How to choose the best distribution transformer?

Distribution transformer usually refers to a power transformer that operates in the distribution network with a voltage level of no more than 35kV and a capacity of 6300kva and below and directly supplies power to end-users.

Generally, distribution transformers should be installed on a column or installed on the ground in the open air. The main function is to carry out power transmission.

There are so many distribution transformers on the market, how do you know which distribution transformer is best for you? This article may give you some inspiration.

What types of distribution transformers are there?

Distribution transformers are classified according to cooling methods, and there are two main categories: Oil-immersed transformer and Dry type transformer.

Oil-immersed transformer

The oil-immersed transformer of the distribution transformer is divided into Substation transformer, Pad-mounted transformer, Pole mounted transformer and Oil filled transformer.

Substation transformer

The standard high voltage of this type of transformer is up to 46kV, and the capacity is up to 15MVA.

The standard high voltage of this type of transformer is up to 46kV, and the capacity is up to 15MVA.

Substation transformer can be designed as top-out mounting bushings or side-out mounting bushings for connection to high and low-voltage cabinet switchgear. The air terminal box on both sides of the transformer is removable, as is the radiator. Devices with alarm contacts. Substation transformers are often used in compact combinations with switchgear, motor controls, bus ducts, or other types of entry and exit equipment.

Substation transformers are generally used in Portable Substation or Skid Mounted Portable Substation, which are widely used in the North American market. Advantages: space-saving, energy-saving, wear resistance and heat resistance, high stability.

Daelim's mini substation transformer can fully meet the IEEE/IEC/CSA/AS design standards, and can design appropriate K coefficients for the substation transformer; to reduce the influence of nonlinear harmonic load conditions. Daelim's substation transformer has been exported to Canada, the United States, Australia, Mexico, and other North and South American markets.

4500 kVA Substation Transformers for Australian Mining Site

2000 kVA Oil immersed Substation Transformer For Portugal Market

13.8 kV 10.5 MVA Substation Transformer for Ecuador

The following video is Daelim’s substation transformer for Canadian market:

Prefabricated Substation

Prefabricated Substation, The functions of high voltage and low voltage power distribution of the transformer are organically combined and installed in a heat-insulated, fully enclosed, and movable steel structure box. It has the functions of moisture-proof, rust-proof, dust-proof, rat-proof, fireproof, and anti-theft.

It occupies a small area; the construction speed is fast, and only the basic parts are required to be constructed on-site; the appearance is beautiful, and it can be coordinated with the environment of the residential area; It has been widely used in factories, mines, oil fields, ports, airports, stations, urban public buildings, concentrated residential areas, institutions, schools, commercial halls, and underground facilities.

There are two types of prefabricated substations, one is Compact substations and the other is Pad-mounted transformer.

Compact substation

Compact substation’s high-voltage chambers are generally composed of high-voltage load switches, high-voltage fuses, and arresters, etc., which can perform power-off and transmission operations and have overload and short-circuit protection.

The main function is to carry out power transmission.

Pad mounted transformer

Pad-mounted transformers are divided into three-phase and single-phase.

Pad-mounted transformers are divided into three-phase and single-phase.

Three phase pad mounted transformer: Capacity 45kva to 5000kva, up to 35kv.

Its structure is divided into two parts, the front part is the wiring cabinet, the wiring cabinet includes high and low voltage terminals, high voltage load switch, plug-in fuse, high voltage tap changer operating handle, oil level gauge, oil temperature gauge, etc.; The box body adopts a fully sealed structure.

The overload capacity is strong, allowing 2 times of overload for 2 hours and 1.6 times of overload for 7 hours without affecting the life of the box. If you use a lot of electricity, three-phase padmounted transformer will be the best choice.

Many of our blockchain customers in North America choose Daelim's three phase pad mounted transformers with the capacity of 2500kva to 3750kva. Daelim is UL listed and can provide UL and CSA labeling services.

Learn more: How to Choose the Best Pad Mounted Transformer for a blockchain Project?

The three-phase pad-mounted transformer adopts an elbow-type plug connector, which can easily connect the high-voltage incoming cable and act as a load switch in an emergency.

Adopt double fuse protection, BAY-o-net is the double sensitive fuse to protect the box from short circuit fault. ELSP is used to protect the high voltage side.

Adopt double fuse protection, BAY-o-net is the double sensitive fuse to protect the box from short circuit fault. ELSP is used to protect the high voltage side.

Single phase pad mounted transformer

The single phase transformer input is single-phase AC power, and the output is als o single-phase AC power, so it can only provide power for loads that require single-phase power. Adopt double fuse protection, BAY-o-net is the double sensitive fuse to protect the box from short circuit fault. ELSP is used to protect the high voltage side.

o single-phase AC power, so it can only provide power for loads that require single-phase power. Adopt double fuse protection, BAY-o-net is the double sensitive fuse to protect the box from short circuit fault. ELSP is used to protect the high voltage side.

