Electrical Transformer Protection Knowledge Guide

An electrical transformer is a more reliable static device with a particularly low chance of failure. However, it is thought that most of the transformers are installed outdoors and will be affected by load and short-circuit faults during operation, so various faults and abnormal conditions may occur.

Daelim Transformer is a professional transformer manufacturer. The transformers produced are mainly used for the international market. We have a technical team specialized in designing international standards, such as ANSI/IEEE/CSA/DOE/AS/NEMA, and so on. Moreover, the market in North America and South America is relatively mature and has done many bidding projects for electric power, helping many customers to win projects and achieving growth in performance. Achieving a win-win situation with customers is the business philosophy of Daelim Enterprises.

Types and characteristics of electrical transformer faults

An electrical transformer is mainly composed of an iron core and windings wound around the iron core. In order to ensure the insulation between the windings and the heat dissipation of the iron core and the winding, the iron core, and the winding are placed in the oil tank with transformer oil. The two ends between the windings of the transformer are guided out of the casing of the transformer through insulating bushings.

Learn more: Prevention and Treatment Measures for Transformer Core Grounding Faults

The fault of a power transformer can be divided into two categories: internal fault of the fuel tank and external fault of the fuel tank. The internal faults of the fuel tank mainly include the inter-phase short circuit of the winding, the inter-turn short circuit between some turns of the single-phase winding, the single-phase grounding short circuit of the single-phase winding through the casing, and the damage to the iron core. The fault in the transformer oil tank is very dangerous. Since the oil tank is full of transformer oil, the strong short-circuit current after the fault causes the rapid decomposition and gasification of the transformer oil, which may produce a large amount of flammable gas, which can easily cause the oil tank to explode. The main faults outside the tank are the phase-to-phase short-circuit and grounding short-circuit that occurred on the bushing and the lead-out line.

The electrical transformer is not operating normally

The abnormal operation state of the power transformer mainly includes overcurrent caused by external short-circuit fault of the transformer, overload caused by load exceeding rated capacity for a long time, cooling capacity decline caused by fan failure or oil leakage, etc. For transformers whose neutral point is not directly grounded, the external grounding short circuit may cause overvoltage at the neutral point of the transformer, threatening the insulation of the transformer. For large-capacity transformers, because the rated working magnetic flux density of the iron core is relatively close to the saturation magnetic flux density, overexcitation is likely to occur when the external overvoltage is too high or the frequency is reduced.

Read more:3 Phase Pad Mounted Transformer

Basic principles of transformer protection configuration

1) Gas protection

Gas protection is used to act in response to the gas or oil flow generated inside the transformer tank. It can defend against various short-circuit faults and oil level reduction in the transformer tank and has high sensitivity. Gas protection is divided into heavy gas and light gas. Generally, the heavy gas reflects the oil flow speed inside the transformer, and the protection action is to trip the power circuit breakers on each side of the transformer. The light gas protection reflects the gas volume inside the transformer, and the protection action is the signal.

Get it now: How to analysis of gases and check the oil levels in a transformer?

Oil-immersed transformers with a capacity of 800kVA and above, should be equipped with gas protection. Gas protection should also be installed on the pressure regulating device of oil-immersed transformers with load regulation.

2) Longitudinal differential protection or current quick-break protection

Transformers of 6300kVA and above running in parallel, transformers of 10000 kVA and above running alone, and important transformers of 6300kVA and above used in power plants or industrial enterprises for their own use shall be equipped with differential protection. Other power transformers should be equipped with current quick-break protection, and the action time limit of its overcurrent protection should be greater than 0.5S. For transformers above 2000 kVA, when the sensitivity of current quick-break protection cannot meet the requirements, longitudinal differential protection should also be installed. Longitudinal differential protection is used to respond to short-circuit faults in power transformer windings, bushings, and lead wires, and its protective action is to trip the circuit breakers on each power supply side of the transformer and send corresponding signals.

Try for free: Unbalanced Current in the Differential Protection Circuit of UHV Transformers

3) Backup protection for phase-to-phase short circuit

The backup protection of phase-to-phase short circuit is used to respond to transformer overcurrent caused by an external phase-to-phase short circuit, and it is also used as backup protection of gas protection and longitudinal differential protection (or current quick-break protection). The action is to trip the circuit breakers on each power supply side of the transformer and send corresponding signals. Generally, overcurrent protection, compound voltage starting overcurrent protection or negative sequence current single-phase low voltage protection are used.

