The Ultimate Guide To IEC 60076 Standard

Transformers are essential components in power transmission and distribution systems. They facilitate the transfer of electricity between various voltage levels, enabling the efficient distribution of electrical energy across different regions. However, the safe and efficient operation of transformers requires adherence to specific international standards, including the International Electrotechnical Commission (IEC) 60076 standard. In this article, we will explore the IEC 60076 standard and its various aspects, including its purpose, transformer codes, and specific sections, such as impedance tolerance and temperature rise type tests.

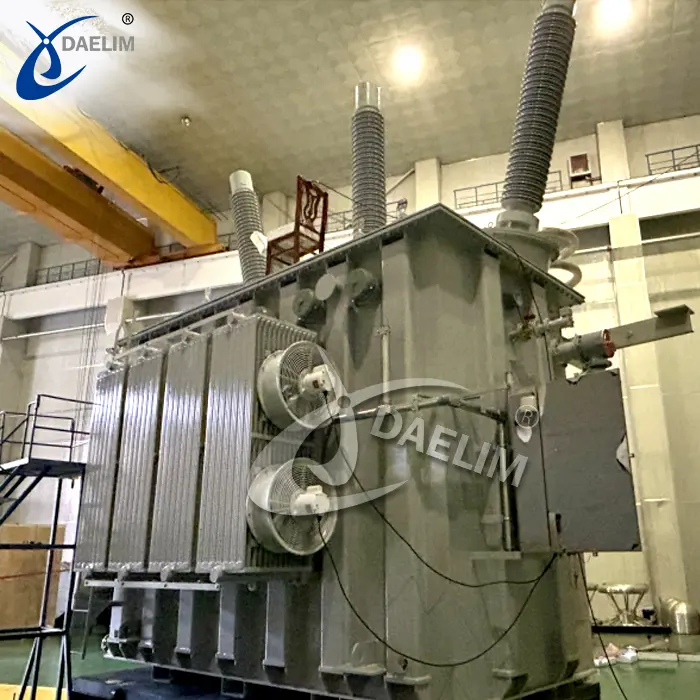

Daelim is IEC, ANSI/IEEE, AS, CSA, and UL transformer manufacturer who has been exported to countries around the world. The transformers supplied by Daelim fully meet and exceed the requirements of the IEC 60076 standard.

What is IEC 60076 about?

The IEC 60076 standard specifies the requirements for power transformers used in electrical power systems. The standard covers the design, manufacturing, testing, and commissioning of power transformers for both indoor and outdoor use. The standard applies to all power transformers with a voltage rating of up to 765 kV, including single-phase and three-phase transformers, autotransformers, and reactors.

The IEC 60076 standard was first introduced in 1953 and has since been revised several times. The most recent revision of the standard was published in 2020. The IEC 60076 standard is recognized worldwide and is used in over 100 countries. It helps ensure the safe and reliable operation of power transformers, which are vital components in the power grid.

The International Electrotechnical Commission (IEC) 60076 is a comprehensive standard that provides guidelines for the design, manufacturing, testing, and commissioning of power transformers. The standard covers the different aspects of transformer design, including the electrical, mechanical, and thermal aspects. It provides specifications for transformers of different voltage levels and power ratings and includes guidelines for the selection of materials, insulation, and construction methods.

Try for free:

3 Phase Pad Mounted Transformer

The IEC 60076 standard also provides guidelines for the testing and performance evaluation of power transformers. It includes different types of tests, including routine tests, type tests, and special tests, that are performed to ensure the quality and reliability of the transformer. The standard specifies the testing procedures, equipment, and acceptance criteria for each type of test.

One of the key aspects of the IEC 60076 standard is the transformer code system, which provides a standardized method of identifying and specifying transformers. The code system includes different parameters, including the rated power, voltage level, impedance, and cooling method, that are used to describe the transformer. The code system enables easy identification and specification of transformers and helps to ensure that the transformers meet the required specifications and standards.

The IEC 60076 standard is used by transformer manufacturers, testing laboratories, and utilities worldwide to ensure the safe and reliable operation of power transformers. Compliance with the standard ensures that the transformers are designed and manufactured to the required specifications and performance standards. It also ensures that the transformers are tested and commissioned to the required standards and that they can operate safely and reliably under normal and abnormal operating conditions.

Related Article:

Power Transformer Manufacturers Around the World

What is the IEC code for the transformer?

The IEC code for transformers is a system of letters and numbers that provides information on the transformer's characteristics. The code is divided into three parts: the first part specifies the type of transformer, the second part specifies the voltage rating, and the third part specifies the power rating.

The first part of the code consists of two letters that indicate the type of transformer. The most common types of transformers are:

• Dyn: Three-phase distribution transformer

• Dy: Single-phase distribution transformer

• Y: Three-phase power transformer

• D: Single-phase power transformer

The second part of the code consists of a number that indicates the highest voltage that the transformer can withstand. The voltage is expressed in kilovolts (kV), and the most common voltage ratings are 6 kV, 11 kV, 33 kV, 66 kV, and 132 kV.

