How Much is a Transformer

Electrical transformers are everywhere. They are in our electrical substations and in our residential areas and in all types of industrial areas. This is because they are the only electrical device responsible for delivering us safe and reliable electricity.

Due to such importance in our electricity distribution system and such widespread use around us, there are buyers of electrical transformers that buy transformers for all types of use and applications. Understanding transformer pricing is very important for any type of electric Transformers buyers, industries and businesses.

It does not matter whether you are purchasing a unit for your manufacturing plant or you are upgrading your infrastructure for a power utility system, budgeting effectively for transformer purchase requires knowing what drives the transformer cost and what aspects are based on the electrical transformer types and your requirements.

The article is all about understanding how much a transformer is. We will help you understand the factors that are involved in deciding the final price of an electrical transformer and how the price can change based on the transformer types and your application requirements.

Get PriceFactors That Influence the Cost of a Transformer

Electrical transformers are complex electrical devices that work to regulate electrical voltage across them. Depending upon the requirements set by the application against which the electrical transformer is being designed and developed, the cost of the electrical transformer can vary. There are several factors that influence how much a transformer is. We will discuss each and every factor here in detail in order to help you understand how this factor defines the final cost of the electrical transformer.

Power Rating (kVA or MVA)

One of the most basic and one of the most prominent factors that influence the cost of an electrical transformer is the power rating of the electrical transformer. The Transformer power rating is measured in kilovolt amperes or in large transformers, megavolt amperes. The higher the value of the electrical power rating of the electrical transformer, the larger the transformer will be and the more materials, design complexity, difficulty in manufacturing and assembly will be involved. All this in the end will add up to the cost of the electrical transformer. There is a very simple relation between transformer power rating and the cost of the electrical transformer the higher the power rating of the electrical transformer, the higher will be the final cost of the electrical transformer.

Type of Transformer

The second factor that plays an important role in deciding the final cost of the electrical transformer is the type of electrical transformer that is specifically needed by the application or demanded by the client. Broadly speaking there are four main types of electrical transformers from which the client can select any one depending on the requirements of its specific application.

Dry Type Transformer

The first type of transformer here is the dry type electrical transformer that uses an epoxy resin to isolate the electrical transformer winding from the outer atmosphere. The same material is also used to insulate the assembly of the core and transformer winding. The dry type transformer uses a dedicated cooling mechanism to remove all types of waste heat that is produced in the transformer during its normal operation.

Due to these unique features, dry type transformers are considered safer and are the preferred choice for indoor applications. However adding these features into the transformer increases its cost many times.

Oil Filled Transformer

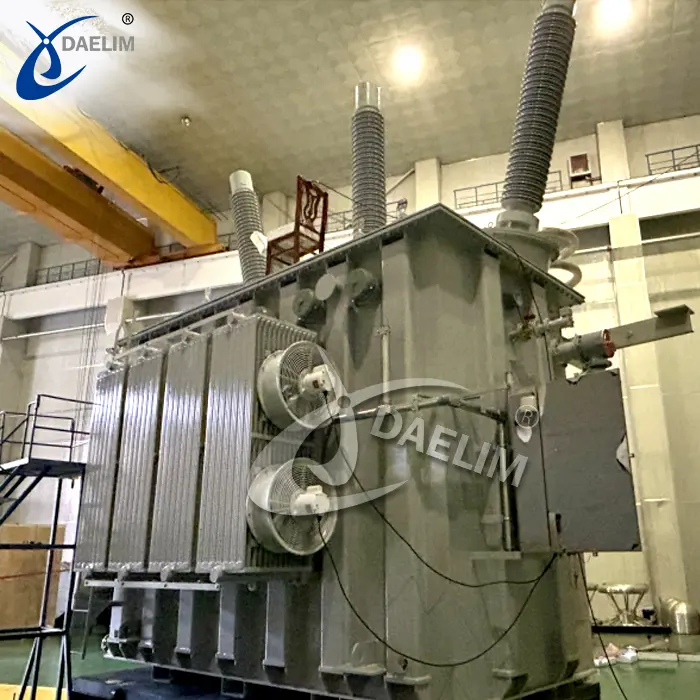

The second type of electrical transformer is the oil filled transformer that uses oil for insulation and isolation purposes. The tank of the transformer contains the core and winding assembly and all other major parts are filled with transformer oil that completely submerges the parts present inside the electrical transformer tank.