This type of transformer has a removable flip-top cover that can be installed directly indoors or outdoors. Widely used in residential areas, commercial centers, airports, schools, hospitals, and other places。

Daelim’s single phase padmounted transformer has very good performance. Capacity from 15 kVA to 250 kVA, up to 34.5 kV. Single phase pad mounted transformer connections generally Dyn1(Delta/Wye) or YNyn0(Ground Wye)

Supply of 37.5 kVA Single Phase Pad Mounted Transformers for Canadian Utility

Single Phase Pad Mounted Transformer For USA Utility

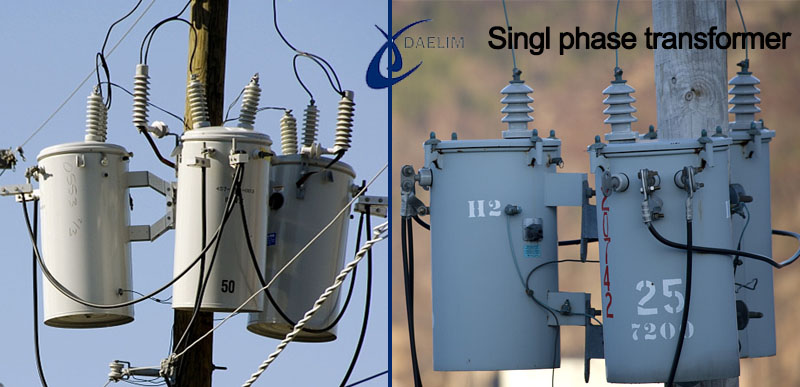

The capacity is below 315kva. Pole mounted transformer is divided into single-phase transformer and 3 phase transformer.

Advantages: It occupies a small area, does not need walls or fences around, and the live part is high from the ground, so it is not easy to cause accidents. Disadvantages: The bench uses a lot of steel, and the cost is higher.

Single phase mounted transformers are generally used in places where three-phase electricity is not used or is rarely used. Single-phase transformers can operate in single-phase, or three single-phase groups can operate as three-phase. Therefore, it is used in low-voltage distribution networks with sparse populations or low load density.

Daelim's Single phase mounted transformer up to 167kva, there are two main types for you to choose from Conventional Type and CSP Type. Daelim single transformer is characterized by low loss, simple and fast installation, beautiful and modern appearance, excellent insulation and sealing system, and lower operating costs. Has helped customers in Canada, Honduras, El Salvador, and other countries to obtain bidding and procurement projects, with thousands of export records. If you have single-phase change needs, you can contact us.

The picture below is the 50kVA, 15kVA and 25kVA single-phase transformers we provide to Canadian customers. This is a bidding project, the quantity exceeds 100 units.

Single Phase Pole Mounted Transformer Project, Canada

Single Phase Pole Mounted Transformer For Guyana

Capacity 50kVA to 5000kVA, up to 35kV

Oil filled transformer is floor-standing, which means that the transformer is placed directly on the ground, and the high-voltage down-conductors, drop-out fuses, and arresters are all on the line terminal poles.

Oil filled transformer installation should pay attention to:

(1) Reliable barriers must be installed around the transformer, and the door must be locked and kept by a special person.

(2) Warning signs such as "High Voltage Danger, No Climbing" must be hung outside the fence.

(3) Since the live part of the transformer is very low from the ground, it is necessary to cut off the power supply before entering the barrier.

More resouces

315kVA Tier 2 Oil Filled Distribution Transformer

500kVA Tier 2 Oil Filled Distribution Transformer

800kVA Tier 2 Oil Filled Distribution Transformer

1000kVA Tier 2 Oil Filled Distribution Transformer

1250kVA Tier 2 Oil Filled Distribution Transformer

1500kVA Tier 2 Oil Filled Distribution Transformer

2000kVA Tier 2 Oil Filled Distribution Transformer

2500kVA Tier 2 Oil Filled Distribution Transformer

Advantage

1. Transformer oil has good insulation performance and good thermal conductivity, and transformer oil is cheap.

2. It can solve the problem of large-capacity heat dissipation of transformers and high-voltage insulation problems.

3. High mechanical strength and strong short-circuit resistance

4. Fastening measures are adopted for the iron core and the winding respectively. The fastening parts such as the height of the device and the low-voltage lead wires are equipped with self-locking anti-loosening nuts.

5. The coil and iron core are dried in vacuum, and the transformer oil adopts the process of vacuum oil filtering and oil injection to minimize the moisture inside the transformer.

Shortcoming

1. Transformer oil is flammable and may burn and explode when encountering flames

2. Transformer oil is harmful to the human body

3. Transformer oil needs to be checked regularly

4. The oil-immersed transformer has poor sealing performance and should be aged. Oil leakage is serious in the operating site, which affects the safe operation of the equipment and affects the environment at the same time.

