Pad Mounted Transformer CSA C227.4 National Standard of Canada

Transformers are vital in our daily lives since they convert alternating current to direct current and transport electricity to your devices, equipment, and others to ensure their durability and efficient performance. Therefore, as a transformer buyer and manufacturer, you should be familiar with the local transformer design requirements and standards. This article tells the Canadian country's transformer standard CSA C227.4, the pad-mounted transformer below 3000kva.

What Is CSA C227.4?

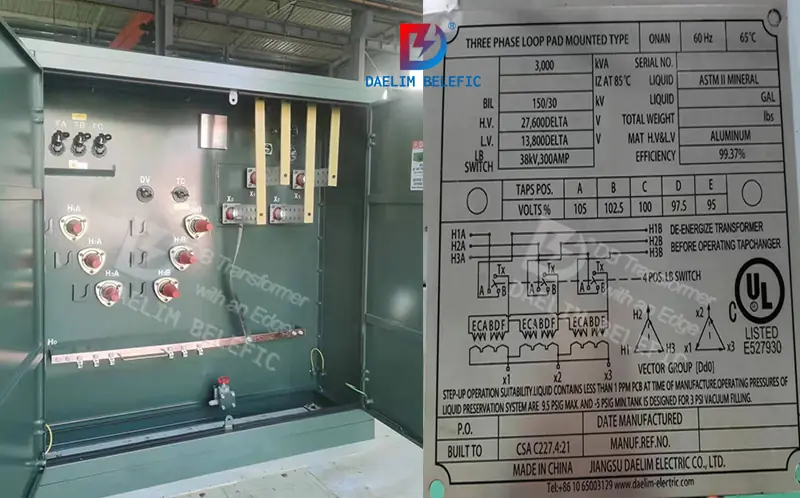

The CSA C227.4 standard is a standard that indicates the specific requirements for three-phase, pad-mounted distribution transformers. These transformers are composed of a transformer and a cable entrance compartment with facilities for separate insulated high-voltage connectors. These transformers are designed to be operated primarily by electric utilities on three-phase underground distribution systems.

Learn more: 3 Phase Pad Mounted Transformer-Daelim Belefic

For instance, if you work in the welding sector, you know that welding is a crucial joining technique utilized in producing distribution transformers. It is required that CSA Standard C227.4 be adhered to assure the quality of the welds and the safety of the distribution transformers' users. This standard outlines certain requirements for the design and construction of distribution transformers, keeping in mind that people use these transformers.

What Is A Pad Mounted Transformer And Its Features?

Padmount or pad-mounted transformers are steel cabinets used for electric power distribution. It is also fully charged, with points securely closed in a grounded metal housing. Electric power distribution lines deploy essential transformers at service drops to reduce the primary voltage on the line and the secondary voltage providing the customer's utility.

Transformers designed to be positioned on a pad can have a power rating anywhere from 15 to 5,000 kVA and typically feature built-in fuses as well as switches. To facilitate repairs and maintenance, primary power lines can be linked with elbow connections that can be activated with a hot stick.

Read more: The Ultimate FAQs Guide 5000kVA Transformer-Daelim

Pad-mounted transformers have a lot of advantages over substation transformers in terms of their functionality. These are the following:

• Decreased need for land and installation expenses

• Decreased need for land and installation expenses

• Enhancement of both aesthetics and safety

• Improved land use efficiency

Pad-mounted transformers have fewer space and expense requirements than substations for the same amount of electricity delivered. Since pad-mounted transformers are self-contained and tamper-proof, they can be installed in unprotected regions without needing an expensive fence or enclosure. The ease of access also facilitates maintenance.

Learn more: 2500 kVA Pad Mounted Transformer

What Are Various Version Of CSA C227.4 Scope Or Standard?

The rate at which standards evolve is much greater than you may anticipate.

Moreover, to determine the differences between each year's version and the evolution of CSA C227.4 over time. Here are the scope and requirements for each version, beginning with CSA C277.4-06.