These transformers usually rely on the transformer oil for cooling during operation; However dedicated cooling mechanisms like forced oil, forced air systems might be used in the case of large power transformers.

These transformers are much larger in size when compared to the dry transformer because these transformers need a huge tank to contain all the transformer parts and transformer oil. However due to simpler design and easy manufacturing, oil filled transformers are much cheaper when compared with the same power rating dry type transformer.

Single phase electrical transformers can be either dry type or oil filled transformers; However they are specifically designed for applications that only involve single phase electrical current. These electrical transformers are very simple in design and are much easier to manufacture and assemble, so they are much cheaper and they are always recommended for light applications such as residential load or light duty industrial load.

Three Phase Transformers

Like single phase transformers, the three phase electrical transformers can also be dry type and oil type transformers. However due to their complex design and high power applications, three phase electrical transformers are most of the time oil filled transformers. These transformers are specifically designed and built for heavy duty applications involving three phase electrical current.

Like single phase transformers, the three phase electrical transformers can also be dry type and oil type transformers. However due to their complex design and high power applications, three phase electrical transformers are most of the time oil filled transformers. These transformers are specifically designed and built for heavy duty applications involving three phase electrical current.

These transformers are most of the time used for heavy duty industrial applications and are always a vital part of electricity distribution systems. The national grid systems and the local distribution systems always distribute electricity in 3 phase electrical current, so all these transformers are always three phase transformers.

Due to the bigger and more complex design of three phase electrical transformers, the cost of these transformers is much higher as compared to single phase electrical transformers.

Voltage Rating

The third factor here is the voltage rating against which the electrical transformer is being designed and developed. The voltage rating plays a key role in deciding the final transformer cost, as transformers designed and developed for delivering high voltage are usually developed in a much more complex and heavy duty manner for safety and reliability of operation. Based on the voltage, electrical transformers are divided into three categories and each has its own range of cost.

The third factor here is the voltage rating against which the electrical transformer is being designed and developed. The voltage rating plays a key role in deciding the final transformer cost, as transformers designed and developed for delivering high voltage are usually developed in a much more complex and heavy duty manner for safety and reliability of operation. Based on the voltage, electrical transformers are divided into three categories and each has its own range of cost.

Our electrical transformers that are designed and developed to deliver voltage ratings of less than 1 kilovolt are considered small electrical transformers and they cost much less than any other transformer due to their simpler construction.

The electrical transformers that are designed and developed to deliver electrical voltage of above 1 kilovolt and less than 70 kilovolts are considered medium voltage transformers and they cost more than low voltage transformers due to high insulation requirements and have much higher cost as compared to the low voltage transformer.

Electrical transformers that are designed and developed to deliver electrical voltage of above 70 kilovolts are considered high voltage transformers and these types of transformers are usually part of substations or power grid systems. These transformers need a suitable insulation system and a dedicated cooling system to tackle the waste heat produced during transformer operation. This significantly increases the final cost of the electrical transformer.

Material Used

The material from which the electrical transformer and most of its parts are manufactured plays an important role in deciding the final cost of the electrical transformer. The electrical transformer core and the transformer winding are two of the most crucial parts of the electrical transformer and the material used for the construction of the transformer core and for the transformer winding plays a significant role in the final price of the electrical transformer.

Manufacturing a high end electrical transformer that can deliver safety, reliability and manage the sensitivity of operation needs high quality material for the manufacturing of transformer winding and the transformer core. These high quality materials cost a lot and thus increase the final cost of the transformer.

High grade silicon steel is a standard material for the transformer core construction and it costs less compared to other materials. The amorphous metal cores reduce losses in the transformer and ensure efficiency and reliability of operation; However it increases the manufacturing cost of the electrical transformer.

Similarly, for transformer winding, aluminum winding is now considered a standard material due to lower cost. However to manufacture a winding that can manage sensitive electrical load, you need to manufacture the transformer winding using high quality copper material. This is because the electrical conductivity of copper material is much more than that of aluminum. However the cost of copper increases the final cost of the electrical transformer.

