Why Do Transformers Hum?

If you live near a transformer unit, you might have heard a transformer humming especially at night, but have you ever wondered why these transformers hum?

There are plenty of reasons why these sounds occur. These noises are no joke and they are not just simple negligible sounds but could be a significant source of noise pollution.

In this article, we will tackle why transformers hum, other contributing factors that may aggravate it, its relationship to the load, how to reduce it, and other FAQs relating to transformer noise.

Why Do Transformers Hum? Where Does the Sound Come From?

Transformer hums mostly come from the transformer core and what takes place within once it is energized.

The transformer works through electromagnetism where a changing magnetic field charges the core and enables the flow of electrons.

Depending on the design and construction, the core is basically composed of different layers of sheeted laminations and insulations.

The laminations can be made with iron and other ferromagnetic materials while the insulations are made with paper or plastic.

Each time the magnetic flux transpires in the core, the core material experiences multiple contractions and expansions. This can then lead to minute alterations in the material dimensions.

Although the potential changes are very minimal, the level of contraction and expansion can be different on each layer thus causing the components to eventually touch each other and produce that audible vibrating or humming sound.

What Are the Other Factors That Contribute to Transformer Noise?

Apart from the core, other transformer parts and factors can also contribute to the transformer humming noise.

This includes these four causes such as the load, cooling system accessories, poor structural supports/mountings, and other environmental factors.

Load Noise

The transformer buzzing sound produced by the load is not that substantial and should be much lower than the noise created by the core. However, note that when a transformer is poorly designed the load noise becomes more profound.

Generally, the load current is accompanied by sound frequencies that are barely audible from afar but it causes some vibrations.

If the electrical transformer design is not that compact, these vibrations shake the entire unit which could add up to the noise produced.

Cooling System Accessories

Transformer windings produce a lot of heat once it is loaded. Different cooling methods are employed to dissipate heat and avoid overheating.

These methods may utilize water, air, or oil as a cooling medium accompanied by various accessories such as cooling fans, heat exchangers, and pumps.

Each of these accessories has its own sound thus throwing more noise altogether while the cooling system is at work.

This type of transformer noise is more predominant in transformers with lower power ratings.

Poor Structural Supports and Mountings

When installing a transformer it needs solid structural support and appropriate mountings which include platform, frames, clamps, shrouds, brackets, fasteners, and many others.

These parts are mostly made with steel and other materials that easily create noise with the slightest vibration. All the more if the transformer has inadequate support or is loosely installed.

Location and Other Environmental Factors

The location also plays a role in the transformer humming sound propagation.

For example, if the transformer is installed in the corner or in a confined area, the humming sound and other noise from the transformer are further amplified.

In addition, the sound produced by the transformer can double if it hits surfaces or materials that are sound-reflective in nature.

Does Transformer Noise Increase When the Load Is Applied?

A transformer can still produce a humming sound even if it is not loaded. Moreover, when a transformer is loaded the sound slightly increases but is most likely negligible compared to the sound generated by the core.

Given that the transformer is well supported and properly installed, the amount of load or the increase in the load is likely a concern since it has very little effect on the transformer noise level.

The sound level contributed by the load shall not go beyond 2 decibels. However, it is important to know that overloading is an exception.

When a transformer unit is overloaded you will notice the humming sound becomes louder but normally the sound is plain and steady.

If this is the case, troubleshoot and remove the excess load. The humming sound should gradually return to normal levels.

Why Does Transformer Humming Sound Get Worse Overtime?

A well-designed transformer is generally engineered to produce low noise. However, as the transformer ages, it undergoes natural wear and tear.

One of the major manifestations is that the laminates are starting to split into fractionations. This is mainly caused by diminishing adhesive in between sheets.

This creates small gaps between the layers. Upon energization, these torn layers tend to rattle and loudly create noise.

In addition, wearing fans and pumps can also be another noise factor that intensifies over time especially when they are not properly maintained.

How Is the Humming Sound Measured?

Measuring the humming sound is done by evaluating the noise level using a sound level meter or as prescribed according to IEC 60076-10, the sound pressure and sound intensity measurement methods.

The following industrial standards based on the transformer type are also applicable:

| Transformer Type | Testing Standard |

| Dry-type transformers (Medium Voltage) | IEEE C57.12.91-2011 |

| Dry-type transformer (Low Voltage) | NEMA ST 20 |

| Dry-type distribution and power transformers | |

| Liquid-immersed distribution transformers, power transformers, and regulating transformers |

Each unit is measured in decibels.

What Is the Allowable Transformer Noise Level Limit?

