The Ultimate Guide to Three Phase Transformer

Three phase transformers are highly designed to handle power in three phases simultaneously. Three phase transformers are widely favored for power distribution and transmission line applications.

Daelim Transformer offers a diverse selection of three phase transformers to cater to various needs and requirements:

-

Three-phase power transformer

-

Three phase pad mounted transformer

-

Three phase oil filled distribution transformer

-

Three phase pole mounted transformer

This article aims to provide a comprehensive overview of three-phase transformers, covering their diverse types, illustrative charts, various sizes, intricate connection methods, and more. By delving into these crucial aspects, readers will gain a deeper understanding of the three-phase transformer.

What is called the 3 phase?

Three-phase refers to an electrical power system that uses three alternating currents to efficiently distribute electricity. It is commonly used in industrial and commercial applications, allowing for powerful machinery operation and efficient power transmission over long distances.

What is a three phase transformer?

Three-phase electricity is to produce equal amplitude, equal frequency, phase difference of 120° potential generator called three-phase generator; Three-phase generator a power supply, called three-phase power supply; The circuit with three-phase power supply is called three-phase circuit. U, V, and W are called three phases, and the voltage between phases is the line voltage, which is 380V. Between the phase and the center line is called the phase voltage, and the voltage is 220V.

Learn more about Three Phase Transformer

What Are The Types Of Three Phase Transformers?

