Step-by-Step Guideline On Installing A Transformer

Power transformers increase the power output in your home or business.

In addition, they increase the current and voltage, both of which are essential for electrical appliances such as fans, heaters, and lights.

Without a suitable quality power transformer, your home or business would be out of electricity when needed most.

This article discusses guidelines for installing power transformers and finding ways to maximize efficiency.

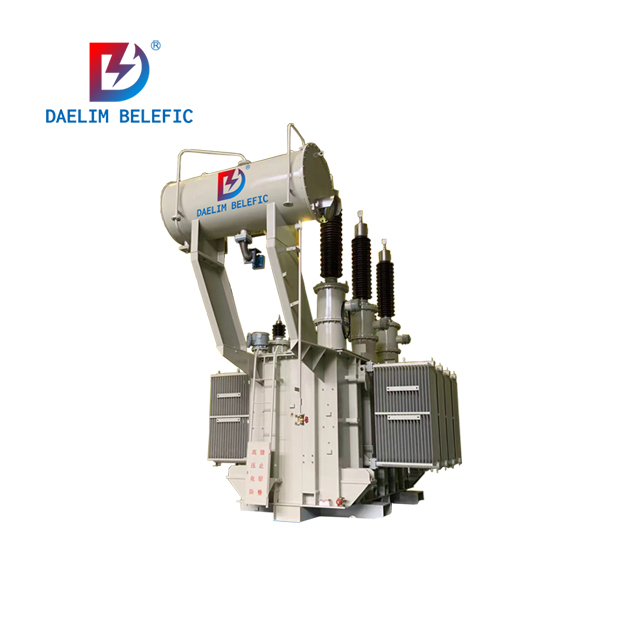

Daelim has professional local after-sales, installation, and maintenance teams in North America, South America, and other regions. Can provide installation and maintenance services for your transformer.

How To Install A Main Transformer?

The installation of power transformers is a complicated procedure. It requires quite a lot of skill, care, and patience to do it correctly.

The installation of power transformers is a complicated procedure. It requires quite a lot of skill, care, and patience to do it correctly.

In addition, you should install the transformer to be efficient from the start and remain functional for a prolonged period without any significant problems.

If not, your installation may be unsafe and cost more than it should.

Let us identify the proper steps and procedures for installing one.

Here is Daelim Main Transformer Installation,Operation Maintenance Manual

Step 1. Area Considerations

Make sure there is enough fresh air and that there are no sources of ignition or corrosion nearby.

Confirm the transformer's nameplate specifications (kVA, frequency, line voltage, and load voltage) are appropriate for the application.

Step 2. Mount the Transformer

Put the transformer in place carefully.

Then, you should disable the mains power supply by using lockout/tagout procedures. Next is to remove the panel covering the wires.

Step 3. Adjust The Correct Tap Setting

After isolating each secondary tap, make any required adjustments to the primary taps.

Before installing or removing any tap, you must remove the protective coating.

It is necessary to clean the tap and coat it with an electrical compound before you can bolt the wire.

Step 4. Route Wires on The Holes

You can use the existing holes or drill to feed cables into the enclosure.

Wireless ventilated devices must enter the device below the terminals and the coil.

Step 5. Ground the Transformer

Connecting the transformer is straightforward, provided you use the principal wiring diagram found on the label.

Next, ensure that you ground the enclosure adequately under the National Electrical Code and other applicable standards.

Related Article

Basic Guide for Grounding Transformer

Step 6. Energize The Transformer

Check to see if the secondary voltage is sufficient for the load as the power comes on.

Then, inspect if you have shut off the main power using lockout/tagout procedures.

Step 7. Connect to Terminals

Ensure that you connect the load to the secondary terminals. Then replace the power supply's cover.

Step 8. Perform A Final Inspection

Once the transformer arrives at its final site, you must assemble and test it before powering it.

Before turning on the electricity, ensure that you inform everyone working on the transformer.

Remember that inside the transformer enclosure, all connection points are fatal voltage.

What Are The Safety Operation Procedures During Transformer Installation?

Upon receipt, users should inspect the transformers thoroughly to rule out the potential for shipping damage.

It is critical to immediately report any damage to the transportation company and make a claim.

Storage

Maintain a steady temperature and humidity level and store transformers in their original packaging.

