operation.

Read more: 1000kVA Pad Mounted Transformer

1000 kVA ONAN Transformer

Transformers in this capacity range are used as service transformers or distribution transformers. Stepping the voltage down to a level that is ready to use by consumers.

How much oil is in a 1000 kVA transformer?

The oil weight of an oil-immersed transformer is within 14% to 20% of its total weight. For a 1000 kVA transformer, oil should be more or less 750L.

How big is a 1000 kVA transformer?

To give you an idea of 1000kVA transformer size and weight, refer to this table:

| Daelim Belefic Transformer | W (mm) | H (mm) | D (mm) |

| 1085 | 1570 | 1800 | |

| 3 Phase Oil- Immersed Small Substation Transformer | 2260 | 1625 | 1500 |

Daelim Belefic Transformer W (mm) H (mm) D (mm)

3 Phase Pad Mounted Transformer 1085 1570 1800

3 Phase Oil- Immersed Small Substation Transformer 2260 1625 1500

Read more: The Ultimate Guide to Three Phase Transformer

1000 kVA transformer weight?

The Daelim Belefic Transformer mentioned above can weigh from 2450 Kg to 3720 Kg. Moreover, the weight of the transformer can differ depending on the model type, accessories, and insulating oil used.

Reading more: 1000 kVA Skid Mounted Transformer

How long will 1000 kVA ONAN transformers last?

Transformers from Daelim are built to the highest standards, ensuring robustness and durability. With proper maintenance, these transformers can provide reliable service for up to 40 to 50 years.

What does KNAN mean by a transformer?

KNAN on the transformer is decoded as:

K - Fluid with > 300°C flash point

N - Natural

A - Air

N - Forced

Notice the first letter K, this letter denotes fluid type with a flash point greater than 300°C. In this case, the KNAN transformer cooling system uses fluids with high flash points as an internal cooling medium through natural convection and uses natural air convection as an external cooling.

ONAN and KNAN are the same principle of natural cooling using oil and air.

KNAN cooling transformer is used explicitly for hazardous applications where the surrounding atmosphere is explosive. KNAN transformer rating and the price could also be higher than transformers designed with the ONAN cooling method.

Learn more: Basic Guide to kVA Transformer

What are the cooling methods of transformers?

To help protect the transformer and its parts from thermal damage and degradation, various ways of cooling are utilized across the industry.

For Oil-Immersed Transformers Cooling Methods are listed in the table below.

Transformer Cooling Method Internal Cooling Medium Internal

| Transformer Cooling Method | Internal Cooling Medium | Internal Cooling Mechanism | External Cooling Medium | External Cooling Mechanism |

| ONAN | OIL | NATURAL | AIR | NATURAL |

| ONAF | OIL | NATURAL | AIR | FORCED |

| OFAF | OIL | FORCED | AIR | FORCED |

| OFWF | OIL | FORCED | WATER | FORCED |

| ODWF | OIL | DIRECTED | WATER | FORCED |

| ODAF | OIL | DIRECTED | AIR | FORCED |

Since we already covered the first two transformer cooling methods, we will now elaborate more on OFAF, OFWF, ODWF, and ODAF methods.

OFAF Transformer

This is one of the most solid transformer cooling methods. As per the table above, OFAF is decoded as oil - forced - air - forced cooling method or class.

It uses a pump to introduce oil, a cooling medium that circulates continuously around the transformer’s radiator and oil tank.

Cooling fans are positioned at the radiator side forcing more air to facilitate rapid cooling. This method of cooling can be used in combination with other methods to increase the power rating.

OFWF Transformer

This is decoded as Oil - Forced - Water - Forced. From its definition, this cooling method utilizes pumps to introduce oil into the heat exchangers.

On the external part of the transformer, it uses water to disperse heat coming out of the heat exchanger.

The heated water is forced to cool down separately and introduced back into the system resembling a closed loop cycle.

ODWF Transformer / ODAF Transformer

In these cooling systems, the dissipation rate of heat is further improved. Additional cooling paths are put in place to direct the cooling oil pass across the windings and then to the radiator to enable a more efficient rate of heat transfer.

To avoid water from leaking out to the oil, the pressure of water should be lower than the pressure of oil in the heat exchangers.

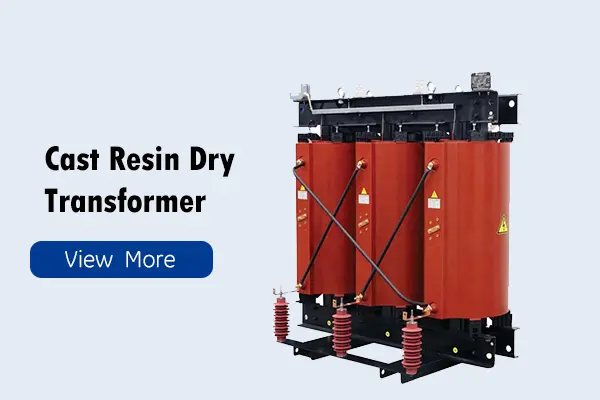

For Dry Type Transformers, Cooling Methods are:

1. AN - Air Natural

2. AF - Air Forced

Read my article on: Basic Guide Of Delta Transformer

ONAN vs KNAN Transformer

If you were able to read from the top, at this point you already know that the difference between these two is the type of oil used and their corresponding fire point.

