Solar Transformer, Get The Best Price

Solar energy is the most abundant energy source on Earth, and contemporary solar technology can be used to generate other renewable energy sources. We can convert solar energy into electricity. Currently, there are two main forms of conversion worldwide: solar photovoltaic power stations and solar thermal power stations. In both photovoltaic and solar thermal power generation, solar transformers are essential.

Daelim is a professional and renowned supplier of transformers. Their designs and production include pad-mounted transformers, substation transformers, and power transformers, offering comprehensive solar power solutions for your projects. With their professional competence and rigorous quality control system, Daelim supplies high-quality transformers globally. The transformers designed and manufactured by Daelim fully comply with international standards such as IEEE/IEC, DOE, AS/NZS60076, CSA, and others. They hold certifications and reports from UL/cUL, CSA, IEEE, CE, CESI, SGS, and other authoritative bodies.

From residential rooftops to commercial and industrial applications, as well as utility-grade power plants, Daelim's solar distribution transformers are specifically tailored to various sizes of solar inverters and their respective applications.

What precisely is a solar transformer?

A solar transformer, also known as a photovoltaic (PV) transformer or PV step-up transformer, is a critical component in the infrastructure of solar energy systems. Its primary function is to facilitate the efficient production and distribution of electricity generated by solar panels. By the way, if you are looking a professional solar panel manufacturer in China, pls check Primroot.com.

In photovoltaic projects, solar transformers are essential for several key functions. One of the primary roles is to step up the voltage output from the solar inverters. Solar panels generate DC (direct current) electricity, which is then converted into AC (alternating current) electricity by inverters. The AC output from the inverters typically needs to be transformed to match the voltage level of the utility grid before it can be efficiently transmitted and distributed.

In a solar power plant setup, the solar transformer usually acts as a step-up transformer. It elevates the AC voltage output from the inverters to the voltage level required by the utility grid. This transformation ensures that the electricity generated by the solar panels can seamlessly integrate into the existing grid infrastructure, allowing it to be used by consumers and businesses connected to the grid.

Furthermore, solar transformers ensure the stability and reliability of the electricity supply from solar power plants. They help in maintaining the quality of the AC power output, ensuring that it meets the standards and requirements set by regulatory authorities and utility companies. This includes factors such as voltage levels, frequency, and synchronization with the grid.

What are the core features of solar transformers?

The transformers designed and produced by Daelim exhibit several core features tailored for solar applications:

-

FR3 Dielectric Fluid: Daelim transformers utilize FR3 dielectric fluid, which enhances fire safety and equipment reliability. Compared to traditional mineral-oil transformers, FR3 extends the projected lifespan significantly. This makes it a crucial component in Balance of System (BOS) solutions for Distributed Energy Resources (DER).

-

Custom-Optimized Designs: These transformers are custom-designed to meet specific requirements such as loading profiles, impedance needs, and accommodating single or multiple inverter connections. This tailored approach ensures optimal performance within varied solar energy system configurations.

-

Increased Overload Capability: They are engineered with increased overload capability beyond their nameplate ratings, without compromising the insulation life. This feature enhances operational flexibility and reliability under varying load conditions.

-

Comprehensive BOS Integration: Daelim transformers fully integrate with solar and energy BOS solutions. This includes DC and AC combiners, disconnects, fuses, breakers, AC recombines, pad-mounted switchgear, pole-mounted reclosers, air switches, capacitors, and a full range of associated services.

In a photovoltaic grid-connected power generation system, the step-up transformer plays a pivotal role. Optimizing the selection of transformers can reduce losses and improve system efficiency. Comparing and analyzing different transformer types enables making informed choices that enhance the overall effectiveness of photovoltaic power generation systems.

You may enjoy: The Ultimate FAQ Guide to Wind Transformers

Specification and Model Selection of Solar Transformer

When selecting a solar transformer, several specifications and models need consideration:

Transformer Capacity Selection

Transformer capacity is calculated using the formula: active power / power factor = apparent power. Different regions specify varied power factors; The sum of the load power should not exceed 80% of the transformer's selected power.

Transformer capacity is calculated using the formula: active power / power factor = apparent power. Different regions specify varied power factors; The sum of the load power should not exceed 80% of the transformer's selected power.

In photovoltaic grid-connected systems, transformers handle the maximum inverter output power. This is influenced by solar panel capacity, installation angle, and location. Inverter output power is generally 0.9 times the panel capacity, aligning with the transformer's power factor, necessitating either a 1:1 configuration or a larger transformer capacity than the panel.