Installation and Accessories

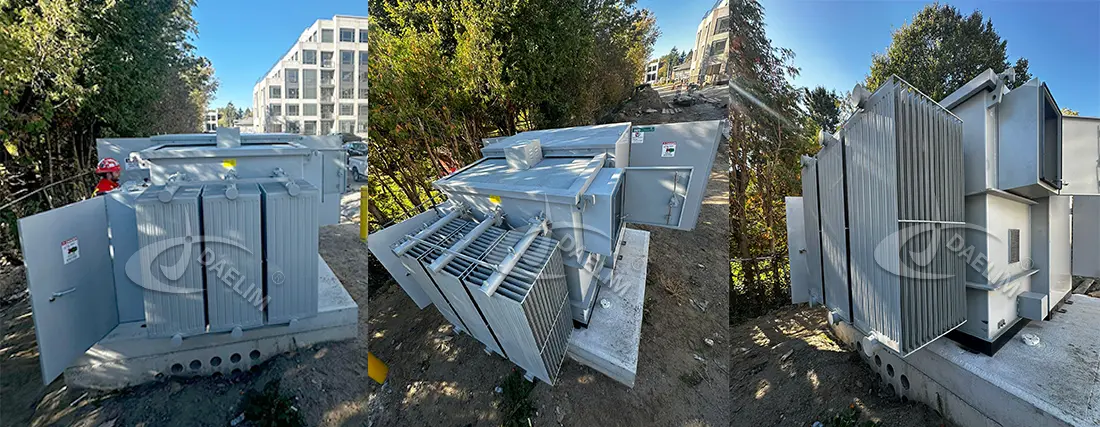

Another factor that is important in understanding the cost of an electrical transformer is the accessories needed with the electrical transformer for any specific application to meet specific requirements set by the client and the installation requirement of a specific site.

Depending on the transformer application or specific location, you might need to have an enclosure for your electrical transformer for its outdoor installation. This will add to the final cost of the product being delivered to the client. Other than this, in most outdoor applications, you might need a specific or dedicated cooling system for your electrical transformer—especially in those areas where the temperature during a hot summer day can reach up to 50 degrees Celsius. The dedicated cooling system will increase the cost of the final product being delivered to the client.

Similarly, depending on the sensitivity of the electrical appliances being operated by the electrical voltage being provided by the electrical transformer, the transformer might need to be equipped with a high quality surge protector to protect the sensitive equipment from any type of voltage or current surge in case of any issue with the transformer or electricity supply system.

With all the accessories, the electrical transformer needs to be transported to the required location and needs to follow a specific installation procedure to safely install the electrical transformer at the required site. Now depending on the distance to be traveled and the physical constraints of the space or the constraints offered by the installation site, the cost of transportation and installation may vary and it might increase the final cost of the electrical transformer to be delivered to the client.

Transformer Cost by Type and Use Case

If we consider different applications and scenarios for which the transformer is being used, then we can divide the transformer into three main categories and we can have an approximate cost that is generally needed to be paid to have a transformer.

Residential Transformers

Residential transformers usually range from a small size to a medium range electrical transformer that can cost you anywhere from $1,000 to $7,000 depending on the power capacity, type of electrical transformer and the voltage rating you need for your residential application.

Industrial and Commercial Transformers

If you need an electrical transformer to satisfy your industrial machinery needs like manufacturing industry machines or data centers or you need to power a specific mine, then you need a medium to large size electrical transformer that can cost anything from $7,000 to $50,000.

Utility Scale Transformers

If you are looking for an electrical transformer for utility scale applications like a power transformer for substations or a power transformer for your national substation, then you are looking for a high power capacity high voltage electrical power transformer that can range anywhere from $30,000 to $200,000.

If you are looking for an electrical transformer for utility scale applications like a power transformer for substations or a power transformer for your national substation, then you are looking for a high power capacity high voltage electrical power transformer that can range anywhere from $30,000 to $200,000.

