Transformer Overcurrent Protection

A Transformer is an important device in the power-distributing and industrial electrical systems. However, like any other piece of equipment, it is also liable to suffer from electrical faults, overcurrent being one of them.

Be it overloads, short circuits, or abnormality in the system, overcurrents can damage the transformer components severely, reduce their life, and impose hefty financial penalties. Therefore, protection from transformer overcurrent is not just best practice; it is essential!

Contact Daelim TransformerWhat is Overcurrent in Transformers?

Transformer overcurrent or overload occurs when the electrical current through the transformer exceeds its current-carrying capacity as designed. There can be several causes for an overcurrent, including a sudden short circuit, prolonged overloading, equipment failure, or an external fault in the connected network. It is important to understand and protect against overcurrent to give protection to the transformer against faults and ensure safety during operation.

The two major classifications of overcurrent are:

Overload Current

When a transformer carries more load than it is designed for over an extended period. Overloading is usually gradual, which results in overheating and thus hastens the aging process of the insulation of transformer. Therefore, overload protection should be provided to the transformer so that such long-term damage can be avoided.

Short-Circuit Current

A short circuit always tends to produce an almost instantaneous current flow, much more than the normal current level, several times. This type of overcurrent may cause immediate and catastrophic failure if not cleared within a fraction of a second by the overcurrent relays used in transformer protection schemes.

Overcurrent here means serious consequences, especially on the insulation system of the transformer. Due to overheating and mechanical stress, insulation may become weak and winding may deform, tremendously affecting the lifespan of the power transformer. So, proper transformer overcurrent protection should be implemented to increase reliability and avoid expensive downtime.

Get it free: How to Manage Transformer Inrush Current?

Why Transformer Overcurrent Protection is Necessary

Transformer overcurrent protection is an important part of power system design to protect the transformer against damage due to excessive current. In the absence of proper protective devices, overcurrent may lead to serious operational and safety problems.

The most immediate danger associated with overcurrent is overheating; overheating rapidly causes degradation of transformer insulation materials. As the insulation weakens, there is an increasing risk of internal faults, which will in turn cause possible transformer failure. This situation is quite critical in a high-load environment, where even minor faults might escalate in no time if no corrective action is taken by the appropriate overcurrent relay for transformer systems.

Besides the technical stuff, transformer failure can have financial consequeses, as outages quickly result in a halt to operations, interruption of power supply, and damage to attached equipment.Using adequate short circuit protection in transformers can help to minimise costly downtime and ensure power continuity.

On the regulatory side, overcurrent protection settings must comply to safety standards to avoid penalties and compliance. International guidelines like IEEE C57, NEC Section 450.3 and IEC gives clear directions for the power transformer. Following those steps not only operates safely but also improves the reliability of the grid and the longevity of transformers beyond that.

You may enjoy: Transformer Protection Devices

Types of Overcurrent Protection for Transformers

Effective transformer overcurrent protection involves deploying a combination of protection devices and schemes to detect and isolate fault conditions. The systems ensure safe operation by keeping excessive current from damaging the transformer. The choice of method depends upon transformer size, application, and system voltage level.

The methods mentioned below demonstrate the most common types of overcurrent protections used on transformers:

1. Overcurrent Relay Protection

An overcurrent relay for a transformer is among the most widely used protective devices. The working principle is that when the current for a certain period exceeds a predetermined limit, it will send a trip signal to circuit breakers, which will then isolate the fault. Depending on the application, the relays would be time delay or instantaneous.

- Instantaneous Overcurrent Relays react to high current surges like a short circuit without any time delay.

- Inverse Time Overcurrent Relays allow temporary overloads but will trip if the overcurrent persists; thus, they are suitable for overload protection.