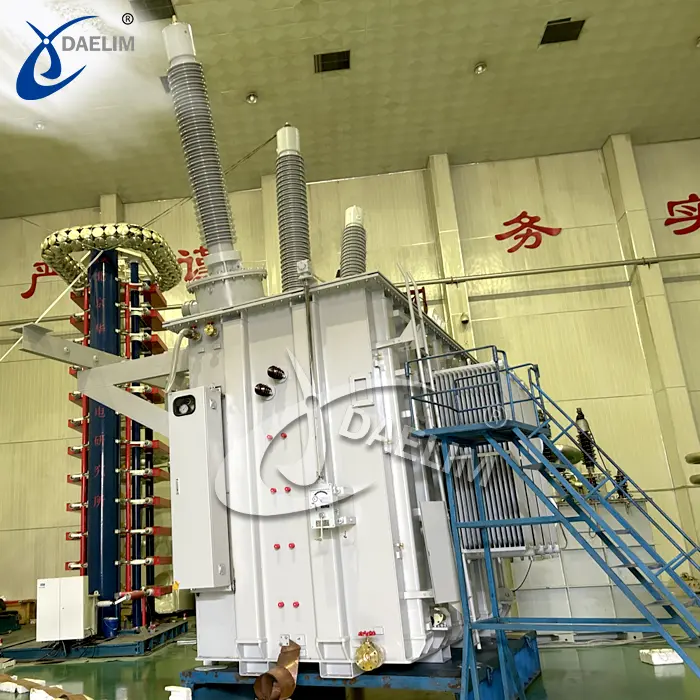

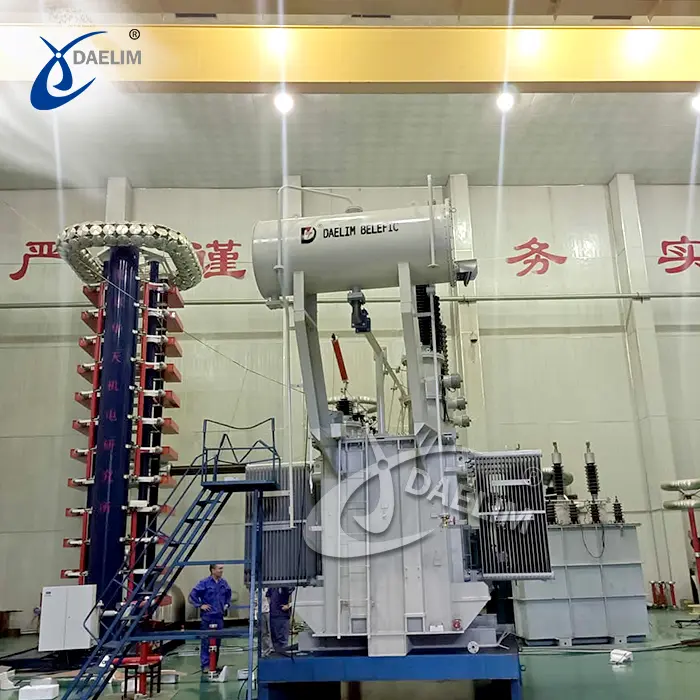

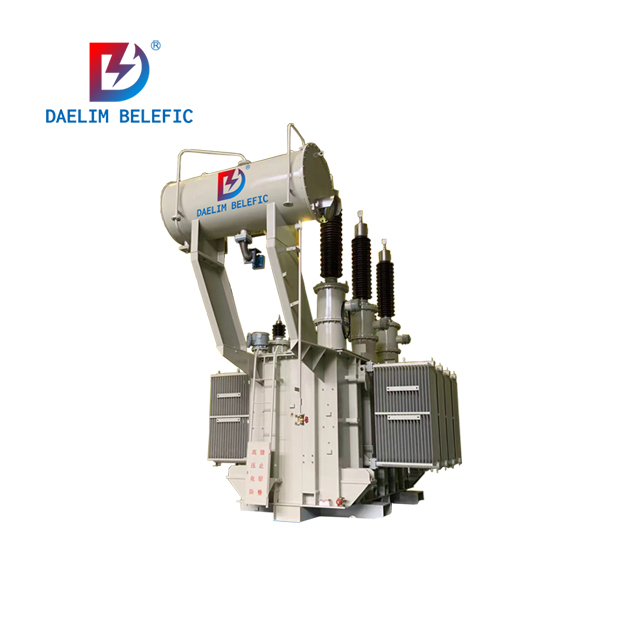

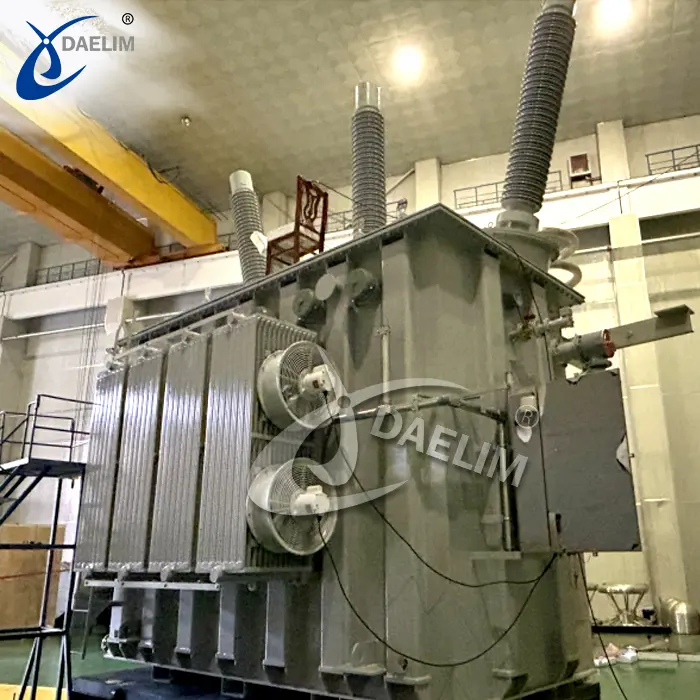

Three Phase Power Transformer

The Three-Phase Power Transformer is a high-capacity transformer designed for voltage levels typically surpassing 46kV and power ratings exceeding 5MVA. It plays a crucial role in power transmission and transformation due to its high voltage levels and substantial capacity. Common voltage levels for three-phase power transformers include 66 kV, 69 kV, 110 kV, 115 kV, 132 kV, 138 kV, 220 kV, and 230 kV.

Send Inquiry Now

Three-Phase Oil Filled Distribution Transformers

Three phase oil filled Distribution Transformers, ranging from 100 kVA to 3150 kVA, feature primary voltages of 3.3 kV, 6.6 kV, 11 kV, and 33 kV, with secondary voltages of 415V, 400V, and 433V.

