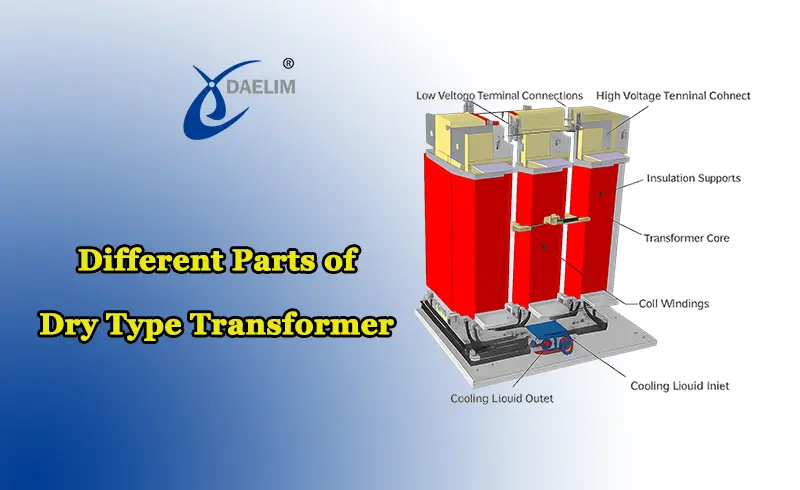

The Different Parts of a Dry Type Transformer

Your dry type transformers are little different from their counterpart the oil type Transformers. These transformers are usually compact in design or much smaller in size and they are usually recommended for low to moderate levels of electrical power and voltage levels.

In this article we will give you a very company about the different parts of a dry type transformer. We will explain how these dry type transformer parts are designed, which material is used for their manufacturing, how each part is manufactured and how these parts work to deliver you a safe and controlled level of electrical current.

Contact Daelim TransformerThe Different Parts of a Dry Type Transformer

The basic working principle of your dry type transformer is exactly the same in any of your other types of Electrical Transformer but the parts that are involved in working are very different from the other types, specifically the oil type transformer.

Different parts of a dry-type transformer are as follows:

- Transformer Core

- Transformer Winding

- Epoxy Resin

- Cooling Mechanism

- Enclosure

- Bushing

- Terminals

- Sensors

- Surge Arrester

- Supporting Frame

Core of Dry Type Transformer

Your dry type transformer has a core as its Centre part and in its most simplest shape it can appear to you like a square frame. You can expect that your dry type transformer core is made of any of the four most commonly used materials for transformer core. Transformer cores can be made of silicon steel, amorphous iron based alloys, magnesium zinc alloy or manganese zinc ferrites or from nickel iron alloy.

There are fair chances that you will use laminated sheets of silicon steel to manufacture the core of your Transformer as it is the most widely used material, because of the lowest hysteresis loss associated with this material. Also of high material Probability and good efficiency in transfer of power from one warning to another. Sheets of silicon steel are used in two different types. You can use either a cold rolled grain oriented steel or a cold rolled non grain oriented steel sheet.

To achieve the highest possible Energy Efficiency from your Transformer core you can use a thin strips of amorphous iron base alloy like Metglas. This material even offers you 70% less core losses as compared to Silicon Steel. This material is also much more environment friendly for your surrounding areas as compared to any other metallic material that you can use for your Transformer core.

If you are manufacturing a transformer core high frequency dry type transformer then it is highly recommended that you use manganese zinc ferrites for your transformer core. However if your dry type transformer is being designed and developed for operating precision instruments then it is highly recommended to use nickel iron alloys for your transformer core manufacturing.

The manufacturing of your dry type transformer core always starts as a thin sheet of metal that is precisely cut into the required sizes. After that the precision punch press machine presses and cuts the sheet into either UI or EI configurations. Several thin sheets of metal are cut and each sheet is then properly laminated and then carefully stacked up to construct a single core of a dry type transformer.

Winding of Dry Type Transformer

Constructing transformer winding of any dry type transformer is the most challenging and complicated stage in manufacturing dry type transformers. Before you start constructing the winding of your director Transformer you need to first select dry type transformer specification and then shape the conductor material of your Transformer winding. Round rectangular and foil type shapes are the most common and widely used shares of conductor material for constructing the Transformer winding of any dry type transformer.

The winding process of the dry type transformer is quite complex, you need to use a precision winding machine to wind the circular wire or rectangular strips in equal and very well calculated numbers of terms. After constructing a single layer of dry type transformer winding, you need to put an insulation layer on to the winding layer before you start winding another layer of Transformer winding.

This insulation layer is applied to develop a non contact assembly between layers of Transformer winding. complete insulation between layers of winding is needed to ensure that there is no short circuit between the layers of winding.

Common Insulation Materials

- Epoxy resin

- Nomex paper

- Enamel coating

- Polyester film

The winding method you adopt for the winding of your Dry type transformer is also very important. You can select a disc winding method where you will wind layers of conducting materials that will be you only in round shape. Each layer of winding you put on in a single disc will be separated using quality insulation material. The best advantage you get from your disc winding method is that the winding of your dry type transformer will have a better cooling capacity and the Disc type winding will offer you better mechanical strength for your transformer.

