Why Load Bank Testing Is Essential for Transformer Maintenance

As transformers are the most important part of the power infrastructure, their reliability is critical. If a transformer fails or breaks down, the entire power system breaks down. So, inspecting and testing them regularly makes sure they remain operational, so power keeps flowing and business keeps running.

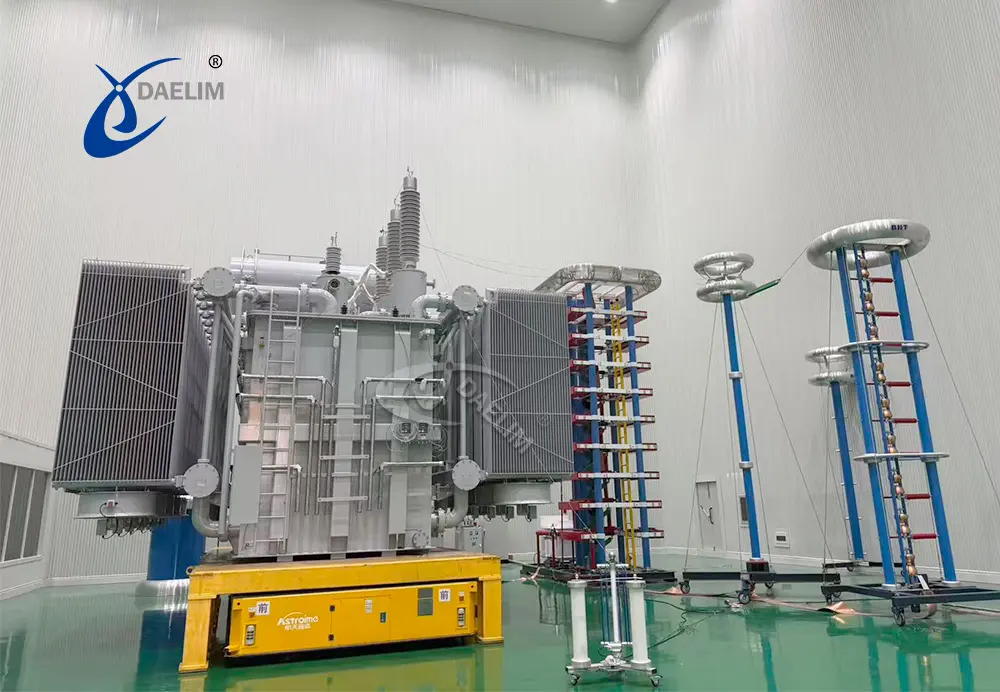

One of the most effective tests to verify transformer capacity, reliability, and detect hidden issues is Load Bank Testing. In this test, the transformer goes beyond simple inspection. The transformer is actively subjected to controlled voltages and loads to measure its capacity, determine how much voltage and current it can handle under demanding conditions, assess power factor, and evaluate heat rise.

Contact Daelim TransformerWhat Is Load Bank Testing?

Load bank testing for transformers is the method that connects a transformer to an electrically controlled load device, called a load bank, for creating conditions similar to its actual operation. Unlike passive inspection, transformer load bank tests actively apply electrical load to determine how well the transformer performs under actual service demands.

Load bank testing for transformers is the method that connects a transformer to an electrically controlled load device, called a load bank, for creating conditions similar to its actual operation. Unlike passive inspection, transformer load bank tests actively apply electrical load to determine how well the transformer performs under actual service demands.

A test of the load bank allows the engineer not just to test the transformer for full rated power, but also for its reaction under variations in power factor, harmonics, and heat rise. Such testing is a very important part of transformer maintenance to identify hidden issues that might not appear in light load conditions.

During a transformer capacity test, several key parameters are measured, including:

- Voltage stability and regulation

- Current handling capability

- Efficiency under load

- Cooling system performance

- Thermal rise and insulation health

Standards as IEEE C57 transformer testing guidelines, make sure that the load bank test is done consistently. Moreover, transformer maintenance testing requirements, such as PRC-005, also allow utility and industrial operators to meet specific regulation requirements on reliability and safety.

Why Load Bank Testing Is Important for Transformers

Transformers are essential for reliable power transmission; however, like any electrical device, they suffer from deterioration over time due to loading, mechanical stress, heating, and insulation aging. Hence, load bank testing transformer procedures are a definite necessity for preventive maintenance.