In Europe, adherence to the 2021 secondary EU Directive 548/2014 and the BSEN60076 standard is typically required for these transformers. Compliance with these standards ensures significant reductions in carbon emissions and energy waste. These transformers are meticulously designed for optimal efficiency and reliability, minimizing power losses attributed to resistance and other factors. Safety is a paramount consideration, and they incorporate protective measures to prevent electrical accidents and fires.

Within a three-phase distribution transformer, the secondary cable plays a crucial role in reducing the voltage produced by the main winding to a level safe for consumer use.

Get Price

Three-phase pad-mounted Transformer

The Three-Phase Pad-Mounted Transformer is extensively utilized in the American market, finding applications in commercial areas, residential zones, solar power plants, wind energy plants, EV charging stations, industries, data centers, and even blockchain facilities.

A distinctive feature of the pad-mounted transformer is its enclosure, meticulously designed to safeguard the transformer and its components from environmental factors such as moisture, dust, and tampering. Typically constructed from robust materials like steel or aluminum, the enclosure is equipped with insulation and cooling mechanisms to ensure optimal operating conditions.

The design incorporates a front compartment with a lock, housing high and low-voltage accessories, instruments, and meters. This configuration enhances its anti-theft and anti-tampering features.

Send Inquiry NowThe Pole-Mounted Three-Phase Transformer is strategically elevated for safety and efficient power distribution to consumers. Typically installed on utility poles, its voltage level generally does not surpass 35kV, and its capacity is capped at 500 kVA. This limitation ensures that the transformer remains lightweight enough for the poles to bear without compromising structural integrity. Primarily designed for power distribution to rural, commercial, and industrial customers, it is particularly useful in areas where underground power distribution proves impractical or cost-prohibitive.

Reading more about Transformer Types

How Are Windings Connected To A 3 Phase Transformer System?

The primary windings connect to the three-phase power system, while the secondary windings secure to the load or the next stage in the power distribution system.

As well as that, a 3 phase transformer is highly applied for various power ratings and is available in a variety of configurations such as delta-delta, delta-wye, wye-delta, and wye-wye.

The choice of configuration depends on the specific application, and each configuration has its advantages and disadvantages.

What Can Be The Connections Of A Three-Phase Transformer?

A 3 phase transformer has three sets of main and secondary wirings to achieve different voltage and current requirements.

1. Delta Delta

In this arrangement, the three main cables are primarily linked via a delta configuration.

Since there are three secondary wires, the configuration is a strong delta.

This connection is mainly used when the voltage transformation ratio is 1:1, and the load is balance.

2. Delta-Star

The three main cables here form a delta, while the secondary cables, three in quantity, make a star.

This connection is typically used when the load isn't spread uniformly and the main power is higher than the auxiliary.

3. Star-Star

The three primary wires form a star connection with the three secondary cables, and vice versa.

4. Autotransformer Connection

In this type of connection, the main and secondary cables frequently share some of the wires.

The autotransformer connection is generally used to provide a variable voltage output and is commonly applied in electrical power transmission systems.

Learn more about Transformer Connection

What is the difference between single-phase and three-phase transformers?

In electrical equipment and wireless circuit, commonly used for lifting voltage, matching impedance, safety isolation, etc. The main functions of the transformer are voltage conversion; Current conversion, impedance conversion; Isolation; Voltage regulator (magnetic saturation transformer); and Autotransformer; High voltage transformers (dry type and oil-immersed type), transformers commonly used core shapes generally have E and C type core, XED, ED CD type.

In electrical equipment and wireless circuit, commonly used for lifting voltage, matching impedance, safety isolation, etc. The main functions of the transformer are voltage conversion; Current conversion, impedance conversion; Isolation; Voltage regulator (magnetic saturation transformer); and Autotransformer; High voltage transformers (dry type and oil-immersed type), transformers commonly used core shapes generally have E and C type core, XED, ED CD type.

The single-phase transformer has lower no-load loss and energy-saving than the three-phase transformer with the same capacity. Some papers list the application example mentioned reform has the economic efficiency, with D10, D11 even D12 series transformer and compare with the capacity of the integrated series transformer, such as mentioned with the capacity of D11 single-phase transformer no-load loss is much lower than the integrated three-phase transformer, single-phase transformer so that more economic than three-phase transformer operation, This is a misunderstanding. In the example, the difference between the two technical levels is ignored. According to JB/T3837-1996 Transformer Product Model Compilation Method, the performance level of transformer model sequencing is stipulated, and the performance parameters of the bigger one should be raised to a new level. For example, the D10 series transformer is designed according to S10 transformer parameters. When demonstrating the effect of reducing losses of the D10 or D11 series transformer, the S10 or S11 transformer of the same model should be selected for comparison. It is unfair to select the S9 series transformer as a reference.