The third part of the code consists of a number that indicates the power rating of the transformer. The power rating is expressed in kilovolt-amperes (kVA) and can range from a few kVA to several thousand kVA.

Many countries have their own national standard, based on this international standard. Each country's standard protects the interests of consumers and provides a framework for product manufacturers to meet those interests.

IEC stands for International Electrotechnical Commission and the IEC is a group that sets standards across various fields such as electronics and energy.

Having a single standard for this product makes it easier for manufacturers to meet safety requirements and assure that consumers get reliable products. The standard also allows countries to adopt common safety checks and policies that apply to all markets.

The IEC code is not a measurement of power but indicates if a unit is used in a factory or motor vehicle application. A transformer that supplies electric power or electric energy in a factory setting is rated at 250 volts or less, sees high-frequency use, has short temperature rise, and is designed only to withstand short-time surges may be labeled as 330VA (335V) and 630VA (650V).

Try for free:

Pad Mounted Transformer CSA C227.4 National Standard of Canada

What is IEC 60076 for power transformers?

IEC 60076 covers the design, manufacturing, testing, and commissioning of power transformers for both indoor and outdoor use. The standard specifies the requirements for the insulation, cooling, protection, and testing of power transformers. It also provides guidelines for the selection of materials, manufacturing processes, and quality control.

The IEC 60076 standard is essential for ensuring the safe and reliable operation of power transformers. The standard helps manufacturers to produce transformers that meet the required specifications, and it helps system operators to select and install transformers that are suitable for their specific application. The standard also provides guidelines for the maintenance and testing of transformers throughout their service life.

Reading more about power transformers:

How To Choose The Suitable 110KV Power Transformer?

What is the impedance tolerance of the IEC 60076 transformer?

The impedance tolerance of a transformer is a measure of the deviation from the nominal impedance value specified by the manufacturer and removes IEC 60076 transformer losses. The nominal impedance is the impedance value that the transformer is designed to have at the rated voltage and frequency. The impedance tolerance of a transformer is the maximum percentage deviation from the nominal impedance value specified by the manufacturer. The nominal impedance is the impedance value that the transformer is designed to have at the rated voltage and frequency. The impedance is calculated as the ratio of the voltage drop across the winding to the current flowing through it.

The impedance tolerance of a transformer is a measure of the deviation from the nominal impedance value specified by the manufacturer and removes IEC 60076 transformer losses. The nominal impedance is the impedance value that the transformer is designed to have at the rated voltage and frequency. The impedance tolerance of a transformer is the maximum percentage deviation from the nominal impedance value specified by the manufacturer. The nominal impedance is the impedance value that the transformer is designed to have at the rated voltage and frequency. The impedance is calculated as the ratio of the voltage drop across the winding to the current flowing through it.

The IEC 60076 standard specifies the maximum impedance tolerance for power transformers based on their rated power and voltage level. For transformers rated up to 500 kVA, the maximum impedance tolerance is 10%. For transformers rated between 500 kVA and 2 MVA, the maximum impedance tolerance is 7%. For transformers rated above 2 MVA, the maximum impedance tolerance is 5%.

Learn more about transformer impedance:

The Impact of Impedance on Transformer Design

What happens if transformer impedance is high for IEC 60076 power transformers?

If the impedance of the transformer is higher than the specified value, it can cause several problems in the power system. The higher impedance leads to a higher voltage drop across the transformer winding, which reduces the voltage supplied to the load. This can cause the load to operate at a lower voltage than required, leading to reduced efficiency and increased losses.

The higher impedance can also lead to increased heating of the transformer winding, which can reduce the lifespan of the transformer. The increased heating can also cause thermal overload, which can lead to insulation breakdown, arcing, and other faults.

Additionally, the higher impedance can cause voltage regulation problems in the power system, leading to overvoltage or under-voltage conditions. This can affect the performance and reliability of other equipment in the power system, including motors, generators, and other transformers.

Get it now: CSA C227.5

What is the temperature rise type test IEC 60076-2?

The temperature rise type test is a test conducted on power transformers to determine the temperature rise of the winding and the insulation. The test is conducted in accordance with the IEC 60076-2 standard and is performed to ensure that the transformer can operate safely and reliably under normal operating conditions.

The temperature rise type test involves applying the rated current to the transformer winding and measuring the temperature rise of the winding and the oil. The temperature rise is measured at different points in the transformer, including the hottest spot, the top oil, and the winding temperature. The test is conducted under normal operating conditions, including the rated voltage, frequency, and ambient temperature.