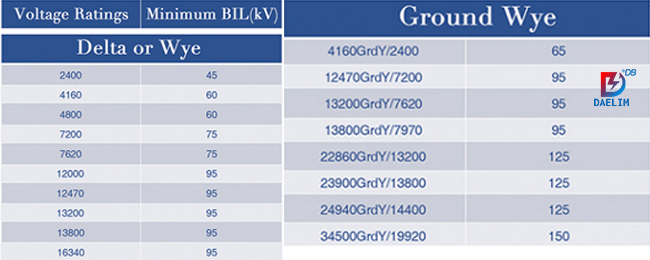

Transformer Voltage Selection

Primary transformer voltage matches photovoltaic system output; secondary coil voltage matches integrated grid voltage, favoring low-voltage three-phase four-wire systems. For example, if a solar inverter outputs 600V, the transformer primary side voltage is 600V; grid integration at 13.8kV means secondary side voltage is 13.8kV.

Transformer Phases Selection

Typically, solar power plant transformers employ three-phase setups.

Transformer Connection Group Selection

Solar plant step-up transformers usually feature Dy1, Dy5, or Dy11 connections. Globally, Dy connections dominate due to harmonic suppression benefits:

Solar plant step-up transformers usually feature Dy1, Dy5, or Dy11 connections. Globally, Dy connections dominate due to harmonic suppression benefits:

Dy connections minimize higher harmonic effects

Third harmonic circulating currents balance third harmonic magnetomotive forces, offsetting low-voltage winding harmonics.

Harmonic electromotive forces circulate within Dy loops, sparing public high-voltage grids.

Dy-connected transformers feature lower zero-sequence impedance, beneficial for low-voltage ground faults.

Dy connections handle unbalanced loads better than Yy, enhancing safety and operation during failures.

Transformer Load and No-Load Loss, Impedance Voltage:

Transformers in photovoltaic setups experience no-load losses regardless of power generation, necessitating minimal load losses for nighttime operation.

Reading more about Transformer Connection

Transformer Operating Environment

Clean, low-dust environments suit dry-type transformers under 800kVA, whereas larger capacities opt for oil-immersed models, selected for natural or air cooling depending on size.

Utility Grid Connection Principles

Prefer self-cooled, low-loss transformers matching photovoltaic module output. Coastal or wind-exposed sites require IP65 or IP54 protection levels for outdoor layouts, with options for dual-winding or split transformers.

Read my article on 5+FAQ About 15kV Transformer

Structure Of The Solar Transformer

The structure of solar transformers closely resembles that of conventional transformers, consisting primarily of a tank, iron core, windings, and bushings.

Since the formal implementation of the Paris Agreement in 2016 and the global focus on carbon neutrality, renewable energy, including wind, solar, and battery storage, has experienced rapid growth. Transformers play a crucial role in solar power plants by boosting voltage from solar inverters, delivering significant economic benefits.

However, conventional power distribution transformers cannot be used for solar inverters due to specific application requirements. Thus, customization is essential, taking into account the unique nature, inverter technology, and operational characteristics of solar power plants. Key considerations include:

-

Harmonic Current Injection: The transformer for photovoltaic power generation must ensure that the harmonic current content does not exceed 5% of the rated current. Exceeding this limit can reduce transformer lifespan. If the total harmonic content exceeds 5%, it necessitates explanation.

-

Electrostatic Shields (ESS): Low-eddy loss electrostatic shields are essential between each low-voltage and high-voltage winding. These shields prevent capacitance coupling, particularly since low-voltage windings are typically ungrounded wye connections in solar power plants. They also prevent high-frequency voltage interference from inverters during voltage reversals and protect against switch operations from high-voltage to low-voltage windings.

-

Grounding and Insulation: Solar transformers should have only one grounding point, which must be securely grounded. Insulation class requirements are at least F for dry-type transformers and A for oil-type transformers.

-

Tank Protection Level: The tank protection level must be at least IP54 to safeguard against environmental factors.

-

Load Loss: Air load loss and load loss parameters in photovoltaic power generation should not exceed specified positive deviations.

-

High Altitude Considerations: In high-altitude areas, U.S.-Merchant-high-voltage cable heads should use fully insulated plug-in cable heads.