CSA-C227.4-06

Scope:

This Standard specifies the criteria for a 3-phase, pad mounted distribution transformer, which consists of a transformer and a cabling entrance compartment with provision for separate insulated high-voltage connectors, and is principally designed for use by electricity companies on multiple underground distribution systems with primary voltages.

Standard:

Its applications are three-phase, pad-mounted, 60Hz, liquid-filled distribution transformers rated at 3000 kVA or less. In addition, its insulation is 18kV or less, and its high-voltage connectors are individually insulated. Transformers can be mounted outside on pads without requiring extra protective enclosures.

Try for free: How To Purchase 3000kVA Transformer In USA & Canada?

It contains voltage values expressed in kVA, test protocols, and mechanical properties. Temperature rise, load capacity, clear sound level, radio effect voltage, and energy efficiency comprise its operating performance.

When this equipment is designed for use by a party besides the electric utility, the purchaser must ensure that the unit complies with the standards of the applicable electrical inspection authority.

This Standard permits replacing a pad-mounted, dead-front unit with a unit with the same basic physical dimensions from various manufacturers without modifying the wires or pad. There are required minimum and required maximum dimensions covered by this Standard for terminal configurations used in radial and loop-feed systems.

Try for free: CSA C227.5 Std

CSA-C227.4-06 2nd Update

Scope:

Pad-mounted, three-phase distribution transformers for use principally by electric utilities on three-phase underground distribution systems with primary voltages as specified in this Standard. This type of transformer comprises cable entrance compartments utilizing separate insulated high-voltage connectors.

Standard:

It applies to 60 Hz, liquid-filled, three-phased, pad-mounted distribution transformers rated at 3000 kVA or fewer with an insulation rating of 18kV or less and separate insulated high-voltage connectors. Transformers can be mounted outside on pads without requiring extra protective enclosures.

Specific mechanical features, as well as test techniques and voltage and kV•A ratings, are included in this Standard. Energy efficiency (as measured against CAN/CSA-C802.1), temperature increase, loading capacities, perceptible sound level, and radio effect voltage are all included in the Standard's performance parameters (RIV).

With this Standard in place, you can switch out a pad-mounted, dead-front unit for one made by a different manufacturer, regardless of whether or not the wires or the pad have been altered in any way. Terminal arrangements, including minimum and particular dimensions, are covered by this standard for radial and loop-feed systems.

Get it now: The Ultimate Guide to Dead Front Transformers

CSA C227.4-21 (The Newest Update)

Scope:

The scope of this Standard is to define the specifications for three-phased, pad-mounted distribution transformers. These transformers consist of a transformer and a cable entry compartment with a requirement for separate and distinct insulated high-voltage connectors. These transformers are designed to use pyroelectric utilities for operation on multiple subsurface distribution networks with primary voltages.

You may enjoy: CSA C227.3 Std

Standard:

This Standard applies to three-phase distribution transformers that operate at 60 hertz, have pad mounting, are filled with liquid, have ratings of 3000 kVA or less, operate at up to 34.5 kV systems nominal voltage, and have separate insulated high-voltage connectors. The transformers can be mounted outside on pads without needing extra protective enclosures because they are weatherproof.

You may enjoy: Do you want to learn more about a 34.5 kV transformer?

This Standard provides specific mechanical features, protocols for testing, voltage, and kVA ratings. The standard also includes the following characteristics: energy efficiency (in line with CAN/CSA-C802.1), temperature increase, loading capability, audible noise level, and wireless influence voltage (RIV).

Moreover, It is the buyer's responsibility to check that the unit satisfies the standards of the relevant electrical inspection authority if it is used by anybody other than a public utility.

The standard stipulates the replacement of a pad-mounted, dead-front unit with another of the same basic physical size from various manufacturers for transformers rated at less than 125 kV BIL, with no modifications to the pads' wires. It also addresses terminal layouts for loop-feed and radial systems and other minimum dimensions and specifications.

