Guide to Transformer Failures

Electrical transformers are the only electrical devices that control the flow of electricity from the power generating plants to the electricity consuming electrical devices. If your Transformer fails then there is nothing else that can replace its working and regulate the flow of electricity from the power plant to the consumers. That's why it is highly important for you to understand Transformer failure. This electric transformer guide will help you understand all the factors that can lead to Transformer failure, different types of transformer failure, the different categories and the different levels of Transformer failure.

Contact Daelim TransformerFactors Leading to Transformer Failure

The electric transformers are quite rigid and reliable devices because they are designed and developed to work 24/7 with minimum maintenance requirements. However there are several factors that can lead to your transformer failure even if there is nothing wrong with your transformer.

Electrical Stress

The first and the most obvious factor you will face that leads to your transformer failure is the electrical stresses that you transfer more face during an entire useful life. Reason why this is the most obvious factor is that the transformer is designed and developed to regulate electricity and even the most normal conditions of electricity flow will produce some extent of electrical stresses on your electrical transformer parts.

Some specific electrical related scenarios that can lead to electrical stress development in your Transformer are as follows.

Overvoltage

Overvoltage is a condition where your electrical transformer receives more or higher electrical voltage than it is designed to operate. The voltage which is beyond the Transformer rating will produce a high level of Electrical stress especially in the Transformer winding and insulation region that can result in the insulation breakdown and development of phenomena called electric parking.

Short Circuit

Any abnormal condition in the electrical circuit that either provides electricity to the Transformer or draws the electricity from your Electrical Transformer can result in sudden surge for drop of electricity within the transformer circuit. This can produce a term called short circuit in any of the electrical connections of the transformer.

Reading more: Measures to Prevent Transformer Short-Circuit Accidents

Switching Surge

If your Electrical Transformer is facing a specific condition where the operating conditions for the demand from the transformer is changing frequently and quickly. Then this frequent switching operation will cause a transient voltage bike that can lead to a severe dielectric stress on the insulation of your Electrical Transformer winding.

Thermal Stress

After the electrical stresses the second most obvious and the most common factor that can lead to Transformer Failure is its thermal stress that is produced in your Electrical Transformer. Independent of the transformer type, size, and power capacity, every transformer produces waste during its operation.

Specific conditions that can produce high thermal stresses leading to the Transformer failure or as follows.

Overloading

Transformer overloading is a condition where you try to draw much more electricity or electricity at a much higher rate than your transformer is designed to provide. This specific overloading condition will make Transformer work continuously as its peak or maximum operating condition. This will result in the transformer producing much more heat at its winding section as compared to the normal working condition. Continuous production of large waste heat at the winding feel produced thermal stresses on the core, winding and transformer insulation. This can result in the deterioration of insulation and winding material.

You may enjoy: Why should the transformer load not exceed 85%?

Poor Ventilation

All Transformers need a proper ventilation system even at their normal working condition to remove the waste heat produced at their winding. If you have installed your Transformer in a place where there is a ventilation issue for the environment is not suitable to quickly remove it then this will produce a lot of thermal stress on your Transformer parts even if the transformer is working at its normal condition.

Try for free: Step-by-Step Guideline On Installing A Transformer

High Ambient Temperatures

Another factor that can produce thermal stresses on your Transformer parts is the high ambient temperature of the region over the place where you have installed your transformer. If you have installed your Transformer in a region where there is usually very high temperature during the date time then this will produce a lot of Thermos dresses on your Transformer parts specially the outer parts like electrical connections, bushing and Transformer tank.

Mechanical Stress

Other than the electrical and thermal stresses there are factors that can produce mechanical stresses in your Transformer parts. Mechanical stresses can result in permanent damage to the Transformer parts usually resulting in need of replacement of the part. The three main factors that produce mechanical stresses in your Transformer are as follows.

Vibrations

If your transformer is installed in house in a factory or manufacturing plant where there is high Mechanical Vibration due to operating machinery, then these mechanical vibrations can very easily be transmitted and transferred to different parts of your electrical transformer and can damage those parts. These vibration can specially and very easily damage any part is loosely connected or is manufactured using brittle material.

Handling Damage

Another factor that can result in your Transformer Failure is a damage part or a damage on the Transformer that has been done during the transportation or installation of the transformer. This is really the case because any such damage is initially removed during the first inspection of the transformer before it is operationalized but there are still changes that any damage to for that is not easily visible or detected during the inspection can result in transformer failure.

Fault Currents

Any faulty surge in the electric current that is flowing in the conducting wires of the electrical transformer can produce a very strong force that can easily damage the transformer insulation, winding or bend the Transformer Core.

Environmental Factors

Among all other factors there are also environmental factors that can result in your Transformer failure. All those factors are very minor and take a lot of time to affect the Transformer or any of its parts to the extent that it can result in transformer failure but there are some factors that can result in your Transformer failure.

