How Much You Know For The Different Types Of Transformers?

Transformers are essential components in the operation of power transmission and distribution systems, serving critical roles in converting electrical energy efficiently across different voltage levels. Understanding the types of transformers and their specific applications is crucial for designing and implementing effective electrical infrastructure.

Based on Number of Phases

Transformers are categorized based on the number of phases they support:

Single Phase Transformers

Single phase transformers are designed to handle single-phase AC power, typically used in residential and light commercial applications where power requirements are relatively low and simpler distribution networks suffice.

Three Phase Transformers

Suited for industrial and commercial applications, three phase transformers efficiently handle higher power capacities and are integral to larger electrical grids. They provide a balanced power supply essential for heavy machinery and industrial processes.

According to Purpose

Transformers are also classified by their specific applications:

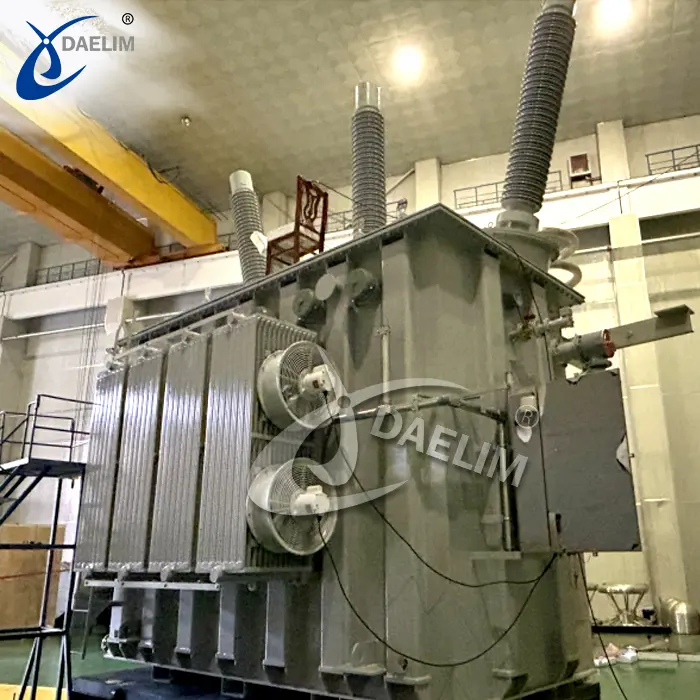

Power Transformers

The Power Transformers are employed in high voltage transmission networks to step up voltage levels for efficient long-distance power transmission and step down voltages at substations for local distribution.

The Power Transformers are employed in high voltage transmission networks to step up voltage levels for efficient long-distance power transmission and step down voltages at substations for local distribution.

Distribution Transformers

Found at distribution substations and pole-mounted locations, distribution transformers reduce high-voltage electricity to lower usable voltage levels suitable for residential and commercial consumers.

Instrument Transformers

This category includes voltage transformers (VTs) and current transformers (CTs), which are used for measuring and monitoring electrical parameters in power systems, ensuring accurate metering and protection.

Special Transformers

Designed for specific applications such as voltage regulation, testing, or unique industrial requirements, special transformers cater to niche needs where standard transformers may not suffice.

Try for free: Electric furnace transformer

Based on Structure

Transformers can be classified based on their structural design:

Core Type Transformers

These transformers have a core made of laminated steel sheets around which primary and secondary windings are wound. Core type transformers are commonly used in power transmission due to their efficiency and compact design.

These transformers have a core made of laminated steel sheets around which primary and secondary windings are wound. Core type transformers are commonly used in power transmission due to their efficiency and compact design.

Shell Type Transformers

In shell type transformers, the windings surround the core. They are typically larger in size compared to core type transformers but offer advantages in terms of easier cooling and higher short-circuit strength.

Coils Configuration

Transformers may differ based on the configuration of their windings:

Double-Winding Transformers

These transformers have separate primary and secondary windings, providing electrical isolation between input and output circuits.

Auto Transformers

Auto transformers have a single winding that serves as both primary and secondary winding, offering advantages in terms of size and cost efficiency but without complete isolation between circuits.

Cooling Methods

Transformers are classified by the method used for cooling:

Oil Cooled Transformers

The oil cooled transformers use oil for insulation and cooling purposes, allowing efficient heat dissipation and insulation properties required for high-power applications and extended operational life.

Dry Type Transformers

Suitable for indoor applications where safety and environmental concerns are paramount, Dry Type Transformers use air or solid insulation materials instead of oil, making them safer and easier to maintain.

Understanding these diverse types of transformers is essential for selecting the right equipment to meet specific electrical needs, ensuring reliable and efficient operation within power distribution networks and industrial facilities. Each type offers unique advantages tailored to different voltage levels, power capacities, and environmental conditions, contributing to the seamless functioning of modern electrical systems.

