What Is Distribution Transformer?

A distribution transformer is an essential component within the electrical power system, playing a crucial role in the transmission and consumption of electrical energy. These devices are vital for converting high-voltage electricity from transmission lines into lower voltages suitable for end-users, including residential, commercial, and industrial facilities.

Distribution transformers are electrostatic devices responsible for distributing electrical energy to homes, businesses, and end-users. Typically, the primary voltage of these transformers is less than 35 kV. They primarily function as step-down transformers, adapting grid-level voltages to levels appropriate for local consumption. Voltage standards for distribution transformers vary across different markets. For instance, common distribution transformer voltages in the American market include 7.2 kV, 13.8 kV, 14.4 kV, 24.94 kV, and 34.5 kV. In Europe and Austrilia, typical distribution network voltages are 3.3 kV, 6.6 kV, 11 kV, and 33 kV.

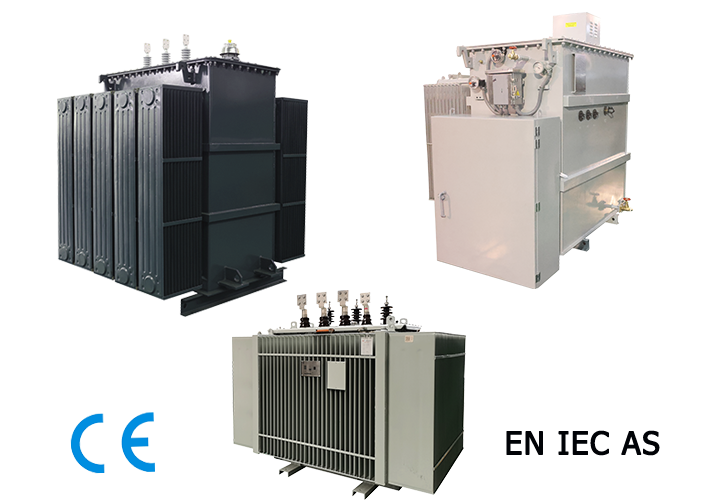

Types of Distribution Transformers

Distribution transformers encompass various types designed for specific installation methods and operational requirements:

Pad Mounted Transformers

Pad mounted transformers are employed in underground distribution systems, supporting high voltages up to 44 kV and capacities up to 10,000 kVA. Widely utilized across North America, South America, Latin America, and the Middle East, these transformers are tamper-resistant and suitable for diverse environments, including residential areas, industrial sites, and renewable energy facilities.

Pole Mounted Transformers

Pole mounted transformers are affixed to utility poles, offering voltage ratings up to 35 kV and capacities up to 500 kVA. Typically deployed in rural and remote distribution systems, they are characterized by their compact size and lightweight construction, designed to endure outdoor conditions while ensuring dependable power distribution.

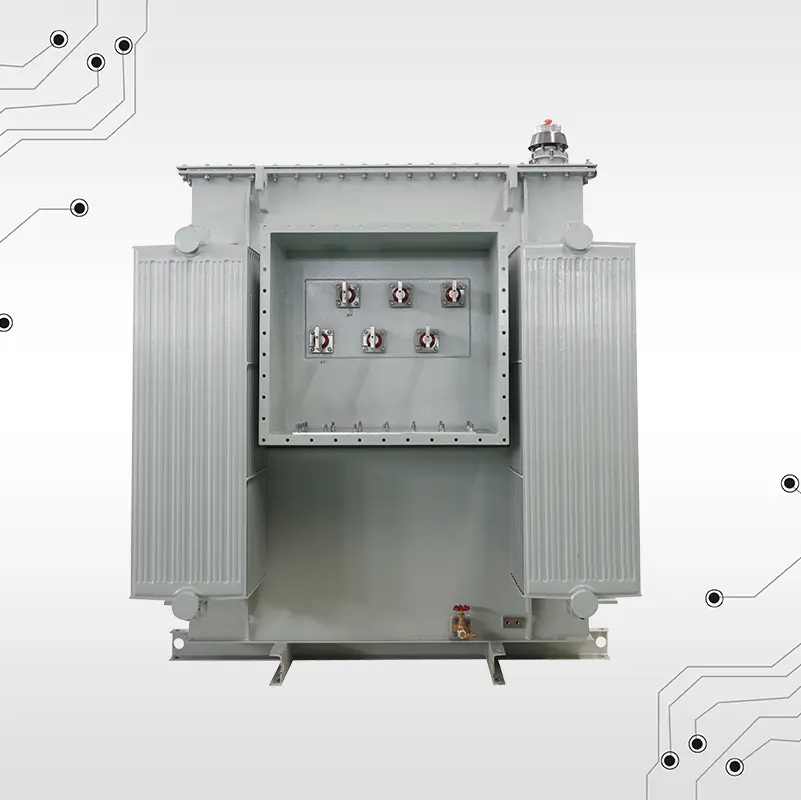

Substation Transformers

Substation Transformers

Substation transformers, which are predominantly utilized in the American market, are installed on the ground similar to pad mounted transformers. They accommodate voltage levels up to 44 kV and power ratings up to 20 MVA. In contrast to pad-mounted transformers, they feature more flexible designs, particularly in terms of the placement and arrangement of bushings.

