CSA C227.3 For Single Phase Pad Mounted Distribution Transformer

Padmount transformers are regularly accessed by the general public and are not normally surrounded by barriers, therefore safety must be the top priority throughout the installation.

What we have here are the Canadian Standards Association standards. This will include the CSA-C227.3 guidelines for single-phase pad mounted distribution transformers.

A single-phase pad-mounted distribution transformer consists of one winding that is generally bonded to one phase of the electric power unit.

The winding of a single-phase transformer is generally linked to the wire and the center tap of the unit itself. At the same time, the 2 and 3-phase transformers are typically possible to mount on the ground.

Let's break down the several CSA C227.3 standards and guidelines and see what they necessarily require.

What is CSA C227.3 Standard?

The requirements of CAN/CSA-C227.3-06 are specific to pad-mounted, single-phase, low-profile distribution transformers with individual insulation for their high-voltage connections.

Refer to this policy for a fast review of welding rules and regulations.

Single-phase pad-mounted transformers that comply with CSA-C227.3 have strict welding requirements.

This guideline and policy aim at electric utilities. Thus importantly, it provides all the technical parameters necessary for pad-mounted single-phase transformers.

These types of pad-mounted and single-phase transformers always rely on welding. This is in terms of the unit's assembly process and production.

Because of the high frequency of distribution transformers, CSA Standard C227.3 specifies strict regulations for their design and construction to guarantee the safest and most secure possible weldings are usually produced.

Learn more about CSA C227.4

What is CSA C227.3 Scope?

This new version of CSA C227.3 overrides all previous editions, which include 1991, 1979, and 1974 versions.

This new version of CSA C227.3 overrides all previous editions, which include 1991, 1979, and 1974 versions.

The goals and parameters have been specifically outlined below.

A. Transformers for single-phase distribution equipped with their insulated high-voltage connectors are the focus of this regulation.

During thorough testing, the electrical inspection authority may impose extra restrictions on the usage of a single-phase transformer. Those are specially utilized by a company.

B. Single-phase transformers that are usually insulated with 61 HZ apply to this rule. A category of 19KV with high voltage units covers this.

C. This rule covers more than simply a maximum voltage and kV.A. These included testing procedures and mechanical specifications.

The policy also covers energy use, temperature rise, load capacity, noise, and radio impact voltage.

D. Units that are permanently hardwired into 241/121 V, three-wire, effectively grounded, underground distribution systems are eligible for this guideline.

E. The purpose of this policy is to allow pad-mounted transformers of different brands but the same basic size to be often swapped out for one another without altering the wiring or the pad.

Manufacturers of transformers can create their own unique cable entry compartments when they want to.

Although some minimum dimensions and characteristics are already stated, this guideline does not specify terminal configurations for a looping system.

Learn More About Single Phase Pad Mounted Transformer

What is Welded Fabrication under CSA C227.3?

Welding is an essential joining process in the production of distribution transformers.

To become and remain certified in fusion welding of steel, a company must adhere to stringent guidelines that are frequently spelled out in great detail throughout the certification process and subsequent renewals.

For compliance with CSA C227.3, the following criteria must be always met. But first, let us identify all the welding standards and their definitions.

CSA W47. 1

These guidelines cover everything from welders/welding operators and welding supervisors to welding engineers and welding procedures.

CSA W59

This policy covers welding parameters for carbon and low-alloy welded steel construction.

CSA W178.1

Any company that provides services like non-destructive testing and inspection to other sectors will gain substantially from this guideline.

CSA W178.2

This specification details the requirements for a welder inspector to pass an examination leading to one of three levels of certification, as well as the standards of behavior that must be generally followed by certified inspectors at all times.

Before welding, make sure to follow the guidelines outlined in W59. The welding fabricator must be CSA accepted under the W47.1 guideline.

Policy W47.1 applies to the following:

- welders

- welding processes

- welding engineering personnel

Contractors performing work to CSA Standard W59 must be highly qualified, as per Standard W47.1, unless the Engineer approves otherwise.

Furthermore, Policy W59 addresses key issues in welding steel, including:

- welding layout

- fabrication plan

- assessment

- inspection

Regular inspections of all key manufacturing stages of the welding process will be always performed by the CWB to guarantee quality and measure.

