Ultimate Guide To IEEE C57 Standard

Electrical transformers are crucial components in the transmission and distribution of electrical power. They play a vital role in converting electrical energy from one voltage level to another for efficient and safe distribution. The design and operation of electrical transformers must meet strict industry standards to ensure their reliability and safety. One of the critical standards used in the design and testing of transformers is the IEEE C57 standard. This article will discuss the IEEE C57 standard in detail, focusing on its purpose, its application in power transformers, and the impedance tolerance it specifies.

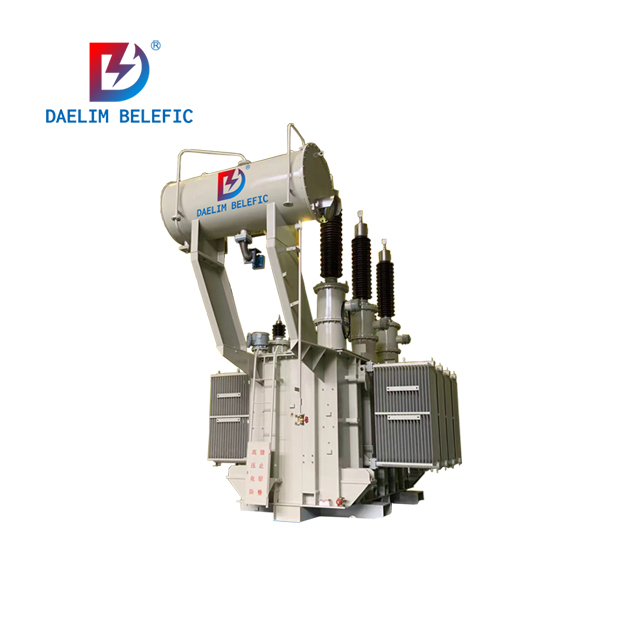

Daelim is a professional IEEE standard transformer supplier and manufacturer. Various types of IEEE standard transformers can be provided, such as pad-mounted transformers, oil-immersed transformers, single-phase pole-mounted transformers, dry transformers, and power transformers. These transformers have many project applications in the United States. If you want to check Daelim's project information in the United States, please contact pinruidan@daelim-electric.com.

What is IEEE C57 about?

The IEEE C57 standard, also known as the "Standard Requirements for Liquid-Immersed Distribution, Power, and Regulating Transformers," provides guidelines for the design, manufacturing, testing, installation, and operation of transformers. It covers transformers used in a wide range of applications, including power generation, transmission, and distribution systems, as well as industrial and commercial applications.

The standard provides detailed requirements for transformer construction, insulation, cooling, accessories, and ratings. It also includes guidelines for transformer testing, including routine tests, type tests, and special tests, to ensure the quality and reliability of transformers.

The IEEE C57 standard is divided into several parts, each covering different aspects of transformer design, testing, manufacturing, and operation. The most commonly used parts of the standard include:

- IEEE C57.12.00 - General requirements for liquid-immersed distribution, power, and regulating transformers

- IEEE C57.12.90 - Guide for loading mineral-oil-immersed transformers

- IEEE C57.12.91 - Guide for loading ester-immersed transformers

- IEEE C57.12.92 - Guide for loading silicone-immersed transformers

- IEEE C57.12.93 - Guide for loading vegetable-oil-immersed transformers

- IEEE C57.12.94 - Guide for loading synthetic-ester-immersed transformers

- IEEE C57.12.95 - Guide for loading natural-ester-immersed transformers

Each part of the IEEE C57 standard covers specific aspects of transformer design and testing. For example, IEEE C57.12.00 provides the general requirements for the design, construction, testing, and operation of liquid-immersed transformers, while IEEE C57.12.90 to IEEE C57.12.95 provides guidelines for loading transformers with different types of insulating fluids.

Compliance with the standard ensures that transformers meet specific performance and safety requirements, operate safely and efficiently, and meet the needs of the power system. The standard has become a crucial guide for transformer manufacturers, designers, testing laboratories, utilities, and other stakeholders involved in the power system, and its importance is expected to grow with the increasing demand for reliable and efficient power systems.

