Stainless Steel vs. TransArmour: Comparing Transformer Corrosion Protection Solutions

Transformers are a very important asset in modern power systems, designed to run safely and smoothly for years to come. But the biggest threat to their performance and longevity is corrosion.

Transformer tanks that can be compromised by moisture, salt, industrial pollutants, and weather lead to failures and downtime. Hence, utilities, data centers, and industrial facilities need to ensure a corrosion protection solution for transformers wisely.

Among the most commonly adopted solutions are acid-resistant steel transformer tanks and the TransArmor coating system. Stainless steel, indeed, has long been favored as a corrosion-resistant steel for such demanding environments. On the other side, the TransArmor coating system is a more modern choice that is lightweight, cost-effective, and highly durable against corrosion.

Contact Daelim TransformerWhy is Corrosion Protection Important for Transformers

Transformers are the most important asset, which is designed to be dependable for decades, but corrosion is a major threat to that. The deterioration of metal surfaces due to corrosion starts with the exposure of transformer tanks and external accessories to harsh environments.

These harsh environments can be regions with salt-laden air, industrial-dense areas with chemical-poisoned air, and highly humid weather conditions. Without transformer corrosion protection, this will gradually damage tanks and external components, which eventually lead to oil leaks and insulation failure, resulting in costly outages.

Corrosion not only compromises the transformer's strength but also poses safety concerns. For instance, rusting of conventional steel tanks will spread like wildfire into outages and increased maintenance costs.

Industries are now turning to rust-proof steel like 316 and 304 stainless steel, and advanced TransArmour coating. This kind of steel protects the transformer against moisture, salts, and acids, which ensures it stays operational even in challenging environments.

Stainless Steel for Transformer Protection

The proven method of transformer corrosion protection is using stainless steel tanks. Unlike traditional steel, stainless steel can easily resist rust, moisture, or chemical attack, and is therefore ideal for use by transformers located in coastal, humid, or industrial areas.

By preventing early surface degradation, these have provided longer service life, less maintenance, and greater reliability.

TransArmour Coating Technology

Stainless steel is a proven solution; however, modern utilities and industries are adopting even advanced techniques like the TransArmour coating system for transformer corrosion protection. Unlike heavy-weight stainless steel transformer tanks, the TransArmor application involves a polymer-based coating that creates a tough barrier against rust, chemicals, and extreme weather. This invention brings together lightweight design and high-performance protection as an alternative to stainless steel.

They are ideal for pad-mounted and pole-mounted transformers in utilities, renewable energy sectors, and remote applications where transportation and installation costs are an issue.

Stainless Steel vs. TransArmour: Comparison

For transformer corrosion protection, stainless steel tanks and TransArmour offer different advantages. The choice among these will be influenced by the environmental considerations, budget, and requirements of the project.

Corrosion Resistance

- 304 stainless steel normally performs well in general conditions, but it may suffer from rusting in chemically heavy areas

- 316 Stainless steel, also called acid-resistant stainless steel, offers resistance against chloride and acid environments.

- TransArmour coating system provides a sealed, non-metallic barrier that resists salt, moisture, and chemicals without the risk of rusting, even in aggressive industrial zones.

Durability and Longevity

- Stainless steel is inherently strong, reliable, and rust-proof for several decades.

- TransArmour coatings offer lightweight yet tough protection with equal or greater lifespan in many applications while eliminating risks of structural corrosion.

Cost and Maintenance

- Stainless steel, especially that of the 316 type, has a relatively higher input cost and weight, which may add to shipping and installation costs.

- TransArmour-coated transformers would be cost-efficient, easy to handle, and require minimal maintenance.

Flexibility and Customization

- Stainless steel tanks are limited by material thickness and fabrication processes.

- TransArmour allows flexibility in design, and it is quite easy to adapt for pad-mounted, pole-mounted, or substation transformers.

Comparison Table: Coated vs Stainless Steel Transformers

| Feature | Stainless Steel (304 / 316) | TransArmour Coating System |

| Corrosion Resistance | Excellent (304: good, 316: superior) but still metallic | Superior, non-metallic barrier against rust, acids, and salts |

| Durability | Heavy-duty, long lifespan | Lightweight, equally long-lasting, with less structural stress |

| Cost | High (especially 316 stainless steel) | Lower upfront and lifecycle cost |

| Weight | Heavier, more costly to ship/install | Lightweight, easier to transport, and mount |

| Customization | Limited design flexibility | Highly adaptable to various transformer types |

Best Use Cases for Each Solution

Both the stainless steel transformer tank and externally applied TransArmor-coating system offer high protection levels, but each performs best under different circumstances.

When Stainless Steel is the Best Choice

- 316 stainless steel is best for marine and coastal applications with very high levels of exposure to salt water. Its acid-resistant and stainless steel properties make it an ideal choice for offshore oil rigs, desalination plants, and chemical industries.

- 304 stainless steel works great in environments with moderate humidity, but in high-chloride areas, it can still show rusting. It is good for inland areas with less exposure to salt or industrial pollutants.

- Stainless steel is also chosen for high-end projects where maximum durability against rusting is more important than cost.

When TransArmour Coating is the Better Option

- The TransArmour coating is a good choice in large utility projects or for renewable energy installations with transformers that are lightweight and easy to handle.

- It performs well in industrial areas with chemical emissions, humid tropical climates, and remote sites where maintenance is difficult.

- For utilities that require efficient and cost-effective transformer corrosion protection, TransArmour has better versatility than inflexible designs of stainless steel.