Less material

The same capacity of the single-phase transformer as a three-phase transformer with 20% less iron, with 10% less copper. Especially when the coil core structure is used, the no-load loss of the transformer can be reduced by more than 15%, which will make the manufacturing cost and use the cost of the single-phase transformer decrease at the same time, to obtain the best life cycle cost.

Low line investment

The single-phase power supply system in the power grid can save 33% ~ 63% of the wire, 42% of the weight of the wire can be saved according to the economic current density, and 66% of the consumption of the wire can be reduced according to the mechanical strength. Therefore, the construction investment of the whole transmission line can be reduced. This is of great significance in the lighting of street lamps and the use of electricity in the rural and urban areas of our country.

Learn More: Single Phase Pole Mounted Transformer

Can a 3-phase transformer be used for single-phase?

Yes. We all know that the dry transformer is composed of single-phase dry transformer or three coherent type transformer, and the single-phase dry transformer is divided into single-phase isolation transformer and single-phase auto-transformer; Three - phase coherent transformer is divided into three-phase isolation transformer and three-phase autotransformer. However, voltage transformers can be connected not only to single or three phases, but also to two phases, six phases, and even, for some DC rectifier transformers, to 24 phases. If we take three single-phase transformers and connect their primary windings to each other. The secondary windings to each other in a fixed configuration (triangle or Y-shape), we can use a transformer on a three-phase power supply.

To make the single-phase transformer connection compatible with the three-phase power supply, we need to connect three single-phase transformers together in a specific way to form a three-phase transformer. Three-phase transformers or 3φ transformers can be made by connecting 3 single-phase transformers together, thus forming a so-called three-phase transformer bank, or by using a pre-assembled and balanced three-phase transformer (consisting of three windings mounted on a laminated iron core).

The advantage of building a single-phase three-phase transformer is that, for the same kVA rating, it will be smaller, cheaper, and lighter than three separate single-phase transformers connected because of the more efficient use of copper and iron cores. The primary and secondary windings are connected in the same way, whether one three-phase transformer or three separate single-phase transformers are used.

You may enjoy: 3 Phase Transformer Power Transformer Manufacturer

What Are The Advantages Of 3-Phase Transformer?

The following are just a few of the many benefits that can be highly gained by using a 3 phase transformer.

Balanced Loading: This means that the load on each of the three phases is relatively equal, which helps to maximize the efficiency of the transformer.

Improved reliability: A 3-phase transformer is less likely to experience voltage drops or power outages due to its balanced loading and lower current requirements.

This means that it can provide a more reliable source of power, which is particularly important in industrial and commercial applications where downtime can be costly.

Increased Stability In Voltage: A 3 phase transformer has a more constant output voltage due to the balanced load on the three phases.

This is because the power is highly distributed over three phases instead of one, which reduces the current flowing through the transformer.

This makes it the preferred option for various industrial and commercial applications.

You can rely on their power generation, transmission, and distribution systems for industrial settings and commercial buildings.

What are the advantages of three-phase over single phase?

1. Power generation: 50% higher than single-phase power supply

2. Transmission: 25% less steel than single-phase transmission

3. Power distribution: three-phase transformer is more economical and easy to access load than single-phase transformer

4. Power transmission equipment: it has the advantages of simple structure, low cost, reliable operation, and convenient maintenance.

The biggest problem of single-phase motor is starting torque, because it can not generate asynchronous start, external means to help, such as starting winding, starting capacitor. And the starting torque is restricted; The power of three-phase motor can be from small to large, and the power range is very wide.

The magnetic field of the phase motor is round, while that of the single-phase capacitor split-phase motor is oval. That is to say: the instantaneous, three-phase magnetic field vector size is consistent, and the capacitor phase has pulsation. The reason is that the windings of the two-phase motor can be made into a 90-degree spatial Angle. But the current cannot be separated 90 degrees by the capacitance.