If you store a transformer without its packing for an extended period, it is essential to plug any ventilation holes.

Of course, you should never store a transformer outside without complete protection from the environment and any potential pollutants.

Safety Operations

Transformers have removable covers to facilitate installation.

However, you must securely fasten it at all times, and you cannot use the devices until you secure the parts.

As transformer personnel, you must conduct a thorough safety protocol. Then review and audit it regularly.

Grounding

For similar reasons, it's essential to ground the enclosure properly.

The National Electrical Code and state and municipal regulations demand that all grounding be safe and correct.

System Loading

When the average outside temperature is over 30 degrees Celsius, and the maximum is over 40 degrees Celsius, a transformer with a higher kVA rating increase is necessary.

At an altitude of more than 3,300 feet, you must adjust and reduce the load on a standard transformer.

Maintenance

Because there are no moving parts in a transformer, it does not require frequent servicing.

However, regular inspection and maintenance are crucial if the transformer operates in a harsh environment.

How To Establish A Pad-Mounted Transformer Installation?

Padmount transformers are steel cabinets used for electric power distribution. They are usually fastened on concrete pads.

Padmount transformers are steel cabinets used for electric power distribution. They are usually fastened on concrete pads.

So, let's figure out how to install a pad transformer and what goes into the process.

Check Daelim Pad Mounted Transformer Installation And Maintenance Manual

Step 1. Secure a Strong Foundation

In areas where the ground freezes, a pad-mounted distribution transformer's base must have deep enough footings to prevent settlement and heave.

Also, ensure the concrete pad is entirely flat so that air doesn't get trapped between the compartment and the base.

The transformer's base includes mounting brackets that allow the pad to be securely fastened to the base.

Carefully lower the transformer to the pad while maintaining the unit level to avoid breaking the cabinet.

You may enjoy: Pad Mounted Transformer

Step 2. Inspect the Seal

Check the fluid-level indicator to see how much fluid is in the tank.

Starting with the pressure-relief valve open, remove the pipe plug from the low-voltage area cautiously.

After each use, it is advisable that you reseal it.

Step 3. Ensure External Electrical Connections

A connection from the system ground to the tank ground is necessary.

If you don't follow these rules, you could hurt yourself or wreck some expensive machinery.

Never exceed the voltage ratings listed on the transformer's label.

You should connect the neutrals on the transformer to the neutrals on the system.

Next is to disconnect all cables and plugs from each other when they are not in use.

Step 4. Close The Cabinet

Before leaving the unit, ensure you lock the cabinet using the padlock and other means provided.

The padlock's shackle should go in and out of its hole without much resistance.

You may enjoy: 3 Phase Pad Mounted Transformer

What Are The Properties Of The Transformer Diagram Upon Installation?

In a standard transformer, the core diagram of a transformer has two coils, one for the primary and one for the secondary winding.

Operating Theory

An alternating current (ac) flows through the primary winding, causing the magnetic flux in the iron core to fluctuate,

Almost all of this flux stays put in the core, with only a tiny fraction making its way into the atmosphere.

It produces a voltage when the alternating magnetic flux connects the secondary windings' turns from the iron core.

Faraday's law of induction explains all of these phenomena. This explains why there are voltages on the primary and secondary, but they are not connected.

Knowledge of each component of a transformer is essential for its successful installation.

Core

The transformer's core is the device's heaviest and most important part.

It's great for conveying magnetic flux because its steel construction results in low magnetic resistance and high magnetic permeability.

Windings

Windings have insulations with copper or aluminum coils.

It has numerous layers of paper sandwiched between the turns.

Tap Changer

The Tap Changer modifies the unit's output voltage throughout a transformer's service life.

Bushings

The bushings link the grounded tank to the network and the windings.

Get it now: 2500 kVA Pad Mounted Transformer

What Are The Necessary Transformer Installation Requirements?

Since it is so important, only a qualified electrician should install a power transformer.

Requirement No 1. Installed by Electrician

To begin, a credible electrician should install and process a transformer device.

Requirement No 2. Choose The Right Nominal Power

When the input voltage varies by as much as 10%, the total power output must run by the same amount.

Requirement No 3. Verify That The Power Factor For The Load Is Valid

When calculating the transformer's apparent power, you must confirm the load's power factor.