Among all other factors there are also environmental factors that can result in your Transformer failure. All those factors are very minor and take a lot of time to affect the Transformer or any of its parts to the extent that it can result in transformer failure but there are some factors that can result in your Transformer failure.

- High moisture content around your Transformer can result in your Transformer failure if the water ingress degrades insulation resistance and promotes provision.

- The accumulation of dust degree and other promoters on your Transformer parts specially on the cooling system parts can result in transformer in efficiency and overheating.

- If your transformer is installed in a high proceed environment especially if it's installed inside a chemical treating plant then the chemical Expo here can accelerate the degradation of metal and insulation components resulting in transformer failure.

Aging and Degradation of Components

The last factor that can result in transformer Failure is the aging and degradation of the transformer parts at the end of its useful life. This is a common practice to replace old parts so that the Transformer can maintain its efficiency but if maintenance is not done in regular manner then the aging and degraded parts can result in transformer failure.

Transformer Failure Modes

Based on the factors that lead to Transformer failure we can either categorise or make different Transformer failure modes to better understand and pinpoint the Transformer failure. If your Electrical Transformer has failed due to any factor then based on the extent of damage we can categorise the Transformer failure in two different levels.

Minor Failure

First level of Transformer Failure is a minor failure where there is a very small issue with any of the transformer parts. The minor failure includes a blown transformer fuse, a broken connection, loose connection, minor insulation damage, or broken wires that either supply or draw current from the transformer. Is failure type can be easily fixed on site and the repair can be done with no to minimal down time.

Moderate Failure

A moderate level of Transformer failure is one where there is a failure of a part that cannot be corrected for repair on site and the only repair that can be done is the replacement of a field part. This failure type results in significant down time of the Transformer and usually in the wall a team is exposed that physically places the part.

Major Failures

The major failure of a transformer is the failure where the entire Transformer blows or its major components like winding of Transformer core or its insulation has been damaged or completely failed. This usually results in the replacement of the entire Transformer as the core or the warning that the Transformer cannot be repaired or replaced on site.

Keep reading: Can a damaged transformer coil be repaired, refurbished or replaced?

Types of Transformer Failure

Concluding the factors that can lead to Transformer failures and the three different modes of Transformer failure we can develop different categories of Transformer failure. The type of Transformer failure will help you understand the services required to repair or replace the Transformer.

Concluding the factors that can lead to Transformer failures and the three different modes of Transformer failure we can develop different categories of Transformer failure. The type of Transformer failure will help you understand the services required to repair or replace the Transformer.

Electrical Failures

Electrical failure of a transformer is a failure Where transformer is not able to provide electricity to the consumer due to any of the problems mentioned by electrical related factors. This failure can be either short circuit, open circuit, broken connection, loose connection, damaged bushing, or Transformer terminal failure. All these electrical failures can be fixed on site with minimal down time.

Thermal failure

A thermal failure of an Electrical Transformer is where the Transformer insulation and isolation system fails due to overheating or overloading or any type of sudden electrical surge. Thermal Failure really happens at the Transformer winding section where overheating or overloading results in the breakdown of Transformer insulation resulting in short circuit within the Transformer winding. This is a major failure with significant on time and need of complete replacement of the transformer.

Mechanical failure

Mechanical failure of different types and this is failure where any part of the transformer mechanically fails under extreme load or part got damaged due to any type of overloading. Mechanical failure of Electrical Transformer usually occurs at Transformer winding where the displacement of winding has passed due to overheating over mechanical stresses.

Mechanical failures can also happen at the Transformer core where the magnetic saturation overheating or sudden electric search can result in structured deformation of the transformer Core. These types of mechanical failures are major failures with significant down time resulting in complete replacement of the Electrical Transformer.

Mechanical failure can also occur in transformer cooling systems where minor repair can fix the problem without any down time. Is type of Transformer Failure is either Miner or moderate level of failure where Transformer can be fixed without any downtime or with very minimal down time.

Preventive Measures to Avoid Transformer Failure

Transformer Failure is not something that is bound to happen to every transformer. The Transformer failure can easily be prevented by understanding the transformer failure symptoms or performing the Transformer failure analysis. The following are some of the preventive measurements to avoid Transformer failure.

- Periodic Transformer inspection and Transformer testing can help you with the Transformer failure analysis or can indicate the Transformer failure symptoms before the total Transformer failure. So always perform the Transformer inspection and perform the needed Transformer test on time.

- Regular maintenance will not only help you avoid Transformer failure but also help you maintain the Transformer efficiency and reliable tea in its operation throughout its useful life. to always perform the maintenance on time every place any show significant Transformer failure symptoms.

- Always install your Transformer by following the instructions provided by the Transformer manufacturer for following the standard procedure of Transformer installation keeping in mind the safety and local regulations.

