CSP VS Conventional Transformer : Which Is Better?

If you were to choose, CSP vs Conventional Transformer, which would be better for you? A CSP transformer operation system? Or a conventional transformer structure?

A conventional transformer has two windings, whereas the CSP transformer is primarily distinguished by its singular winding. Daelim will help you figure out which one to choose. Keep reading to know which transformer suits your need!

Contact Daelim TransformerWhat Is A CSP Transformer?

A CSP transformer can be generally defined as a Completely Self Protected device. Also known as self-protection transformer. It is pole mounted transformer.

A CSP transformer can be generally defined as a Completely Self Protected device. Also known as self-protection transformer. It is pole mounted transformer.

It is common practice for a CSP transformer to utilize its secure methods and features to guard against harm.

During the installation process, you won't need to install any specialist safety features, which will save you both time and money in addition to eliminating a potential hassle.

If it is appropriately applied, a CSP transformer can protect itself against damage.

In addition to this, a CSP transformer is beneficial to consumers since it is efficient and can handle overloads.

Components of the CSP transformer can also be highly utilized to locate regions that require improved load control.

What Is The Concept Of a CSP Transformer?

A CSP transformer is widely recognized for its high performance.

It can minimize the operation and maintenance expenses that are typically associated with conventional transformers.

A CSP transformer may offer protection not just against momentary but also against sustained overloads of significant damage.

Additionally, the system can also alert the user through both audible and visual means in the event of such occurrences.

CSP technology protects the distribution system in the event of a failure.

In the event of a transformer malfunction, it will become disconnected from the surrounding infrastructure.

In the case of a transformer malfunction, it effectively eliminates any internal and downstream faults as a secondary protective measure, without exhibiting any apparent indications of malfunction.