The IEC 60076-2 standard specifies the maximum allowable temperature rise for the transformer winding and the oil. The maximum temperature rise is based on the insulation class of the transformer and is specified in degrees Celsius. The temperature rise test is an essential part of the transformer testing process and is performed to ensure that the transformer can operate safely and reliably under normal operating conditions.

IEC 60076-2 is an international standard for the temperature rise of thermocouples. It defines the limits on the increase of temperature at a thermocouple (or sensor) after it has been subjected to a cercfvvides guidelines on how to evaluate such rises afterward in order to detect anomalies, performance failures, and damage caused by overheating. The standards determine that correct operation must be ensured up to a certain maximum rise in temperature and then specify the allowable levels beyond this point as well as their tolerances.

Read my article on:

How to test a power transformer?

What are the limits of temperature rise?

There is no limit to the temperature rise, but if a thermocouple is operated up to the 3rd limit and its temperature rises beyond 1.5K, then it is likely that there are problems with the integrity of the thermocouple conductors or excessive heat generation through internal resistance rather than due to overheating. There is also no requirement for a maximum rise in temperature at any point on a phase sequence diagram within the scope of IEC 60076-2 which may be specified by other standards.

Try for free: Pad Mounted Transformer

What is IEC standard 60076-7?

The IEC 60076-7 standard provides guidelines for the transportation, storage, installation, and commissioning of power transformers. The standard covers the different aspects of transformer handling and installation, including the lifting, transportation, and positioning of the transformer. The standard also provides guidelines for the installation of the transformer, including the foundation, cable connections, and earthing.

The IEC 60076-7 standard provides guidelines for the transportation, storage, installation, and commissioning of power transformers. The standard covers the different aspects of transformer handling and installation, including the lifting, transportation, and positioning of the transformer. The standard also provides guidelines for the installation of the transformer, including the foundation, cable connections, and earthing.

The IEC standard is the first international electrical code, published in 1881. The standard includes the requirements for Transformers up to 50 MV. The standards specify the sizes of the core, bobbin, and oil-filled transformers with a current rating not exceeding 50 mA and power rating not exceeding 10 W. Nowadays with multiple safety circuits in place, these are no longer available for use even on low voltage or for specialty applications.

However, there is an updated version of this code called IEC 60076-7 which was published in 2005 with multiple sections that include requirements from countries ranging from being low valued up to high-valued transformers (1 to 100 MW). As the name implies, this version of the IEC standard covers transformers up to 100 kVA.

You may enjoy:

The Ultimate Guide To 100 kVA Transformer

The important thing to note is that for very high Voltage Transformers that generate high currents (long cables), there are other IEC standards that can be or have been referred to. For example, Maximum Voltage per Phase (MV/Ph) and Short Circuit Current per Phase (MC/Ph) are part of all IEC standards; these are often used by industry to specify transformers in the very high voltage and high current range.

Why should you buy the Daelim Transformer?

Well-crafted product quality without compromising on resources and cost efficiency are some of the most notable features which have made it an industry leader with growing demand. It is the company's policy to ensure that its products are in compliance with international standards, ensuring customer satisfaction by offering product guarantees. So, if you are looking for a company that can deliver top-quality products while staying competitively priced and meeting your production deadlines, Daelim is the right choice.

Besides having a well-differentiated brand value with the best competitive price and absolute delivery guarantee, Daelim also has an experienced aftersales team that will help recommend options to suit your specific needs. It has strong sales networks spread across the globe to support its global customers with efficient after-sales services and technical support. Its outstanding performance can be attributed to its innovative state-of-the-art products and high level of technological competence.

Daelim guarantees superior quality and meets stringent customer demands. It has emerged as a top-tier supplier of specialty electrical transformers which are utilized in applications in the high-tech sector including railway, nuclear, and petrochemical industries. The company's commitment to high performance, quality, and safety has made it an industry leader in the global marketplace.

In Conclusion

Transformers play a critical role in the transmission and distribution of electrical power. They are used to step up or step down the voltage level of the electrical power to match the requirements of the load. The International Electrotechnical Commission (IEC) 60076 standard provides guidelines for the design, manufacturing, testing, and commissioning of power transformers. This article explores the different aspects of IEC 60076, including transformer codes, impedance tolerance, temperature rise type tests, and IEC 60076-7 standard.

Related Products

Related Article

Pad Mounted Transformer CSA C227.4 National Standard of Canada

As a transformer buyer and manufacturer, you should be familiar with the local transformer design requirements and standards. This article tells the Canadian country's transformer standard CSA C227.4, the pad-mounted transformer below 3000kva.

What you need to know about Large power Transformers?

This paper introduces the meaning of large power transformers, components, manufacturers, cooling methods, inspection, and maintenance of basic knowledge.

Transmission Transformer | At The Power Lines Core

Transmission transformers also known as power transformers are primarily used for power transmission and can also be used as a power receivers.