Requirement No 4. Validate The Input-Output Voltage

When you turn on the power, you must double-check that the input-output voltage on the line attaching the transformer while it is under full load.

Try for free: Pole Mounted Single Phase Transformer

What Is The Method Statement For Transformer Installation?

The main part of the method statement for transformer installation is to prevent the device from being damages by other environmental hazards.

Thus, users must unload the transformers close to the installation site.

A. Users should know they should store the transformer in a dry, cold, and secure location.

If transformers show evidence of damage, it is essential to look into whether it was during shipping.

B. The International Electrotechnical Commission (IEC) will check all shop drawings and project requirements to ensure that the medium-voltage liquid-filled transformers are correctly settled.

C. The installation of cables, wires, raceways, supports, cable ends, and termination fittings would adhere to the relevant sections of the project specification.

D. As part of this procedure, technicians will tighten all electrical connections and connectors to the manufacturer-recommended torque values.

Download Transformer Installation Manual

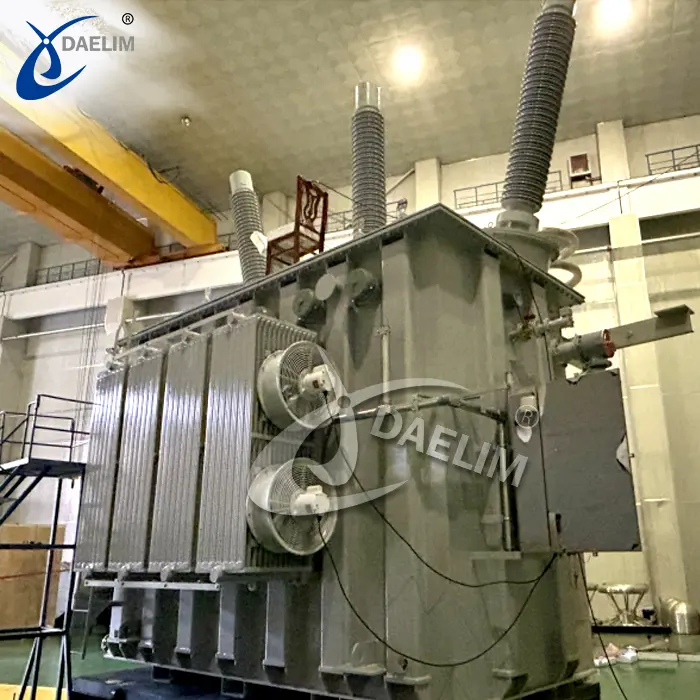

Small Substation Power Transformer

What is Commissioning? Is it Necessary for Transformer Installation?

The purpose of the commissioning process is to test the functionality of the power transformer.

Before being put into service, the transformer should undergo pre-commissioning checks and instrument tests.

Initial tests include:

- The effectiveness of the protection system

- Tests for Insulation Resistance (IR)

- Capacitance and dissipation of a bushing

- Capacitance and dissipation factor testing of windings

Turning on the power requires a series of pre-commissioning inspections and testing to ensure the transformer is in proper working order.

The buyer is typically responsible for the distribution transformer's setup and commissioning.

However, in some cases, the manufacturer will allow the customer to install and commission the product with their supervision.

Contact Daelim For Transformer Installation Remote Guidance.

Related Products

Related Article

Residential Transformer: The Small Green Electrical Box in the Neighborhood

Daelim residential transformer has UL and CSA certificates. Meet DOE 2016 efficiency value. Daelim Belefic is a Chinese transformer brand and a list of American transformer suppliers. Daelim is a famous professional transformer manufacturer.

Pad Mounted Transformer CSA C227.4 National Standard of Canada

As a transformer buyer and manufacturer, you should be familiar with the local transformer design requirements and standards. This article tells the Canadian country's transformer standard CSA C227.4, the pad-mounted transformer below 3000kva.

Step Up Transformer VS Step Down Transformer

Daelim is ANSI/IEEE, UL transformer manufacturer who has been cooperating with many popular brands such as AMAZON, EATON, and SOLOMON brands in the US. Daelim production of step up and step down transformers meet various international standards. Such as: IEEE/ANSI, CSA, AS/NZS, GOST, EN, etc.