Get it now: Basic knowledge about telephone pole transformer

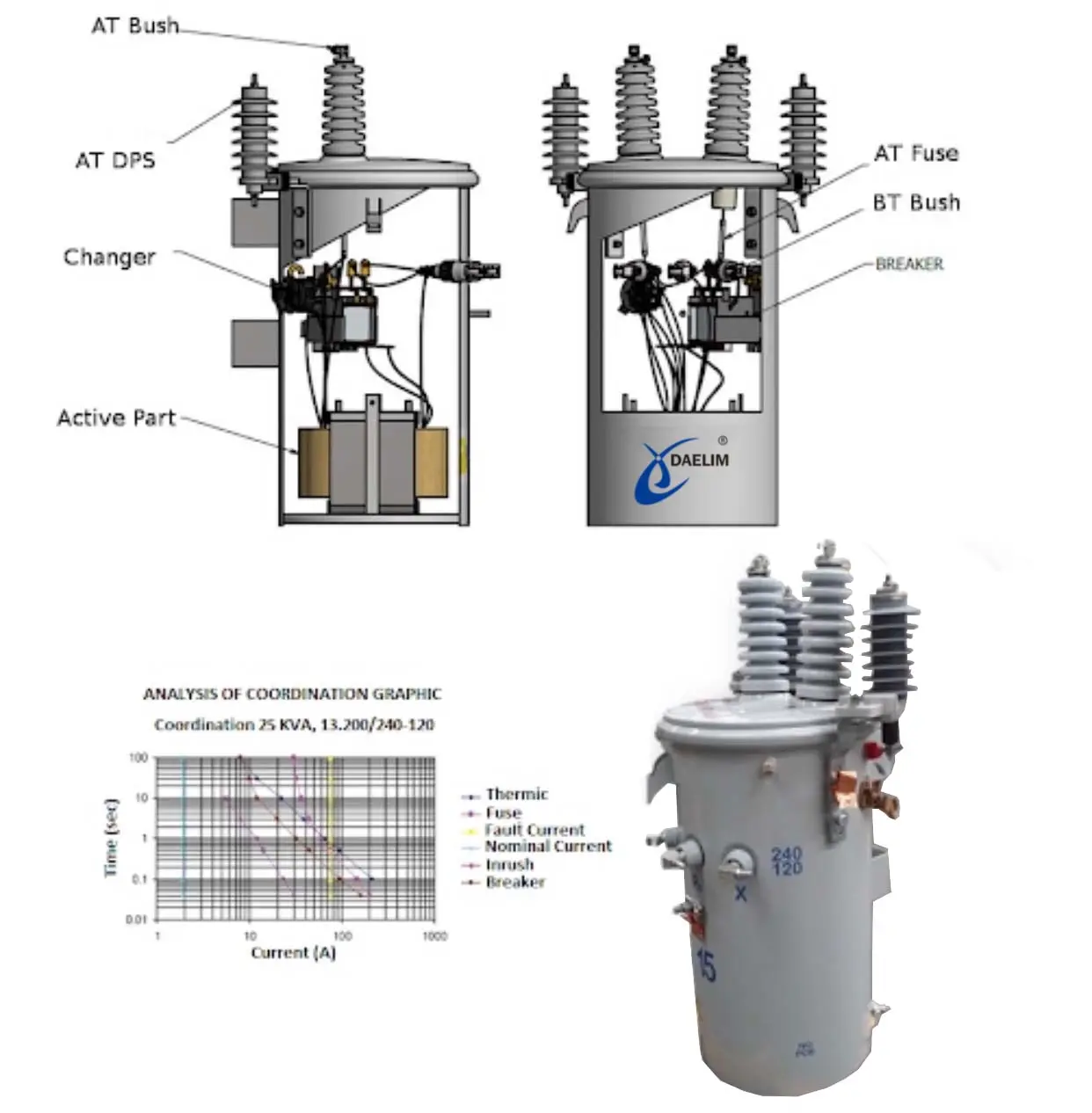

What Are the Components Of The CSP Transformer?

The fundamental components of a CSP transformer comprise the following elements.

1. lifting lugs

1. lifting lugs

2. arrester mounting pads

3.cover-mounted high voltage porcelain bushing(s)with eyebolt terminal

4. low voltage bushings with eyebolt terminals5.low voltage neutral grounding strap (not shown)(10-50 kva class b-2 and b-3 only)

6. Ansi support lugs (hanger brackets)with laser inscribed nameplate on the lower bracket

7. polyester insulated cover

8. self-venting and resealing cover assembly

9. core

10. coil

11. centerline core/coil assembly support brackets12.low voltage leads

13. oil fill plug with the cover ground strap

14. tank ground pad

the following additional features are all standard on self-protected type csp units only15.primary protective link (mounted in high voltage bushing)

16. surge arrester

17. secondary circuit breaker

18. secondary breaker operating handle with emergency overload reset and overload signal light