So there are a lot of problems, three-phase motor performance is much better than two-phase.

Keep reading: Steps In Power Transformer Manufacturing Process

What Are The Disadvantages Of Three-Phase Transformers?

3 phase transformers, like any other technology and equipment, have some drawbacks. Here are some of them:

Increased Initial Investment: Three-phase transformers incur higher costs. This is because they require more complex construction and manufacturing techniques.

This is because they require more copper, iron, and other materials to build, as well as more complex manufacturing processes.

Size and weight: 3 phase transformer is larger and heavier than single-phase transformers, which makes them more difficult to install and transport.

This can be a disadvantage in situations where space and weight are highly limited, such as in residential or small commercial buildings.

Maintenance: 3 phase step up transformer require regular maintenance to ensure that they are functioning properly.

This can be time-consuming and expensive, especially in large power systems where many transformers are in use.

Faults and failures: In some cases, three phase pole mounted transformers can be prone to faults and failures, which can cause power outages and other problems.

These faults and failures can be mainly caused by a variety of factors, including overheating, insulation breakdown, and mechanical stress.

Complexity: Three-phase distribution transformers are more complex than single-phase transformers, which can make them more difficult to understand and troubleshoot.

This complexity can also make it more difficult to find replacement parts or skilled technicians to perform repairs.

Read my article on Ultimate Guide to Utility Transformer

Why Three Phase Transformers Are Essential?

A three phase transformer is highly used in a wide range of applications, including industrial, commercial, and residential settings.

To increase the overall efficiency of the energy generating and distribution processes in power plants, 3 phase transformer systems are periodically implemented.

Many industrial machines, such as pumps, compressors, and motors, use three-phase power to operate.

By utilizing 3 phase transformer, it is possible to generate more electricity while simultaneously reducing overall energy consumption.

In addition to that, you can apply a three phase pad mounted transformer

on air conditioning and heating systems.

Keep in mind that 3 phase transformer is commonly used in many commercial and industrial air conditioning and heating systems to provide efficient and reliable heating and cooling.

Many modern elevators use 3 phase transformer to operate the motor that moves the elevator car up and down.

Lastly, a three phase pole mounted transformer can power up high-power appliances: These include electric stoves and ovens, to provide sufficient power for cooking and baking.

Above all, three-phase systems are generally used in many applications where high power output, efficient operation, and reliable performance are important.

Get it now: What You Need To Know About Overhead Transformers

Why Do We Use Three-Phase Transformers Instead Of Single Phase?

Three-phase transformers are always preferred over single-phase transformers in power transmission and distribution systems due to several reasons.

Reason 1. According to Power Transformer Market, 3-phase transformers have a simpler design with fewer moving parts, which reduces the chance of failure.

The balanced nature of three-phase systems results in lower current and voltage levels per phase compared to single-phase systems.

Reason 2. The size and number of conductors necessary for a three-phase distribution transformer are considerably fewer as compared to those needed for a single-phase power system, which results in substantial savings on expenses.

Reason 3. A three-phase pad-mounted transformer provides a more stable voltage output, which reduces the likelihood of voltage fluctuations and electrical disturbances in the network.

Reason 4. Under their design and configuration, three-phase transformers are capable of delivering significantly more power compared to their single-phase counterparts.

This increased power capacity allows three-phase transformers to effectively manage the demands of power-hungry systems and equipment.

What Are The Common Uses Of Three-Phase Transformers?

Three-phase transformers find widespread usage in electrical power systems, serving various purposes.

This makes them indispensable components in industries, commercial buildings, power generation plants, and other settings where electrical energy needs to be converted, distributed, or transmitted reliably and effectively.

1. Power Distribution

Because the voltage coming out of the transmission lines is often too high to be directly used by residential and commercial properties, a 3 phase transformer is typically required to bring it down to a more manageable level.

2. Industrial Applications

These are all businesses that demand large amounts of electricity:

- Steel

- Mining

- Oil and Gas

- Chemical

- Automotive

They facilitate the reliable transmission of electricity for diverse processes such as refining, distillation, mixing, pumping, and heating, ensuring smooth and uninterrupted operation of the plants.

