Station Service Transformers: Functions, Types, and Applications

Station service Transformer (SST transformer) plays a crucial role in electrical power generating plants that are used to produce electricity for different purposes. These Transformers appear to be similar to any other standard Electric Transformer; however, they are designed and developed to perform a particular task in electricity generating plants.

Our article is about understanding the SST Transformers. We will discuss what the station service Transformers are, what their key functions and features are. We will also discuss the different types of electrical Transformers that are used as station service Transformers and we will also consider the sizing and selection criteria of these SST transformers.

Contact Daelim TransformerWhat Is a Station Service Transformer?

A station service transformer is a special type of Electrical Transformer that has been specifically designed and developed to take high voltage electricity from a substation or a power generating plant and deliver it in lower voltage that can be used to power the systems and control equipment of that power plant or the substation.

These electrical transformers are installed within the power plant or the electrical substation to ensure that all the internal systems of the substation or power plants like the battery release charger, switchgears, the HVAC system of the power plant and the lighting of the substation get safe and reliable electricity.

You might consider the station service Transformer as a basic distribution transformer; however, the distribution transformer is responsible for distributing electricity to the end users, whereas as per station service transformer working principle, they are only responsible for providing electricity to the auxiliary systems of the electrical power plant or electrical substation.

Key Features and Functions

There are certain features and functions of the Station service Transformer that separate it from a standard Electrical Transformer that you use in the distribution of the electricity. The following are the key features and functions of a standard station service transformer.

- Station service transformer is always a step down Electrical Transformer as it is responsible for receiving high voltage electricity and stepping it down to a lower voltage electricity that can be utilised by the machinery and electrical equipment of the substation.

- The main responsibility of the station service transformer is to supply electricity to the auxiliary systems like station lights, control system of the substation, circuit breakers of the electricity distribution system and the lubrication unit of the main substation.

- One of the key features of the station service transformer is that these electrical Transformers are designed and developed to work continuously 24 hours a day and 7 days a week under high load without failure and without compromising the efficiency of the system.

- To ensure that these Transformers remain reliable, these Transformers are designed by keeping in mind the rated capacity, thermal protection and monitoring systems required for the reliable operation of substations and electrical power generating plants.

- As the station service Transformers are a key part of the electric power supply system of the substation and electrical power generating plants, they are built with robust safety features like fire resistance and features like surge arresters and insulation monitoring sensors are also installed to ensure safety to the maximum.

- Like any standard Electrical Transformer operation, the station service Transformer operation also produces a lot of waste heat and to remove that waste, there are several types of cooling system options available for station service transformers. Depending on the type of Electrical Transformer used in station service applications, you can either have a dry type cooling system or oil immersed based cooling system.

Types of Station Service Transformers

Depending on the unique application of the electrical power generating plant or the substation, there are different types of station service Transformers that can be used. There are 4 main categories from which you can select any one type of Electrical Transformer to be your station service transformer.

Dry Type Station Service Transformers

The dry type station service transformer is a dry type Electrical Transformer whose winding has been isolated and insulated using epoxy resin. As these Electrical Transformers do not use any type of oil for insulation and isolation purposes, the cooling cannot be done using oil, so a natural or air forced cooling system is used in these Electrical Transformers.

The dry type station service transformer is a dry type Electrical Transformer whose winding has been isolated and insulated using epoxy resin. As these Electrical Transformers do not use any type of oil for insulation and isolation purposes, the cooling cannot be done using oil, so a natural or air forced cooling system is used in these Electrical Transformers.

These electrical Transformers are best suitable for indoor station service applications where you will install your station service transformer inside a building or inside an enclosure. These transformers should only be used for station service applications where there is a low risk of fire.

These dry type station service transformers need less maintenance; however, they have limited power capacity and cannot be recommended for high power and large electrical power generating plants or substations.

