Understand the Transformer Lifespan

Just like every other electrical device the electrical Transformers have a defined lifespan. However, unlike other electrical devices, these electric transformers are so important and crucial in our electrical distribution system that the transformer lifespan is usually termed as the useful life of a transformer. This is because any sudden transformer failure will disturb the entire electricity Distribution system, so we need to replace the transformer after it passes its useful life.

To have a better understanding of the transformer life span why will explain you why Transformer like span is termed as the useful life, what are the factors that affect the Transformer lifespan, how you can calculate or predict the remaining life of transformer and how you can increase the expected useful life of your Electrical Transformer.

Contact Daelim TransformerFactors Affecting Transformer Lifespan

There are several different factors that can affect the Transformer lifespan and We will discuss each factor in detail to make you understand how each factor affects the Transformer lifespan.

There are several different factors that can affect the Transformer lifespan and We will discuss each factor in detail to make you understand how each factor affects the Transformer lifespan.

Design and Manufacturing Quality

First and the most important factor that affects the Transformer life Is how the transformer is designed and manufactured to deliver the power output. The Transformer lifespan highly depends on the quality of design calculations made before the actual designing of the transformer.

It also depends on the actual designing of the transformer parts and on the quality of the material used for the manufacturing of parts. At last it depends on the quality of manufacturing process and standards followed during the manufacturing of the transformer. All these design and manufacturing related Aspects pile up to define the useful life of a transformer.

Learn more about Transformer Design:

Key Principles of High Voltage Transformer Design

The Impact of Operating Environment on Transformer Design

Operating Conditions

The second factor that highly influences the Transformer lifespan is the operating conditions under which your Electrical Transformer has to perform. The operating conditions include the loading condition like operating load and the frequency of overloading and fluctuation of load between the minimum and maximum Power capacity of the transformer.

The operating condition also includes the temperature under which the Transformer has to perform and also the voltage stresses that the overvoltage and overloading conditions that are induced in the Transformer.

Environmental Factors

Environmental factors also play a crucial role in defining the transformer useful life. Environmental factors like the installation location, ambient temperature, humidity, and the weather together will influence the transformer lifespan.

A high ambient temperature will significantly increase the operating temperature of the Transformer and this will induce high thermal stresses in transformer parts like the Transformer winding. Similarly, the humidity and the weather will influence the quality of operations of a transformer like any due to lightning Strike will highly influence the Transformer.

Other surrounding factors of the installation site like the Mechanical Vibration and other types of mechanical stresses will also influence the Transformer lifespan.

Maintenance Practices

Maintenance is another factor and it is one of the most important factors that will influence the Transformer life span. After the design and manufacturing aspect the maintenance is the most important factor that can influence the Transformer useful life.

Maintenance is another factor and it is one of the most important factors that will influence the Transformer life span. After the design and manufacturing aspect the maintenance is the most important factor that can influence the Transformer useful life.

This is because the operating conditions and the environmental factors will always be there and they will influence to reduce the Transformer useful life but the maintenance factor is one that can overcome and reduce the impact and influence of the environmental conditions and the operating conditions on the Transformer.

Regular maintenance of Transformer will reduce the impact that extreme operating and environmental conditions have on the Transformer parts. So regular inspection, testing of Transformer parts, replacement of Transformer parts, cleaning and tightening of electrical connections will significantly improve and increase the Transformer.

Human Factors

Human factor is another aspect that can define the Transformer lifespan because in the end it is humans that are designing, manufacturing, operating, and maintaining these Electrical Transformers. Any incorrect design calculation or not following the standard procedure during the manufacturing of the transformer will significantly influence the transformer lifespan.

Similarly any mistake made during the operating of the transformer will highly influence the life of Transformer parts. Any mistake made during the maintenance of the transformer will also reduce the large fan of Transformers.

How long do transformers live?

The term Transformer useful life represents a lifespan in which the efficiency, reliability, safety, and maintenance of an electrical transformer remain in an acceptable range. This range of efficiency, reliability, safety, and maintenance can be either dependent on the application or is predefined by the manufacturer of the transformer.

There is no one single answer or a fixed number which we can give you on how long do Transformers live. The Transformer lifespan depends on the Transformer type, its size, its power capacity, material quality, build quality, and the manufacturer.

