Transformer Pressure Relief and Fault Detection Devices

Transformers are the most important core elements of any modern power system; however, enough to say that absence of certain precautions is make their operation dangerous under adverse conditions. Some forms of transformer failure, such as high pressure, excessive heating, or internal arcing, either damage the installed equipment, cause a power outage or explosion. So to mitigate these kinds of risks, safety devices are integrated into designs.

Some of the important ones are pressure relief devices, pressure sensors, transformer temperature sensors, and Buchholz relay transformers. These devices work together, providing protection to the transformer and ensuring early detection of abnormal conditions, thus preventing catastrophic failures.

Contact Daelim TransformerWhy Transformer Safety Devices Are Critical?

As the most important part in a power system, if the transformer is not properly protected, it becomes vulnerable to faults. Even a single fault in a transformer can lead to costly equipment damage, big downtime, and then expensive replacement. These faults can occur due to overheating, internal arcing, or insulation breakdown

Proper installation of safety devices in a transformer contributes to the prevention of risks by early detection of abnormal conditions and providing timely intervention.

The protection elements play an important role in monitoring operational conditions and identifying issues earlier. The protection devices ensure transformer protection against pressure buildup, gas accumulation, or sudden temperature rise.

Lack of safety devices results in failures that eventually escalate to explosions, fires, or long outages. Proper safety devices protect equipment, ensure grid stability, and operator safety, as well as the reliability of the system.

More resources:

All you need to know about transformer surge protection

Temperature Protection and Maintenance for Transformers

What Is a Transformer Pressure Relief

(PRD)?

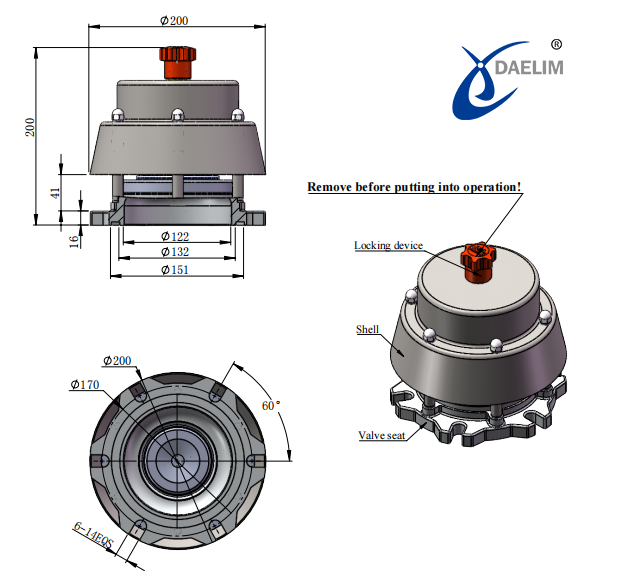

The pressure relief device (PRD) is one of the most important devices for the safety of a transformer. During abnormal operating conditions, like when internal arcing or insulation failure happens, gases from inside og transformer tank form and cause pressure buildup. If it is ignored or not checked on time, this pressure can rupture the tank and create danger.

Pressure relief devices, or PRD, are designed to safely release excessive pressure that can damage the equipment and the surroundings. It consists of a spring-loaded valve or a bursting disc, which opens when internal pressure reaches a dangerous level. Means eliminating a serious transformer fault.

The PRD is a frontline device for safely venting internal gases, thereby enhancing transformer reliability, safety, and longevity.

Types of Fault Detection Devices in Transformers

Early detection of faults is the first principle in transformer protection. Different types of protection devices are built to protect transformers from abnormal conditions. Each device has a distinct function to ensure complete transformer safety concerning different fault scenarios.

Buchholz Relay Transformer

The Buchholz relay transformer is one of the most common gas measuring devices. It observes gas buildup in the oil-immersed transformer with a conservator. A slow rate of gas accumulation indicates insulation weakening, while rapid build-up indicates severe internal faults.

Pressure Sensors

A pressure sensor continuously monitors internal tank pressure. When the pressure value rises beyond permissible limits, this sensor signals an alarm. So, pressure damage in a tank is prevented before the pressure relief device (PRD) becomes active.

