Analysis of electric transformer noise problem

What is the reason for transformer noise?

Specifically, the transformer noise has three sound sources, one is the core, the other is the winding, and the third is the cooler, the noise, load, and cooling system cause noise.

The iron core produces noise because the silicon steel sheet that constitutes the iron core undergoes a small change, that is, magnetostriction, under the action of an alternating magnetic field. Magnetostriction causes the iron core to vibrate periodically with the change of the excitation frequency, and the magnetostrictive deformation of the iron core is caused by the electromagnetic force in the winding, the transformer tank, and the magnetic shield.

The reason for the vibration of the winding is that the electromagnetic force is generated in the current winding, and the leakage magnetic field can also cause the vibration of the structure. The reason for the electromagnetic noise is that the magnetic field induces the longitudinal vibration of the core laminations to generate noise.

The vibration amplitude is related to the magnetic flux density in the core laminations and the magnetic properties of the core material but has little to do with the load current. The electromagnetic force (and vibration amplitude) is proportional to the square of the current, while the emitted sound power is proportional to the square of the vibration amplitude.

How to analyze transformer noise?

Outdoor distribution transformers make different sounds in normal operation or failure. If it is possible to determine the operation of the transformer by judging the sound from the transformer, it saves time and saving manpower. Now let's look at how"Listen to the good and bad".

Outdoor distribution transformers make different sounds in normal operation or failure. If it is possible to determine the operation of the transformer by judging the sound from the transformer, it saves time and saving manpower. Now let's look at how"Listen to the good and bad".

Normal sound of operational transformers: Uniform electromagnetic sound of "weng"

It is indicated that the transformer is operating normally. The current generates an alternating magnetic flux through the iron core, which will issue a uniform electromagnetic sound of "weng weng", and the strong weakness of the sound is more than the size of the load current.

Sound of abnormal operational transformers:

sound of “buzzing”

Divided into two cases:

(1) When the separation switch is adjusted, the sound is heavier, and the DC resistance value is tested by the double arm bridge, which is caused by 2% of the factory original data, the contact is poor, and the contacts are dirt.

Treatment method: Spool open the wind and hood of the switch, remove the lock screw, rotate the axis of the discharge switch 10 to 15 times with the wrench to eliminate this phenomenon, and then install reduction immediately.

(2) Terminal pole leads to the falling fuse to take a naked aluminum or bare copper strand, but the tension is not enough, and the porcelain bottle is relaxed. At dusk and dawn, you can see the little sparks send a "beep" sound, which is distinct from the " beep "of the transformer.

Handling method: Use the holiday arrangement to be repaired, excluding troubleshooting.

"pipa" crisp iron sound

This is a high-pressure porcelain sleeve lead, and the discharge sound of the transformer oil tank is passed through the air. It is caused by the lack of oil in the transformer tank.

Treatment method: Insert the oil in the oil pillow with the clean funnel, add the test qualified column transformer oil (which can not be mixed), and the amount of replenishment is added to the oil surface temperature + 20 ° C, then Good oil. Otherwise, oil is thermally expanded. If the conditions are allowed, vacuum oil injection can be used to exclude bubbles in the coil.

“Zhi la” Like magnet surges the sound of a small iron piece

Send this kind of sound, while the monitoring device of the transformer, the voltage meter, current meter, and the thermometer are normal. This is often due to the negligence of the new assembly or hanging core, and the screw or iron pad is not tight or fallen into the small iron part, which is caused by electromagnetic force.

Treatment method: Exclude while waiting for the transformer hanging core to repair.

Voice like frog

When the wind, when the time is interrupted, arc and spark occurred during contact, but the sound is uneven, the power is weak, and the passage is transmitted to the transformer. The indication value of them can be combined with the indicator value of the voltage meter, if B is smoke, the voltage is substantially: U1-2 = 230V, U1-3 = 400V U2-3 = 230V, U1-0 = 230V U2-0 = 0V, U3 -0 = 230V.