-

Connection Methods: The high-voltage side should employ the bottom-line method, while the low-voltage side should use bottom-line sideline connections with low-temperature circuit breaker lightning-resistant (surge protector) ten bus bronze volumes. Busbar copper rows should accommodate multiple cable connections with sufficient height reserved for installation.

-

Temperature Monitoring: Transformers for photovoltaic power generation should incorporate special temperature monitoring devices. These devices must:

- Use PT100 temperature sensors to display oil surface temperature.

- Include independent alarm contacts and provide PT100 temperature remote signal or 4~20mA signal output or 485 communication interface.

- Install temperature sensors at the hottest point in transformer oil.

- Have two pairs of independent electrical contacts for alarm and trip functions.

- Operate within a temperature range of -40 to 70°C.

-

Component Requirements: Technical parameters of all components used must meet the operational environment requirements of photovoltaic fields.

These specifications ensure that solar transformers are optimized for efficiency, reliability, and safety within the context of photovoltaic power generation systems.

Special transformers used in solar power plants

Split Transformer:

In the realm of solar transformers, a split transformer stands out due to its specialized design on the low-voltage side. Here, one or more windings are segmented into distinct branches of equal rated capacity. These branches remain electrically isolated but are magnetically coupled with substantial impedance between them. A notable example is the double-winding double-split transformer, featuring a single high-voltage winding and two split low-voltage windings, each rated identically. This configuration proves particularly beneficial in solar power plants where it serves dual busbars. In the event of a short circuit on one busbar, the transformer effectively limits the short-circuit current while maintaining stable voltage levels on the other busbar, ensuring continuous operation and reliability of photovoltaic systems.

Isolation Transformer:

In the context of solar energy systems, the isolation transformer plays a critical role in enhancing safety and performance. It completely isolates electrical appliances on both primary and secondary sides and isolates circuits, effectively safeguarding against electrical hazards. With a specialized iron core design that minimizes high-frequency losses, the isolation transformer prevents the introduction of high-frequency noise into critical control circuits within solar power installations. It is typically employed in scenarios with lower power demands and shorter transmission lines, where its ability to minimize grounding currents significantly enhances personal safety by reducing the risk of electrical shocks. However, while effective for general safety measures, it may not provide comprehensive protection against severe electrical injuries, underscoring its primary function in ensuring operational safety and reliability in solar energy applications.

Selection principle of solar transformers

-

Preference for Self-Cooling(ONAN), Low-Loss Transformers: Opt for transformers that are self-cooling and have low losses.

-

Capacity Selection Based on Photovoltaic Module Output: Determine the capacity of the step-up transformer based on the maximum output power of the photovoltaic array module.

-

Selection of Prefabricated Substations: Choose high-voltage/low-voltage prefabricated box-type substations or open-type equipment comprising transformers and high and low-voltage electrical components. For solar power stations located in coastal or windy environments, outdoor layouts require a coastal protection level of at least IP65, and those exposed to heavy wind and sand should meet IP54 protection standards.

-

Transformer Type Options: Select either a double-winding transformer or a split transformer.

-

Non-Excitation Voltage-Regulating Transformer: Opt for a transformer that operates as a non-excitation voltage-regulating type.

-

Electrostatic Shielding for High-Low Voltage Isolation: Include an electrostatic shielding layer between high and low voltages to prevent mutual inductance between them.

Read my article: The Ultimate FAQs Guide To GSU Transformer

Daelim Solar Transformer Selection Parameters

1. Rated output kVA:

• Based on inverter output ratings, load diagram, harmonic content, weather patterns, and unusual service conditions

2. Nominal Voltage:

• Designed for Inverter Transformer to be compatible with the Pulse voltage shape of inverters

3. Winding connection diagram and vector group:

• Inverter operation is not affected by vector groups like Dy1, Dy5 or Dy11

• No Neutral required on the Primary LV side

• Isolated neutral point on Secondary HV side transformer

4. Electrostatic Shield (ES):

• Recommended installation of ES between primary and secondary windings to minimize the potential transfer of high-frequency voltage disturbances (harmonics, pulses, surges) from primary to secondary

• Windings typically connected to inverter circuits are ungrounded

DAELIM fully complies with C57.159 – 2016 IEEE Guide for Application in DPV Power Generation Systems.

Try for free: What are the types of prefabricated substations?