The noise level limit varies per transformer rating. As per NEMA standards, a transformer with a 1000kVA rating falls under the 64 decibels maximum allowable limit. Subsequently, the allowable limit becomes lower for transformers with smaller kVA ratings.

The allowable limit can also vary per country, some countries like Australia and Germany have more stringent laws, especially in the areas of power generation.

How To Reduce Transformer Noise?

Taking the initial steps in reducing transformer noise involves assessing the condition and health of the transformer. It is easier to address the issue if you can pinpoint the problem or where the noise comes from.

One way to assess the problem is by identifying the abnormal sound produced by the transformer through noise recording and physical inspection.

Once you identify the problem, here are some of the best options you can do to cut off and manage the transformer noise level on site.

Location is Key

There is no single approach to stop the transformer from humming. Although it is manageable, the ultimate way to live by it is by installing it in areas away from the populace.

However, most of the time installations are required to be near or within the infrastructures where the transformer has to cohabitate with people.

To make the most of the available space, here are some of the actions to take upon installation to avoid future complaints:

Do not install a transformer in a confined or narrow area surrounded by hard walls. Stray away from tricornered walls and areas close to the ceiling as well.

These areas have a large potential of amplifying whatever noise or vibrations the transformer may produce.

Choose a room that is less populated or less accessible to traffic. Avoid crowded areas like stairways, canteens, and admin offices.

Ideally, transformers are located near machine rooms or control stations. Moreover, observing at least a 10 ft distance to the next equipment should also be noted.

Verify if there's a specific noise level requirement in the installation area and assess if the noise level of your transformer is within the limits.

For example, in the worst-case scenario, your transformer noise level reaches 100 decibels. An exposure of 15 minutes would already mean that the exposed worker has already reached 100% of its allowable noise dose per day according to the NIOSH exposure limits.

Proper Mounting

How you mount your transformer is crucial in mitigating vibrations and noise levels. That is why choosing the right method and techniques is highly beneficial in cutting off potential noise. To ensure proper mounting, take a look at the following checklist:

Apply flexible mounting techniques and utilize vibration isolation pads or matting. This material has the capability to absorb vibration and reduce noise.

When it comes to wiring and cable management, opt for flexible connections. This will also help prevent the noise and vibrations from traveling through the conduits.

Check if the mounting surface is rigid and heavy enough. To avoid noise propagation you would want your mounting surface to be 10 folds heavier than the weight of your transformer.

Refrain from installing them on wood mezzanines and other areas with less stable foundations.

Soundproofing

A popular way to effectively handle noise in populated areas is soundproofing. This is also applicable for handling transformer noise.

Here are some sound-proofing materials you can try:

There are commercially available sound barriers designed to inhibit the noise and vibrations associated with transformers.

They can also be used for outdoor applications. For example, power transformers and substation transformer for electric utilities that are located close to residential areas.

To isolate the transformer noise, install acoustical dampening materials on the walls surrounding your transformer.

There are plenty of available options in the market. This includes acoustic wall covers made with composite fabrics or mineral wool and industrial acoustic panels made with aluminum or steel.

This is by far a cheaper option but this will not isolate the noise but will only reduce or redirect it. For this method, wood panels, bricks, or concrete are typically used to build the screen walls.

Watch Out for Loose Ends

Small things are often neglected but a little noise when left unattended can be dangerous in the long run. As much as the big things it is also equally important to pay attention to the following minute details upon transformer installation:

Make sure the covers of the transformer enclosures are tightly fitted. Loose covers create additional noise once it senses vibrations.

Same with access doors for transformers situated in a room, tight fittings are a must. This will prevent the noise from passing through the gaps. If door gaps are observed, apply acoustic caulk or door seals.

Upon transport, the transformer could have additional bolts or fasteners for the purpose of securing it while in transit.

However, during installation note that these things are no longer necessary. If these are not removed, they will only cause additional noise during the transformer operation.

Like any other machine, every transformer needs a regular check-up. Periodic maintenance of the core, cooling system accessories, mountings, and other attachments should be practiced.

This is to make sure that none of these are damaged and all the efforts exerted in reducing transformer noise are wasted.

Quality Above All

The transformer humming sound might not be completely eliminated because it's part of how a transformer works.

The first step in combating these latent noise issues beforehand is to acquire a high-quality transformer from a reputable transformer manufacturer.

There are several things that a good quality manufacturer can do. Having a compact core design or at least an effective cooling system without employing excessive accessories are only some of the few.

In addition, keep in mind that other transformer noise issues can only be addressed upon installation. Thus, installation should be done with proper planning.