Learn more: The Ultimate Guide To IEC 60076 Standard

What is standard IEEE C57?

The IEEE C57 standards cover a wide range of topics related to power transformers, including specifications for insulation, load capacity, cooling systems, and more. The standards are designed to ensure the safe and efficient operation of power transformers, and they are widely used in the power industry around the world.

By following the guidelines set out in the IEEE C57 standards, transformer manufacturers and operators can be sure that their transformers meet important safety and performance standards, helping to prevent accidents and improve the reliability of the electrical grid.

You may enjoy: Pad Mounted Transformer CSA C227.4 National Standard of Canada

What is IEEE C57 for power transformers?

The IEEE C57 standard is a crucial standard for the design and testing of power transformers. The bar provides guidelines for designing, manufacturing, testing, and operating power transformers used in high-voltage power systems. Power transformers are used to step up or down the voltage level of electrical energy in power systems, enabling efficient transmission and distribution of electrical power.

The IEEE C57 standard provides specific power transformer design, construction, insulation, cooling, and rating requirements. The standard also specifies the testing procedures and acceptance criteria for power transformers. The tests include routine tests, type tests, and special tests, which are performed to ensure the transformer's quality, reliability, and safety.

Compliance with the IEEE C57 standard is essential for power transformer manufacturers, utilities, and other stakeholders involved in the power system. It helps to ensure that power transformers are designed, tested, and operated safely and efficiently and meet the specific performance requirements of the power system.

Get it now: Solar Photovoltaic System Solution

What is the impedance tolerance of the IEEE C57 transformer?

Impedance tolerance is a critical parameter in the design and testing of transformers. It refers to the maximum deviation from the rated impedance of the transformer, which is the ratio of the voltage drop across the transformer to the current flowing through it. The IEEE C57 standard specifies the impedance tolerance for power transformers, which is typically between 5% and 7%.

The IEEE C57 standard specifies the impedance tolerance to ensure that transformers meet specific performance requirements and operate and efficiently. Compliance with the impedance tolerance specified in the standard helps to ensure that transformers operate reliably and meet the voltage regulation requirements of the power system.

The IEEE C57 standard is a crucial guide for the design, manufacturing, testing, installation, and operation of transformers, including power transformers. Compliance with the standard ensures that transformers meet specific performance and safety requirements, safely and efficiently, and meet the power system's needs.

Related article:

The Impact of Impedance on Transformer Design

What happens if the transformer impedance is high?

Transformer impedance is a crucial parameter in power transformers' design, operation, and protection. It determines the voltage regulation, the efficiency, and the short-circuit strength of the transformer. The impedance of a transformer is defined as the ratio of the voltage drop to the current flowing through the transformer. It is usually expressed as a percentage of the transformer's rated voltage at its rated current.

When the transformer impedance is high, the transformer has a low current-carrying capacity compared to its voltage rating. This can lead to various problems that can affect the performance, reliability, and safety of the transformer and the power system.

Here are some of the possible effects of high transformer impedance:

High transformer impedance can cause a significant voltage drop between the primary and secondary windings of the transformer. This can lead to a reduced voltage level at the load end, resulting in under-voltage conditions, poor power quality, and reduced efficiency. The voltage drop can also affect the operation of other equipment connected to the transformer, such as motors, drives, and control systems.

Poor voltage regulation: The impedance of a transformer is a critical parameter in voltage regulation. A high-impedance transformer will have poor voltage regulation, which means that the voltage at the load end will vary significantly with changes in the load current. This can lead to unstable operation of sensitive equipment and affect the performance of the power system.

Reduced efficiency

High transformer impedance can lead to increased losses in the transformer, which can reduce the efficiency of the transformer. This can result in higher energy consumption, increased operating costs, and reduced equipment life.

Related Article

Transformer Efficiency: The Ultimate FAQs Guide - Daelim

Overheating

When a transformer has a high impedance, it means that the current flowing through the transformer is low for a given voltage. This can cause the transformer to operate at a higher-than-normal temperature, which can lead to insulation breakdown, reduced life, and safety hazards.