Eco Design Transformers

The Ecodesign distribution transformer is a type of transformer widely used in the European market. It adheres to ecological design standards aimed at reducing secondary transformer losses (EU Directive 548/2014) and complies with the BSEN60076 standard. These transformers are available in power ratings ranging from 50 kVA to 3150 kVA.

The Ecodesign distribution transformer is a type of transformer widely used in the European market. It adheres to ecological design standards aimed at reducing secondary transformer losses (EU Directive 548/2014) and complies with the BSEN60076 standard. These transformers are available in power ratings ranging from 50 kVA to 3150 kVA.

Key features of the Ecodesign distribution transformer include HV and LV flanges compliant with BS2562, designed for mounting bolt-on HV and LV cable boxes, LV transformer-mounted feeder posts, or ACB/MCCB cabinets. They also meet ENATS standards for HV transformer-mounted switchgear.

These transformers utilize two core materials: CRGO and Amorphous. Amorphous transformers, known for their lower hysteresis loss compared to CRGO transformers, are categorized as energy-saving transformers under Class II regulations. By reducing energy waste and carbon emissions, they contribute significantly to cost savings and environmental benefits.

Functions and Uses

The primary functions and uses of distribution transformers include:

Voltage Transformation

Converting high-voltage electricity (e.g., 24.94 kV, 34.5 kV) to lower distribution levels (e.g., 480V, 220V) suitable for consumer use.

Power Distribution

Supplying electricity to residential, commercial, and industrial sectors efficiently and safely.

Load Management

Balancing and distributing electrical load across distribution lines to ensure a steady power supply.

Voltage Regulation

Maintaining consistent voltage levels within the distribution network to protect appliances and equipment.

Integration into Grids

Facilitating seamless integration of renewable energy sources (e.g., wind, solar) into the power grid.

Resilience and Efficiency

Withstanding overloads and faults while minimizing energy losses, contributing to energy conservation and reduced carbon emissions.

Reading more about Transformer Efficiency

Cooling Methods

Distribution transformers can be categorized based on their cooling methods:

-

Oil Immersed Transformers: Cooled by transformer oil, these transformers are available in mineral oil or vegetable oil variants.

-

Dry Type Transformers: Cooled by air, these transformers are safer and easier to install, suitable for indoor applications where oil-filled transformers are impractical.

Materials and Cost Considerations

Distribution transformers may feature aluminum or copper windings. Aluminum windings are typically preferred due to their lower cost and lighter weight unless specific project requirements necessitate copper windings.

Conclusion

In conclusion, distribution transformers are essential components of the electrical power infrastructure, facilitating efficient and reliable electricity distribution across various sectors. Choosing the right type of transformer depends on factors such as installation environment, voltage requirements, and specific application needs. Understanding these aspects ensures optimal performance and longevity, meeting the diverse demands of modern power distribution systems worldwide.

Choose Daelim as your distribution transformer supplier and experience the difference that quality, expertise, and dedication can make.

Welcome to contact Daelim Transformer for the best price offer & professional technical support.

Related Products

Related Article

500 kVA Distribution Transformer for the Greek Market

Today, we're thrilled to showcase a European transformer project tailored for the Greek market. This project involves the supply of 500 kVA distribution transformers, with an input voltage of 20 kV and an output voltage of 400V. The client has requested adherence to both IEC and TIER-II energy efficiency standards. With a total quantity of 5 units, this project marks another milestone in Daelim Transformer's commitment to delivering high-quality solutions worldwide.

Overview of Oil-Immersed Distribution Transformers

This article mainly describes the oil-immersed distribution transformer, including the oil transformer application, characteristics, types, and other issues of the transformer.

Transformer Solutions For Utilities

DAELIM provides a wide range of transformer solutions, including power transformers and distribution transformers, with our power transformers for utilities ranging from 15kVA to 10 MVA. Additionally, we offer transformer maintenance, repairs, and retrofits.

Daelim Transformers Solutions For Energy Storage

Transformers in Energy Storage Systems play a crucial role in renewable energy generation and storage systems by changing the voltage and current levels. In renewable energy generation systems, transformers are used to increase the voltage from low to high levels to transmit energy to the grid. This reduces transmission losses and resistance, thereby decreasing the cost and increasing the efficiency of energy.

CSA C227.3 For Single Phase Pad Mounted Distribution Transformer

What we have here are the Canadian Standards Association standards. This will include the CSA-C227.3 guidelines for single-phase pad-mounted distribution transformers.

Transformers Solution For Data Center and Blockchain

Daelim Transformer is UL Listed transformer manufacture, understands their crucial role in powering data centers and blockchain. They have been offered transformers to numerous top blockchain companies in North America, ensuring a stable and reliable power supply. With high electricity demands in these industries, Daelim Transformer's solutions support efficient operations.