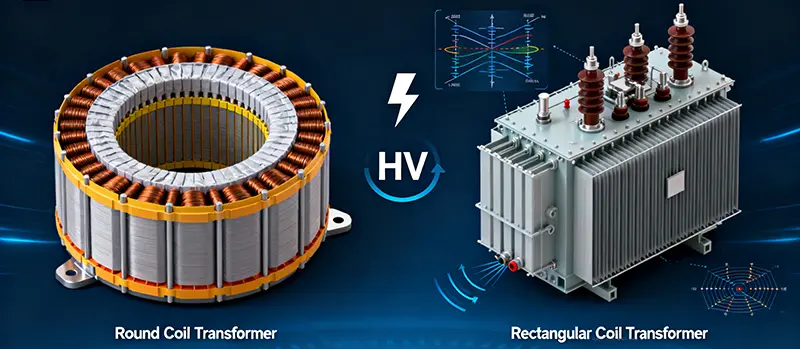

Round Coil vs. Rectangular Coil for Transformers

One of the major transformer parts is the transformer coil which actually receives the incoming voltage and works to control the outgoing voltage. In this article we will give you a very comprehensive overview about the transformer coil and how round coils and rectangular coils work in transformers. We will also discuss important design and working aspects of each transformer coil and how one coil type works better than the other in some specific scenarios.

Contact Daelim TransformerRound Coil for transformers

The round coils of electrical transformers are made from either copper or aluminium wires that have circular cross section profiles. The circular wire is winded into a cylinder or toroidal shape constructing cylinder or toroidal primary or secondary winding. This round coil is commonly used in round transformers or also known as toroidal transformers and also in high frequency transformers.

The round coils of electrical transformers are made from either copper or aluminium wires that have circular cross section profiles. The circular wire is winded into a cylinder or toroidal shape constructing cylinder or toroidal primary or secondary winding. This round coil is commonly used in round transformers or also known as toroidal transformers and also in high frequency transformers.

Key Features of Round Coil

Better Magnetic Flux Distribution

The circular winding constructed using a round coil provides a uniform magnetic field when current passes through its copper wires. This helps a lot in reducing the flux leakage and thus improving the overall efficiency of the round transformer.

Learn more about Transformer Efficiency

Less Material and lower weight

In any given number of turns and cross section area, the circular winding constructed using a round coil uses much less material as compared to any other cross section profile and winding type. Less material being used means the winding will be light weight and will cost much less as compared to other cross section profile and winding types.

Lower Resistance and Improved Efficiency

The circular winding constructed using round coil has smaller wire length compared to rectangular winding affected using rectangular coil so it offers much lesser resistance to the current flowing through the entire length of wire. This significantly improves the overall efficiency of the circular coil round transformer winding as compared to rectangular coil transformer.

Less Material Wastage

The process of constructing a round transformer winding using a round coil produces much less waste material as compared to the other shapes and winding types. This reduces the overall cost of the transformer winding and thus reduces the cost of overall transformer manufacturing.

Drawback of Round Coil

There are some certain drawbacks of using the wrong coil to construct circular winding.

When you make two turns of copper wire having a round cross section. Then you will observe that the two adjacent round wires have a small gap in between them. This small gap is only due to the circular cross section of the coil wire.

As this gap will be there between each two adjacent round wires so the packing density of circular winding that is constructed using round wire is much lower as compared to the world of using rectangular coil. Lower packing density means greater core volume and larger round transformer size for the same power rating and capacity when compared to the rectangular coil.

Another drawback of the round coil is that it became quite challenging to properly wind a round transformer winding using a round coil specially for large round transformers. The circular shape seems to be less stable as compared to the rectangular or square shape.

Rectangular Coil for Transformers

The rectangular coils windings of electrical transformers are also made from either copper or aluminium wires that have rectangular cross section profiles. The rectangular wire is winded into a square or rectangular shape constructing square or rectangular primary or secondary winding. This rectangular coil is commonly used in large power transformers, medium size power transformers, distribution transformers, and in all types of industrial transformers.

The rectangular coils windings of electrical transformers are also made from either copper or aluminium wires that have rectangular cross section profiles. The rectangular wire is winded into a square or rectangular shape constructing square or rectangular primary or secondary winding. This rectangular coil is commonly used in large power transformers, medium size power transformers, distribution transformers, and in all types of industrial transformers.

Get it free: Transformers Solutions for Industrial and Commercial Buildings

Key Features of Rectangular Coil

Higher Packing Density

Rectangular coils offer higher packing density as compared to the round coil. This is because there are no air gaps between two adjacent rectangular coils when the rectangular wire is being turned to construct the rectangular or square transformer winding. The angular shape of the wire is the only reason here, as wire has plane sides that when turned for transformer winding, does not allow any air gaps to be built between two adjacent wires.

Better Mechanical Stability

The square or rectangular transformer winding that is constructed using a triangular coil of much more and better mechanical stability as compared to circular or round transformer winding. In case of any electrical surge due to a fault or short circuit, the rectangular coil tends to maintain its shape and winding geometry much better as compared to the round coil.

Improved Heat Dissipation

The rectangular coil has much more surface area as compared to the round coil so it tends to dissipate the waste heat in a much better and efficient way as compared to the round coil. More surface area means more area being exposed to the cooling mechanism that can be natural air or transformer oil. This directly improves the winding and transformer life.

Reliability in Operation

The rectangular oil offers much more reliability and stability in operation of the Electrical transformer as compared to a round coil. This is because the rectangular coil has better stability in terms of mechanical structure, the separation and the ability to maintain the shape and continue to perform operation even after an electrical search for a fault like a short circuit.

