What is a Live Front 25kv Pad Mounted and Substation Transformer Specification ?

Whether dead front or live front transformers, Daelim Transformer possesses extensive production experience and annually exports thousands of units to America, all certified with UL, cUL, and CSA certifications.

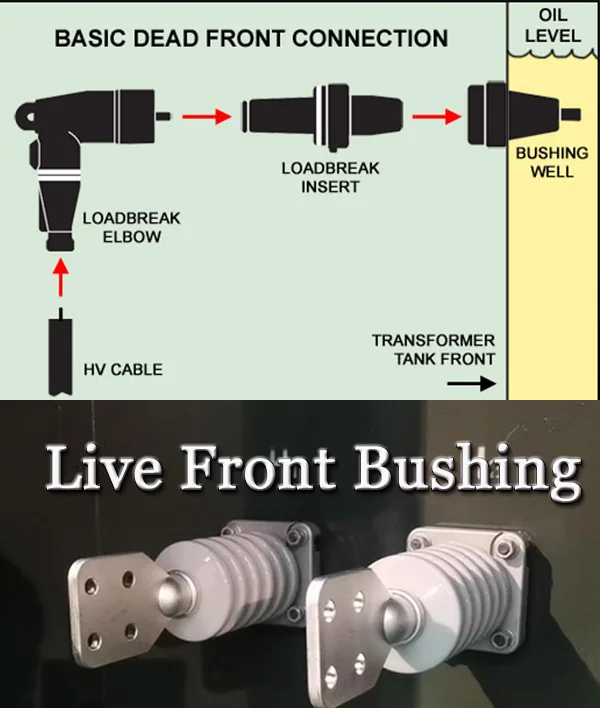

Now we mainly introduce the Live Front Transformer to you. The bushing is an insulator that allows the conductor to pass safely through the transformer tank wall without making electrical contact.

Learn more: How to choose a pad-mounted transformer for your project?

It is called live because the terminal is exposed. There is currently flowing through it. Touching a live front hub can cause an electrical shock. You won't even want to get too close due to arc flash issues.

Fully stabilized ZrO2 ceramic material has good oxygen ion conductivity, chemical stability, and excellent thermal stability in high-temperature environments, and is a widely used solid electrolyte material in the oxygen sensor manufacturing industry. With the advancement of science and technology in the steel industry, the demand for zirconium ceramic bushings in thermal fields such as steel and metallurgy is also increasing.

The oxygen sensitivity and thermal stability requirements of the material are also higher. A large part of the domestic zirconium ceramic shell still needs to be imported, mainly because the performance of domestic products is unstable and the price is not very competitive. In terms of the manufacturing process, the zirconium ceramic production process is difficult to control, and the technical performance is difficult to improve. The zirconia material itself has the characteristics of polycrystalline transformation. When the temperature is raised, monoclinic zirconia will transform into tetragonal crystal format 1000-1100°C, accompanied by 7%-9% volume shrinkage; when the temperature is lowered, the tetragonal crystal type zirconia reversibly transforms into monoclinic zirconia at 700-900℃, accompanied by obvious volume expansion, which makes the zirconia ceramic sleeve prone to cracking and deformation during the process of cooking, and the performance of the product is not up to par. When the technical requirements are met, defects such as poor thermal stability, poor mechanical strength, and poor external geometry of the ceramic sleeve occur.

The hub itself has several components. The blade is on top of the hub. This is where the actual termination is done using mechanical lugs or crimp lugs. Below the shovel is a bush consisting of small ridges called waffles or huts. These waffles help prevent what is called creep. Creep is where a small arc travels across a surface area by "creeping" along with a small amount of water, dust, or oil. The waffles provide the necessary clearance to prevent slippage by providing a larger surface area. Finally, there is a bolt and the sleeve is internally connected to the core and the coil.

Read more: How to choose pad mounted transformer for blockchain?

What is a Live Front 25kv Pad Mounted and Substation Transformer?

"Live" and "Dead" are terms commonly applied to oil-filled pad-mounted transformers. "Live front" refers to the exposed end of the cable and terminals. For example, the cable can be stripped at the end and inserted into the eyebolt terminal of the porcelain bushing.

What is the difference between a Live Front 25kv Pad Mounted Transformer and a Dead-front transformer?

High voltage connectors, surge arresters, or fuses of Livefront terminals are exposed to the operator after the cabinet is opened. Front End (Separable Insulated Connector Type): Often referred to as the Front Sleeve. Safety is improved as no current-carrying parts are exposed to the operator.

Keep on reading:3 Phase Pad Mounted Transformer-Daelim Belefic

What parameters and accessories for a 25kV live front pad-mounted transformer are required?

Live-front (porcelain type): The live part is exposed. High voltage connectors, surge arresters, or fuses of the Live front terminals are exposed to the operator after the cabinet is opened.

Front End (Separable Insulated Connector Type): Commonly referred to as the Front Sleeve. Safety is enhanced as no current-carrying parts are exposed to the operator.