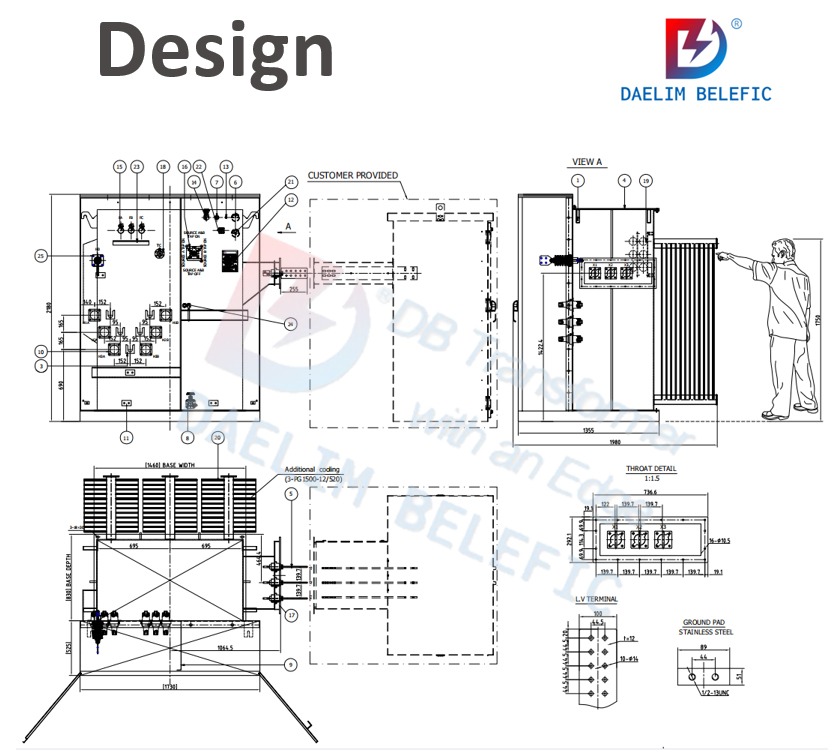

Solar Transformer Design

Solar transformers' design can be applied to any environmental conditions. Customized design to meet the requirements of all customers. Daelim's solar transformers have the advantage of energy conservation, and according to solar power generation capacity and collecting array voltage level rated, they can fully meet all applicable international standards and regulations. Daelim mainly designs the following two solar transformers.

3 Phade Pad-mounted transformer

3 phase pad mounted transformer is an easy-to-install distribution transformer with an anti-tamper and anti-theft design. It is widely used in photovoltaic projects in the North American market and is used to connect solar inverters to integrate electric energy into the grid.

The picture below is the 3-phase pad-mounted transformer drawing designed for the Canadian photovoltaic project. It is different from the ordinary transformer in appearance. The low-voltage terminal is designed side-top on the side of the tank.

Learn more about 3 Phase Pad Mounted Transformer

Phases: Three

Frequency: 50 Hz, 60Hz

Standard: IEEE, CSA, IEC

Tank Type: Padmount

Base rating: 750 kVA through 10,000 KVA

High Voltage (HV): 2.5 kV through 44 kV

Low Voltage (LV): 600/800 V

Windings: Copper, Aluminum

Solar pads are available in various configurations to accommodate typical inverter connections and performances

Reading On: Daelim Solar Transformer Projects

Substation transformer

Phases: Three

Frequency: 50 Hz, 60Hz

Standard: IEEE, CSA, IEC

Base rating: 750 kVA through 10,000 KVA

High Voltage (HV): 2.5 kV through 35 kV

Low Voltage (LV): 600/800 V

Windings: Copper, Aluminum

Solar pads are available in various configurations to accommodate typical inverter connections and performances

Solar energy transformer solution

The transformers provided by Daelim can match any size inverter in solar photovoltaic power generation.

1. Fast submit the drawing

In order not to affect the delivery time, the DAELIM engineer team delivered the drawings in batches. 60% of the drawings were delivered within two weeks and production was arranged in time . The remaining drawings were successfully delivered in the remaining two weeks.

2. Make a good production plan

DAELIM's management pays much attention to the needs of customers and has communicated with the production team and our supplier team many times. The workers worked overtime to ensure the delivery of customer requests.

3. 100% meet the standard requirements

Our team of engineers studied the CSA Standard carefully. Because they are based on IEEE standards, DAELIM designed and produced them according to them. For the existing technical problems or differences, our team has carried out hundreds of e-mail and telephone communication with customers.