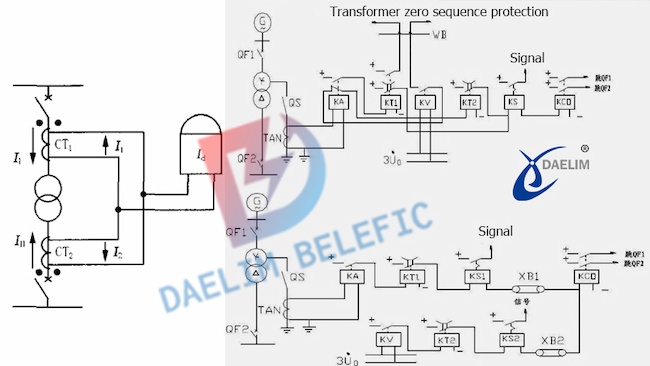

4) Zero sequence protection of grounding short circuit

For the transformer in the neutral point directly grounded system, zero-sequence protection should be installed. The zero-sequence protection is used to respond to the high-voltage side (or medium-voltage side) of the transformer and the grounding short circuit of external components.

For the autotransformer and the three-winding transformer whose neutral point on the high and medium voltage sides are directly grounded, a zero-sequence directional element should be added when there is a selective requirement.

When only part of the centerline of the transformer in the power grid is grounded, in order to prevent the occurrence of a grounding short circuit, after the neutral point grounding transformer is tripped, the transformer whose neutral point is not grounded (with power supply on the low voltage side) may continue to operate with a ground fault. As a result, overvoltage is generated, which threatens insulation. Therefore, zero-sequence overvoltage protection and gap zero-sequence current protection should be installed according to the situation.

Get it now: Comprehensive Guide to 1000kVA Transformers by Daelim Transformer

5) Overexcitation protection

Ultra-high voltage large transformers need to be equipped with over-excitation protection. Since the magnetic flux density B in the transformer core is proportional to the ratio U/f of voltage and frequency when the voltage increases and the frequency decreases, the transformer will be over-excited, making the excitation current If it increases, the iron loss will increase, the core temperature and the winding temperature will increase, and in severe cases, local deformation will be caused and the surrounding insulating medium will be damaged. Over-excitation protection is reflected in the ratio of the actual working flux density to the rated working flux density (over-excitation multiple). Within the allowable over-excitation range of the transformer, the over-excitation protection acts on the signal and can act on tripping when the over-excitation exceeds the allowable value.

6) Other non-electrical protection

The transformer is usually also equipped with non-electrical protection that reflects the characteristics of oil, gas, and temperature in the oil tank, mainly including the temperature protection of the transformer body and the on-load voltage regulation part, the pressure release protection of the transformer, the protection of starting air cooling after the transformer is under load, Overload lockout with load voltage regulation protection, etc.

Transformer grounding protection

There is only one transformer in the step-up substation, and the transformer adopts the operation mode of the neutral point directly grounded;

For substations with several transformers running in parallel, a part of the transformers are grounded at the neutral point of the substation;

For large transformers of 220kV and above, the high-voltage windings generally use graded insulation: the neutral point with a low insulation level must be directly grounded for operation; the neutral point with a high insulation level can be directly grounded, or without losing the grounding point in the system Ungrounded operation, when a single-phase short circuit occurs in the system, the ungrounded operation of the transformer should be able to withstand the voltage applied directly to the neutral point and the ground.

Keep reading: Basic Guide Of Electrical Transformer

Therefore, part of the transformer is arranged to operate with grounding, and the other part of the transformer is arranged to operate without grounding.

1) Zero-sequence current protection of the neutral point directly grounded transformer

In order to reduce the influence scope of the ground fault and improve the speed and reliability of the subsequent protection action, two-stage zero-sequence power protection is generally configured, and each stage also has a two-stage delay.

2) The grounding protection of the transformer when the neutral point may be grounded or not grounded

Classified Insulation Transformer with Neutral Discharge Gap

Graded insulation: The main insulation around the neutral point has a lower insulation level than the insulation ends.

Discharge gap: It is used to protect the insulation of the neutral point of the transformer when impulse voltage and power frequency overvoltage occur. Once the gap is discharged, the discharge time should also be avoided for too long. Zero-sequence current and voltage protection should still be installed; the purpose is to cut off the transformer in time to prevent the gap from discharging for a long time.

For a graded insulation transformer with a discharge gap that may or may not be grounded at the neutral point, the grounding backup protection consists of:

A. Zero-sequence current and voltage protection with action delay set according to the ladder principle;

B. Instantaneous action gap zero-sequence current protection;

C. Instantaneous action zero-sequence voltage protection

The reason for installing the discharge gap at the neutral point of the transformer is that when a ground fault occurs in the system, the neutral point of the transformer will have power frequency overvoltage and the insulation of the neutral point will be threatened.