Learn more about Transformer Accessories

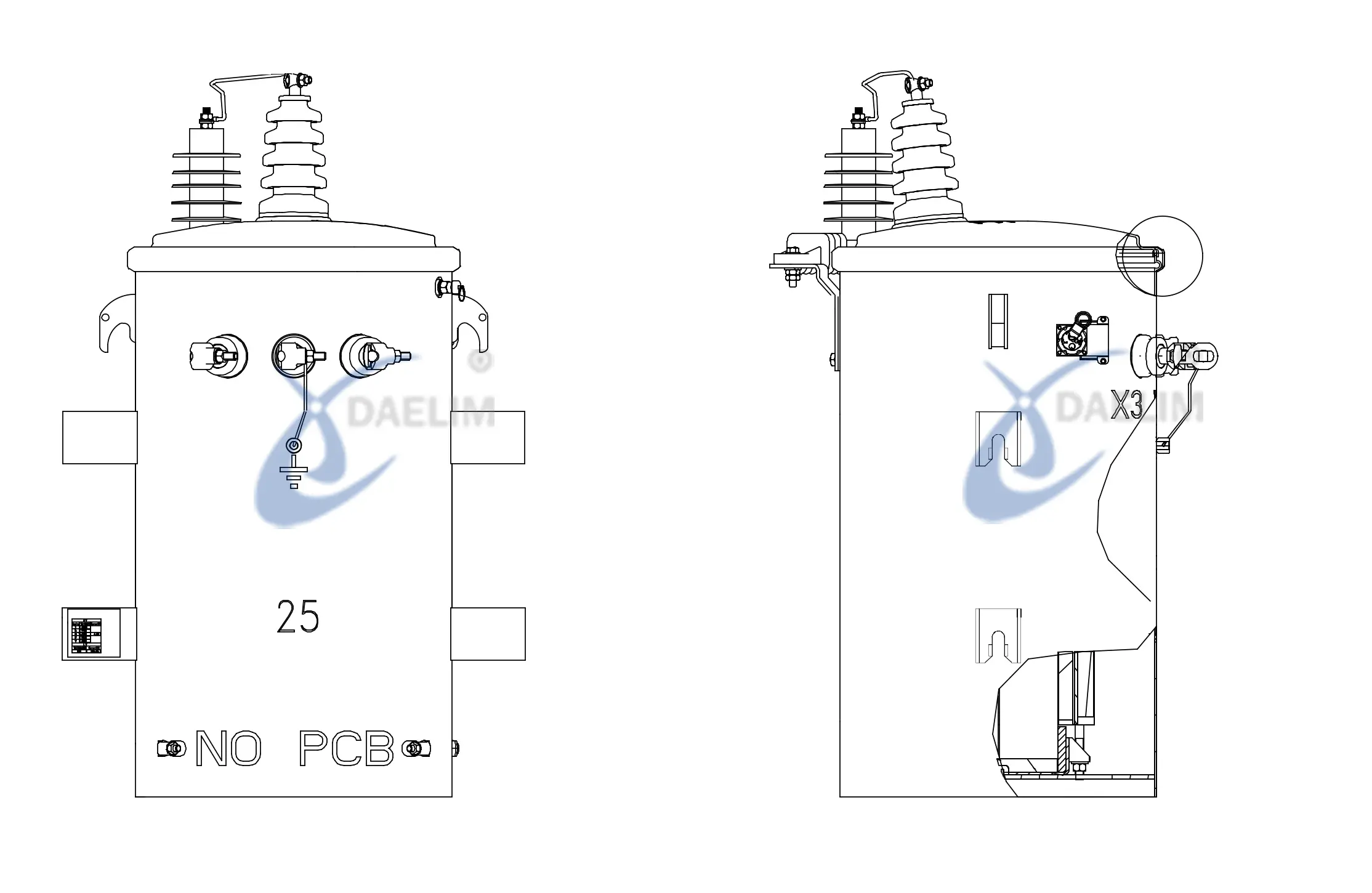

CSP Transformer Diagram

The CSP transformer diagram is divided into a design outline drawing and a production drawing. Daelim Transformer will typically send the outline drawing of the CSP transformer to the customer for confirmation within 1-2 weeks after receiving the order notification. Once the customer confirms the accuracy of the outline drawing, the subsequent production drawing will be created. Workers will then produce and assemble CSP transformers based on the production drawings designed by engineers.

Reading more about Transformer Diagram

What Is the Advantage Of The CSP Transformer?

Reduce the environmental damage that could occur if transformers fail

- There is less potential for fire.

- The risk of transformer explosions can be highly eliminated.

- In the event of an oil leak, the protective system will automatically turn off the transformer.

Ensure the safety of the maintenance team

- Fixing a faulty transformer takes place in its tank.

Integration

- The tight integration of protections ensures a secure system as a whole.

Coordination

- Customer contact is necessary for protection to guarantee CSP system selectivity.

Flexibility

- CSP transformer functionality can be generally preserved in the face of varying network protection strategies by employing several fuses.

- It is feasible to assemble the part without using an oil-level sensor.

Safety

- Keeping users, their data, and the network itself secure is a top priority.

Savings

- The high degree of protection integration provides an opportunity to simplify the substation.

Quality

- CSP transformers can enhance the energy delivery quality by minimizing the shut-down time.

You may enjoy: Transformer Solutions For Utilities

CSP Transformer Operation, How Does It Work?

Once the electrical current from a CSP transformer is mainly lowered, the electricity can be then used efficiently.

Then it can be successfully connected to the primary electrical grid.

As you can see, the primary fuse in a CSP transformer is generally designed to be reliable and safe, as it is highly encased in oil and attached to a series of electrical wiring.

Consumers will be able to protect the distribution transformer from potential failures by installing a discharge fuse upstream of the CSP transformer.

This affords us protection against any malfunctions that may occur in the distribution transformer.

How Does A CSP Function During A Failing CSP Transformer Operation?

If the operation of the CSP transformer fails for any reason, most often owing to an excessive flow of current, the circuit will be highly safeguarded by a fuse that blows.