Daelim solar transformers can be applied to any environmental conditions. Customized design to meet the requirements of all customers. Daelim's solar transformers have the advantage of energy conservation, and according to solar power generation capacity and collecting array voltage level rated, they can fully meet all applicable international standards and regulations.

Click here for specific solar transformer solutions

What are the types of solar transformers?

There are different types of solar transformers including three-phase pad mounted, oil immersed, substation, and dry transformer. All solar transformers have special needs that affect cost. Dry uses air as the cooling medium, while liquid uses oil.

Learn more: How Much You Know For The Different Types Of Transformers?

Three phase pad mounted transformer

A three-phase pad-mounted transformer is a kind of oil transformer, and it is also a very common solar transformer in recent years. Especially in the US and Canadian markets in North America. The pad-mounted transformer is widely loved by the market due to its compact structure, tamper-proof design, and easy maintenance.

Daelim's pad mount transformer has SGS, CSA, and other test reports, UL/cUL, CSA, IEEE, and other certificates, transformers less than 2500kVA can also be designed to meet the US DOE efficiency value standard. Daelim's pad mount transformers are exported to North America in large quantities, and there are after-sales service teams in markets such as the United States and Canada.

Learn more about 2500 kVA Pad Mounted Transformer

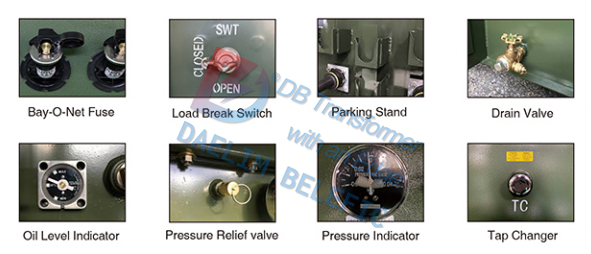

Daelim's pad mount transformer can be designed with dual voltage and meet the K factor rating. Pad mount transformer conventional capacity up to 10MVA.

Daelim's pad mount transformer optional accessories: Oil level gauge, Liquide temperature gauge, Pressure vacuum gauge, Primary termination: externally clamped bushing wells with load break inserts/Integral load break or non-load break bushings, Secondary termination: externally clamped bushings with NEMA 4-hole, 6-hole, 8-hole, 10-hole or 12-hole spades, overvoltage protection, etc. For the above accessories, you can choose Qualitrol, ABB, and other internationally famous brands.

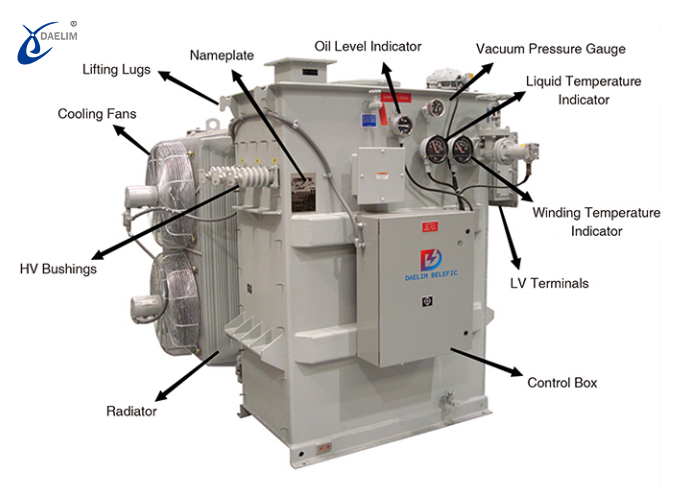

Substation transformer

A substation transformer is also a commonly used transformer in solar power plants. It is characterized by low loss, and the radiator and air terminal chamber can be disassembled for easy transportation and movement.

Daelim's substation transformer with high voltage of up to 34.5kV, and rating up to 20 MVA. Design and production conform to CSA/ASUL/DOE and other standards, with a UL certificate. There are four structural layouts of American Standard. The high and low voltage bushings are sides out on both sides, the high and low voltage bushings are on top sides, and one side is out and the other side is on top. Substation transformers are usually colored gray and green.