If you are manufacturing a high capacity dry type transformer for your application, then we highly recommend you to Select the helical winding method for your transformer. In this method the round conducting material wire will be when done with a helix angle. The helical winding will offer you the reduced stray losses and we also provide you with better short circuit strength.

If you are performing the winding process for low voltage winding then it is highly recommended to go for foil winding using a thin strip of the conducting material. Thin trip of conductor material will be winded around the Core and it will provide a very uniform current distribution. The foil winding is highly recommended for your high current application.

Insulation System in Dry Type Transformers

After you complete the winding of conductive material on your transformer core, you need to insulate the entire winding and core assembly in order to protect it from all types of external factors including electrical and environmental factors.

The insulation system will help you protect your Transformer winding from all types of electrical Short circuits and help you transfer and handle High Voltage with safety. The insulation system also helps you manage the heat and the separation of Transformer winding more effectively. This system when combined with the Transformer cooling system will help you prevent any type of overheating within the Transformer and also have you get more from your transformer in terms of its improved efficiency.

The Insulating system in a dry type transformer is done in a manner that it also improves its mechanical strength. You completely enclose the entire Core and winding assembly in a hard shell that protects it from any type of external force and vibration. It also reinforces the winding that improves its mechanical strength and resistance against any type of external force.

Insulation systems also help you protect the transformer winding and the core from all types of external environmental factors that your transformer might face. This includes the moisture, the dust, and debris, the water during a rainstorm and also direct sunlight.

The proxy reason is the most widely used material for insulating the internal components of the Transformers. This is because the proxy has several properties that offer significant advantages to A dry type transformer. These advantages include excellent dielectric properties that offer complete and perfect insulation of all the electrical components and protect any type of short circuit. When cure and hardens the foxy offers significant increase in mechanical strength of the transformer winding section. The proxy also offers a great level of production against all types of environment Factors like rain, moisture, and direct sunlight.

There are several steps involved in encapsulating the dry type transformer winding in epoxy resin. You need to select the appropriate type and quantity of chemicals to make the epoxy resin. The type of chemicals and the quantity of each chemical and the total quantity of the epoxy depends on the Transformer type, size, capacity, and the voltage rating.

Before applying the poxy on the dry type transformer winding you need to cover the outermost layer of the winding with the insulating paper. You can use Nomex paper or varnish to protect the winding.

In the third step you will apply the proxy on to the Transformer winding and there are two methods you can use to apply the proxy and properly insulate the dry type transformer winding. The first method is called vacuum pressure impregnation and the other method is called cast resin encapsulation.

In vacuum pressure impregnation, you first need to place the Transformer Core and winding assembly in a vacuum chamber and then you need to apply the vacuum pressure that removes all types of air washer from the chamber. After that you need to introduce the proxy in the vacuum chamber that the vacuum inside the Chamber will draw from the special Chamber of the machine and start feeling the vacuum chamber. The vacuum shows that each and every corner of the winding assembly is properly covered and field with the proxy and there is no bubble or moisture left on the winding.

In cast resin encapsulation, You first need to manufacture a mould according to the size design and requirements of your dry type transformer winding. After that you place your Transformer Core and warning in that mould and introduce the epoxy in the mold, under pressure. Once the epoxy feels the mould you leave the mould for curing.

You depend upon the type of chemicals used in the proxy and the size of the transformer winding that determines how you cure your epoxy. You can either place your mould inside the oven and use heat to cure the epoxy and it might take you several hours to achieve full polymerization.

The curing process is complete, you need to remove your Transformer winding from the mode It will be covered inside a hard share of epoxy. you will need to smooth all the short edges Round up all the corners to avoid any injury during the transportation, assembly or maintenance.

Cooling System and Enclosure of Dry Type Transformer

The dry type crossword depends on the natural air and in some cases on cooling fans to provide all types of cooling and removal of waste from the wind. Depending on the type of cooling system installed on your dry try transfer your Transformer tank will be designed to facilitate specific cooling systems.

If your dry type transformer is designed to work with a natural air cooling system then your Transformer tank will be designed with open went to enable natural flow of air to inform the Transformer winding.

If your transformer is designed to work with a cooling fan then your transformer tank will be designed to facilitate the installation and flow of air from the fan towards the Transformer winding. Your Transformer tank minute has several cavities or holes to facilitate the easy flow of air in and out of the transformer tank.

You may enjoy: What is Transformer Cooling and How is it done?

Bushings of Dry Type Transformers

The bushing of your dry type transformer will help you develop a non contact and isolating passage through your metallic Transformer tank. The Transformer bushings help you develop electrical insulation and avoid all types of electrical short circuits that might happen between the connecting wires and the Transformer tank.

These bushings also help you provide mechanical sport by holding the conductors family in place and reducing any drive of stress that might happen due to vibration of these conductors. These bushings also protect your electrical connections from all types of environmental factors like dust, moisture, and contamination.

You can manufacture these bushings from three main insulating materials including epoxy resin, ceramic, and from the polymer or composite material.

The proxy provides the most period type of insulation and high level of resistance and it is also the most used material for wishing manufacturing for a dry type transformer. These ceramic busheens or the most highly durable bushes and the applications involving an outdoor installation.