Reading more: Ultimate guide of cast resin dry type transformer

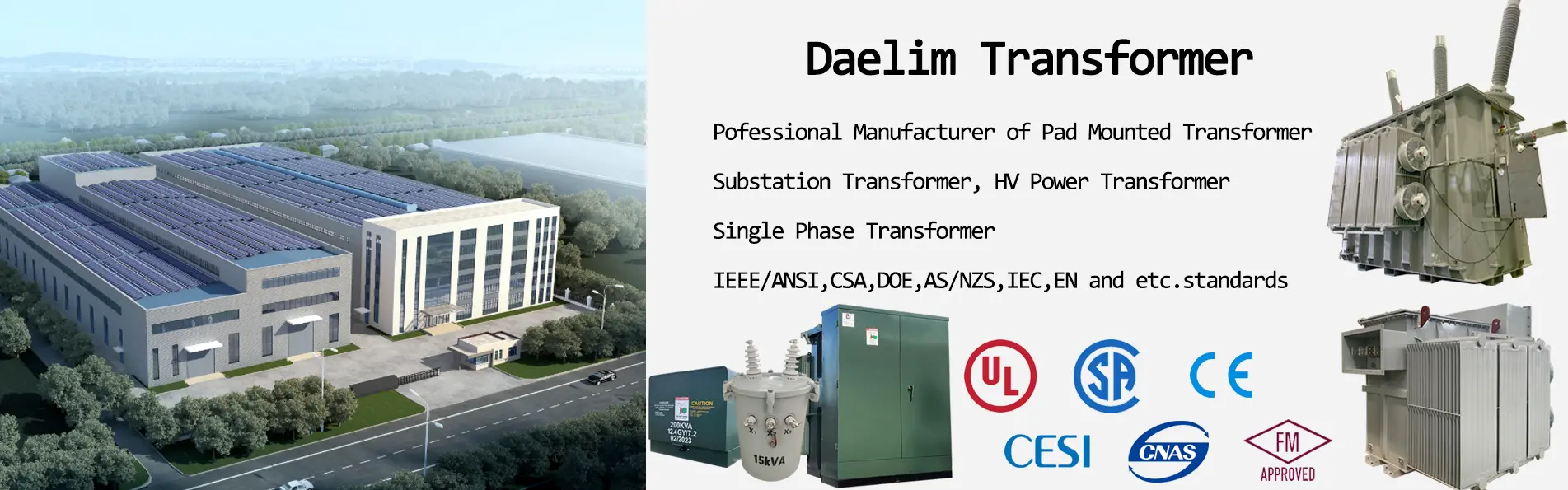

Daelim Transformer

As a distinguished manufacturer in the transformer industry, Daelim Transformer specializes in power transformers and single-phase/three-phase distribution transformers. With over 20 years of experience, Daelim Transformer has established a global presence, serving clients across five continents with customized production capabilities adhering to a variety of international standards.

Key Products Offered by Daelim Transformer

Daelim Transformer’s product lineup includes:

- Power Transformers up to 345kV: Critical for high-voltage applications requiring efficient power transformation.

- Distribution Transformers up to 35kV: Essential for localized power distribution networks ensuring reliable electricity supply.

- Pad Mounted Transformers up to 44kV: Ideal for outdoor installations, featuring robust construction and advanced insulation.

- Pole Mounted Transformers up to 34.5kV: Designed for specific applications requiring elevated positioning and operational resilience.

- Dry Type Transformers up to 35kV: Offering a safe and maintenance-free alternative for indoor installations where oil-filled transformers are impractical.

Related Products

Related Article

13.8 kV 10.5 MVA Substation Transformer for Ecuador

A customer from Ecuador contacted Daelim Transformer for a 10.5MVA substation transformer (13.8kV high voltage, 2.4kV low voltage). Daelim Transformer provided a customized solution, conducted virtual factory tours, ensured rigorous quality control via video inspections, and offered post-delivery online training and ongoing support, fostering a successful partnership.

2600 kVA Pad Mounted Transformer For Blockchain In Kansas

This morning, I received the on-site photos of the pad-mounted transformers from the customer, and I was overwhelmed with excitement and joy. These pad-mounted transformers are installed at a 20MW blockchain site in Kansas, USA. A total of 5 sets of 2600 kVA pad-mounted transformers, all UL-listed, are being deployed at this site. Currently, 3 sets have already been installed onsite and are scheduled to be powered on imminently.

20MVA Power Transformer for the United States

This project involves the development of a 20 MVA three-phase power transformer tailored for the United States market. The primary voltage is 24.94kV, and the secondary voltage is 4.16kV, indicating it functions as a step-down transformer. The design and production fully comply with IEEE C57.12.00 standards and have passed third-party UL team testing. All accessories also adhere to IEEE standards. FR3 vegetable oil serves as the insulating liquid for the transformers.

2 MVA Pad Mounted Transformer for Utility

Behold the backbone of Canada's utility infrastructure—the 2MVA pad mounted transformer. With a primary voltage of 4160Grdy/2400V and a secondary voltage of 800GrdY/461V, this transformer stands as a testament to efficiency and reliability in power distribution. Crafted in strict accordance with CSA standards and CAN/CSA802.1 energy efficiency guidelines, it embodies the pinnacle of engineering excellence.

1500 kVA Transformer for Australian Mining Project

Introduce the 1500 kVA transformer tailored for Australian mining projects. The transformer operates in a three-phase configuration, with a total of four units deployed. Notably, its primary voltage stands at 11kV, while the secondary voltage is 1kV. Characterized by its compact size, emphasis on safety, and unwavering reliability, this transformer is meticulously designed and manufactured to meet the stringent requirements outlined in AS 60076 and AS efficiency value standards.Let's delve into the key features and specifications of this essential solution.

2600 kVA Pad Mounted Transformer for Blcokchain

Daelim Transformer successfully provided three customized 2600 kVA pad mounted transformers to power a state-of-the-art blockchain facility in Texas, USA. Our transformers were meticulously designed to meet the unique demands of the mining operation, ensuring seamless power distribution with unwavering reliability and efficiency.