This is one of its great features since it shows that the current and the loads that they serve can be mostly exchanged.

Because each wire is protected by its mechanism, the system that supplies the power is extremely trustworthy and safe.

During the operation of a CSP transformer, this assures, above all else, that any problems with the load will not affect the functioning of the other loads.

Try for free: Technical Standards for Transformers Across The Globe

What Is A Conventional Transformer?

A conventional transformer is an electrical device that consists of two coils of wire (primary and secondary) wound around a common iron core. When an alternating current (AC) flows through the primary coil, it creates a magnetic field that induces a voltage in the secondary coil.

The transformer works on the principle of electromagnetic induction and can step up or step down the voltage of an AC power signal. The ratio of the number of turns in the primary and secondary coils determines the voltage transformation ratio.

Transformers are widely used in power distribution systems to increase or decrease the voltage of electricity as it is transmitted over long distances. Some of their applications include residential regions, as well as in light commercial and industrial settings respectively.

Typically, the secondary circuit in a conventional transformer does not have a breaker to protect it.

Read my article on Everything you need to know about Refurbished Transformer

What Are The Applications For Conventional Transformer?

Medium-voltage distribution systems often employ indoor or outdoor conventional distribution transformers.

These devices are generally made to change the voltage from high to low or from low to high.

Although they are frequently used in the commercial and industrial sectors, their principal application is in the domestic service industry.

Even though there are substation-ready variations of conventional transformers they are primarily intended for pole attachment.

Remember that the buyer is responsible for ensuring the safe use of these transformers, as well as providing surge arresters and other forms of overvoltage and overload protection.

You can rely on conventional transformers for these common uses:

- When it comes to adjusting either the voltage or the current of the electrical grid, there is a significant amount of room available.

- In most cases, the primary and secondary conductors, which are physically distinct from one another, are the ones that are generally utilized to achieve the desired level of electrical isolation between two distinct circuits.

- To achieve an appropriate level of impedance matching.

Reading on: A Comprehensive Guide to Transformer Specifications

What Is The Construction Of A Conventional Transformer?

A conventional transformer consists of the following main components:

Core: The core is the main part of a transformer, and it is usually made of laminated steel. The core provides a low reluctance path for the magnetic field and reduces the energy lost as heat due to eddy currents.

Primary winding: The primary winding is the coil of wire that is connected to the input voltage source. The number of turns in the primary winding determines the input voltage to the transformer.

Secondary winding: The secondary winding is the coil of wire that is connected to the output load. The number of turns in the secondary winding determines the output voltage of the transformer.

Insulation: The primary and secondary windings are insulated from each other and from the core to prevent electrical arcing and short circuits.

Tap changer: Some transformers have a tap changer that allows the number of turns in the primary or secondary winding to be changed, which enables voltage regulation.

Enclosure: The conventional transformer usually has a sealed tank (cylindrical or square) to prevent damage and ensure safety.

The construction of a conventional transformer is straightforward, but its performance depends on the quality of the materials and the precision of the winding process. A well-designed transformer can operate efficiently with minimal energy loss and provide reliable performance over a long lifespan.

Learn more about Transformer Construction

What Are The Benefits Of Conventional Transformer?

Some benefits of conventional transformers are:

Efficient energy transfer: Conventional transformers can efficiently transfer electrical energy from one circuit to another with minimal energy loss due to the high magnetic coupling between the windings.

Reliable performance: Transformers are designed to operate for many years without requiring maintenance, making them a reliable source of electrical power.

Voltage regulation: Transformers can step up or step down the voltage of an AC power signal, which enables voltage regulation and ensures that the electrical equipment receives the required voltage.

Electrical isolation: Conventional transformers provide electrical isolation between the input and output circuits, which prevents electrical shock and reduces the risk of damage to equipment.

Noise reduction: Transformers can reduce electrical noise and interference, which is beneficial for sensitive electronic devices that require a clean power supply.

Cost-effective: Conventional transformers are cost-effective compared to other voltage regulation methods, making them a popular choice in power distribution systems.

Overall, conventional transformers provide many benefits that make them essential components in various electrical and electronic systems.