- During installation always make sure that the Transformer has a proper and needed ventilation system and the cooling system installed and working properly.

- Always do proper load calculation so that the Transformer is installed as the required Power capacity and voltage rating to provide you reliable and safe electricity. This also prevents Transformer overloading and overheating.

- During maintenance and replacement of the Transformer part always make sure that the bird you are a blessing is of high quality and matches the exact specification and application of the replaced part.

Try for free: What are Different Types of Transformer Repair & Field Service

Conclusion

Transformer failures can have severe consequences for power systems leading to costly downtimes and reduced reliability. Understanding the factors that contribute to these failures and recognizing the different types and categories of failure is important. It is also important to implement the preventive measures that are essential for ensuring the longevity and efficiency of transformers. Regular maintenance, careful load management and the use of high quality components play crucial roles in preventing transformer failure.

Follow Up

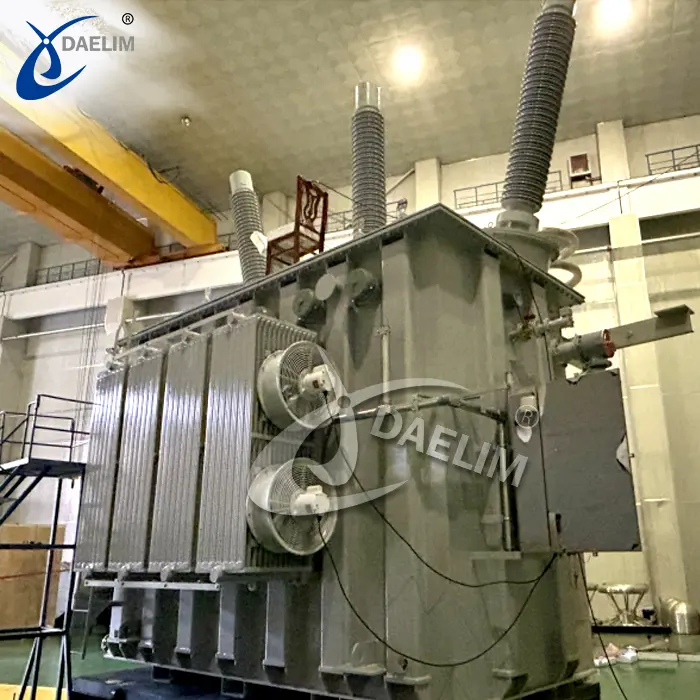

Electrical transformers are sophisticated electrical Devices that work 24/7 to regulate the electricity provided in your home and in your industry. These electrical devices need continuous care maintenance inspection and testing to avoid all types of Transformer failures. We at Daelim Transformer offer transformers of all types, sizes, and power capacity and all our transformers are built to deliver reliability and safety in their operations. We follow all types of internal standards including ASTM, ISO, ANSI, IEEE and others during transformer manufacturing, assembly, installation, and maintenance.

IF you have any questions about transformers, Contact Us and our representative will talk you through the process.

Related Products

Related Article

Manufacturing of Large Power Transformer

Large power transformers are vital for electricity distribution, requiring precise design, manufacturing, and testing. Key parts include the core, windings, and tank, all built with high-quality materials and strict processes. Challenges include size, cost, skilled labor shortage, and environmental concerns. Precision equipment and expert handling are essential for high performance and reliability.

What are Different Types of Transformer Repair & Field Service

This article explains the importance of transformer repair and field services for maintaining continuous, safe electricity distribution. It covers when repairs are needed, common transformer issues, types of repair and maintenance services, diagnostic tests, emergency services, retrofits, and factors to consider when choosing a service provider to ensure reliable operation.

Addressing the Iberian Blackout: A Wake Up Call

A major blackout in Spain and Portugal exposed critical grid vulnerabilities, especially with renewable integration, transformer infrastructure, and reactive power control. Daelim offers fast-delivery, high-quality, custom transformers—ideal for modernizing outdated systems and supporting renewable energy projects. Contact Daelim for reliable, future-ready transformer solutions.

Distributed Energy and Temporary Power

Daelim Transformer provides reliable, efficient solutions for the growing demands of distributed energy and temporary power systems, including solar, wind, and data center applications. With deep expertise and proven performance, Daelim ensures safe and sustainable electricity delivery while addressing the unique challenges of today’s evolving energy landscape.

The Impact of Operating Environment on Transformer Design

Electrical transformers are custom-designed based on specific application needs, not a one-size-fits-all model. While voltage input/output is important, other operating conditions also impact design. This article explores how environments like renewable energy plants and data centers influence transformer design, highlighting the importance of tailored solutions for efficient electricity distribution.

Dry Type Transformer Cooling Methods

This article explains various cooling methods for dry type transformers, detailing how each method works, the components involved, and their pros and cons. It aims to help readers choose effective and efficient cooling solutions by understanding different systems and their performance characteristics in transformer operation.