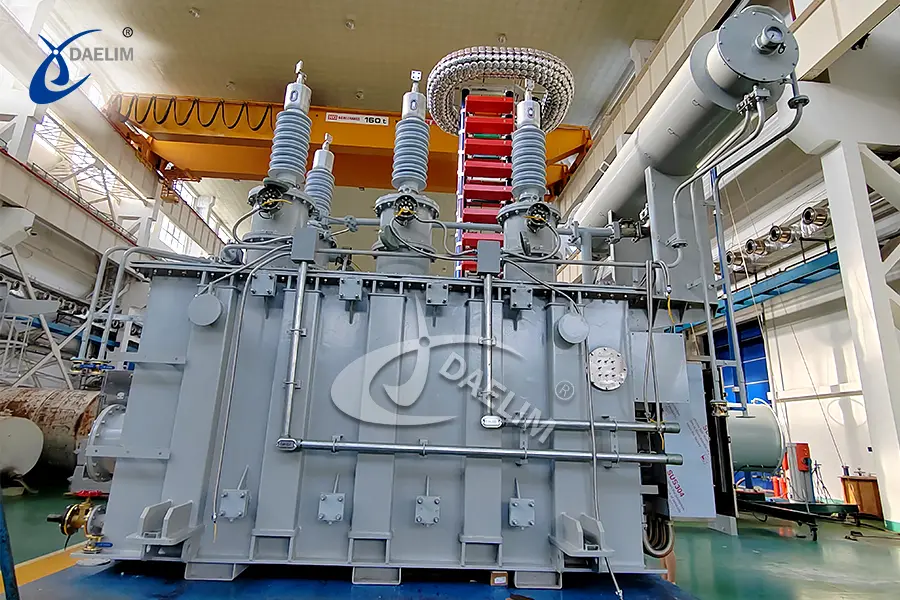

Oil-immersed power transformers

This type of transformer, often known as oil-filled transformers, is an electric voltage that uses ways to cool the oil in order to lower transformer temperatures.

Unlike dry transformers, the body of an oil-immersed transformer is fitted inside a welded steel tank that has been filled with oil insulation. When an oil-immersed transformer operates, its iron core heats the coil, which is subsequently transported into the insulation fluid and then onto the medium to cool. The voltage of Daelim's oil-immersed transformer can reach 345kV, and the maximum capacity can reach 500MVA.

Learn more about HV Power Transformer

Dry-Type Transformers

This type of transformer has no moving parts. They are inert devices that utilize thermal insulation technologies that are environmentally friendly.

This type of transformer has no moving parts. They are inert devices that utilize thermal insulation technologies that are environmentally friendly.

The word "dry" refers to the fact that the transformer is kept cool through natural ventilation rather than using silicone, oil, or liquids to cool the coils and electrical core.

Dry-type transformers are not required to be housed in fireproof vaults or catch basins. This type of transformer is safe and may be used in a variety of locations, they can be placed close to the equipment and indoors, making the entire process more efficient.

Learn more: Ultimate guide of cast resin dry type transformer

What is the difference between solar photovoltaic and solar thermal power generation?

The main difference between solar photovoltaic power generation and solar thermal power generation is:

1. Solar thermal power generation has large investment, large construction site, long construction period, and high construction cost;

2. Solar thermal power generation is more controllable than photovoltaic power generation, and the power is stable and adjustable;

3. The transformer capacity for solar thermal power generation is larger and the running time is longer

Read my article on 167 kVA Transformers: The Ultimate FAQ Guide

What are the requirements for transformers used in solar power generation?

1. Requires lower loss;

2. Strong voltage overload capability;

3. There are both DC waves, and a shielding layer should be placed between the high and low to prevent high and low voltage mutual inductance

What is the difference between solar transformer and normal transformer?

There are three main differences between transformers used in solar photovoltaic projects:

1. With Electrostatic Shields Design;

Transformers used in solar power plants must have an electrostatic shielding design, which exists to eliminate electromagnetic interference from solar inverters;

2. With NEMA 4X/3R Control Box

Transformers on solar power plants usually need to be used for remote control. Therefore, oil temperature gauges, oil level gauges, pressure gauges, etc. need to have contacts, and these accessory contacts with contacts need to be assembled in a control box.

Due to the design of the electrostatic shield and the control box, the solar transformer price is higher by 10-20%.

The following table is the solar transformer specification, and the part marked in yellow is the special requirement of the solar transformer in the PV project.

| Solar Transformer | Ordinary Transformer |

| HV: 12470Y/17200V | HV: 12740 |

| LV: 480deltav | LV: 480Y/1.732 |

| 60HZ ONAN | 60HZ ONAN |

| NEMA 4x Control Box | |

| Primary Surge Arresters | Primary Surge Arresters |

| Nitrogen Blanket | Mineral oil 45# (PCB FREE) |

| Electro Static Shields | |

| BUILT TO IEEE C57.12.34 Std and DOE St | BUILT TO IEEE Std. C57.12.00 IEEE Std. C57.12.90 IEEE Std. C57.12.34 |

What kind of voltage or current waveform will the PV Inverter provide to the transformer?