Major Changes In The New CSA C227.4 Standard

The following is a list of the significant additions and adjustments made in this edition:

- Broadened the scope to include systems with nominal voltages of 34.5 kV, and did away with the phrases insulating category and preferred voltages;

- References that have been brought up to date with other industry standards;

- Elucidated requirements about the off-voltage taps and included an explanatory remark on dual-voltage transformers that have taps;

- Additional requirements to the ratings of the entirely voluntary load break switch because the old IEEE references are no longer valid;

- Conditions have been amended and clarified about the two-fuse system, and tables containing manufacturer-specific part numbers have been removed;

- Requirements for improved routine testing to better accord with IEEE standards. For instance, no-load inefficiencies and stimulating current will be calculated based on the rated voltage of 100% rather than 105%;

- Caution markings were not put on the internal fuses;

Its language was clarified and expanded, and it now includes new options. For instance, based on the knowledge and practices of users, regular leakage testing has been incorporated;

The continuation of the provision of the electrical parameters that pertain to the transformers that are covered by such a Standard and that were originally given in CAN/CSA-C2;

Reading on: Exploring Everything About 2000 kVA Transformer

What Are The Electrical And Mechanical Features Of CSA C227.4?

Transformers, in general, should have dimensions, and their design should be as minimal as possible to indicate accessories, features, capacity, and special features to the buyer.

Cable Entry Compartment

The transformers and cable entry compartment configuration must be designed so that the high-voltage and low-voltage facilities are positioned next to one another on the transformer tank. A hinged hood shall be required to provide access to the cable entrance chamber.

The hood and sill must be configured so that a simple padlock may be used to secure the unit. ANSI C57.12.28 must be complied with for the compartment's locking features.

Due to the risk of galling, bolts made of stainless steel cannot be used in receptacles made of the same material. However, the bolt and its thread mating device shall be mounted to permit the threads to function, notwithstanding a minor misalignment between the axes of the respective parts.

You may enjoy: Pad Mounted Transformer

Due to galling risks, it is not permissible to fasten stainless steel bolts into stainless threaded receptacles. The installation of the bolt, though, and its threaded mating mechanism shall be designed to accommodate a minor misalignment between the axes of the component pieces while allowing the threads and requiring their attachment correspondingly. In particular, the pentahead bolt must be captive to prevent loss and thread damage during hood operation, which involves lowering the hood from its fully open position. A minimum of 80 mm must separate the center of the hasp from the bottom of the sill. The maximum acceptable sill height is 150 mm.

The hood must be capable of opening to a minimum range of 160 degrees. The hinges must be constructed from corrosion-resistant material and be robust enough to survive harsh operating conditions. A device must be supplied to prevent the hood from being accidentally removed.

Reading on: The Ultimate FAQs Guide To 13.8kV Transformer

Pad Mounted Transformer Tank

The transformer base must be configured so that the bottom of the tank doesn't touch the pad. At least one of the three intersecting upper corners of the transformer must be rounded to a minimum radius of 25 mm. Any protruding face on covers that are mechanically fastened must be rounded off.

Drain Plugs And A Pressure-Relief Valve

The transformer must have appropriate strength and resist a pressure gauge of 50 kPa without leaking or irreversible deformation of the tanks that surpasses 0.5% of the diagonal dimension of the affected surfaces. And a pull-ring-type pressure-relief mechanism should be provided.

Removing Restrictions

The unit's structure must be skidded or slid onto the mounting pad and raised into position without disturbing high or low-voltage lines. Elevating provisions will be installed on the tank, similar to how lifting the transformer prevents overturning.

The safety factor of 5 per ANSI/IEEE C57.12.25 is incorporated into the recessed lifting bosses. The minimum depth of the bosses is 0.625 inches, and they have 5/8-11 NC thread. These four leaders should be installed 100mm from the tank's rim. 64 mm (2.50 in) long 5/8-11 NC bolts are included.