Read my article on: Unveiling the Best Ways to Buy Electrical Transformers

3) Fully insulated transformer

Fully insulated transformer: The insulation level at the beginning and end of the winding is the same, and the neutral point of the transformer has a relatively strong ability to withstand overvoltage. In the event of a grounding short circuit, the action requiring grounding protection should first trip the transformer whose neutral point is grounded to cut off the short-circuit current loop and reduce the harm of the short-circuit current. transformer.

4) Transformer touch case protection

In the power system, in order to ensure the safe use of electricity and avoid the danger of electric shock due to insulation damage, the base and shell of motors, transformers, electrical appliances, and lighting fixtures in operation must be grounded; for transformer cores, in order to prevent When the induced voltage exceeds a certain value, the discharge to the ground occurs, and it must also be grounded.

When the transformer adopts the protection method of touching the casing, the other parts of the transformer casing should be insulated from the ground.

The advantages of transformer collision protection are: simple wiring, quick action, flexible

High sensitivity, especially for transformer longitudinal differential protection, when the transformer bushing current transformer is used, the protection range is very small. The protection will not work. At this time, the protection can be instantaneously actuated to remove the fault by touching the shell. Otherwise, the fault can only be removed by the backup protection of the transformer or the protection of other power supply components, which prolongs the operating time and may even cause non-selective action.

Read more: How to test a power transformer?

The disadvantage of the protection is that it cannot be used as backup protection for grounding short circuits outside the transformer; in addition, when this protection method is used, the transformer casing is not allowed to be connected to other additional parts such as the substation grounding device or the transport track, otherwise due to the effect of the shunt, the external The protection may act non-selectively in the event of a short circuit, and the sensitivity of the protection will be reduced in the event of a short circuit to the case to ground. The disadvantage of the protection is that it cannot be used as backup protection for grounding short circuits outside the transformer; in addition, when this protection method is used, the transformer casing is not allowed to be connected to other additional parts such as the substation grounding device or the transport track, otherwise due to the effect of the shunt, the external The protection may act non-selectively in the event of a short circuit, and the sensitivity of the protection will be reduced in the event of a short circuit to the case to ground.

Transformer protection device

The protection device of the transformer mainly includes an oil conservator, a moisture absorber, a pressure relief valve, a gas relay, a temperature measuring device, and an oil purifier.

The protection device of the transformer mainly includes an oil conservator, a moisture absorber, a pressure relief valve, a gas relay, a temperature measuring device, and an oil purifier.

■ Oil conservator

The role of the oil conservator is also called an oil pillow or an expander, which is mainly used to reduce the contact area between oil and air, reduce the degree of moisture and oxidation of the oil, slow down the aging of the oil and prolong the service life of the transformer oil. At the same time, it provides buffer space for transformer oil with the change of temperature load.

(1)Ordinary oil conservator

The oil surface in the oil conservator is in direct contact with the air, without any anti-aging device, and the oil surface is in contact with the atmosphere through the moisture absorber, which causes the problem of transformer oil oxidation and moisture. Therefore, it is generally only used on small transformers.

(2) Sealed oil conservator

An anti-aging device is installed in the oil conservator. According to its different structures, there are capsule oil conservator, diaphragm oil conservator, and metal expander oil conservator. The transformer oil is isolated from the air, so that the moisture in the air and the Oxygen do not contact the transformer oil, preventing the immersion of oxygen and moisture in the air, which can prolong the service life of the transformer oil and has a good anti-oil aging effect.

Learn more: Substation Transformer Ultimate Guide

■ Moisture absorber

(1) The role of the moisture absorber

The moisture absorber, also known as a respirator, is equipped with granular silica gel (or alumina) in the middle. It is used to remove and dry the impurities and moisture in the air entering the oil conservator due to the temperature change of the transformer.

(2) Precautions for use

1) During the process of delivery, storage, and transportation of the transformer, the oil sealing bowl is sealed with a rubber ring so that the transformer oil is isolated from the atmosphere. Before the transformer is put into operation, the sealing rubber ring must be removed, and the oil sealing bowl must be filled with qualified transformer oil.