Try for free: How To Choose The 2500 KVA Transformer For Your Project In 2022?

There are two basic types of power distribution system configurations:

1. Circulatory system:

These system configurations can be used alone or in combination with each other in different parts of the power distribution system. The main difference is between multi-circuit and radial single circuits.

2. Radial system:

This is used for special customer requirements. The disadvantage is that if any circuit accessories fail, all subordinate accessories need to be powered off and cannot be used continuously. In our example, the transformer is equipped with a fuse to isolate the circuit for protection. This type of circuit is mainly used in remote underdeveloped rural areas. And therefore, this circuit system only requires the use of a high-voltage bushing because no current circulates through any transformer.

Keep Reading: 2500 kVA Pad Mounted Transformer

What are the main accessories for a Live Front 25kv Pad-Mounted?

The particularity of the general ceramic bushing is that it is necessary to install a lightning arrester for protection at the same time.

How will the arrester protect the transformer?

When the transformer is not protected by a lightning arrester, the overvoltage generated by the lightning may directly invade the transformer winding, thereby breaking down the winding. There are three types of arresters currently used in transformers: valve arresters, magnetic blow valve arresters, and zinc oxide arresters.

1. Lightning arrester protection of transformers

A lightning arrester is the most important basic element to protect power generation equipment and power transmission and transformation equipment, and it is also the basis for determining the insulation level of high-voltage electrical equipment. It is a protective device installed in front of the transformer. The valve arrester is mainly composed of two parts: spark gap and non-linear resistance. When the overvoltage generated by lightning strikes the transformer, it must first pass through the arrester. At this time, the spark gap of the arrester is discharged, thus limiting the overvoltage value on the transformer insulation. During the discharge process, due to the good volt-ampere characteristics of the nonlinear resistor, the residual voltage on the arrester (the voltage drop caused by the discharge current passing through the nonlinear resistor) is limited to a value that is not dangerous to the transformer. The lower the residual voltage, the lower the insulation level of the transformer. After the gap is broken down, the power frequency voltage acting on the arrester also produces a power frequency current passing through the arrester, that is, the accompanying current. Due to the nonlinearity of the valve plate resistance, it limits the accompanying current to a small value, generally below 50a, and is cut off when it passes through the zero value for the first time.

Get it now: What You Need To Know About Substation Transformer In 2022

When the overvoltage passes, the valve-type arrester can automatically cut off the power frequency freewheeling by the function of the valve plate and the gap, so that the working voltage of the power transmission system is isolated from the ground, and the arrester can be restored to the normal state before the lightning strike. However the current valve-type arrester can not fully protect the operating overvoltage.

The magnetic blowing valve arrester adopts the magnetic blowing current-limiting gap to ensure the stability of the discharge voltage of the arrester. At the same time, the gap itself has the characteristics of an elongated arc. A considerable arc voltage drop is produced, which increases the reliability of the arrester arc extinguishing. The valve plate is a high-temperature valve plate. Therefore, the current capacity is large, and the residual voltage when the inrush current passes through is low. Not only can the insulation of the transformer be protected from lightning overvoltages, but it also can limit certain types of operating overvoltages. There is no gap in the zinc oxide arrester, and the residual voltage is lower. The ultra-high voltage transformer has been protected by this arrester.

2. Lightning arrester protection of transformer neutral point

When the neutral point of the transformer running the neutral point effective grounding system is not grounded, a lightning arrester should be installed on the neutral point. When the neutral point of the transformer running in the neutral point ungrounded system should also consider installing a lightning arrester on the neutral point; if the neutral point is grounded through the arc suppression coil, in order to eliminate the possible overvoltage at the end of the arc suppression coil, the Install a surge arrester in parallel with the arc suppression coil.

Try for free:3 Phase Pad Mounted Transformer

3. Lightning arrester protection on the low-voltage side of distribution transformers

Although the low-voltage side of the distribution transformer is 400v, it must be protected by a surge arrester or varistor with the corresponding voltage level, otherwise, the high-voltage winding will be easily broken down when the low-voltage side is subjected to lightning overvoltage.

4. Arrester protection at the emergent end of the autotransformer

When the arrester is installed at the outlet end of the high voltage side and the medium voltage side, it is required that no knife switch be installed between the outlet end and the arrester to prevent the possibility of disconnection between the arrester and the line end of the transformer, and to ensure that the arrester is still cut off at the outlet end of the transformer. connected to the outlet of the transformer. In this way, when the high voltage side is struck by lightning, the incident wave voltage on the medium voltage side is prevented from appearing at the beginning; when the medium voltage side is struck by lightning, the triple incoming wave voltage on the high voltage side is prevented; the insulation of the incoming wave line is protected; A lightning arrester is installed on one side of the low-voltage side outlet end to prevent the danger caused by the overvoltage of the low-voltage open-circuit electrostatic induction component. When the low voltage is double split, a lightning arrester should be installed on the split winding of each phase.

