What are different components of electrical substation

An electrical substation is a key part of our electricity distribution system. It is responsible for controlling the voltage levels, switching the power circuits, and ensuring that there is a stable electricity supply from the electrical power generation plant to the electricity consumers.

Electrical substations are responsible for distributing electricity efficiently and safely to the industries commercial buildings and residential areas. To control, switch, and ensure safe supply of electricity, all the electrical substation components need to work efficiently. The substation should have a protective mechanism to safeguard all of its electrical equipment and personnel from faults and overloads.

Contact Daelim TransformerMajor Components of an Electrical Substation

The Electrical substation needs a series of substation parts that are connected to each other to regulate, switch, and ensure safe and stable supply of electricity from the power generation station to the further substations. Will discuss all major components of the electrical substation here in detail.

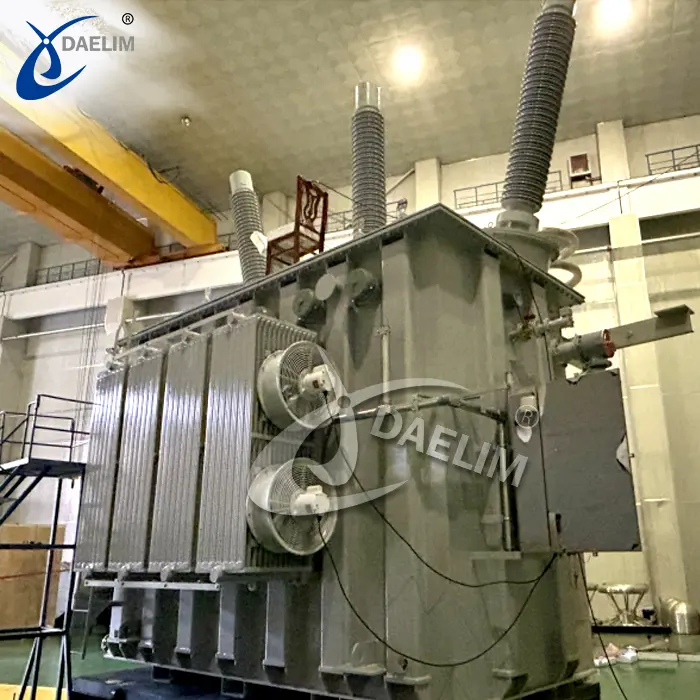

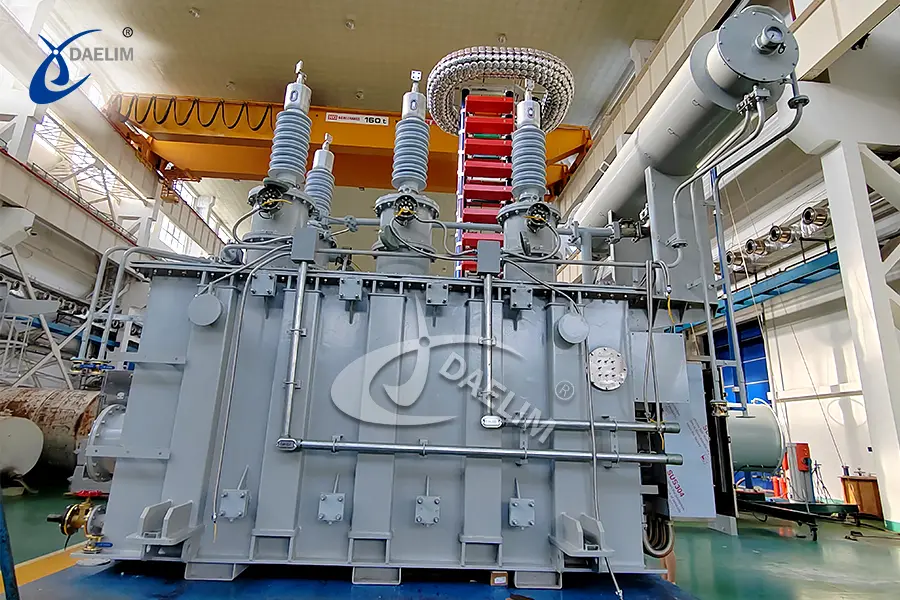

Transformers

Electric transformers are the heart of electrical substations as they regulate and ensure safe and continuous supply of electricity. Depending on the type of the electrical substation, an electrical substation can have either a large power transformer or a medium size power transformer or it can have distribution Transformers of different sizes and capacity.

Also depend on the function of the electrical substation whether the electrical transformers are Step Up Transformers or step down transformers.

The electrical power regulating capacity and efficiency of the electrical substation depends on the capacity and the efficiency of its electrical transformer. Build quality and the reliability of the transformer defines the quality and reliability in operations of the electrical substation.

Circuit Breakers

After the electrical Transformers the circuit breakers are the most crucial and highly important part of any electrical substitution. These electric circuit breakers offer protection of the components of electrical substation against any type of short circuit and for overloading conditions.