The thing that we can provide you on how long do transformers last, is the arrangement of years including the minimum number of years and the maximum number of years which can be considered as the useful life of a transformer.

Power Transformers Lifespan

Almost all Power Transformers are big with Power capacity ranging from hundreds of kilowatt to Mega Wars and they are always designed and 12 to perform in long term operations. They are mainly possible for regulating and transferring electricity from the power generating plants to the local distribution centres. The average power transformer lifetime or the number of years of its useful life changes from 30 to 40 years or can be even more depending on the manufacturer.

Distribution Transformers lifespan

Unlike power transformers the distribution Transformers are quite versatile in their design, size, and power capacity. Your power can have a distribution transformer of a few kilowatt to several hundreds of kilowatt in power capacity. The distribution transformer lifespan is relatively shorter than that of the Power Transformer and the main reason behind is the load type which is much more fluctuating than that of the Power Transformer and the distribution transformers are always subjected to harsh environment conditions as well. The distribution transformer life in Spain ranges from 20 to 30 years on average but this can be lower or higher depending on the application of the distribution transformer.

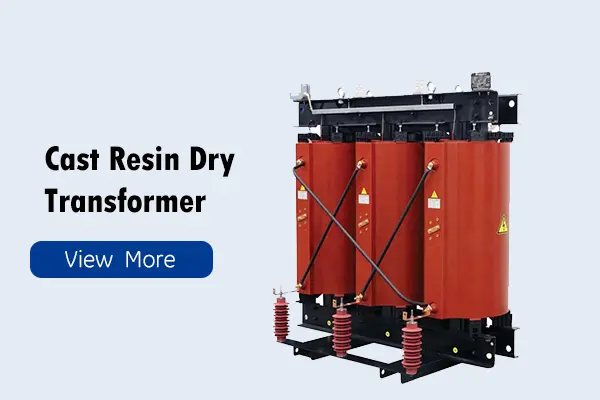

Dry Type Transformers Lifespan

Most electrical Transformers you see around your residential area are usually dry type Transformers and a wide range of distribution transformers are also dry types Transformers. These transformers are made robust and rigid to deliver safe electricity to residential and dedicated industrial sectors.

Most electrical Transformers you see around your residential area are usually dry type Transformers and a wide range of distribution transformers are also dry types Transformers. These transformers are made robust and rigid to deliver safe electricity to residential and dedicated industrial sectors.

With minimal maintenance requirement Dry type transformer lifespan ranges from 15 to 30 years but it is highly variable because the transformer size range is too wide to even deliver an approximate range of the lifespan of these transformers.

You may enjoy: Dry Type Transformer Cooling Methods

Oil Filled Transformers Lifespan

A good range of distribution transformer and the complete range of power transformer or all oil filled transformer.The all type transformers are usually big and they are designed and developed to deliver kilowatt Mega Awards of electricity and they are always installed for their ability in the operations. Any typical oil filled transformer life expectancy is between 25 years to 35 years depending on the level and commitment to the regular and scheduled maintenance of these Transformers.

Instrument Transformers Lifespan

The instrument transformers are the dedicated type of electrical Transformers and their design and development for metering and protecting the electrical systems. The lifespan of an instrument Transformer depends upon the accuracy required to protect the electrical system and the operating conditions under which the instrument Transformer has to perform. These instrument Transformers need regular inspection and testing to ensure performance and the extended useful life. An instrument Transformer life span ranges from 20 to 30 years.

High Frequency Transformers Lifespan

The high frequency transformers are another type of dedicated Transformers. These transformers are designed and developed for dedicated applications like switch mode power supply and inverters. The high frequency Transformer life span is usually 10 to 20 years and can be even lower due to the high frequency operations that induce much higher levels of stresses and thermal cycle in the Transformer winding section then any other standard or normally operating Electrical Transformer.

How to Inspect and Assess Transformer Lifespan

Understanding that the Transformer lifespan is highly influenced by the factors like manufacturing, design, operating condition maintenance and environmental factors, it's become highly important to regularly inspect and do transformer life expectancy calculation. This is because of the fact that any of the above mentioned factors can significantly reduce or worst case scenarios and the life of the transformer.