Transformer Temperature Sensors

Excessive heating is very often dangerous in a transformer as well, as it leads to insulation failures and winding damage. The temperature sensors come here to play by monitoring the top temperature of oil and winding in the transformer. When these temperature exceeds critical set values, this sensor activates an alarm and automatically activates the cooling mechanism, which enhances the overall protection of the equipment.

Sudden Pressure Relays

Sudden pressure relays are used for detecting rapid changes in pressure, which usually arise from arcing faults. In response to such drastic changes, the sudden pressure relays act instantaneously, providing an additional layer of safety to the transformer.

Placement of Fault Detection Devices in Transformers

The correct placement of safety devices on a transformer is very important in order to get accurate monitoring and reliable operations. The pressure relief device is mounted on the top cover of the transformer tank in order to avoid excessive pressure and vent gases when a fault occurs in a transformer.

The pressure sensors are positioned on the tank body to continuously sense internal pressure. The transformer temperature sensor is installed either at the winding hot spots or near the surface layer to promptly detect overheating early.

As for oil-immersed units that have conservators, the Buchholz relay transformer is positioned in the pipeline that connects the tank with the conservator, within which it senses the accumulation of gas and movement of oil caused by an internal fault.

Reliability in operations and improved safety of transformer installations are assured through proper installation, calibration, and sealing of each device.

Conclusion

By integrating safety devices such as a pressure relief device, a pressure sensor, a transformer temperature sensor, and a Buchholz relay, effective protection of the transformer is possible.

These devices can continuously monitor and detect abnormal conditions, then handle them without escalating to serious faults. Transformer protection can be further enhanced with Periodic testing and continued maintenance.

Daelim Transformer – Your Trusted Partner in Safety

At Daelim Transformer, we understand how importance of the safety of transformers and how it can ensure power reliability. We integrate all necessary protection devices like PRDs, relays, and sensor systems in our transformer solutions.

Whether you need custom solutions, oil-immersed, or eco-efficient designs, Daelim Transformer is here to provide you with a transformer with complete protection. With years of experience in design and installations in more than 30 countries, we not only provide reliable transformers; we’ll give you peace of mind.

Related Products

Related Article

K Factor Transformer Explained

In modern electrical systems, nonlinear loads are common in residential, commercial, and industrial applications, creating harmonic currents that stress transformers. The K-factor is a key transformer rating that measures its ability to handle these thermal effects and operate reliably under complex conditions. This article explains the basics of K-factor transformers, essential design considerations, and how they differ from standard transformers.

A Complete Guide to Nuclear Power Plant Transformer

Nuclear power plant transformers are specialized electrical transformers designed to endure extreme conditions. They ensure reliable power distribution, safety, and stability in nuclear facilities. This article introduces their design, performance requirements, and key features for engineering students and technicians interested in understanding their operation and manufacturing principles.

Round Coil vs. Rectangular Coil for Transformers

The transformer coil is a key component that manages incoming and outgoing voltage. This article provides a detailed overview of transformer coils, explaining the structure and function of round and rectangular types. It also compares their design, performance, and advantages in different applications to highlight which type works best in specific conditions.

Station Service Transformers: Functions, Types, and Applications

Station Service Transformers (SSTs) are essential in power plants, supplying electricity for internal operations. Though similar to standard transformers, they are designed for specific generation tasks. This article explains their functions, features, and types, and discusses key sizing and selection criteria to help understand their role in efficient power plant operation.

Power Transformer Solutions for Blockchain Computing Facilities

A successful blockchain computing operation requires not only high-performance hardware but also a reliable power infrastructure. Transformers play a central role by stepping down grid voltage to the precise levels needed for computing units. Choosing the right transformer enhances efficiency, reduces downtime, prevents electrical stress, and protects costly equipment, ultimately improving operational stability and profitability.

Stainless Steel vs. TransArmour: Comparing Transformer Corrosion Protection Solutions

Transformers are vital in power systems, but corrosion from moisture, pollutants, and weather threatens their performance and lifespan. To prevent failures and downtime, facilities use corrosion protection solutions such as acid-resistant stainless steel tanks or the modern TransArmor coating system, which offers lightweight, cost-effective, and highly durable protection for long-term transformer reliability.