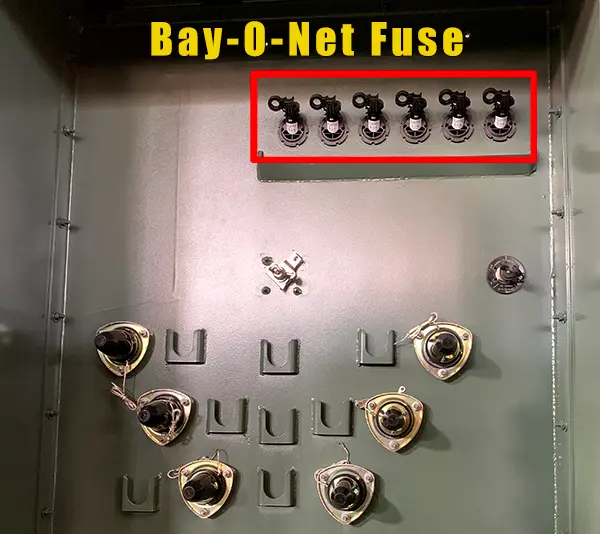

2. Fuses

Fuses are simple, cheap devices that give short-circuit protection in the transformer. When the current exceeds the rated value, the fuse element melts, breaking the circuit. They're commonly used in distribution transformers where cost and simplicity are key.

Learn more: Guide to Pad Mounted Transformer Fuse

3. Differential Protection

These relays measure the current entering and leaving the windings of the transformer and trip the instant a discrepancy between these two currents occurs. Although not generally regarded as overcurrent devices, differential relays are generally applied to medium to large-sized transformer protection schemes.

4. Thermal Overload Relays

These instruments protect against damage from overload currents, generating heating and gradually increasing temperature due to these currents. Monitoring temperature or simulating thermal effects helps to avoid insulation breakdown due to prolonged overcurrent.

5. Digital Protection Relays

Now, most modern transformers have digital or numerical relays, which perform all functions concerning over-current, overload, and transformer failure protection. These relays are programmable, more accurate, and enable remote monitoring and diagnostics.

Each of these protection arrangements forms part of the reliability, safety, and efficiency of transformer operations. The right permutation will, therefore, ensure complete protection of the power transformer against a wide spectrum of faults.

Conclusion

Protecting transformers from overcurrent is an important aspect of maintaining the safety, performance, and lifetime of electrical systems. Upgrading or designing a power infrastructure will always be a work in progress, with transformers as one must partner with a reliable transformer manufacturer.

Daelim Transformer could be the much-admired answer for transformer manufacture and supply because it brings its promises forth by making quality transformers with value-added modern protection features to meet the needs of various industries.

Get the best benefits from your investment by choosing Daelim Transformer to get advanced, reliable solutions that comply with standards on transformers. Contact us now and find out how we can support your next project with reliable products and expert service.

Related Products

Related Article

Electrical Transformer Protection Knowledge Guide

Electrical Transformer Protection Knowledge Guide, Transformers are very important equipment in the power system, so it is critical to ensure the normal and safe operation of transformers.

Difference Between Surge Protector and Lightning Arrester in Transformers

Transformers are vital in power systems but vulnerable to voltage surges from switching or lightning. Surge protectors and lightning arresters safeguard them. Though often confused, surge protectors handle internal transients, while lightning arresters defend against external lightning-induced overvoltages, each serving distinct protective roles to prevent damage to transformer components.

Transformer Neutral Protection Knowledge Guide

Daelim Transformer provides a comprehensive guide on transformer neutral protection, focusing on grounding faults. For directly grounded neutral points, zero-sequence current protection is recommended to isolate faults effectively. For ungrounded neutral points, zero-sequence voltage protection or gap zero-sequence current protection should be employed to prevent overvoltage risks. Additionally, transformers are equipped with various protective devices, such as gas protection, moisture absorbers, pressure release devices, and temperature measuring instruments, to ensure safe and efficient operation.

Future Trends in Transformer Technologies and Sustainable Solutions

The energy sector is moving toward sustainability, digitalization, and decentralization, driving rapid transformer evolution. Modern transformers go beyond voltage regulation, offering smart features, higher efficiency, and adaptability. They play a crucial role in addressing today’s energy challenges, supporting cleaner, more resilient, and technologically advanced power systems worldwide.

How Transformers and PDUs Work Together for Data Center Power

In data centers, uninterrupted power is crucial. Transformers step down high-voltage grid power to usable levels, while PDUs distribute it to IT infrastructure. Together, they maintain continuous, efficient power flow, preventing costly disruptions even during brief outages.

How much electricity is lost in Transmission

When electricity is transmitted from a utility to consumers, some energy is inevitably lost, making it a costly aspect of modern power systems. These losses occur during transmission and distribution, affecting both energy efficiency and operating costs. Annually, about 5–8% of generated electricity is lost, highlighting the need for improved infrastructure and energy management strategies.