Understanding that the Transformer lifespan is highly influenced by the factors like manufacturing, design, operating condition maintenance and environmental factors, it's become highly important to regularly inspect and do transformer life expectancy calculation. This is because of the fact that any of the above mentioned factors can significantly reduce or worst case scenarios and the life of the transformer.

Following are the different types of inspections and testing that you can perform on your Electrical Transformer to access its remaining usefulness.

- A visual inspection test will help you determine the physical condition and any type of physical damage done on the Transformer parts. It will help you to locate corrosion or leak in the transformer and will help you remove or repair the affected Transformer part thus increasing its useful life.

- Electrical testing like the insulation resistance test, transformer load test, and the partial discharge detection test will help you identify any type of electrical issues with your Electrical Transformer. They will help you locate the problem and will guide you how to repair or replace that specific part so that that does not affect the Transformer lifespan.

- Similar to the electrical testing, the thermal scanning of the transformer will help you locate any type of defects caused by the overheating or will help you decide whether your transformer is overheating or not. This will prevent potential failure of your transformer.

Extending the Lifespan of a Transformer

Following are some tips that you should keep in mind to extend your Transformer lifespan.

- Always follow the international standards like that of ISO ASTM, ANSI, IEEE and more during the calculation designing and manufacturing stage of the transformer.

- Always install your Transformer using the standard installation manual provided by the Transformer manufacturer and always make sure that you transfer money is being installed in a well ventilated area and in location with minimum environmental influence and mechanical vibrations.

- Always make sure that your transformer is being regularly maintained and inspected and made in equal intervals.

- Always make sure that any damaged pod is replaced using the exact scene specification parts that are designed and manufactured following the same standard as that of the original part.

Conclusion

Understanding transformer lifespan is crucial for ensuring reliability, efficiency and cost effectiveness. Implementing proper maintenance, monitoring and operational best practices help transformers achieve their maximum service life, reducing failures and downtime. By addressing these factors through proper design, operation and maintenance the lifespan of a transformer can be significantly extended up to 10 additional years.

Follow Up

Electrical transformers are expensive and the Transformer lifespan is one of the most important factors during the selection and purchase of any specific Transformer type or transformer brand. We at Daelim Transformer offer transformers that are designed, manufactured, installed, operated, and maintained on international standards like ISO, ASTM, ANSI, IEEE and more. Our transformers offer extended useful life thus giving you the best value of your money.

If you have any questions related to transformers and their lifespan. You can contact us and we will talk you through the process.

Related Products

Related Article

What are Different Types of Transformer Repair & Field Service

This article explains the importance of transformer repair and field services for maintaining continuous, safe electricity distribution. It covers when repairs are needed, common transformer issues, types of repair and maintenance services, diagnostic tests, emergency services, retrofits, and factors to consider when choosing a service provider to ensure reliable operation.

Addressing the Iberian Blackout: A Wake Up Call

A major blackout in Spain and Portugal exposed critical grid vulnerabilities, especially with renewable integration, transformer infrastructure, and reactive power control. Daelim offers fast-delivery, high-quality, custom transformers—ideal for modernizing outdated systems and supporting renewable energy projects. Contact Daelim for reliable, future-ready transformer solutions.

Distributed Energy and Temporary Power

Daelim Transformer provides reliable, efficient solutions for the growing demands of distributed energy and temporary power systems, including solar, wind, and data center applications. With deep expertise and proven performance, Daelim ensures safe and sustainable electricity delivery while addressing the unique challenges of today’s evolving energy landscape.

The Impact of Operating Environment on Transformer Design

Electrical transformers are custom-designed based on specific application needs, not a one-size-fits-all model. While voltage input/output is important, other operating conditions also impact design. This article explores how environments like renewable energy plants and data centers influence transformer design, highlighting the importance of tailored solutions for efficient electricity distribution.

Dry Type Transformer Cooling Methods

This article explains various cooling methods for dry type transformers, detailing how each method works, the components involved, and their pros and cons. It aims to help readers choose effective and efficient cooling solutions by understanding different systems and their performance characteristics in transformer operation.

Guide to Transformer Failures

Transformer failure disrupts power flow from plants to users, with no substitute device available. This guide explains causes, types, categories, and severity levels of transformer failure, helping users understand and prevent such critical breakdowns to maintain reliable electricity distribution.