Reading more about IEEE CS7 Std

Insulating liquid

Mineral oil, or an alternative liquid insulant meeting the requirements of CAN/CSA-C50, must be used unless otherwise indicated in accordance with Clause 11(q). The mineral oil must be at least Class B and Type I; Class I or Type II are acceptable alternatives. When the transformer is sold, the dielectric strength must be at least 40 kV when tested according to ASTM D 1816 with a 2 mm electrode spacing.

Transformer Construction And Cooling

All transformers must be built so that cooling is performed solely by the tank surfaces; external cooling devices, such as fins, radiators, etc., are prohibited. The entire transformer assembly must be sealed and stay successfully closed over a –40 °C to +105 °C oil temperature range.

Read my article on The ultimate guide to ONAN transformers

What Are The Various Accessories Of CSA 227.4?

Transformers may be supplied with the various optional accessories if the purchaser so requests:

- corrosion-resistant for use in highly polluted regions;

- corrosion-resistant for highly contaminated environments;

- a drainage plug and filler plug; and

- load-break switches.

- The number stenciled on the hood's front is the customer stock code.

- Tabs for securing the clamps to the bushing wells

- a 25 mm-diameter hole covered by a detachable stainless steel plate positioned at the bottom of the cylinder;

- Use as a remote failure indicator light;

- two foundation clamps configured differently with high-voltage taps;

- Locking provisions for load-break switches;

- low-voltage bushings of the stud- or spade-type;

- load-break inserts with dust cap included;

- two foundation clamps are organized differently

- high-voltage connections;

- impulse testing: This test considered a routine test, can be requested by the purchaser and must be carried out.

- Based on the ANSI/IEEE C57.12.90 standard

- Permanent or temporary bar code label according to ANSI/IEEE C57.12.35;

- minimal impedance to limit short-circuit current at service equipment:

Learn more: The Impact of Impedance on Transformer Design

CSA 227.4 Quality Of Work And Finish

ANSI C57.12.28 is the standard that the exterior finish needs to meet. The color must be either equipment green, with a Munsell value of 9GY1.5/2.6, or seafoam green, with a Munsell value of 4.82 G 4.07/3.35. The supply will be of a seafoam green hue if no color is chosen. The CSA W59 standard must be followed in all welding. The fabricator must meet all qualifications and receive approval from the Canadian Welding Bureau to comply with CSA W47.1.

Unless otherwise indicated, the following shall be the dimensions' tolerances:

- on all sizes under 300 mm, 5 mm;

- on all measurements 300 mm and higher, 10 mm; and

- all holes were nominal dimensions.

Pad Mounted Transformer Markings And Exterior Information

If decals are utilized, they must conform to the Type A label criteria of CSA C22.2 No. 0.15 and retain their integrity at –40 °C. Regarding decals, you must meet the Type A label standards of CSA C22.2 with No. 0.15 and preserve their integrity at temperatures as low as –40 °C.

Moreover, transformers must be equipped with a combination nameplate and wiring diagram. The nameplate must contain all of the information required in Clause 10.2.3, and it must remain visible for the lifetime of the transformers under normal operating conditions.

The identity of terminal connections must be provided on the tank itself and the nameplate that combines its functions as a connection diagram and a terminal connection diagram.

Read more: The Ultimate FAQs Guide To Transformer Connection

Details About The Interior Of The Transformer Compartment

The following information is located within the transformer compartment. These formations shall be stenciled on the surface of the tank compartment using 15 to 25 mm:

- Voltage is high terminal designations

- Voltage is low terminal designations

- dual voltage switch (if present); and TC (tap changer switch), if present.