Considerations for the environment, typically ambient temperature.

Modern PV inverters usually produce a sinusoidal voltage and the current waveform is similar to the ideal sine wave. So grid-tie transformers generally do not need to be large in the event that solar power inverters operate them. General-purpose transformers are typically specifically designed. Non-linear loads could cause the voltage and current to cause Total Harmonic Distortion (THD) which could impact the transformer's performance and cause an increase in heating. A K=4 transformer can manage the distortion typical of non-linear loads when that's an issue. Changes in load speed should not have any effect on the effectiveness of dry-type transformers.

The environmental conditions, like ambient temperature, must also be taken into consideration. Grid-tie transformers typically don't experience a maximum load or, if they do, it will last less than an hour, based on typical load curves for solar facilities. Dry-type transformers with 220 to C insulation and 150 degrees C temperatures are built to handle their highest load for as long as the temperature of the surrounding area is not more than 40 degrees C and averages around 30 degrees C during any 24-hour time period. In areas that have high temperatures in the air in the winter, lower temperatures for dry-type transformers must be taken into consideration. 130 o C Temperature rise raises the maximum ambient temperature to sixty 60C while the median of 50 o C in a 24-hour span. A 115 or C temperature rise is capable of handling more extreme ambient temperatures if required. It is usually more economical to choose transformers with lower temperature rises rather than manually increase the power for the particular transformer.

You may enjoy: The Ultimate Guide to delta wye transformer

Conclusion

Advantage:

1. Experience in supplying multiple projects in American Countries such as U.S. and Canada

2. Qualified with UL, cUL, CSA certificate, SGS test report, etc.

3. Complete after-sales service and installation teams in Canada, USA, etc.

4. Strong design ability for high efficiency, special ambient, low sound level,50 Hz and 60 Hz,k-factor rating, etc

5. 6-7 weeks of production time

Daelim believes that it is essential to produce high-quality products at reasonable prices. Within each component, they never compromise on performance or environmental responsibility. Because of this dedication, they are your one-stop shop for all things electrical. If you have any questions about your project, you can contact the Daelim team, and their professional team will provide quick feedback.

Related Products

Related Article

Solar Photovoltaic System Solution

DB Transformer serves the world's renewable energy field. Here are solutions for some solar projects provided by Daelim for the United States, Canada, and other countries.

MV Skid Compact, Premier Choice for Utility-Scale Solar and Energy Storage

MV Skid Compact represents the pinnacle of cost-effective solutions for Utility Scale Solar and Energy Storage projects. It seamlessly integrates MV transformers, inverters, and medium voltage switches into a single unit, facilitating swift and hassle-free deployment. By consolidating these essential components, MV Skid Compact drastically reduces civil engineering requirements and on-site installation and commissioning times.

230 kV Three Phase Power Transformer For USA Market

In 2023, Daelim Transformer designed and manufactured a cutting-edge 230 kV three-phase power transformer for a client in Nevada, USA. The client recently shared installation and operational photos, showcasing the successful deployment of this remarkable transformer. Let's delve into the specifics of this transformer project!

Canadian 69 kV Substation Transformer Project

Today, we are excited to present a case study on a 69 kV substation transformer project by Daelim Transformer. Our Canadian client required a step-down transformer for their substation to connect with the hydroelectric grid in Quebec.

Pad Mounted Transformer for BESS System 4.0 MVA in Riverside County, California

Today, Daelim Transformer is proud to introduce a pad-mounted transformer for a 4.0 MVA Battery Energy Storage System (BESS) project located in Riverside County, California. The transformer is meticulously crafted to comply with the specifications outlined in the California Electrical Code Article 450.

2000 kVA Oil immersed Substation Transformer For Portugal Market

Today, we introduce Daelim Transformer's export of a 2000 kVA oil-immersed substation transformer to Portugal. This transformer represents our commitment to delivering high-quality electrical solutions to global markets. With meticulous design and engineering, this transformer is tailored to meet the specific needs of our customers in Portugal, ensuring reliable performance and efficiency. Daelim Transformer continues to uphold its reputation for excellence, providing innovative solutions that power progress and reliability worldwide.