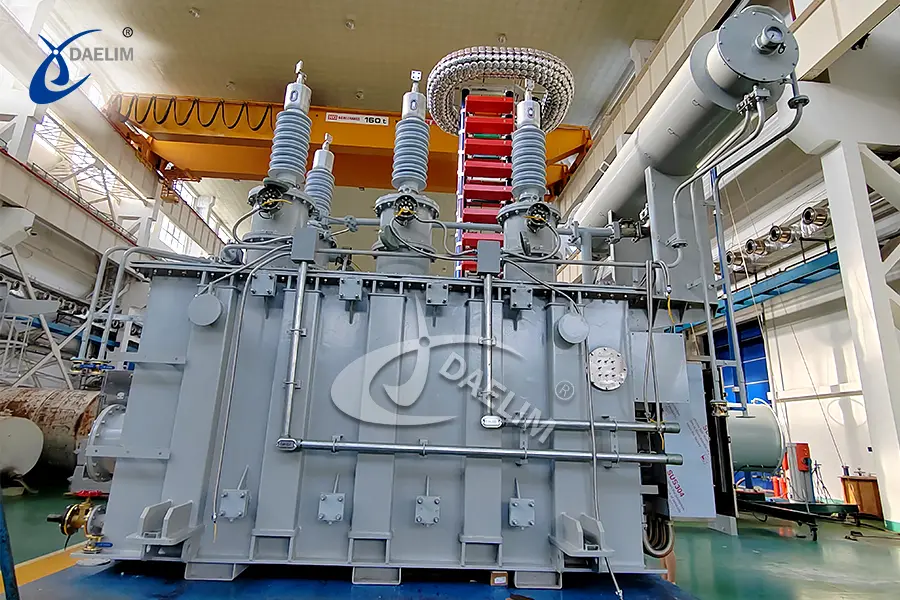

Daelim Quality

At Daelim, quality always comes first. Daelim aims to earn every customer's trust by being committed to upholding the highest quality standards armed by comprehensive testing and certifications.

With over 20 years of export experience, Daelim has established familiarity with transformer noise regulation over different regions, particularly in the US, Europe, Australia, Asia, Africa, and the Middle East.

With that, you can guarantee that the Daelim transformer's noise level is kept at a minimum not just for compliance but primarily because it is purposely designed and built with strong electrical and mechanical properties.

More than that, Daelim transformers are manufactured in strict conformance with all international laws not only for noise level requirements but with other international standards including IEEE, IEC, CSA, AS/NZ, and GOST.

If you are looking for a reliable partner for your transformer installation requirement, contact Daelim Transformer to ensure that you get the ultimate transformer quality you deserve.

Related Products

Related Article

230 kV Three Phase Power Transformer For USA Market

In 2023, Daelim Transformer designed and manufactured a cutting-edge 230 kV three-phase power transformer for a client in Nevada, USA. The client recently shared installation and operational photos, showcasing the successful deployment of this remarkable transformer. Let's delve into the specifics of this transformer project!

Canadian 69 kV Substation Transformer Project

Today, we are excited to present a case study on a 69 kV substation transformer project by Daelim Transformer. Our Canadian client required a step-down transformer for their substation to connect with the hydroelectric grid in Quebec.

Single Phase Pad Mounted Transformer For USA Utility

Introducing a utility transformer project tailored for the USA, located in Virginia. This utility initiative requires 215 units of single-phase pad-mounted transformers, all UL listed, including 175 units of 25 kVA and 40 units of 50 kVA. The end user's project timeline is 90 days. Adherence to IEEE standards is imperative for single-phase transformers. Additionally, the design of transformer components and markings must be customized to meet project specifications.

Pad Mounted Transformer for BESS System 4.0 MVA in Riverside County, California

Today, Daelim Transformer is proud to introduce a pad-mounted transformer for a 4.0 MVA Battery Energy Storage System (BESS) project located in Riverside County, California. The transformer is meticulously crafted to comply with the specifications outlined in the California Electrical Code Article 450.

2000 kVA Oil immersed Substation Transformer For Portugal Market

Today, we introduce Daelim Transformer's export of a 2000 kVA oil-immersed substation transformer to Portugal. This transformer represents our commitment to delivering high-quality electrical solutions to global markets. With meticulous design and engineering, this transformer is tailored to meet the specific needs of our customers in Portugal, ensuring reliable performance and efficiency. Daelim Transformer continues to uphold its reputation for excellence, providing innovative solutions that power progress and reliability worldwide.

2550 kVA Pad Mounted Transformer For Data Center in Mexico, Missouri

Today, we're excited to showcase Daelim Transformer's involvement in a project supplying four 2550 kVA pad mounted transformers tailored for a data center located in Mexico, Missouri. Data centers, known for their substantial power demands, require reliable solutions to ensure seamless operation during peak electricity usage.