Oil Immersed Station Service Transformers

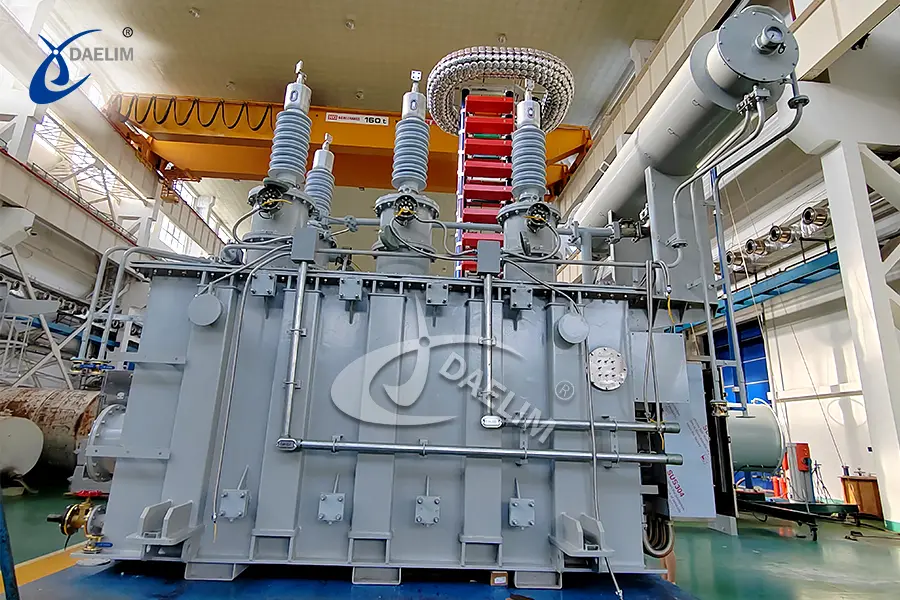

Oil immersed electrical Transformers are one of the most widely used types of station service Transformers. These Electrical Transformers use a specific type of oil for the insulation and isolation of their winding and core assembly and the same oil is used for the cooling purpose. In this manner, one single part of the Electrical Transformer performs multiple functions. The cooling capacity of this transformer oil is much more than that of the dry type cooling system of Electrical Transformers. This makes these oil type electrical Transformers far superior in cooling capacity than that of the dry type station service transformer.

These oil immersed station service transformers are recommended for applications where the Electrical Transformer will be installed in an outdoor environment because the size of these Electrical Transformers is much greater than that of the dry type Transformers and cannot be recommended for indoor applications. These Transformers can handle much higher load capacity than that of the dry type Electrical Transformer, so they are also recommended for all types of large electrical power generating plants and substations.

Pole Mounted and Pad Mounted Station Service Transformers

Depending on the size of the station service Transformer and the nature of the application for which the station service transformer is being utilised, you can have either a pole mounted Electrical Transformer or a pad mounted station service electrical transformer. The pole mounted electrical transformers are widely used for light applications where the Electrical Transformer is much more lightweight and compact in design and they are commonly installed in remote substations.

The pad mounted electrical transformers are usually preferred for heavy duty applications where the Transformer size is large and the Electrical Transformer is much heavier as compared to the pole mounted Electrical Transformer. These station service Transformers are installed on the ground after making a proper base for the installation and these Transformers are usually secured on the foundation using an enclosure.

Applications of Station Service Transformers

There are multiple scenarios and environmental conditions in which the station service Transformer can operate. Based on that, the following are the four main applications for which the station service transformer can be used.

- The station service transformers are most widely used in electrical power generating plants. Independent of the nature of electrical power generating plants, these station service Transformers can be used in thermal power plants, hydroelectric power plants and nuclear power plants where they can be used to power the control systems of the turbines of thermal power plants, the control systems of the hydroelectric power plants, the pumps, fans and the cooling systems of the nuclear power plant.

- These station service Transformers are also widely used in substations where these electrical transformers are used to power different functions and features of a substation. These Electrical Transformers can power the relay rooms, SCADA systems and the communication panels of the substation.

- These station service Transformers can be found in heavy industrial facilities, mostly related to the petroleum industry, where the industry has its own power generating systems and these station service Transformers are responsible for powering the control systems of the power generating setup.

- The station service Transformers can also be used as an emergency or a backup system in the case of any accident or fault in the main electrical system. These station service Transformers can remain operational and power the crucial and critical components of the electrical power generation and distribution system.

Station Service Transformer Sizing and Selection Criteria

It is very important to select a station service transformer that has been properly sized and properly designed for your specific application. The selection of a station service Transformer will depend on the auxiliary load demand and operating conditions under which the Transformer will operate.

Power Capacity

The first factor in the station service Transformer sizing and selection criteria is the power capacity against which you need the station service transformer. This will define the maximum electrical load that you need to connect to the station service transformer.

You may enjoy: Ultimate Guide To Transformer Sizes and Ratings

Load Profile

The second factor is the load profile against which you need a station service transformer. Depending on the application, a station service Transformer might face a continuous load profile, peak load profile, or a fluctuating load profile. You need to design a special Electrical Transformer for each type of load profile.

Voltage Range

When designing or selecting the station service Transformer for your specification, you should keep in mind the voltage range that you will be providing to your Electrical Transformer and the voltage range that your electrical load will demand from the Electrical Transformer. The Transformers selected for the application must satisfy the specific voltage range in order to ensure safe and reliable supply of electricity in an efficient manner.

Safety Margin

Depending on the sensitivity and critical nature of the application, you need to put a reasonable safety margin when selecting the power capacity and voltage range of your station service transformer. For example, for a station service Transformer installed in a nuclear power plant, you need much more safety margins and redundancy due to the critical nature of the application compared to a small diesel generator powered electrical power generating plant.