- voltage indications of voltage selector switch locations;

- numerical tap position of the tap changer switch (if an indicator plate is provided). The numerals must be at least 8 mm tall. Disconnecting switches

Warning labels that comply with the criteria are required to be affixed to the area adjacent to the handles of transformers that feature off-circuit switches that can be operated externally. Before operating the switch, the label must indicate the necessary safety precautions that must be completed. In addition, to electrical hazards, warning labels are required to be installed accordingly, and there should be identical signs that the purchaser will submit to the manufacturer for installation.

Try for free: The Ultimate Guide To Renewable Power Plants

CSA C227.4 Three Phase Pad Mounted Transformer Manufacturer

Daelim has cultivated the Canadian market for many years and has a transformer cUL certificate. The DAELIM team knows the various technical requirements and experimental requirements of the CSA standards of the transformer. There are thousands of transformers exported to Canada each year. In addition, Daelim has installation and after-sales teams in Canada to quickly solve any problems you encountered in the local area.

Whether you are a transformer distributor, Utilities, or an end user, you can contact Daelim through the mailbox service@daelim-electric.com and telephone: +86-13051965423.

In Conclusion

The above content mainly talks about the design standard of CSA C227.4: 21. Regarding the design specifications and requirements of 3 Phase Pad Mounted distribution Transformers' electrical characteristics to ensure the standard and safety of the transformer. To achieve the security and energy saving of transformers in applications.

Related Products

Related Article

Pad Mounted Transformer Project Cases

3750kVA Primary 13.8kV, Secondary:0.415kV Loop-feed Pad-mounted Transformer, 12 sets for US market;

What is a Live Front 25kv Pad Mounted and Substation Transformer Specification ?

"Live" and "Dead" are terms commonly applied to oil-filled pad-mounted transformers. "Live front" refers to the exposed end of the cable and terminals. For example, the cable can be stripped at the end and inserted into the eyebolt terminal of the porcelain bushing.

Skid Mount Transformer Solution With 3 Phase Pad Mounted Transformer Inside

Daelim Transformer's skid mount solutions with 3-phase pad mounted transformers represent a pinnacle of modern power distribution technology, catering to the stringent demands of various industries including renewable energy, mining, data centers, and transportation sectors. Their innovative design, coupled with robust performance and ease of deployment, makes them indispensable in today's rapidly evolving energy landscape. Whether for large-scale utility projects or specialized applications like electric vehicle charging infrastructure, these solutions exemplify efficiency, reliability, and adaptability in power distribution solutions.

Knowing More on A Pad Transformer

Daelim's pad-mounted transformers are outdoor electrical devices enclosed in tamper-resistant cabinets. They integrate components like high-voltage load switches, fuses, and transformer oil for insulation. Typically rated between 75 kVA and 7,500 kVA, these transformers feature sealed oil tanks and are designed for safety and durability. They are commonly used in urban areas, near residential or commercial buildings, and are suitable for applications such as electric vehicle charging, renewable energy systems, and utility distribution.

How Much is a Transformer

Electrical transformers are essential for safe, reliable electricity in residential, industrial, and utility systems. Buyers must understand pricing, which depends on transformer type, application, and specifications. Proper budgeting requires knowing cost-driving factors, including design, capacity, and usage requirements, to ensure the right transformer is purchased for specific industrial, utility, or infrastructure needs.

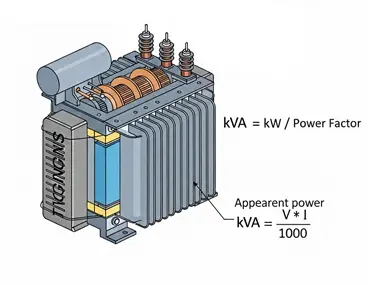

Transformer Calculation Table

Electric transformers are crucial for stepping voltage up or down in power distribution. Proper transformer calculations, considering consumer requirements and international design standards, are essential for accurate voltage regulation. Understanding transformer specifications, formulas, and sizing methods is key. The article provides examples and a calculation table to guide readers through the transformer design and selection process effectively.