The CSA's creation of W47.1 is a strict standard with no international parallels.

Welding Inspection

All welding must be generally approved by a detailed visual inspection in accordance with Policy W59.

A certified welding inspector or welding inspection agency is necessary to check the welding against the CSA W178.2. They must also adhere to W178.1.

Only welding that meets the standards of CSA W186 and Policy W59 is officially regarded to be of sufficient quality and quantity.

Try for free: CSA C88 Standard For Power Transformers

What Is Single-Phase Pad-Mounted Distribution Transformer?

Single-phase pad-mounted distribution transformers are generally intended for mounting and connected to a feeder.

One can find these transformers with ratings varying from 15kVA to 250kVA.

As mentioned earlier, single-phase pad-mounted transformers are units that had only one winding.

They are linked to one phase of the electric power grid.

One winding of this transformer is always linked to the center and common line of a single phase of electrical power grids.

Pad-mounted transformers, especially single-phase ones have primary winding that you can track down on an insulation area.

You can also see them outside the transformer box.

Keep reading: 250 kVA Transformer

What Are The Main Characteristics Of A Single-Phase Pad-Mounted Transformer?

Let's take a look at what makes a pad-mounted, single-phase transformer unique.

Design Capacities

- Scale: from 15kVA to 250kVA

- Maximum primary voltage of 34.5kV

- Dual Secondary Voltage of 120/240

- Made to order and compliant with the energy efficiency standards set forth by the Canadian Standards Association (CSA) C227.3 and C802.1

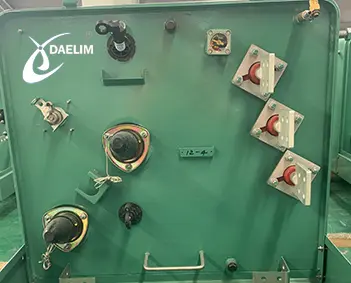

Standard Accessories and Functions

- Protection from a bay-o-net and a current-limiting fuse

- Engraved on an aluminum plate

- A release valve for excessive pressure

- Low Voltage and High Voltage Bushings

- Plug for draining and filling

- Bracket for earthing and X-0 strap

- Pull Over and Park Here

- The external coating that meets standards

Optional Accessories and Features

If a buyer so chooses, a transformer can come equipped with any of the following extras:

- A corrosion-resistant skirt

- Pressure release valves

- Thermometer

- Circuit breakers for loads

- Low voltage bushings of the stud or spade type

- Complete with dust cap

- Stenciling and stock codes

- Clamps with safety release tabs for the bushing well

- Preparation for a Distant Fault Indicator

- Circuit taps with a high voltage

- Buyer-specified impedance constraints;

- A biodegradable, fire-resistant insulating fluid called FR3

You may enjoy: IEEE C57 Standard

What Is The Purpose Of A Single Phase Pad-Mounted Transformer?

You can usually see single padmounted transformers frequently installed at service drops. They are typically located on underground electric power distribution grounds.

Their cables function to convert the higher primary voltage to the safer secondary voltage used by utility consumers. They are cute square boxes, mostly Munsell green, but also Ansi gray. It can be well integrated with the surrounding environment. Therefore, you can often see them in residential areas or parks.

Power can be greatly distributed from a single transformer to a large building. They can also allocate electricity to a collection of smaller homes.

These transformers, which are often oil-filled, necessitate a dry and level surface for installation.

The transformer's core and coils are often stored in a steel oil-filled tank.

Additionally, a mounted, single-phase transformer doesn't need a wall around it to be widely erected in a certain spot.

Thus, it only needs to be completely enclosed.

Many homes in the area get their power from these pad-mounted, single-phase distribution transformers that can be widely located on roadways.

Get it now: CSA C802 Standard

Are Pad-Mounted Transformers Always Safe?

Pad-mounted transformers are comparable to those mounted transformers on line power.

To put it simply, they take power from a higher voltage and lower it to a level where it may be safely utilized in a home.

While single-phase pad-mounted transformers are generally connected to underground power lines, those mounted on poles are directly wired to overhead wires.

To prevent unauthorized access, pad-mounted transformers are usually locked and prominently marked.