3. Motor Control

A 3-phase transformer finds utilization in the regulation of speed and direction for motors, which serve as vital components across diverse industrial sectors.

4. Power Generation

Moreover, in hydroelectric, thermal, nuclear, wind, and solar power plants, three-phase transformers play a critical role in voltage upscaling for electricity generated.

These include turbines, boilers, reactors, turbines, or solar panels, before transmitting it to the power grid.

Without these transformers, the electricity would not be able to transmit over long distances to consumers at the appropriate voltage levels.

5. Renewable Energy

Similarly, in solar and wind power plants, 3 phase transformers are mainly used to step up the voltage of the electricity generated by the solar panels before transmitting it to the power grid.

These transformers play a critical role in enabling the efficient and reliable transmission of electricity generated by renewable sources, helping to reduce dependence on fossil fuels and promote sustainable energy practices.

Try for free: Daelim Transformers Solution For Renewable Power Plant

6. BESS

In Battery Energy Storage Systems (BESS), three-phase transformers play a crucial role in enabling the integration of the storage system with the electrical grid. They facilitate the conversion of the alternating current (AC) produced by the BESS to the appropriate voltage and frequency required for grid connection. This ensures smooth and efficient power transfer between the BESS and the grid, enabling effective energy management, grid stability, and support for renewable energy integration. Additionally, three-phase transformers allow for balanced power distribution and reduce losses during energy conversion and transmission, enhancing the overall performance of the BESS.

Get it now: Daelim Transformers Solutions For Energy Storage

What happens if one phase of a 3-phase transformer fails?

When the three-phase power supply is phase deficient, one of the power cables has no voltage or low voltage, or the power supply line is disconnected. The main performance is the following problems:

1, the performance of the motor jitter can not work, or weak rotation and noise. The controller easily burns out when it works in phase - missing condition.

2, the motor ammeter indicates a higher than normal value or zero;

3. The temperature of the motor body and coil increases;

4. The motor vibration increases and the sound is abnormal;

5. Motor speed decreases;

6, the motor load output is insufficient.

Try for free: Analysis of electric transformer noise problem

What is the working principle of a 3-phase transformer?

Three-phase group transformer is composed of three single-phase transformers with the same core, so the three-phase no-load current is strictly symmetrical.

The three-phase transformer has three iron cores, each of which wraps two coils of the same phase -- high voltage coil and low voltage coil -- and outputs three-phase power.

The high voltage windings of the transformer are connected in Y connection (phase voltage can be equal to 57.7% of line voltage). The connection between medium voltage windings and low voltage windings is determined according to the relationship between the voltage phasor of medium-voltage transmission system and the voltage phasor of low voltage transmission system.

What Are The Standard Sizes Of 3-Phase Transformers?

Depending on the exact application and industry standards, 3 phase standard transformer sizes can change.

Low Power transformers: These types of power transformers typically have 5 kVA or 10 kVA and 500 kVA ratings. They are frequently used in light commercial, manufacturing, and home environments.

Medium Power Transformers: These types of transformers have kVA ratings that commonly vary from 500 kVA to 10 MVA (for example, 1 MVA, 2 MVA). They have a frequent place in power distribution systems, medium-sized retail establishments, and applications in the industry.

High Power Transformers: These include transformer sizes with high power and have kVA ratings from 10 MVA, 20 MVA, 25 MVA, or even higher. Large manufacturing facilities, nuclear plants, substations that operate, and utility transmission lines are common places to find these kinds of transformers in use.

How To Measure A 3 Phase Transformer Using A Sizing Chart?

Using a 3 phase transformer chart perform the following procedures to measure a 3-phase transformer:

Step 1. Collect Information

Compile the relevant information regarding your electrical system and requirements. The main and secondary currents the frequency, load type (such as resistive or magnetic), the amount of load or KVA, and any unique application requirements are often included to determine the 3 phase transformer sizes.

Step 2. Acquire A 3 Phase Transformer Chart

Obtain an accurate 3-phase transformer sizing chart.

(insert image)

Please note that this is a compressed sample and that the full table would usually offer a larger range of KVA ratings and voltage options.