Treatment method: Instant power outage immediately. Generally occurring on high-pressure frame empty lines, such as wires and isolation switch, the contact point of the drop fuse, and the broken joint, loose, resulting in oxidation, overheating. The operation is allowed to be run after troubleshooting.

Slightly screaming

When the capacity of the transformer is small (100 kVA or less), the start current impact is affected by the individual electrical equipment, for example, the arc of the 26kW DC arc welder, and the driving of the 22KW 250KG air hammer, and the wire is transmitted to the transformer Scream。

Approach: For example, protection, monitoring devices, and other electrical components have no abnormal signs, which should be normal.

"Tiger roaring" sound

When the low-voltage line is short-circuited, the short circuit current suddenly causes this "tiger roaring" sound.

Treatment method: The inspection and test of the transformer body, checks the handle of the appearance, referring to the "sound weakening" processing method.

"godu godu" is like boiling water

The transformer coil is short-circuited, and the short-circuit current is increased, or the core is strong, resulting in burning, causing the insulator to be burned, producing fuel injection, smoke.

Treatment method: First break the low-pressure load switch, so that the transformer is in a no-load state, then cut off the high voltage power supply and disconnect the drop fuse. The running system is released to arrange a hanging core.

Special noise

Due to the change in the load and the ambient temperature, the oiled veneer of the oil pillow changes, so water vapor is accompanied by the air and is inhaled into the oil pillow, and it is condensed into the water to promote the internal oxidation, and the degree of accumulation is intensified. Will fall to the lower part of the oil pillow. Rust passes through the inlet pipe of the oil pillow with the tank, which is stacked on a portion of the yoke, thereby generating vibration under the action of the electromagnetic force, emitting special noise. This will also cause increasing impurities of the transformer operating oil machine to deteriorate the oil.

Treatment method: The cleaning of the oil pillow and the ductor is carried out simultaneously, and should be determined according to the load of the transformer. It is recommended to clean once in two years.

How can you reduce the noise of a transformer?

The noise of the transformer in operation is usually referred to as the noise of the body noise synthesis of the transformer and the noise synthesis of the cooling device. Therefore, in order to reduce the noise of the transformer, effective technical measures should also be taken from both aspects.

On the one hand, the body noise of the transformer can be controlled by reducing the vibration of the core and reducing the divergence of noise; can also be decayed in the propagation path by damping and sound absorption, sound absorption.

On the other hand, the noise of the cooling system is controlled, and the noise is close to or lower than the body noise level, and the transformer noise can be effectively reduced.

Reduce transformer body noise

Technical measures are taken by the core

1: The high-quality silicon steel sheet of magnetostrictive ε is used to increase the integrity of the crystalline orientation, and the special coating increases its anti-tension, thereby reducing its magnetostrictive ε. When the magnetic flux density is 1.5t, the magnetopause ε of the high-grained silicon steel sheet is only 60% of the general silicon steel sheet. Therefore, under the same magnetic tract, the magnetos ε of the high-quality silicon steel sheet is small, the generated vibration is correspondingly small, and the noise can be reduced by 2 to 4 dB (a).

1: The high-quality silicon steel sheet of magnetostrictive ε is used to increase the integrity of the crystalline orientation, and the special coating increases its anti-tension, thereby reducing its magnetostrictive ε. When the magnetic flux density is 1.5t, the magnetopause ε of the high-grained silicon steel sheet is only 60% of the general silicon steel sheet. Therefore, under the same magnetic tract, the magnetos ε of the high-quality silicon steel sheet is small, the generated vibration is correspondingly small, and the noise can be reduced by 2 to 4 dB (a).

2: Reduce the magnetic flux density of the core of the core

The rated working magnetic blending B is usually dependent on the value of noise and no-load loss. The experimental results show that the rated magnetic tie B is in the range of 1.5 to 1.8T, the magnetic tester is reduced by 0.1T, and the noise of the core can be reduced by 2 to 3 dB (a). The noise change amount ΔLPA caused by magnetic tight changes can be determined by the following formula:

In the above formula:

B1, B2 - work magnetic (T) before and after changes, respectively

GFE2, GFE1 - Correspondence (kg) of B1, B2

It should be noted that the magnetic density reduction not only results in an increase in the volume and weight of the transformer, but the economic indicator is deteriorated, but also increases the surface area of the noise emission, resulting in an increase in the acoustic power level of the transformer.