Additionally, keep your kids away from them and out of harm's way.

Landscaping should not be mainly planted around the boxes since the roots of such plants could impair the operation of underground power lines, which may be necessary in the future.

Moreover. no digging should ever be strictly made close to a pad-mounted transformer.

It is just as important to exercise caution around pad-mounted transformers and buried power lines as it is to do so around overhead ones.

These types of transformers lack safety and security compared to transmission headquarters.

Although power tools and other electrical equipment may appear harmless when utilized as workbenches and climbing obstacles, they offer a risk to everyone who comes into contact with them.

Overall, surrounding users and the community should be extremely cautious and keep a safe distance at all times.

Try for free: 3 Phase Pad Mounted Transformer

How Long Do Single-Phase Pad-Mounted Transformers Last?

Like any other component of the electrical system, single-phase pad-mounted transformers eventually wear out and need to be generally replaced.

These residential transformers typically last 30 years but can deteriorate more quickly in severe settings, notably those with frequent applications of road salt.

Whenever a single-phase pad-mounted transformer needs maintenance, the electric company will temporarily cut power to the entire block or neighborhood.

It can take anywhere from two to eight hours to replace it.

Scheduled power outages will ensure the safety of customers and employees alike during maintenance and replacement procedures.

You may enjoy: Pad Mounted Transformer

In What Ways Could A Single-Phase Pad-Mounted Distribution Transformers Fail?

Overloading, corrosion, power surges, dampness, and lightning strikes are the most common reasons for transformer failure.

Moreover, the appearance of a partial discharge during voltage testing is usually suggestive of a mechanical failure.

It is good knowledge that line surges are both an indicator of electrical problems and a leading cause of transformer failure.

Whatever puts it in motion, the result might be remarkable.

In order to keep transformers at a stable temperature, mineral oil is usually applied. When batteries are typically overcharged or undercharged, the wiring might overheat. Thus, it can also catch fire.

When a transformer is usually subjected to tremendous overpressure, it may burst, resulting in a loud bang and a brilliant flash.

Certainly, it can cause a fireball seen from far distances.

Daelim can provide vegetable oil with ul certification to minimize the probability of the above accidents. Therefore, Daelim can provide you with safer and more reliable single-phase pad mounted transformers.

Learn More 25kVA Single Phase Pad Mounted Transformer

How Often Should Single-Phase Pad-Mounted Distribution Transformers Be Serviced?

Every six months, you should check the electrical transformer's dielectric strength and dielectric breakdown voltage.

As well as the flash point, sludge content, acidity, water content, and dielectric strength should be thoroughly serviced.

Much like any other electronic device, transformers aren't perfect. Actual transformers have power loss, while theoretical ones wouldn't.

In theory, a transformer's output power should be identical to its input power, but in fact, this is rarely the case.

Modern transformers are currently constructed with more exacting standards than their counterparts.

To maintain and sustain your single-phase pad-mounted transformer effective and functioning, frequent maintenance and testing are all necessary.

This is to ensure ongoing operation and services.

Final Thoughts

As an alternative to just searching for equivalent products, Daelim's Transformer Service Center can aid in the design and manufacture of distribution transformers that are specifically adapted to your needs.

Overall, the Daelim system satisfies the requirements of Canadian Standard Association (CSA) C227.3. As a producer with skilled engineers on staff, we may modify our offerings to meet your unique requirements.

Related Products

Related Article

Pad Mounted Transformer CSA C227.4 National Standard of Canada

As a transformer buyer and manufacturer, you should be familiar with the local transformer design requirements and standards. This article tells the Canadian country's transformer standard CSA C227.4, the pad-mounted transformer below 3000kva.

CSA C88 Standard For Power Transformers

CSA C88 is a comprehensive standard for power transformer and reactor bushings in Canada and across the globe. Daelim is a professional supplier of CSA standard transformers. Not only has CSA product certification but also cUL listed. It can provide CSA and cUL labeling services for your transformer.

CSA C802 For Minimum Efficiency Values For Power Transformers

The Canadian Standards Association has issued and produced CSA C802 as a national standard and policy for the country. This policy explicitly shows the performance and efficacy levels of power transformers rated from 501 to 10000 kVA.