According to variables like transformer efficiency, power factor, and load characteristics, the Full Load Amps figures listed in the table may not be exact.

Step 3. Locate the Main Voltage

This is the electrical output that the transformer will receive from an electrical source, as shown in a diagram of a three-phase transformer.

Step 4. Identify the Secondary Voltage

Make a note of the appropriate secondary voltage on the chart. It determines the voltage transformation between the primary and secondary sides of the transformer.

Step 5. Calculate the kVA Rating

In order to calculate the 3 phase transformer kva rating, we need the following:

- primary voltage

- primary current

- power factor

A 3 phase system's kVA rating reflects the total power capacity. It represents the maximum apparent voltage that the transformer can handle without surpassing its thermal energy limits.

Step 6. Consider Other Factors

Other factors can affect the actual kVA rating required for a specific application.

- Power Factor

- Efficiency

- Load Type

- Harmonics

- Future Expansion

Reading on: Ultimate Guide To Transformer Sizes and Ratings

How Accurate Is 3 Phase Transformer Chart?

The quality of a 3 phase transformer chart and the validity of the source both affect how accurate it is. In general, the best sources for accurate sizing charts are transformer manufacturers and trustworthy engineering references.

A 3 phase transformer chart frequently follows recognized business practices and regulations. These guidelines guarantee a particular level of precision and uniformity in transformer sizing procedures.

The reliability of the sizing information presented in the 3 phase transformer chart is generally enhanced by compliance with accepted standards.

Although 3-phase transformer charts might be a good place to start when sizing transformers, it is recommended that you consult with electrical experts or transformer producers to guarantee the results of the sizing are accurate.

How Should We Calculate For 3 Phase Transformer kVA Rating Chart?

When dealing with 3 phase systems, you should follow the 3 phase transformer kVA rating chart. kW is generally computed as (V I PF 1.732) 1,000.

Assuming a power factor (PF) of unity, you can modify the equation to solve for "I," and the resulting equation is as outlined below:

I = 1,000kW ÷ 1.732V.

When looking at the following equation "1,000 1.732V," it is evident that you need to divide the amount into 1,000. Then multiply the result by 1.732.

The result of this formula can be generally applied to multiply the value of "kW" to figure out the electrical draw of a load operating on corresponding three-phase electricity.

What Are The Formulas For Determining A 3 Phase Transformer Amperage Chart?

For 3 phase transformer, you must know the line-to-line voltage (VL) or line-to-neutral voltage (VN), as well as the power factor (PF), to determine the amperage on a 3 phase transformer amperage chart.

Here's how to figure it out:

Load Power (in KW) This is the actual power required by the load with the power factor.

Primary Voltage (Vp): The voltage supplied to the transformer's primary side.

Power Factor (PF): The proportion of actual to apparent power.

Depending on the kind and associated load, generator power factors can change. If the power factor is not specified, make an educated guess based on the characteristics of the generator or contact the generator's maker.

Amperage (A) = (3 VL PF) / 1000 kV

Where:

The transformer's output of current is essentially measured in amperes (A).

The transformer's power rating is in kVA.

The square root of three is three or 1.732.

The transformer's power factor is PF.

For example:

225 x 1000 % 230 x 1.73 = 39.43 amperage

You may enjoy: Transformers Solutions for Industrial and Commercial Buildings

Are There 3 Phase Transformer Calculation Formulas Available As Online Tools?

Yes, there are several 3 phase transformer calculation formulas from internet resources that can help with transformer sizing.

Based on the input parameters, these tools are highly intended to streamline the procedure and deliver speedy results.

Transformer Manufacturers' Websites

Several transformer manufacturers provide 3 phase transformer calculation formulas. These tools can help determine transformer specifications, perform sizing calculations, and obtain other relevant information.

The necessary inputs, such as loading size, both the main and secondary currents and specific application requirements, are frequently supported by these tools.

Engineering Platforms and Websites

Online transformer sizing calculators are accessible on several technology websites and platforms as part of the resources they offer. These programs might have advanced features like a transformer sizing calculator that let you enter more factors like energy factors, the emission of harmonics, and certain market standards.

Electrical Engineering Software

Software for electrical engineering professionals frequently has modules or tools like transformer sizing calculator. Regarding system design and optimization, these software solutions offer a complete 3 phase transformer kVA rating chart and 3 phase transformer amperage chart based on specific project requirements.