Reduced short-circuit strength

Transformer impedance also affects the short-circuit strength of the transformer. A high-impedance transformer will have a lower short-circuit strength, which means that it will be more susceptible to damage from short-circuit faults. This can lead to equipment damage, extended downtime, and safety hazards.

Increased harmonics

High transformer impedance can cause increased levels of harmonic distortion in the power system. This can result in equipment damage, reduced power quality, and interference with communication and control systems.

Increased voltage regulation

High transformer impedance can lead to increased voltage regulation. This means that the voltage at the load end will vary significantly with changes in the load current. This can lead to unstable operation of sensitive equipment and affect the performance of the power system.

To prevent or mitigate the effects of high transformer impedance, the following measures can be taken:

- Use transformers with lower impedance ratings: Lower impedance transformers will have a higher current-carrying capacity and are less susceptible to high impedance effects.

- Use parallel transformers: Parallel operation of transformers can increase the current-carrying capacity and reduce the overall impedance of the system.

- Use tap changers: Tap changers can be used to adjust the transformer impedance and maintain the voltage level at the load end.

- Use reactive compensation: Reactive compensation can reduce the load's reactive power demand and improve the power factor. This can reduce the voltage drop and improve voltage regulation.

High transformer impedance can cause a wide range of problems that can affect the performance, reliability, and safety of the transformer and the power system. It is essential to design, operate, and protect transformers with appropriate impedance ratings to ensure the power system's efficient, reliable, and safe operation. The use of lower impedance transformers, parallel operation

You may enjoy: Pad Mounted Transformer

What is the temperature rise type test IEEE C57?

The temperature rise test is an important type of test conducted on electrical transformers, which is used to evaluate the thermal performance of a transformer under operating conditions. The test is conducted in accordance with the IEEE C57 standard, which specifies the requirements and procedures for conducting the temperature rise test.

The temperature rise test is an important type of test conducted on electrical transformers, which is used to evaluate the thermal performance of a transformer under operating conditions. The test is conducted in accordance with the IEEE C57 standard, which specifies the requirements and procedures for conducting the temperature rise test.

The temperature rise test is designed to simulate the operating conditions that a transformer will experience during its service life. This is achieved by applying a specific load to the transformer and measuring the temperature rise that occurs as a result. The test is typically performed on transformers rated at 500 kVA and above, and the test results are used to verify that the transformer is capable of operating within its designed temperature limits.

The IEEE C57 standard specifies that the temperature rise test should be conducted in a controlled environment, with the ambient temperature maintained at a constant level. The test is typically conducted at the manufacturer's facility, and it involves connecting the transformer to a test set-up that is designed to provide the specified load. The load is typically a combination of resistive and reactive elements, which are used to simulate the load that the transformer will experience during its service life.

During the test, the temperature of the transformer is measured at various points, including the windings, core, and oil. The temperature rise is calculated by subtracting the ambient temperature from the highest temperature measured during the test. The temperature rise is then compared to the transformer's rated temperature rise, which is the maximum temperature increase that the transformer is designed to withstand under normal operating conditions.

The temperature rise test is a critical type of test for electrical transformers, and it is conducted in accordance with the IEEE C57 standard. The test is used to evaluate the thermal performance of a transformer under operating conditions, and it provides valuable information about the transformer's ability to dissipate heat. The results of the test are used to verify that the transformer is capable of operating within its designed temperature limits and to identify any potential issues with the transformer's cooling system.

Try for free: How to test a power transformer?

IEEE c57 standards list

Here are some of the IEEE C57 standards and their brief descriptions:

-

IEEE C57.12.00 - This standard provides a standard for general requirements for Liquid-Immersed Distribution Transformers, Power Transformers, and Regulating Transformers;

-

IEEE C57.12.20 - This standard provides a standard for Overhead-Type Distribution Transformers 500 kVA and Smaller: High Voltage 34 500 V and Below; Low Voltage 7970/13 800Y V and Below

-

IEEE C57.12.26 - This standard provides a standard for Three-Phase Distribution Transformers for Use With Separable Insulated High Voltage Connectors (34 500 Grd Y/19 920 V and Below;2500 kVA and Smaller)