These circle breakers provide protection to the power system by acting as a switch that automatically and rapidly opens and closes to control the electrical circuit.

There are four basic types of circuit breakers used in different types of electrical substation components.

The first type is an air circuit breaker that uses air to extinguish the electric arc that is formed during the short circuit. The second type is the oil type circuit breaker that uses high quality oil as an insulator to quench the electric arc.

Third type is the SF6 circuit breaker that uses a specific gas called sulphur hexafluoride gas. This gas is a superior quality insulator and can be used to extinguish any type and intensity of electricity formed during a short circuit.

The fourth type is a vacuum circuit breaker that uses a vacuum developed across the important electric circuits to extinguish electric arc developed during short circuit.

The busbars

The busbars are a simple looking substation part but they do an important job of connecting all the other parts of the substation. These are conductive bars and their use for distributing electricity within the substation. There are many types of busbar in the electrical substation, Single busbar, double busbar and the main and transfer busbar system.

The single bus pass system is the simplest of all the three systems but it lacks redundancy. The double busbar system provides high flexibility and reliability in its operation and is thus recommended in all high power electrical substations.

The main and transfer bus power systems allow you to do the maintenance work without any type of power interaction during the maintenance work in the electrical substation.

The Isolators (Disconnectors)

Isolators also known as the disconnectors are not an integral part of an electrical station. These isolators or disconnects are only used to disconnect parts of the substation during the maintenance work. These isolators or disconnectors operate under no load condition and they show the safe handling of electrical equipment.

There are three types of isolators or disconnects, the single break isolators, the double break isolators and the pantograph isolators. Single breaks isolated are those that have a single gap also called the break in a circuit when they are open. Single breaks consist of two fixed contacts and one moving contact. The moving contact is used to open or close the circuit.

A double break isolator creates a gap or breaks when the circuit is open. The double break isolated consists of two fixed points and one moving arm that connects both of them. When the circuit is needed to open, the moving on rotates and gets disconnected from both fixed points, thus creating a two gap in an electric circuit.

The pantograph isolators as their name says has a pantograph mechanism to achieve the highest level of disconnection in an electric circuit. These pantograph isolates are best known for their compact design and highly recommended for application with compact spaces. It consists of scissors that move vertically to make or break any electrical circuit.

Surge Arresters / Lightning Arresters

Surge arresters also called the lightning arresters are also an important safety and protection related substation part. As its name implies its function is to worker surge arresters specifically when there's a lightning strike.

In the case of surge like that, these surge arresters work as an alternate path for current flow thus shielding are other important and sensitive electrical substation equipment from potential damage and failure.

There are two common types of surge arresters mainly based on the material.

First type is the metal oxide surge arrester where a surge arrester made of metal oxides varistors, specifically the zinc oxide is used. Zinc oxide had a very high nonlinear voltage current characteristic.

This means when normal voltage is applied and current flow is also normal, it offers very high resistance but when lightning strikes a surge of electricity enters the system, its resistance drops so low that it offers the minimum resistance path to all the current. So all the surge current passes through the arrester and enters the ground.

The second type of surge arrester is the silicon carbide material based surge arrester. It is a bit older type and technique as compared to metal oxide surge arresters. This type uses silicon carbide discs that are installed in a series with a fixed gap between them. The gap between the discs contains air.

During normal operation, the gap works as an isolator but when surge occurs, these gaps get ionized allowing all the surge current to easily pass through this route and get into ground.

Current and Potential Transformers

Other than the main transformer the electrical substation also has a current transformer and a potential transformer. The main purpose of the current transformer is to reduce the current produced or provided by the main electric city generating power plant to a lower measurable level for the protective electrical relays and meters.

The working of these current transformers is a bit different from conventional working. The primary winding of current transformers are connected in series with the main power line. The secondary riding produces a reduced level of current.

The reduced current is usually proportional to the primary winding. These reduced currents allow the measuring instruments like release and metres to measure the exact value of a large current with safety and without direct exposure to the high voltage and current lines.

Similarly to measure the voltage, we have potential transformers in electrical substation. The primary warning of potential transformers are connected in parallel to the high voltage line and the secondary winding of the potential transformer reduces the voltage typically to the level of 110 volts.

The measuring devices are connected to the secondary winding and they safely and easily measure the high voltage without any exposure to the high voltage.

Capacitor Banks and Reactors

The main purpose of electrical substations is to deliver stable electricity efficiently. There are two specific electrical substation equipment that are installed so that the substation can deliver stable electricity efficiently. One is called capacitor bank and other is called shunt reactor.

The main purpose of the capacitor bank is to improve the power factor of the electrical substation and it does so by generating the reactive power. The capacitor bank generates the reactive power that in return reduces the burden on the power source.