Reading on: Technical Standards for Transformers Across The Globe

Introducing Daelim's Expertise in 3-Phase Transformer Charts

At Daelim, we have greatly developed an informational 3-phase transformer chart that is a useful tool for technicians, electricians, and engineers. Daelim 3-phase transformer chart is meticulously designed to give you complete and current information on 3 phase transformer sizes, kVA ratings, 3 phase transformer calculation formulas, and other standard transformer sizes.

With this chart at your fingertips, you can quickly and effectively establish the best transformer size for your unique application. In addition to that, our 3-phase transformer chart stands out because of the thorough research and knowledge that went into its development.

Daelim 3-phase transformer chart not only provides an extensive amount of technical information but also makes the choosing process easier.

Above all, you can rely on Daelim as your go-to source for 3-phase transformer charts.

Single Phase And Three Phase Transformer Are Available From Daelim

It is necessary to have a reliable transformer supplier if you want to ensure the safety and efficiency of the electrical system that you have.

You can experience outstanding customer service with a proven track record of delivering high-quality products that meet industry standards and regulations.

Daelim Transformer offers a wide range of 3 phase transformer

- Three phase pole mounted transformer type

- 3 phase step up transformer type

- Three phase distribution transformers type

- Three phase pad-mounted transformer type

Here at Daelim, we offer competitive pricing without compromising on quality.

We provide after-sales support, including maintenance, repairs, and replacement parts.

Rest assured that we can handle complex logistics, such as international shipping, if necessary.

Related Products

Related Article

13.8 kV 10.5 MVA Substation Transformer for Ecuador

A customer from Ecuador contacted Daelim Transformer for a 10.5MVA substation transformer (13.8kV high voltage, 2.4kV low voltage). Daelim Transformer provided a customized solution, conducted virtual factory tours, ensured rigorous quality control via video inspections, and offered post-delivery online training and ongoing support, fostering a successful partnership.

2600 kVA Pad Mounted Transformer for Blcokchain

Daelim Transformer successfully provided three customized 2600 kVA pad mounted transformers to power a state-of-the-art blockchain facility in Texas, USA. Our transformers were meticulously designed to meet the unique demands of the mining operation, ensuring seamless power distribution with unwavering reliability and efficiency.

20MVA Power Transformer for the United States

This project involves the development of a 20 MVA three-phase power transformer tailored for the United States market. The primary voltage is 24.94kV, and the secondary voltage is 4.16kV, indicating it functions as a step-down transformer. The design and production fully comply with IEEE C57.12.00 standards and have passed third-party UL team testing. All accessories also adhere to IEEE standards. FR3 vegetable oil serves as the insulating liquid for the transformers.

1500 kVA Transformer for Australian Mining Project

Introduce the 1500 kVA transformer tailored for Australian mining projects. The transformer operates in a three-phase configuration, with a total of four units deployed. Notably, its primary voltage stands at 11kV, while the secondary voltage is 1kV. Characterized by its compact size, emphasis on safety, and unwavering reliability, this transformer is meticulously designed and manufactured to meet the stringent requirements outlined in AS 60076 and AS efficiency value standards.Let's delve into the key features and specifications of this essential solution.

2 MVA Pad Mounted Transformer for Utility

Behold the backbone of Canada's utility infrastructure—the 2MVA pad mounted transformer. With a primary voltage of 4160Grdy/2400V and a secondary voltage of 800GrdY/461V, this transformer stands as a testament to efficiency and reliability in power distribution. Crafted in strict accordance with CSA standards and CAN/CSA802.1 energy efficiency guidelines, it embodies the pinnacle of engineering excellence.

2600 kVA Pad Mounted Transformer For Blockchain In Kansas

This morning, I received the on-site photos of the pad-mounted transformers from the customer, and I was overwhelmed with excitement and joy. These pad-mounted transformers are installed at a 20MW blockchain site in Kansas, USA. A total of 5 sets of 2600 kVA pad-mounted transformers, all UL-listed, are being deployed at this site. Currently, 3 sets have already been installed onsite and are scheduled to be powered on imminently.