You can use polymer or composite material for your busing manufacturing if you are looking to manufacture a very light weight but high strength transformer bushing. The polymer and composite material bushings also provide very high resistance to all types of environmental factors like rain moisture and direct sunlight.

Terminals of Dry Type Transformers

Need to use dedicated terminals to connect your Transformer from to the grid and also connect your local low to the Electrical Transformer. Your Transformer terminals provide you a path to connect the grid with the warning and warning with the electrical load.

You can use basic types of electrical terminals for your dry type transformer. These types include bolt type terminals, clamp type terminals, plug in or quick connecting terminals, and busbar terminals.

You can use bold type terminals for any low or medium voltage application. This type of terminal ensures a strong and rigid electrical connection using mechanical bolts and provides high strength in all types of connections. The clamp type terminals are best suitable for high current applications of dry type transformers. This type of terminal is a very easy installation and low maintenance.

If you are designing a compact Transformer then it is highly recommended to use leg in or quick connector minutes as these are very small and compact terminals and they are designed for fast connection and disconnection without any use of tools.

If your dry type transformer is a part of your high power transmission or is a high power transformer then we highly recommend you to use the busbar terminal for all types of electrical connection. These types of terminals provide very low resistance and they are very highly efficient for power transmission purposes.

Protection and Monitoring Devices for Dry Type Transformers

you need to equip your dry type transformer with a number of dry type transformer protection and monitoring devices to ensure safety and reliability in its operations. You need to install a number of temperature monitoring sensors like thermistors, thermal relays, or temperature control units (the electronics thermostat).

Temperature sensors monitor the temperature of different sections of your dry type transformer and provide a consolidated output on a screen to inform you about the temperature of the entire transformer.

Protect the dry dry Transformer from any type of overcurrent or short circuit you need to install circuit breaker, fuses, and overcurrent relays in your dry type transformer. These devices will help you protect your dry type transformer by disconnecting the Transformer from the input and output if they get any over current from either the input or the output.

You also need to install a surge arrester and grounding system to deal with any type of electrical search in case of either thunderbolt striking or fault within the Transformer.

Working of these sensors depends on how you really want to control and monitor your dry type transformer. if you are working on an application where you can very easily assess your dry type transformer. Then all these dry type transformer protection and monitoring devices can be of normal simple and Manual type where you can do all manual work to control and take reading from these devices.

However, if you are working on a large application where manual work on these devices is not possible then you can install the dry type transformer protection and monitoring devices that can be remotely controlled using smart dry type transformer protection systems like SCADA integration for transformer monitoring systems where real time data can be recorded and controlled.

Conclusion

Dry type transformers are very important in our existing Electricity Distribution mechanism and in this article we have delivered you very Comprehensive information on different parts of dry type transformers. We have tried to explain to you the importance of each part, how material plays an important role in working and living you specific results from each part. and we have also tried to explain to you how different types of each part is used for specific applications.

Follow Up

Dry Type transformers are one of the two basic and important types of electrical transformer. We at Daelim are designing and developing dry type transformers of all types, sizes, and power capacity. Each of our dry type transformers can satisfy all international standards related to transformers manufacturing, operation, and safety.

If you have any questions about dry type transformers, Then Contact Us and we will talk you through the process.

Related Products

Related Article

Dry Type Transformer Cooling Methods

This article explains various cooling methods for dry type transformers, detailing how each method works, the components involved, and their pros and cons. It aims to help readers choose effective and efficient cooling solutions by understanding different systems and their performance characteristics in transformer operation.

Should Dry Type Transformers Be Installed Indoors or Outdoors?

This article compares indoor and outdoor dry type transformer installations, covering requirements, applications, ventilation, safety, and pros and cons. Indoor setups offer better protection and security but require more space and cooling. Outdoor installations save indoor space and reduce fire risks but need weatherproofing and enhanced security. Installation choice depends on environment, safety, and application needs.

The Critical Role of Transformers in Grid Edge Solutions

The power grid is rapidly changing due to renewable energy, EVs, and digital technologies. To meet new demands, the grid edge requires smarter and more flexible solutions. Modern transformers play a key role by enabling performance monitoring, load management, and renewable integration. They ensure safe, reliable, and efficient electricity delivery despite growing system complexity.

What are different components of electrical substation

Electrical substations regulate voltage, switch circuits, and maintain stable power flow from generation plants to consumers. They ensure efficient, safe distribution to industrial, commercial, and residential users. Reliable operation of all components and strong protective mechanisms are essential to prevent equipment damage, safeguard personnel, and manage faults or overloads. These systems support continuous service and overall grid reliability and stability.

Transformers at the Heart of NVIDIA’s 800 V HVDC Power Architecture

AI-driven data centers are rapidly increasing power demand from hundreds of kW to multi-MW levels, driving a shift toward new power architectures like NVIDIA’s 800V HVDC. Despite advances in semiconductors and converters, conventional transformers remain critical in grid-to-rack power distribution. This article highlights their role, Daelim Transformers’ custom solutions, and the future transition to solid-state transformers.