5. Lightning arrester protection for three-winding transformers

When the medium-voltage or low-voltage windings of the three-winding transformer are in open-circuit operation for a long time, in order to avoid the harm of electrostatic induction on the middle and low-voltage winding insulation, when the medium and low-voltage windings are Y-shaped, the neutral point can be grounded; it is D-shaped. When connecting, you can ground any phase line end. If the temporary open circuit operation is often performed, a surge arrester equivalent to the phase voltage or line voltage should be installed to replace the neutral point or any phase grounding.

Learn more: How to choose the best distribution transformer

What is Live Front 25kv pad-mounted transformer Monitoring?

The host is installed on the pole of the monitored power line or next to the transformer. Once you get close to the transformer, the infrared detector will detect it immediately and start the imaging system to take photos and upload them to the monitoring center immediately. Notify relevant leaders and maintenance personnel, and dispatch police to the scene to verify the situation and deal with the theft. Technical Parameter Name of Distribution Transformer Remote Monitoring System Technical Index Communication Mode Industrial Grade 900/1800MHz GSM Module Alarm Mode GSM Chinese and English Short Message Standby Power Consumption ≤5W Rated Working Voltage Single Phase AC220V Backup battery 7.4V/6000mAH (polymer battery) Electromagnetic interference IEC55022 Insulation Class B Protection class IP66 Working environment Temperature -40℃~+75℃ Humidity ≤95% Non-condensing Appearance Cast aluminum, fully sealed, waterproof Size 290 × 180 × 130 (mm) Distribution transformer Remote monitoring system The main features are as follows:

1. Using 3G, GPRS, and CDMA mobile phone cards to transmit video, intuitive and unlimited transmission distance.

2. It has 1 switch detector input port, which can be equipped with sensors such as disconnection and displacement.

3. With all forms of video, video or image can be transmitted, simple and flexible, saving cost.

4. It is convenient and straightforward to set host parameters through network central management and mobile phone remote short messages.

5. The system has a remote call function.

6. Aluminum die-casting fully sealed housing, good waterproof performance, suitable for field installation. In order to ensure the operation of power facilities, reduce property losses, ensure the smooth progress of industrial and agricultural production, and meet the needs of economic construction and electricity for people's lives, the company's power supply company has installed remote monitoring systems for distribution transformers in several locations. The remote monitoring system of distribution transformers can alarm and take pictures, which can help the power supply company's transformer anti-theft work.

For more detailed product requirements, please click to contact us

Related Products

Related Article

2 MVA Pad Mounted Transformer for Utility

Behold the backbone of Canada's utility infrastructure—the 2MVA pad mounted transformer. With a primary voltage of 4160Grdy/2400V and a secondary voltage of 800GrdY/461V, this transformer stands as a testament to efficiency and reliability in power distribution. Crafted in strict accordance with CSA standards and CAN/CSA802.1 energy efficiency guidelines, it embodies the pinnacle of engineering excellence.

2600 kVA Pad Mounted Transformer For Blockchain In Kansas

This morning, I received the on-site photos of the pad-mounted transformers from the customer, and I was overwhelmed with excitement and joy. These pad-mounted transformers are installed at a 20MW blockchain site in Kansas, USA. A total of 5 sets of 2600 kVA pad-mounted transformers, all UL-listed, are being deployed at this site. Currently, 3 sets have already been installed onsite and are scheduled to be powered on imminently.

Supply of 37.5 kVA Single Phase Pad Mounted Transformers for Canadian Utility

Today, we are excited to introduce a project undertaken by Daelim Transformer aimed at supplying transformers to a Canadian utility. This project involves the delivery of 80 units of 37.5 kVA single-phase pad mounted transformers, specially designed to meet the utility's requirements. With a high voltage (HV) rating of 24940GRDY/14400 V and a low voltage (LV) rating of 240/120 V, these transformers are vital components in the utility's infrastructure.

2600 kVA Pad Mounted Transformer for Blcokchain

Daelim Transformer successfully provided three customized 2600 kVA pad mounted transformers to power a state-of-the-art blockchain facility in Texas, USA. Our transformers were meticulously designed to meet the unique demands of the mining operation, ensuring seamless power distribution with unwavering reliability and efficiency.

Pad Mounted Transformer CSA C227.4 National Standard of Canada

As a transformer buyer and manufacturer, you should be familiar with the local transformer design requirements and standards. This article tells the Canadian country's transformer standard CSA C227.4, the pad-mounted transformer below 3000kva.

2000 kVA Pad Mounted Transformers for Canadian Utility

Daelim Transformer is pleased to announce its contribution to a utility project in Toronto, Canada, involving the supply of two units 2000 kVA pad mounted transformers. These transformers are integral to enhancing the power infrastructure in the region. The project demands adherence to CSA standards, with a stringent delivery deadline of 10 weeks to meet the urgent needs of the client.