3: The core structure of the full oblique deserted seam is in the conventional pillar and iron yoke. The magnetic wire is transversely crossing the silicon steel sheet in the seam, which generates eddy current and magnetic saturation, resulting in noise and airborne loss. Increase. The full oblique defect seam is used to ensure that the pillar and iron yoke are connected, and the magnetic flux distortion is reduced to ensure the integral mechanical strength of the core. The practice has proved that when magnetic is 1.7T, the core is reduced by 3 to 5 dB (a) using a full oblique ligation.

4: Increase the test of the core seam, indicating that when the transformer core is changed from the two-stage seam to a three-stage seam, its noise can reduce by 3 to 6 dB (a). This is because in the two-stage seam, the corresponding two-seam gaps only span a laminated sheet, and the three-stage seam spans the two layers and causes the magnetic tester at the end of the laminate by each layer. Noise is lowered.

5: Increase the test of the core seam, indicating that when the transformer core is changed from the two-stage seam to a three-stage seam, its noise can reduce by 3 to 6 dB (a). This is because in the two-stage seam, the corresponding two-seam gaps only span a laminated sheet, and the three-stage seam spans the two layers and causes the magnetic tester at the end of the laminate by each layer. Noise is lowered.

6: Control the core clamping tightness indicates that when the iron core clamping force is 0.08 ~ 0.12 MPa, the transformer is lowest. In the process of core manufacturing, the clamping force can be reasonably controlled by a torque wrench; at the same time, the insulation rod can be placed at the heart level, so that the strumpet is uniform, preventing the magnetostrictive ε due to unevenness of the core force. With the above measures, the body noise of 3 to 6 dB (a) can be reduced.

7: Advanced processing process magnetostrictive ε is extremely sensitive to stress. Under the same magnetic tester, a larger stress silicon steel sheet is increased sharply with a smaller silicon steel sheet. Therefore, advanced, reasonable machining measures are used as using automated horizontal, vertical cut lines, control silicon steel blade, non-supermarket iron yoke, pre-compression to the oil passage and clamp insulation, etc. Equivocal measures can reduce the stress of silicon steel sheets, thereby reducing transformer noise.

8: Place a damping rubber between the iron cushion foot and the bottom of the transformer oil tank, as previously described, the magnetostrictive vibration of the core is passed through the two paths of the foot and insulating oil to the oil tank. Place the damping rubber between the iron cherry foot and the bottom of the transformer oil tank, which enables the rigid contact between the body and the transformer oil tank to be elastic contact. Thus, blocking partial vibration is transmitted, and the body noise is reduced.

Technical measures are taken by transformer oil tank

1: Increase the intensity of the transformer oil tank, reduce the amplitude of the oil tank wall to reduce the amplitude of the oil tank wall, and must increase the overall rigidity of the tank. To this end, it is possible to increase the wall thickness or reasonable arrangements of reinforcing thumbers and control the spacing of the ribs. At the same time, the reasonable welding process is supplemented, reducing the welding deformation of the box wall, and reducing the residual stress in the manufacturing process. In this way, it is possible to improve the strength of the box wall, reduce the amplitude of the oil tank wall, and reduce noise.

2: Increase the transformer oil tank damping of the rubber sheet in the inner wall of the tank. For a magnetized transformer, the rubber sheet can be placed between the tank wall and the magnetic shield. In the reinforced gluten welding ordinary industrial steel plate, 2-3mm thick damping material is applied online, which does not affect the heat of the tank, and reduces the vibration of the oil tank wall, which reduces noise.