-

IEEE C57.12.34 - This standard provides standard requirements for Pad-Mounted, Compartmental-Type, Self-Cooled, Three-Phase Distribution Transformers,10 MVA and Smaller; High-Voltage, 34.5 kV Nominal System Voltage and Below; Low-Voltage,15 kV Nominal System Voltage and Below;

-

IEEE C57.12.36 - This standard provides standard requirements for Liquid-Immersed Distribution substation transformers;

-

IEEE C57.12.40 - This standard provides a standard for network Three-PhaseTransformers 2500 kVA and Smaller; High Voltage 34 500 V and Below; LowVoltage 600 V and Below; Subwayand Vault Types (Liquid immersed);

-

IEEE C57.12.80 - This standard provides standard terminology for the Power and Distribution Transformers

-

IEEE C57.12.90 - This standard provides a standard Test Code for Liquid-immersed Distribution, Power Transformers, and Regulating Transformers.

-

IEEE C57.12.91 - This standard provides a guide for Loading Mineral-Oil-Immersed Transformers and Step-Voltage Regulators.

These are just some of the many IEEE C57 standards that cover a range of topics related to transformers and other power distribution equipment. These standards are developed by industry experts and are widely recognized and used throughout the power industry to ensure the safe, reliable, and efficient operation of power systems.

Related Article

3 Phase Pad Mounted Transformer

IEEE power transformer standards

Here are some of the IEEE power transformer standards and their brief descriptions:

- IEEE C57.105 - This standard provides guidelines for the thermal evaluation of power transformers, including procedures for testing and monitoring temperature rise.

- IEEE C57.12.01 - This standard provides the requirements for liquid-immersed transformers used in power and distribution applications.

- IEEE C57.104 - This standard provides guidelines for the interpretation of dissolved gas analysis (DGA) of insulating fluids in power transformers.

- IEEE C57.109 - This standard provides guidelines for installing liquid-immersed power transformers.

- IEEE C57.110 - This standard provides guidelines for the insulation design and evaluation of the windings of liquid-immersed transformers.

- IEEE C57.124 - This standard provides guidelines for the measurement of the frequency response of power transformers and reactors.

These are just a few of the many IEEE standards that apply to power transformers. By following these standards, power system engineers can ensure that power transformers are designed, installed, and operated in a safe and efficient manner.

Get it now: Solar Transformer - Your ultimate guide

IEEE Transformer Cooling Classes

The Institute of Electrical and Electronics Engineers (IEEE) has established cooling classes to classify electrical transformers based on their ability to dissipate heat. These cooling classes are designated by a letter, with each letter indicating a specific cooling capability.

Transformers with higher cooling classes are able to handle higher power loads and operate more efficiently. For example, a transformer with a cooling class of ONAN can operate at full power without overheating, while a transformer with a cooling class of A may only be able to operate at a fraction of its full power capacity before overheating.

Therefore, understanding the cooling classes of transformers is important in determining their suitability for a particular application and ensuring their safe and efficient operation.

Get it now: CSA C227.5

IEEE Transformer For Sale

Daelim has more than 15 years of experience in the production of IEEE standard transformers and has IEEE and UL certifications. Daelim's professional technical team can customize transformers for you according to technical requirements. Professional local after-sales service and long quality guarantee period will definitely satisfy you. Contact the Daelim team to get the latest transformer price.

Related Products

Related Article

The Ultimate Guide To IEC 60076 Standard

Daelim is IEC, ANSI/IEEE, AS, CSA, and UL transformer manufacturer who has been exported to countries around the world. The transformers supplied by Daelim fully meet and exceed the requirements of the IEC 60076 standard.

Pad Mounted Transformer CSA C227.4 National Standard of Canada

As a transformer buyer and manufacturer, you should be familiar with the local transformer design requirements and standards. This article tells the Canadian country's transformer standard CSA C227.4, the pad-mounted transformer below 3000kva.

High Voltage vs Medium Voltage Transformer

Daelim is a transformer manufacturer specializing in producing Medium Voltage and High Voltage Transformers. Has a series of certificates: UL/CUL, CSA, CESI, CE, SGS, IEEE, etc. Transformer technical standards exceed ANSI/IEEE, CSA, AS/AZS, GOST, IEC, etc. It has the advantage of fast delivery.