These load bank tests simulate the actual world electrical load exerted on the transformer and thus ensure that the unit can operate safely and efficiently before being kept in service.

One of the key satisfactions of load bank testing is the early detection of problems. When a transformer is inspected without a controlled load, issues like heating, insulation, and efficiency go unnoticed until they result in costly failures.

A capacity test shows that the transformer can handle its rated output, ensuring that power systems will not fail under peak-demanding conditions.

So, this resistive reactive load bank testing gives engineer peace of mind that their transformer will meet operational requirements, which avoids downtime and extends its service life. The business benefits from lower maintenance expenses, more stable systems, and higher returns.

Load Bank Testing Process

The transformer load bank tests follow a step-by-step procedure in testing how a transformer performs under controlled electrical demand. Unlike simple inspection methods, this procedure captures real-life conditions to ensure that reliability, safety, and efficiency are analyzed accurately in the assessment.

Step 1: Preparation and Safety Checks

Before testing, the transformer for oil levels, insulation integrity, and cooling system readiness needs to be checked. Following the guidelines of IEEE C57 transformer testing, grounding and protective equipment are also verified to ensure safe operation.

Step 2: Connecting the Load Bank

A load bank is connected to the transformer. The resistive elements show the actual kW load, and the reactive components test the kVAR handling ability and power factor response. This makes a perfect combination for transformer capacity testing.

Step 3: Applying the Load

The transformer is gradually loaded in controlled increments (e.g., 25%, 50%, 75%, and 100% of rated capacity). During every stage, technologists measure some of the performance indexes, like:

- Voltage regulation and stability

- Current balance across phases

- Power factor and harmonic distortion

- Cooling system performance and thermal rise

Step 4: Monitoring and Data Collection

During the load bank testing of the transformer, data is being recorded all along for further analysis. Any abnormality, such as overheating, failure of voltage balance, or poor efficiency, delineates an area needing attention.

Step 5: Evaluation and Compliance Verification

Results are compared against design specifications and industry standards that include PRC-005 maintenance testing and IEEE C57 transformer testing. This ensures that the transformer meets the operational technical design and also fulfills the requirements for reliability set for utilities, data centers, and industrial premises.

Through this structured testing methodology for transformer maintenance, operators can spot early warning signs that confirm operational readiness and plan maintenance activities effectively.

Common Issues Found with Load Bank Testing

Unlike normal routine checks and inspections, load bank testing goes beyond by putting real-world demanding conditions to see any issues with it, which are often missed. This helps spot and eliminate problems earlier and prevent breakdowns.

Some of the common issues include weakened insulation from heat and stress, overheating due to bad cooling or excess load, and voltage imbalance. It can also spot reduced efficiency, which is usually caused by core losses as well.

Spotting these issues under controlled conditions gives a big edge. These issues can be eliminated in time before they grow, and you can be saved from a power failure.

Conclusion

Load bank testing is not just an optional step in maintenance, but this is very critical for ensuring reliability, safety, and efficacy of the transformer. By doing this load bank test on the transformer, the engineer can verify capacity and any hidden issues that could lead to breakdown. Having regular load bank testing extends the life of the transformer and ensures it stays operational.