Installation Environment

The station service Transformer sizing and selection also considers the installation environment where the Electrical Transformer will be installed and operated. The Transformer design, size and selection criteria will change depending on applications like indoor installation, outdoor installation, or based on operating environment conditions like humidity and ambient temperature.

Following are some examples of station service transformer sizing and selection.

| Application Area | Load (kVA) | Suggested Transformer Size |

| Small Substation | 20–50 | 75 kVA |

| Large Substation | 100–200 | 250–500 kVA |

| Thermal Power Plant | 300–1000 | 1 MVA+ |

Station Service Transformer Price

It is not possible for us to deliver you a single station service Transformer price here because the station service Transformer price depends on several factors that we have experienced.

It is not possible for us to deliver you a single station service Transformer price here because the station service Transformer price depends on several factors that we have experienced.

- The first factor is the rated power capacity of the transformer and the rule is simple here: the larger the rated power capacity of the Electrical Transformer, the higher will be the cost.

- Station service Transformer price also depends heavily on the type of transformer used for the specific application. Oil filled Electrical Transformers cost more than dry type Electrical Transformers.

- The voltage class of the Electrical Transformer also affects the price of the station service transformer. The higher the voltage required for the specific application, the higher will be the cost of the Electrical Transformer.

- The number of functions and features added into the Electrical Transformer will also increase the cost of the station service transformer. So, the cooling system attached to the Electrical Transformer and the protection system like fire detection systems, thermal detectors and other monitoring systems attached to the Transformer will increase the cost.

- Another factor that will affect the final cost of the station service Transformer is the installation requirements for your specific application. The infrastructure you need to set up before installation of the transformer will define the installation cost of the Electrical Transformer.

Get it free: How Much is a Transformer?

Conclusion

Station service transformers are a vital part of our electricity generation and distribution system because these Transformers are installed in power generating plants and substations and they are responsible for providing electricity to the control systems, safety systems and other tagged systems of the power generating plants and substations. These electrical Transformers are always step down Electrical Transformers because they are responsible for taking high voltage electricity from the power generating plant or substation input and converting that high voltage electricity to a level of voltage that can be considered safe and reliable for the load.

Follow Up

We at Daelim design, develop and supply station service Transformers of all types, sizes, power capacities and voltage ranges. Our team of expert engineers can design and develop station service Transformers for any custom needs and as per client requirements. With decades of experience, our team can design Electrical Transformers that satisfy all types of international standards like those of IEEE, IEC and others.

If you have any questions related to station service Transformers, contact our team and they will help you through the process.

Related Products

Related Article

GIS Mobile Substation Project , Ecuador

Built in 2015, this GIS was built in a power plant in Ecuador. The high-voltage components are filled with SF6 gas as insulation and arc extinguishing medium. The main function is to protect, measure and dispatch the power system.

13.8 kV 10.5 MVA Substation Transformer for Ecuador

A customer from Ecuador contacted Daelim Transformer for a 10.5MVA substation transformer (13.8kV high voltage, 2.4kV low voltage). Daelim Transformer provided a customized solution, conducted virtual factory tours, ensured rigorous quality control via video inspections, and offered post-delivery online training and ongoing support, fostering a successful partnership.

Canadian 69 kV Substation Transformer Project

Today, we are excited to present a case study on a 69 kV substation transformer project by Daelim Transformer. Our Canadian client required a step-down transformer for their substation to connect with the hydroelectric grid in Quebec.

2000 kVA Oil immersed Substation Transformer For Portugal Market

Today, we introduce Daelim Transformer's export of a 2000 kVA oil-immersed substation transformer to Portugal. This transformer represents our commitment to delivering high-quality electrical solutions to global markets. With meticulous design and engineering, this transformer is tailored to meet the specific needs of our customers in Portugal, ensuring reliable performance and efficiency. Daelim Transformer continues to uphold its reputation for excellence, providing innovative solutions that power progress and reliability worldwide.

4500 kVA Substation Transformers for Australian Mining Site

Today, we introduce a project by Daelim Transformer aimed at supplying transformers to a mining site in Australia. This project entails the provision of two units of 4500 kVA substation transformers tailored to fit the narrow confines of mining tunnels. Due to space constraints, the transformers need to be compact in size and mounted on mobile racks for easy maneuverability within the mine shafts. This necessitates meticulous design to meet the strict dimensional requirements set by the client.

69 kV Power Transformer for Substation in Pennsylvania

Daelim recently completed the design, supply, and installation of a custom 69 kV transformer for a substation in Pennsylvania. This high-efficiency, three-phase transformer is engineered for reliability, scalability, and long-term performance, ensuring a stable power supply to the substation. Key features include low load losses, minimal maintenance, high insulation levels, and flexible cooling options. The solution enhances grid stability, supports future expansion, and minimizes energy consumption, reinforcing Daelim’s commitment to quality and innovation in power systems.