ONAN uses mineral oil(fire point below 300°C) while KNAN uses non-mineral oil(fire point greater than 300°C).

Non-mineral oil can either be natural or synthetic, both types have high fire points thus safer to be used within Zone 1 and Zone 2 danger zones which are defined as explosive areas.

The tank design and footprint of KNAN transformers are bigger in comparison to transformers that use mineral oil.

Mineral oil is suited for A-class design. Its dissipation factor is higher which means the ONAN transformer’s footprint is smaller.

In application, mineral oil when used absorbs or transfers more heat which results in a smaller oil quantity. The radiator and cooling surface area are also smaller, making the ONAN transformer’s overall weight lighter.

ONAN Transformer Specification

15/25/35KV Class

Three Phase Oil-Immersed Distribution Transformer

| High Voltage (KV) | Low Voltage (KV) | Connection Symbol | Short Circuit Impedance | No-load Loss (W) | No-load Loss (W) | Reference Dimension | Reference Weight |

| 4.16 / 12 or others | 208/120 or others | Dyn1, Ynyn0 or others | 2.7 or others | 1160 | 11500 | 1085x1570x1800 | 2450 |

3 Phase Pad Mounted Transformer

| No-load Loss (W) | No-load Loss (W) | Reference Dimension | Oil Weight(L) | Total Weight (Kg) |

| 1150 | 10300 | 2260x1500x1625 | 1325 | 3720 |

More about Transformer Specifications

Dry Type Transformer Cooling Types

Dry-type transformers as the name suggests, do not use oil for cooling making this method a more environmentally friendly option.

It is designed with a comparably larger build than that of an oil-immersed transformer. This will make more room for better airflow in between its windings.

Using the surrounding air dry-type transformer is cooled down naturally. For some dry-type transformers in cabinets, air circulation is facilitated by a proper ventilation system.

Cooling for dry-type transformers

AN or Air Natural

The air natural method is self-explanatory. For this cooling method, no external force or medium is used. Cooling is simply done by natural convection.

Rating capacity for air natural dry-type transformers is usually not fully exhausted to protect the unit from burning out.

AF or Air Forced

This dry-type transformer is cooled by forced air from blowers and cross-flow fans.

For this cooling method, depending on the number of blowers or fans, dry-type transformer capacity can be increased up to 50%.

Related Products

Related Article

2000 kVA Pad Mounted Transformers for Canadian Utility

Daelim Transformer is pleased to announce its contribution to a utility project in Toronto, Canada, involving the supply of two units 2000 kVA pad mounted transformers. These transformers are integral to enhancing the power infrastructure in the region. The project demands adherence to CSA standards, with a stringent delivery deadline of 10 weeks to meet the urgent needs of the client.

4500 kVA Substation Transformers for Australian Mining Site

Today, we introduce a project by Daelim Transformer aimed at supplying transformers to a mining site in Australia. This project entails the provision of two units of 4500 kVA substation transformers tailored to fit the narrow confines of mining tunnels. Due to space constraints, the transformers need to be compact in size and mounted on mobile racks for easy maneuverability within the mine shafts. This necessitates meticulous design to meet the strict dimensional requirements set by the client.

Supply of 37.5 kVA Single Phase Pad Mounted Transformers for Canadian Utility

Today, we are excited to introduce a project undertaken by Daelim Transformer aimed at supplying transformers to a Canadian utility. This project involves the delivery of 80 units of 37.5 kVA single-phase pad mounted transformers, specially designed to meet the utility's requirements. With a high voltage (HV) rating of 24940GRDY/14400 V and a low voltage (LV) rating of 240/120 V, these transformers are vital components in the utility's infrastructure.

500 kVA Distribution Transformer for the Greek Market

Today, we're thrilled to showcase a European transformer project tailored for the Greek market. This project involves the supply of 500 kVA distribution transformers, with an input voltage of 20 kV and an output voltage of 400V. The client has requested adherence to both IEC and TIER-II energy efficiency standards. With a total quantity of 5 units, this project marks another milestone in Daelim Transformer's commitment to delivering high-quality solutions worldwide.

1750 kVA Pad Mounted Transformer for the Dominica Market

Today, we're excited to present a transformer project tailored for the Dominican market. Our 1750 kVA pad mounted transformer is designed to meet the specific requirements of our clients in Dominica. This step-down transformer boasts a primary voltage of 13.8 kV and a secondary voltage of 480Grdy/277V, adhering to the IEEE C57.12.34 standard. With its robust features and reliable performance, this transformer is set to enhance the power distribution infrastructure in Dominica.

Three Phase Power Transformers for Block Chain Facility in Texas!

Daelim Transformer thrilled to share details of our project - the supply of 90 units of three-phase power transformers for a large-scale block chain operation in Odessa, Texas. Each transformer is rated at 2500(3000)KVA with a primary voltage of 34.5kV Delta and a secondary voltage of 480GrdY/277. With strict UL certification requirements and a focus on high-quality accessories from reputable brands, this project demanded precision, efficiency, and reliability.