The power system has components like inductive loads that include motors and transformers that can consume reactive power. So the capacitor bank generating reactive power produces a burden on the system and it also reduces the land losses and improves the voltage stability.

With capacitor banks there can be scenarios where there is an expressive reactive power that can develop voltage search in light loading conditions. So to protect the system from that voltage search there is another equipment installed called a shunt reactor.

The shunt reactor works opposite to the capacitor bank and absorbs the excess reactive power generated by the capacitor bank. This helps stabilize the voltage output of the electrical substation and this also prevents the sensitive electrical substation components from the sudden voltage surge.

Protective relays

Protective relays are the most important safety equipment installed in electrical substations. This is because these relays are responsible for detecting any abnormal activity related to electricity. If the protective relay detects any normal condition it will initiate the circuit breaker operation and will work to isolate default from the other electrical substation equipment.

There are three main types of protective relays, the electromechanical relays, static relays, and the microprocessor.

The electro-mechanical relays use magnetic and mechanical components like lever's or coils to operate. The electro-mechanical relays are mostly found in older electrical substations that rely on mechanical mechanisms for operations.

Static releases use a typical solid state electronics component for operation rather than any mechanical mechanism. As they do not have any moving parts they require much less maintenance and they work much faster and more accurately compared to electromechanical relays.

The microprocessor based digital relays are the most advanced and nowadays widely used in all types of electrical substations. These relays operate on Microprocessor and software terms to detect any types of faults.

Earthing and Grounding

Just like in every high electrical power system the electrical substation and all its equipment need proper earthing and grounding systems. This system will help protect the sensitive equipment from any type of electricity search.

There are three main types of earthing systems available, the plate earthing. the Rod earthing, and the grid earthing.

Conclusion

The electrical substations are a critical part of our current electricity power generation and distribution setup. These substations show that the electricity provided to the consumer is stable, reliable and is being delivered efficiently. To perform their electrical substation have a number of equipment and substation parts that all work together to deliver us electricity. These electrical substations have all the required safety equipment that ensure that any type of fault or external factors lightning does not affect the sensitive equipment and working of the electrical substation.

Follow Up

The electrical substation equipment includes power transformers, distribution transformers, circuit breakers, busbars, potential transformers and all types of safety equipment. All these equipment needs to work efficiently to deliver electricity in safe, reliable, and efficient manner.

We at Daelim offer transformers of all types, sizes, capacity, and power rating. We design and manufacture our own transformer that can pass any international standards related to transformers, their manufacturing, and safe operation.

If you have any questions related to transformers and electrical substations. Contact Us and our team will talk you through the process.

Related Products

Related Article

13.8 kV 10.5 MVA Substation Transformer for Ecuador

A customer from Ecuador contacted Daelim Transformer for a 10.5MVA substation transformer (13.8kV high voltage, 2.4kV low voltage). Daelim Transformer provided a customized solution, conducted virtual factory tours, ensured rigorous quality control via video inspections, and offered post-delivery online training and ongoing support, fostering a successful partnership.

Canadian 69 kV Substation Transformer Project

Today, we are excited to present a case study on a 69 kV substation transformer project by Daelim Transformer. Our Canadian client required a step-down transformer for their substation to connect with the hydroelectric grid in Quebec.

4500 kVA Substation Transformers for Australian Mining Site

Today, we introduce a project by Daelim Transformer aimed at supplying transformers to a mining site in Australia. This project entails the provision of two units of 4500 kVA substation transformers tailored to fit the narrow confines of mining tunnels. Due to space constraints, the transformers need to be compact in size and mounted on mobile racks for easy maneuverability within the mine shafts. This necessitates meticulous design to meet the strict dimensional requirements set by the client.

69 kV Power Transformer for Substation in Pennsylvania

Daelim recently completed the design, supply, and installation of a custom 69 kV transformer for a substation in Pennsylvania. This high-efficiency, three-phase transformer is engineered for reliability, scalability, and long-term performance, ensuring a stable power supply to the substation. Key features include low load losses, minimal maintenance, high insulation levels, and flexible cooling options. The solution enhances grid stability, supports future expansion, and minimizes energy consumption, reinforcing Daelim’s commitment to quality and innovation in power systems.

Why Load Bank Testing Is Essential for Transformer Maintenance

Transformers are critical to power infrastructure, and their reliability ensures uninterrupted electricity and business operations. Regular inspection and testing are essential, with Load Bank Testing being highly effective. This method subjects transformers to controlled voltages and loads, verifying capacity, handling of voltage and current, power factor, and heat rise, while detecting hidden issues to ensure optimal performance.

The Critical Role of Transformers in Grid Edge Solutions

The power grid is rapidly changing due to renewable energy, EVs, and digital technologies. To meet new demands, the grid edge requires smarter and more flexible solutions. Modern transformers play a key role by enabling performance monitoring, load management, and renewable integration. They ensure safe, reliable, and efficient electricity delivery despite growing system complexity.