Conclusion

Corrosion protection for transformers is important for reliability, safety, and a prolonged service life. Stainless steel tanks and TransArmor coating are both for protection against corrosion, and each has its own advantages.

316 stainless steel has the highest durability and rustproof properties, making it a great choice for harsh industrial environments. 304 stainless steel is still good for moderate conditions. The TransArmour coating system is a light, cost-effective alternative that gives great transformer corrosion protection without incurring the cost and weight burden of stainless steel.

In deciding between a coated or stainless steel transformer, the choice eventually depends on project needs; stainless steel for premium mission-critical environments, TransArmour for scalable base solutions where flexibility and ease of installation are prioritized.

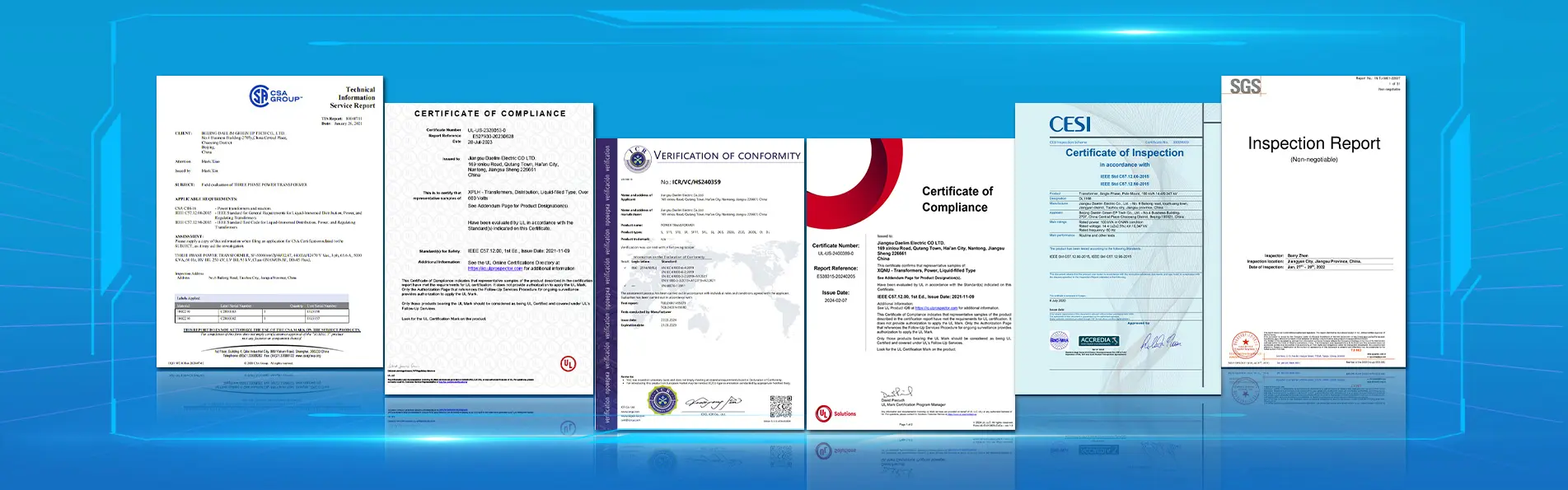

Daelim Transformer manufactures both stainless steel transformer tanks and an advanced solution featuring the TransArmour coating, enabling utilities, data centers, renewable energy projects, and industrial clients to select the best option for their specific environment. With decades of experience and global certifications, Dealim is able to provide transformer solutions that balance durability, performance, and cost efficiency.

Related Products

Related Article

Fundamental of Medium Voltage Transformer

Medium voltage transformers regulate electricity between generation and distribution systems. They operate at intermediate voltages, ensuring efficient power transfer. This article explains their structure, working principles, components, applications, maintenance, and installation requirements, emphasizing their crucial role in stable, safe, and reliable electricity distribution networks.

K Factor Transformer Explained

In modern electrical systems, nonlinear loads are common in residential, commercial, and industrial applications, creating harmonic currents that stress transformers. The K-factor is a key transformer rating that measures its ability to handle these thermal effects and operate reliably under complex conditions. This article explains the basics of K-factor transformers, essential design considerations, and how they differ from standard transformers.

A Complete Guide to Nuclear Power Plant Transformer

Nuclear power plant transformers are specialized electrical transformers designed to endure extreme conditions. They ensure reliable power distribution, safety, and stability in nuclear facilities. This article introduces their design, performance requirements, and key features for engineering students and technicians interested in understanding their operation and manufacturing principles.

Round Coil vs. Rectangular Coil for Transformers

The transformer coil is a key component that manages incoming and outgoing voltage. This article provides a detailed overview of transformer coils, explaining the structure and function of round and rectangular types. It also compares their design, performance, and advantages in different applications to highlight which type works best in specific conditions.

Station Service Transformers: Functions, Types, and Applications

Station Service Transformers (SSTs) are essential in power plants, supplying electricity for internal operations. Though similar to standard transformers, they are designed for specific generation tasks. This article explains their functions, features, and types, and discusses key sizing and selection criteria to help understand their role in efficient power plant operation.

Power Transformer Solutions for Blockchain Computing Facilities

A successful blockchain computing operation requires not only high-performance hardware but also a reliable power infrastructure. Transformers play a central role by stepping down grid voltage to the precise levels needed for computing units. Choosing the right transformer enhances efficiency, reduces downtime, prevents electrical stress, and protects costly equipment, ultimately improving operational stability and profitability.