3: Set the damper at the bottom of the transformer oil tank and the foundation damper in the bottom of the transformer oil tank and the damper, avoid the rigid connection between the bottom of the tank and the foundation so that the vibration is attenuated by the damper to achieve the purpose of reducing noise. Usually used are rubber dampers and spring adhesive dampers。

Adding sound layers to reduce noise

The transformer oil tank structure is divided into two types combined and highly efficient. The combination is: the external structure of the transformer oil tank makes the sound-absorbing plate into a plurality of pieces, and the absorbing material is placed in the steel sheet. The sound-absorbing materials are rock cotton, glass fiber, etc. The soundproof wall can transmit partially noise reflected back in the transformer body; when the noise passes through the acoustic wall, it can also be absorbed, and it is placed to reduce the noise.

Single-piece soundproofing bolts are fixed to reinforce iron, respectively, and this soundproofing can reduce noise 10-15dB (a). It is also possible to use a high-efficiency soundproof board, and two strengthened iron is placed, and the thin spring steel plate is fixed. The frame-shaped additional heavy object adjusts the vibration characteristics of the high-efficiency sound absorption, making it significantly lower than the reinforcing iron amplitude, effectively shielding the transformer body to emit noise, and can reduce noise by 5-10 dB (a).

Reduce transformer cooling system noise

A low noise cooling device should be selected from the selection process of the cooling device. The new low noise fan with multiple traffic has the following advantages: First, the fan is uniform, can provide uniform cooling; second, a set of fans fails, the remaining fans can still operate normally, improving The reliability of the cooling system; third, under the premise of the total cooling air volume, its motor power is only 70% to 75% of the large flow fan, and noise reduces 2 to 3 dB (a).

The noise of the transformer body using the damper device passes through the vibration of the cooling device through the box wall and the oil, and the following measures can effectively control its vibration. First, an anti-vibration head is employed between the fuel tank and the heat sink. The anti-vibration head can be made from corrosion-resistant rubber or stainless steel. The test results show that the anti-vibration head typically reduces the vibration noise of the self-cooling radiator by 5 to 8 dB (a). Second, for the side blow or bottom blown radiator cooling mode, in order to avoid the vibration of the fan exacerbating the cooling system, the fan bracket cannot be directly fixed to the heat sink, but should be fixed to the wall and should be provided with a damper rubber pad. . Third, a transformer mounted by the cooling system and the body, the fan should be fixed based on the special basis.

Other methods

When designing low-air noise transformers, try to use self-cooling so that the fan and oil pump noise is removed. When the capacity is difficult to meet the needs, the large-capacity transformer is satisfied, and the low noise potential pump and the low rotary fan cooler are used. With a low-speed fan, the self-cooled transformer capacity can be increased by 33%, and noise reaches 69dB (a). For details, a double-speed fan can also be used. When the load is small, the low-speed fan is opened, and the noise can be reduced accordingly; the high-speed fan can be opened when the load is large, and the self-cooled transformer capacity can be increased by 67%, but at this time, the noise is large, reaches 75 dB (a).

When designing low-air noise transformers, try to use self-cooling so that the fan and oil pump noise is removed. When the capacity is difficult to meet the needs, the large-capacity transformer is satisfied, and the low noise potential pump and the low rotary fan cooler are used. With a low-speed fan, the self-cooled transformer capacity can be increased by 33%, and noise reaches 69dB (a). For details, a double-speed fan can also be used. When the load is small, the low-speed fan is opened, and the noise can be reduced accordingly; the high-speed fan can be opened when the load is large, and the self-cooled transformer capacity can be increased by 67%, but at this time, the noise is large, reaches 75 dB (a).

When the transformer is arranged indoors, it should be considered that the noise increases can be increased by the noise wall reflection. This value is a rational function of the transformer surface area and the transformer chamber surface area and is related to the wall surface and the ceiling sound absorbing coefficient. With slam or similar material to wall coating, the sound-absorbing coefficient can be increased to make noise reduction.