2) Observe the color change of the silica gel, and replace the silica gel after discoloration

3)Regularly replace the transformer oil in the oil seal bowl, and clean the dirt deposited at the bottom of the oil seal bowl to keep breathing smoothly

■ Pressure relief valve

The pressure relief valve has a metal diaphragm, which is normally pressed against the valve seat by the spring. The transformer failed and increased pressure in the tank. When the pressure in the tank exceeds the pressure of the pressure relief valve spring, the metal diaphragm is lifted up, and the transformer oil can be ejected between the diaphragm and the valve seat, thereby releasing the excess pressure in the oil tank and protecting the oil tank. When the pressure in the fuel tank is quickly released, the internal pressure decreases, the metal diaphragm returns to its position under the action of the bomb, and the fuel tank is resealed. The opening time of the pressure release valve is required to be no more than 2ms. When the pressure release valve is in action, the upper sign rod is pushed out as a mechanical signal, and at the same time, the microswitch is driven to act, and an activation signal can be generated.

Reading more: Pad Mounted Transformer Gauges, indicators and Valve

■ Gas relay

The role of gas relay (also known as the gas relay) is generally used in transformers of 800kVA and above. It is installed on the connecting pipe between the transformer cover and the oil conservator as the main safety protection device for internal faults of the transformer. When a fault occurs inside the transformer and gas or oil flow is generated, the signal or trip circuit is connected so that the relevant device sends a signal or the transformer is cut off from the power grid. In addition, when the oil tank leaks and the oil level drops to the gas relay, the gas relay will also turn on the signal circuit.

■ Temperature measuring device

In order to monitor the operating temperature of the transformer, the transformer needs to be fitted with a thermometer. According to the different parts of the temperature measurement, there are thermometers for measuring the temperature of the upper oil and thermometers for measuring the temperature of the windings. Among them, the thermometers used to measure the upper oil temperature include glass thermometers, pressure thermometers, and resistance thermometers. The temperature measuring elements of all thermometers should be placed in the thermometer seat on the box cover, and transformer oil should be injected into the thermometer seat, and then sealed.

■ Oil purifier

The oil purifier is a continuous regeneration device for transformers, which is filled with adsorbents. Generally, the weight of the porous silica gel or activated alumina adsorbents is about 0.5%-1% of the total weight of the transformer oil. Filters should be installed at the inlet and outlet of the oil filter to prevent adsorbents from entering the transformer tank. When the transformer oil flows through the adsorbent, the moisture, free acid, and oxides that accelerate insulation aging in the oil are absorbed.

Read on: Daelim international projects cases.

Different types of transformers will have different requirements for protection devices. For example, dry transformers do not need transformer oil so they do not need oil conservators, pad mounted transformers do not need oil conservators, and small equipment does not require oil conservators. Daelim's transformers will be equipped with transformer protection devices according to the type of transformers and customer requirements to help customers reduce costs on the basis of ensuring the safe operation of transformers.

Daelim can design and produce IEEE/IEC/CSA/DOE/AS and other standard distribution transformers, dry transformers, mounted transformers, high voltage transformers, and single transformers. Daelim has a full-range UL certificate for transformers. If you need a transformer quotation, please contact Daelim Transformer .

Related Products

Related Article

Differential Protection of UHV Transformer

Differential protection is the primary protection mechanism for transformers. By analyzing the arrangement of current transformers (CTs), the function and protection range of each differential protection in UHV transformers can be determined.

Unbalanced Current in the Differential Protection Circuit of UHV Transformers

Unbalanced current in UHV transformers' differential protection circuits can arise from inconsistencies in CT ratios, CT transmission errors, excitation surge currents, and transformer voltage regulation. These issues can affect the reliability of differential protection systems. Measures to mitigate unbalanced currents include using balancing coils and software adjustments, electronic and photoelectric transformers, methods to suppress and identify excitation surge currents, and compensating for voltage regulation effects. Implementing these strategies enhances the reliability and stability of UHV transformer protection systems.

Protection and Maintenance Methods for Oil Transformers

Prevent oil transformers from moisture and leakage, regularly monitor oil levels and temperature, ensure proper installation, and timely oil changes and drying. Pay special attention to storage time, sealing, and maintenance to ensure normal operation and insulation performance.

Temperature Protection and Maintenance for Transformers

Transformers require precise temperature protection, monitoring insulation grades, and appropriate oil types. Dry-type transformers trip at 130°C, oil-immersed at 90°C. In cold climates, FR3 fluid is recommended for its effective performance at -50°C.

The Harm of Outlet Short-Circuit Faults to Power Transformers

Outlet short-circuit faults in power transformers cause winding deformation, insulation damage, and overheating, affecting dynamic and thermal stability. Analysis via oil chromatography and electrical testing guides timely repair planning.

Relationship Between Dissolved Gas in Oil and Transformer Faults

Transformer oil serves as insulation and cooling. Faults cause chemical decomposition, producing gases. Analyzing dissolved gases in the oil helps determine fault presence, nature, and severity. Key gases include CH4, C2H6, C2H4, and C2H2, indicating different fault types and temperatures.