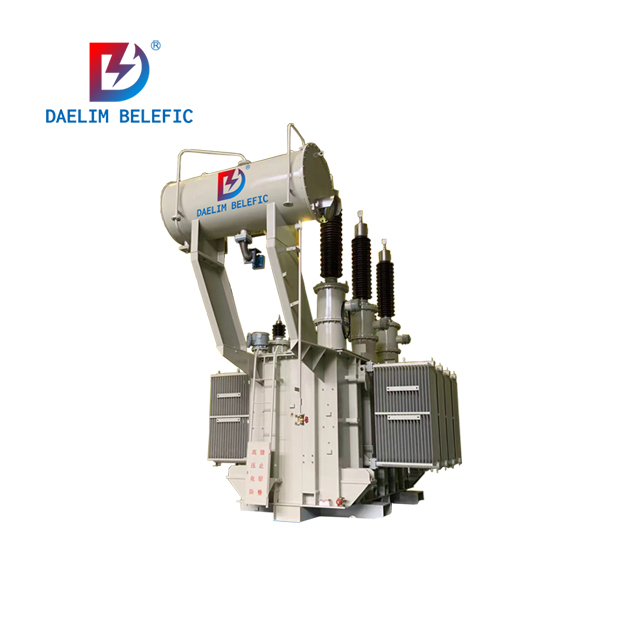

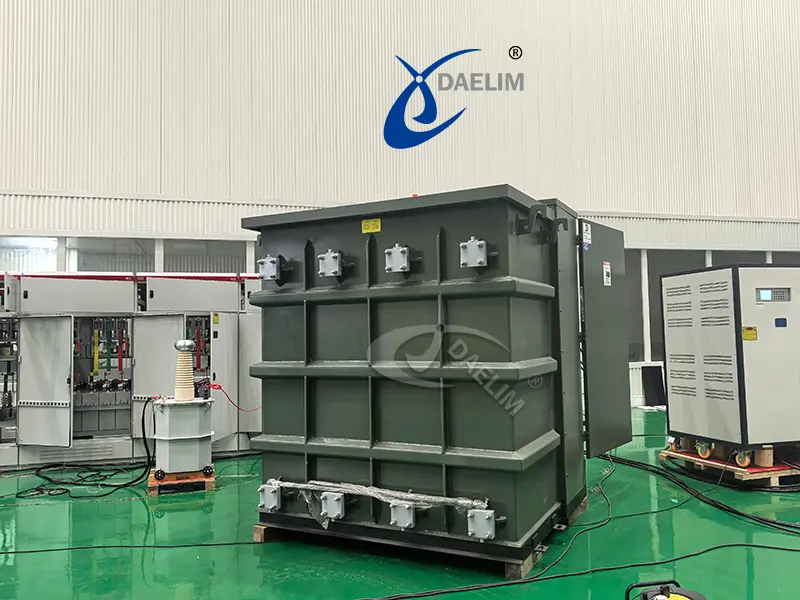

At Daelim Transformer, we understand the importance of the reliability of the transformer and how it ensures reliable power. That’s why every unit we make goes through a strict quality check process, capacity validation, and testing before it is dispatched.

Partner up with Daelim if you are looking for a transformer built to perform and tested to prove. With global certifications, fast delivery, and decades of experience delivering to big names, we give you peace of mind that our transformer provides reliability.

Related Products

Related Article

Round Coil vs. Rectangular Coil for Transformers

The transformer coil is a key component that manages incoming and outgoing voltage. This article provides a detailed overview of transformer coils, explaining the structure and function of round and rectangular types. It also compares their design, performance, and advantages in different applications to highlight which type works best in specific conditions.

Station Service Transformers: Functions, Types, and Applications

Station Service Transformers (SSTs) are essential in power plants, supplying electricity for internal operations. Though similar to standard transformers, they are designed for specific generation tasks. This article explains their functions, features, and types, and discusses key sizing and selection criteria to help understand their role in efficient power plant operation.

Power Transformer Solutions for Blockchain Computing Facilities

A successful blockchain computing operation requires not only high-performance hardware but also a reliable power infrastructure. Transformers play a central role by stepping down grid voltage to the precise levels needed for computing units. Choosing the right transformer enhances efficiency, reduces downtime, prevents electrical stress, and protects costly equipment, ultimately improving operational stability and profitability.

Stainless Steel vs. TransArmour: Comparing Transformer Corrosion Protection Solutions

Transformers are vital in power systems, but corrosion from moisture, pollutants, and weather threatens their performance and lifespan. To prevent failures and downtime, facilities use corrosion protection solutions such as acid-resistant stainless steel tanks or the modern TransArmor coating system, which offers lightweight, cost-effective, and highly durable protection for long-term transformer reliability.

Transformer Pressure Relief and Fault Detection Devices

Transformers are critical in modern power systems, but without precautions, they can fail dangerously due to high pressure, overheating, or internal arcing. Safety devices—such as pressure relief valves, pressure sensors, temperature sensors, and Buchholz relays—are integrated to detect abnormalities early, protect equipment, and prevent outages or catastrophic failures.

Underground vs. Overhead Power Distribution: Which Transformer Solution Fits Your Needs

There are two main types of power distribution systems: overhead and underground. Overhead systems are cost-effective and easy to install, commonly used in rural areas. Underground systems offer better reliability, safety, and aesthetics but come at a higher cost. Each system has its advantages depending on the project's needs and budget.