Drawbacks of Rectangular Coil

Just like a round coil, the rectangular coil also has some drawbacks and most of these are only due to this specification of the coil.

As the rectangular coil has much larger perimeter compared to the ground coil, the length of the coil used in rectangular transformer winding will be much more as compared to the round coil. This means the rectangular coil will offer much more resistance in current flow as compared to the round coil. This means less efficiency and more losses during a standard transformer operation.

Another drawback of the rectangular coil is that its shape needs a dedicated and specialised winding technique to properly adjust each adjustment and wire and layer of transformer winding. Unlike circular wire that can itself adjust against the adjacent circular wire, the rectangular wire needs either manual or automatic adjustment to properly adjust each adjacent wire of the transformer winding. Increases the manufacturing time and cost of the end product.

Round Coil vs. Rectangular Coil for Transformer

Electrical resistance

The rectangular coil has much more electrical resistance as compared to the round coil and it is due to the fact that the rectangular coil has a higher perimeter as compared to the round coil.

Cooling Efficiency

The heat dissipation ability of the rectangular coil is much more than that of the round coil and it is due to the fact that the rectangular coil has much more surface area exposed to the cooling mechanism as compared to the round coil.

You may enjoy: What is Transformer Cooling and How is it done?

Electrical efficiency

The overall electrical efficiency of the round coil is much more as compared to that of the rectangular coil and it is due to the fact that the round coil has lesser perimeter and has offered smaller resistance to the current flows, improving the overall efficiency of the transformer.

Manufacturing Difficulty and Cost

Both round coil and rectangular coil have difficulties of their own during the manufacturing process but the round coil is a bit simple to manufacture when it comes to small scale winding but the difficulty increases as the winding size increases. The rectangular coil has a difficulty of its own and requires specialized winding up for efficient winding process. The final cost of the winding is always a bit less for Round coil and always a bit higher for a rectangular coil.

Get it free: How Much is a Transformer?

Space Utilization

The rectangular coil offers much better packing density compared to the round coil and has much smaller size as compared to the round coil. However, the smaller perimeter of the round means it utilizes much less material as compared to the rectangular coil. So the final weight of the round coil is much less than that of the rectangular coil. Also means the round coil needs less material and thus material cost of the round coil is less than that of the rectangular coil.

Applications

Due to the factors like lower heat dissipation lower packing density and mechanical stability issues the round coil is only use in small and light electrical applications whereas the rectangular coil due to its better mechanical stability, efficient heat dissipation, higher packing density, and moderate efficiency is used in all type of power and distribution transformers.

Conclusion

The round coil and rectangular coil both offer unique advantages of their own but also have limitations or drawbacks. The choice between the two depends on the specific application and performance requirements like heat dissipation, packing density, efficiency, material usage, ease of manufacturing and final cost of the winding. Engineers must evaluate these parameters to select the most appropriate coil type for their transformer designs.

Follow Up

A transformer coil or the transformer winding is a crucial part of any Electrical transformer. Round coil and rectangular coil of the two most commonly used types of coil in electrical transformers. Each type has its own advantages but also has limitations.

At Daelim Transformer, our engineers know the exact type of transformer coil that your specific application needs and will deliver you a transformer that best suits your project needs. All our transformer manufacturing processes meet international standards and all our electrical products meet international and regional standards including but not limited to IEEE, ASTM, ANSI, ISO, and others.

If you have any questions about electrical transformers, then Contact Us, and our team of experts will talk you through the process.

Related Products

Related Article

2MVA Live Front Transformer for a Residential Community in Canada

In 2024, a new 300-resident building in Ontario required a robust power solution to withstand extreme weather and meet rising urban demands. Daelim Transformer supplied a 44 kV 2 MVA live-front transformer, designed for dense residential environments. Installed in fall 2024, it now ensures safe, reliable electricity for daily needs and essential communal systems.

Strengthening Electricity Distribution Infrastructure in Canada through 500 kVA Platform Transformers

In 2024, a Canadian utility launched a grid modernization initiative to meet rising electricity demand. Central to the project were 60 custom 500 kVA single-phase platform transformers from Daelim Transformers, enhancing distribution reliability and service quality for hundreds of thousands of residential and small commercial customers across urban, rural, and remote communities.

All you need to know about transformer surge protection

Transformer surge protection ensures electrical transformers remain safe, reliable, and efficient by guarding against power surges caused by lightning or internal faults. The system uses sensors and protective mechanisms to prevent damage or failure. Understanding its components, operation, and recent advancements helps enhance transformer performance, minimize losses, and maintain continuous, safe electricity supply for industrial and residential use.

Fundamental of Medium Voltage Transformer

Medium voltage transformers regulate electricity between generation and distribution systems. They operate at intermediate voltages, ensuring efficient power transfer. This article explains their structure, working principles, components, applications, maintenance, and installation requirements, emphasizing their crucial role in stable, safe, and reliable electricity distribution networks.

K Factor Transformer Explained

In modern electrical systems, nonlinear loads are common in residential, commercial, and industrial applications, creating harmonic currents that stress transformers. The K-factor is a key transformer rating that measures its ability to handle these thermal effects and operate reliably under complex conditions. This article explains the basics of K-factor transformers, essential design considerations, and how they differ from standard transformers.

A Complete Guide to Nuclear Power Plant Transformer

Nuclear power plant transformers are specialized electrical transformers designed to endure extreme conditions. They ensure reliable power distribution, safety, and stability in nuclear facilities. This article introduces their design, performance requirements, and key features for engineering students and technicians interested in understanding their operation and manufacturing principles.