Reading on: The Ultimate FAQ Guide To 167 kVA Transformers

What Are The Drawbacks Of A Conventional Transformer?

These are some of the problems with conventional transformers.

- Insulating materials mainly used in conventional transformer windings rapidly deteriorate when highly subjected to temperatures.

- Conventional transformers require a substantial amount of space to perform their functions effectively. This is primarily due to the size and weight.

- The high volt value as well as the vast number of transformers contribute to the increased chance of a power failure.

- Conventional transformers are typically enormous and bulky.

- Power quality control is only possible with current transmission systems that have some degree of flexibility.

CSP vs Conventional Transformer

CSP transformers and conventional transformers differ in several ways:

Efficiency: CSP transformers can achieve efficiencies of up to 99%, compared to around 95% for conventional transformers.

Size and weight: CSP transformers are much smaller and lighter than conventional transformers.

Power density: The CSP transformers have a higher power density than conventional transformers, meaning they can handle higher power levels in a smaller form factor.

Response time: CSP transformers can respond much faster to changes in load than conventional transformers, making them well-suited for use in applications where fast load changes occur frequently.

Flexibility: CSP transformers are more flexible in terms of input and output voltage ranges, making them suitable for a wider range of applications.

Reliability: CSP transformers increase reliability and reduce the likelihood of failure and downtime compared to conventional transformers

Costing: CSP transformers are more inexpensive.

In summary, CSP transformers offer several advantages over conventional transformers, including higher efficiency, smaller size and weight, higher power density, faster response time, increased flexibility, and improved reliability. Of course, the CSP transformer price is higher.

You may enjoy: High Voltage vs Medium Voltage Transformer

CSP vs Conventional Transformer: Which Is Better?

When considering both price and footprint, a CSP transformer is the superior option.

When compared to the cost of operating and maintaining a CSP transformer, the cost of operating and maintaining a conventional transformer is much higher.

Not only is a CSP more effective, but it also needs a noticeably smaller quantity of winding material than a conventional transformer.

When compared to the conventional transformer that it takes the place of, it offers a significant reduction in the amount of expense incurred.

By utilizing a CSP transformer, losses can be highly reduced, which in turn results in a large reduction in power usage.

In addition, it is more capable of transferring power by induction as well as through a direct electrical connection.

On the other hand, consumers can still rely on a conventional transformer.

CSP Transformer And Conventional Transformer Supplier

At Daelim Transformer, we design and manufacture high-quality CSP and conventional transformers that are tailored to the unique needs of customers in a variety of industries. Daelim transformers stand out from the competition with higher efficiency, smaller size and weight, faster response time, and improved reliability.

Daelim's team of experts has a deep understanding of transformer technology and can work closely with you to provide custom solutions that meet your exact requirements. Daelim Transformer is committed to customer satisfaction and support and strives to exceed expectations at every step of the process.

In addition to Daelim's expertise and commitment to quality, Daelim has also earned UL/cUL and CSA certifications that demonstrate Daelim's excellence in transformer manufacturing. We are proud to have served a wide range of customers, from small businesses to multinational corporations, and have a proven track record of delivering reliable and high-performance transformers. Daelim transformers are widely used in North and South America.

Whether you need a CSP or conventional transformer, Daelim has the experience and expertise to deliver a solution that meets your needs. Contact us today to learn more about our products and services, and see how we can help you achieve your goals.

Related Products

Related Article

Single Phase Pole Mounted Transformer Project, Canada

Used in Saskatoon, Canada, 2019. We provided single phase transformers of 2.4kv, 7.,2kv, 13.8kv and 14.4kv. They are used for remote village net work.

What do you need to know about power pole transformer ?

Power pole transformer refers to a power transformer installed on a wooden pole or a concrete pole. Power pole transformer is often used to reduce the voltage of distribution level to the consumption level, with the purpose of supplying power to nearby residential areas or residential areas.

The Ultimate Guide to Pole Mounted Transformers

Pole-mounted transformers are those generally used by utilities that are highly positioned at wire height on a wooden or concrete electrical service pole. This type of electricity transformer is mainly suspended on poles in an outdoor setting. These transformers are vital to the delivery of power to residential areas. Daelim offers the best possible quality, and we are highly known as one of the most successful pole-mounted transformer manufacturers across the globe.