Price Breakdown by Transformer Size

| Size | Power Rating | Typical Applications | Approx. Price Range (USD) |

| Small | ≤ 100 kVA | Residential, small offices | $2,000 – $5,000 |

| Medium | 100 – 1000 kVA | Industrial, commercial | $7,000 – $30,000 |

| Large | ≥ 1000 kVA | Utilities, large industry | $30,000 – $200,000 |

Transformer Price Estimates and Examples

| Type | Power Rating | Approx. Price (USD) | Typical Use Case |

| Dry Type | 100 kVA | $2,000 – $5,000 | Commercial buildings |

| Oil Filled | 500 kVA | $7,000 – $15,000 | Small industrial plant |

| Pad Mounted | 1000 kVA | $20,000 – $35,000 | Utility distribution |

| Substation Grade | 5 MVA | $30,000 – $200,000+ | Power stations, substations |

Learn more about Utility Transformer

How to Get an Accurate Transformer Quote

We have delivered you a very complete and concise piece of content on how many factors there are that decide the final cost of an electrical transformer and now we have some tips for you to get an accurate transformer quote.

- You need to specify whether you need a standard transformer or if you have any custom requirements.

- You need to provide very specific load requirements like the input voltage of the transformer, the output voltage that you need from the transformer, the frequency at which you need the voltage and the environmental conditions like indoor/outdoor installation, temperature, humidity and expectations of thunderstorms or snowstorms.

- You need to select the manufacturer or the service provider that can ensure compliance with all types of international standards and offer warranty support.

- There are a number of tests that are performed on electrical transformers called factory acceptance tests and site acceptance tests. These tests add a significant cost to the transformer and you need to be clear with your service provider whether they will provide the tests from their end or you need to hire a third party to perform these tests.

Get it free: A Complete Guide on Transformer FAT Test

Conclusion

Electrical transformers are a crucial part of our electricity distribution system and one of the most important parts of our existing living infrastructure. These electrical transformers are everywhere and part of everything that needs electricity to operate. These electrical transformers can cost you a fortune, as they can prove very costly if you do not understand how the cost of these transformers is decided. We have delivered you different factors that influence how the final cost of an electrical transformer is decided and you need to follow specific procedures to understand what the cost of your final product will be.

Follow Us

Daelim Transformer offers electrical transformers of every type, size, power capacity and wide voltage range. Each and every electrical transformer that is designed and developed by us is done by following all types of international standards specified by our respected clients. We are providing high quality and standard services throughout the United States of America and we have a complete distribution network in Canada, Australia, Europe and other countries around the globe. If you have any questions related to the electrical transformer please contact us and our team will help you get the best quote for your specific requirements.

Related Products

Related Article

Future Trends in Transformer Technologies and Sustainable Solutions

The energy sector is moving toward sustainability, digitalization, and decentralization, driving rapid transformer evolution. Modern transformers go beyond voltage regulation, offering smart features, higher efficiency, and adaptability. They play a crucial role in addressing today’s energy challenges, supporting cleaner, more resilient, and technologically advanced power systems worldwide.

How Transformers and PDUs Work Together for Data Center Power

In data centers, uninterrupted power is crucial. Transformers step down high-voltage grid power to usable levels, while PDUs distribute it to IT infrastructure. Together, they maintain continuous, efficient power flow, preventing costly disruptions even during brief outages.

How much electricity is lost in Transmission

When electricity is transmitted from a utility to consumers, some energy is inevitably lost, making it a costly aspect of modern power systems. These losses occur during transmission and distribution, affecting both energy efficiency and operating costs. Annually, about 5–8% of generated electricity is lost, highlighting the need for improved infrastructure and energy management strategies.

Transformer Overcurrent Protection

A transformer is vital in power distribution and industry but vulnerable to overcurrent faults from overloads, short circuits, or system issues. Such conditions can damage components, shorten lifespan, and cause financial losses. Hence, overcurrent protection is not optional but essential to ensure reliability, safety, and cost efficiency in transformer operations.

Top 5 Mistakes to Avoid When Choosing Transformers for Blockchain

Reliable electricity is essential for blockchain. A key factor in every successful mining farm is the right transformer. Whether for small setups or large-scale industrial blockchain operations, choosing an efficient, dependable transformer ensures stable power, maximizes performance, prevents costly downtime, and supports the growing energy demands of blockchain infrastructure.

Beginner Guide To Iron Core Transformer

Iron core transformers are widely used due to their efficient magnetic flux transfer between primary and secondary windings. Their performance depends on core design and material quality. Made from iron, these cores offer superior magnetic properties. This article covers types, manufacturing processes, advantages, disadvantages, and applications, highlighting why iron cores outperform other materials in transformer construction.