Oil-immersed transformers produced by Daelim are low in price and easy to maintain.

Dry-type transformers also named cast resin transformers, are widely used in local lighting, high-rise buildings, airports, terminals, CNC machinery, equipment, etc. Dry-type transformers refer to iron cores and windings that are not immersed in insulating oil, generally insulated with resin, and cooled by natural air or fan. Transformers that use air as the cooling medium of the transformer without using other media.

Dry-type transformers also named cast resin transformers, are widely used in local lighting, high-rise buildings, airports, terminals, CNC machinery, equipment, etc. Dry-type transformers refer to iron cores and windings that are not immersed in insulating oil, generally insulated with resin, and cooled by natural air or fan. Transformers that use air as the cooling medium of the transformer without using other media.

In practical application, dry-type transformers can save 33% of no-load loss and 15% of load loss. At the same time, they have strong super-nameplate performance. In some specific cases, the load capacity can be improved, so that they can reach the rated power. The capacity is about 1.5 times.

Compared with oil-immersed transformers, dry-type transformers have the advantages of being oil-free and fireproof, with simpler installation steps, higher reliability, and easy cleaning and maintenance. However, this type of transformer also has certain shortcomings, mainly due to its limited capacity (generally designed at 2500kva and below), poor moisture and dust resistance (generally indoors), large volume, and relatively high cost, probably oil-immersed transformers about twice.

Therefore, if you have a sufficient budget, special fire protection requirements, environmental cleanliness requirements, and no maintenance, dry change will be your best choice.

Daelim can provide B, F, H, C class dry type transformer, and can provide IP20/IP23 protective enclosure. It has the characteristics of impact resistance, good mechanical strength, good crack resistance, moisture resistance, low noise, and good heat dissipation. Daelim's cast resin transformer has been exported to Chile, Algeria, Vietnam, and other regions.

Reading more about Cast Resin Dry Type Transformer

Through the above description, I believe you have a better understanding of the distribution transformers.

What principles should be followed when choosing a distribution transformer?

When selecting a transformer, it is necessary to know how much capacity the transformer is to use, which is usually considered according to the load of the actual power system.

Usually, before determining the capacity of distribution transformers, you should investigate the nature of electricity consumption, load conditions, the number and capacity of electrical equipment (kW), in which seasons, how many hours per day, and the total number of equipment used at the same time. How many kilowatts, how many kilowatts is the capacity of the largest motor directly started by a piece of equipment, etc. Specifically, the selection of the capacity of the distribution transformer should follow the following principles:

(1) When installing the transformer, a surplus capacity of 15% to 25% should be reserved.

(2) The capacity of the transformer should be greater than the total apparent calculated load of its power supply site.

(3) Make full use of the capacity of the transformer. Under normal circumstances, the load should be about 75% of the rated capacity of the transformer. For example, the capacity of the equipment is 750KW, then the capacity of the transformer equipped for this equipment is 1250 kVA. Transformer capacity: 750kw/0.8 (power factor)/0.75=1250kVA

(4) The operation of the transformer should be economical, reliable, and have a certain room for development.

When selecting the capacity of the power transformer, the simultaneous power of the electrical equipment should be considered. The transformer capacity can be selected according to 1.25 times the actual maximum load.

For the characteristics of scattered users in remote areas, low load density, strong seasonal load, and large gap, transformers with adjustable capacity can be used. The transformer can adjust the capacity of the transformer at no load or under load according to the size of the load. It is suitable for places with obvious seasonal changes in load.

For substations or industrial and mining enterprises with large loads, two transformers (one large and one small) are generally used for power supply. One of the large transformers is configured according to the maximum load, and the other small transformer is selected according to the low load state, which can greatly improve the power supply capacity.

Of course, budget is also a very important consideration.

Introduction of Daelim Transformer Manufacturer

Daelim has 20 years of experience in transformer design, production, and export, and can design and produce various types of distribution transformers: Substation transformer, pad-mounted transformer, pole-mounted transformer, oil-filled transformer, and dry type transformer.

Daelim has 20 years of experience in transformer design, production, and export, and can design and produce various types of distribution transformers: Substation transformer, pad-mounted transformer, pole-mounted transformer, oil-filled transformer, and dry type transformer.

These transformers can fully comply with various international standards, IEEE/IEC/ANSI/CSA/AS, etc. Daelim's distribution transformer series has UL listed.

Daelim's professional engineer team can design the most suitable transformer solution according to your specific needs and budget range.

Daelim has installation and after-sales teams in North America, South America, and other regions, which can provide you with convenient installation and after-sales services. If you need the distribution transformer specifications, outline drawing, and the distribution transformer price, please contact us.