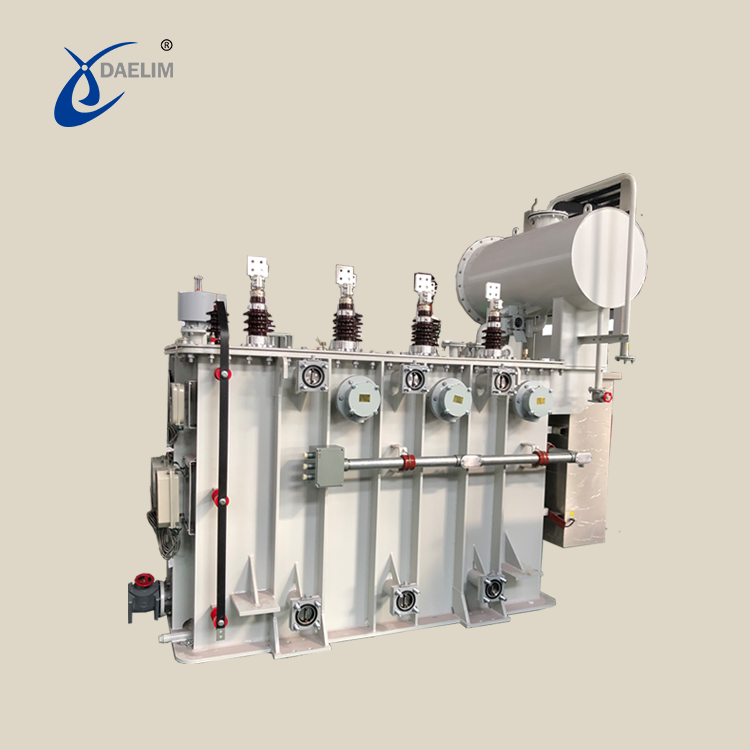

Daelim is a transformer manufacturer with 20 years of transformer export experience. The transformers of Daelim have the characteristics of strong mechanical properties, good electrical properties, low noise, and long service life. Transformer production time is about 8-10 weeks.

The market is concentrated in South America and Australia. There are professional technical teams and sales teams to provide you with professional services. The transformers designed and produced can meet the IEEE / ANSI / CSA / DOE / AS international standards. The annual export volume exceeds 1,000.

Learn more now: Daelim Tnternational Project

The main transformers are power transformer, substation transformer, distribution transformer,single-phase transformer and dry type transformer, if you have an associated transformer business, you can contact Daelim.

Related Products

Related Article

Advantages of Transformer Yyn0 Vector Group

The Yyn0 vector group transformer offers distinct advantages in suppressing high-order harmonic currents and managing low-voltage single-phase ground short-circuit faults. However, it does have limitations regarding the handling of single-phase unbalanced loads, where the Dyn11 connection demonstrates superior performance. These characteristics should be carefully considered when selecting the appropriate transformer connection for specific applications to optimize performance and reliability.

Impact of Operating Temperature on Transformers

Maintaining an optimal operating temperature is crucial for the longevity and reliability of transformers. Excessive temperatures accelerate the aging process of the winding insulation, leading to a significant reduction in service life. Ensuring that the hottest point temperature remains within safe limits can help in maximizing the operational lifespan of transformers and maintaining their performance. For long-term efficiency and reliability, it is essential to monitor and control the operating temperature of transformers.

Transformer Drying Methods and Procedures

The article outlines transformer drying methods: oil tank iron loss, zero-sequence current, and vacuum dehumidification, emphasizing controlled heating and moisture removal for enhanced insulation reliability.

Transformer Oil Aging, Regeneration, and Purification

Effective management of transformer oil ensures prolonged equipment lifespan and reliable performance in electrical applications.

Technical Requirements for Transformer Installation

The article outlines critical technical requirements for transformer installation, covering support, grounding, cable management, safety measures, and fan operation to ensure safe and efficient electrical system performance.

Basic Knowledge of Transformer Transportation

Transformer transportation varies by size. Below 80 tons, use oil with dry air above oil level. Above 80 tons, use dry gas, monitor pressure, and conduct tests. Ensure sealed integrity and monitor regularly during storage.