Guide to Common Industrial Transformer Voltages

It doesn't matter which industry you consider or in which industry you are working, your industrial operations totally rely on the consistent, stable and reliable supply of electricity to run your machinery equipment and all types of control systems like the lighting and the HVAC systems and more. To get this consistent stable and reliable supply for electricity our Electricity Distribution system heavily relies on the electrical Transformers of different voltages and power capacities.

Whether you need to step up the electricity that is produced at the electrical power generating plants or you need to step down electricity for consumption or distribution systems, there is a dedicated Electric Transformer for your application based on its voltages. This article is about understanding the Transformer voltages and how industrial Transformer voltages are categorised for better understanding and division for industrial applications.

Contact Daelim TransformerImportance of Selecting the Right Transformer Voltage

Electrical machinery equipment and devices of all types and sizes have their own unique electrical power needs. that electrical power is just a combination of electrical voltage and the electrical current. to be exact the electrical power is a product of electrical voltage and electrical current that machine utilizes to perform any specific task.

Electrical machinery equipment and devices of all types and sizes have their own unique electrical power needs. that electrical power is just a combination of electrical voltage and the electrical current. to be exact the electrical power is a product of electrical voltage and electrical current that machine utilizes to perform any specific task.

It is not a simple concept that you provide whatever electrical voltage and current whose product equals the electrical power that electrical machine requires for operation. How this works is you need to deliver an exact value of electrical voltage and electrical current whose product equals the power requirement of a specific machine.

So to operate any industrial machinery equipment or electrical devices you need an electrical setup in which the industrial Transformer voltages and The Power capacity is what the electrical machinery of that specific industry needs.

Other than this electrical Transformers are not only responsible for providing electricity to the industrial machinery and equipment. There are power transformers that are responsible for taking electricity from the electricity power generating plants and delivering it to the distribution system that further distributes the electricity to smaller regions or areas.

The distribution system that takes electricity from the Power Transformers distributors is to these smaller regions or areas using another type of Transformers called distribution transformer. So electric Transformers are everywhere. They are part of our electricity generating system, they are part of our Electricity Distribution system and they are part of our local and industrial electricity consumption system.

Keeping in view the above importance and integration of Electrical Transformer into our existing electricity system, you need to select Transformer voltage very carefully as this will define the performance efficiency and working of your industrial equipment and will protect it from any kind of electrical damages.

Furthermore, selecting the right transformer Will help reduce all types of energy and power losses that happen in the electricity distribution system and will also help you ensure compliance with all types of national and international electrical standards. any mismatched Transformer voltage in the system will lead you to lower performances, extended downtimes and even failure of the entire industrial setup.

You may enjoy: Ultimate Guide To Transformer Sizes and Ratings

Key Factors Influencing Voltage Selection in Industrial Applications

As we have explained to you how important it is for you to select a proper Transformer voltage for your industrial performance. Now here is the question, what are the factors that influence that transformer voltage selection for any industrial application. Here are 6 different factors that you need to consider when you are making the transformer voltage selection for your specific needs whether it is Industrial or residential needs.

- The first factor is the load requirement that the Electrical Transformer voltage will be supplying. You need to know the exact power demand of the electrical load and you need to know it in KVA (kilo Volts Ampere). With this you will know the exact electrical power and the voltage with electrical current that your Electrical Transformer needs to supply to run the specific machinery.

- If you are selecting a Transformer for the electricity distribution system then you need to know the distance between the electricity generating electrical plants and the either local distribution system or the electricity consuming industry or residential set up. This is because the reason that you need much higher voltage is to deliver electricity to a longer distance considering the electrical losses that happen in the Electricity Distribution system.

- Third factor here is the type of electrical load or electrical equipment machinery for which the Electrical Transformer needs to provide voltage. For specialised machinery you need a dedicated Transformer that can provide the voltage in the most stable and safe manner. In such applications the industrial Transformer voltage fluctuation can easily damage the sensitive machinery equipment attached to the Transformer.

- The fourth factor here is the local, national or International standards related to the industry or the rules and regulations and standards related to the electrical Transformers and Electricity Distribution system. Each country or region of this world has their own rules and regulations for standards about the Transformer voltage and level above which or below which does not allow the Transformer voltage operation.

- The fifth factor here is the energy efficiency goals for standards that limits you to select Transformer voltage or specific Transformer for your industrial application. Selecting the right Transformer voltage range will help you get the best out of your Electricity Distribution and consumption system because the right voltage minimizes the energy losses and waste of electricity. This will potentially reduce your operational cost and will help you financially in longer turn.

It is not like that you need a specific industrial Transformer voltage to create some or few of your electrical machines of your industry and you select a transformer that supplies that specific voltage. Need to consider any further or future expansion that might happen in your residential area or in your industry. So you need to select the Transformer voltage that does not only meet your current need, but has the ability to provide the voltage for any future expansions.

Transformer Voltage Formula

Common Industrial Transformer Voltages by Category

Low Voltage Transformers

The low voltage transformers are usually small electrical Transformers that are designed and developed for Industries that have low voltage but very sensitive machinery. Like we have HVAC systems in residential or industrial buildings, elevators in commercial buildings and light duty machineries and electrical equipment in various industries.

Typical industrial Transformer voltage for low voltage transformer is either one of the following

- 120V / 208V

- 240V

- 277V / 480V

- 600V

Now it depends on the regional national or International standard that what voltage does the equipment or machinery need to operate. If the machinery needs any of the above mentioned voltages or any other voltage that lies within this voltage range then we will categorise it as low voltage Transformer for industrial applications.

Medium Voltage Transformers

The medium size Industry that needs voltage is more than that of the mentioned low voltage Transformers but less than few kilowatt then that industry will specifically need industrial Transformer voltage that lies in medium voltage transformer.

The industries like manufacturing industries, the mining Industries large Hospital large commercial building, the data centre mining centre and industrial power plants and other industrial setups fall in the category of medium level industry and they need medium voltage Transformers for their applications.

Typical industrial Transformer voltage range for medium voltage transformer is either of the following

- 2.4 kV

- 4.16 kV

- 13.8 kV

- 34.5 kV

Similar to the low voltage Transformer, The specific voltage of the medium voltage Transformer depends on the unique industrial needs and the national or International electrical standards that are being followed in that specific industry or region.

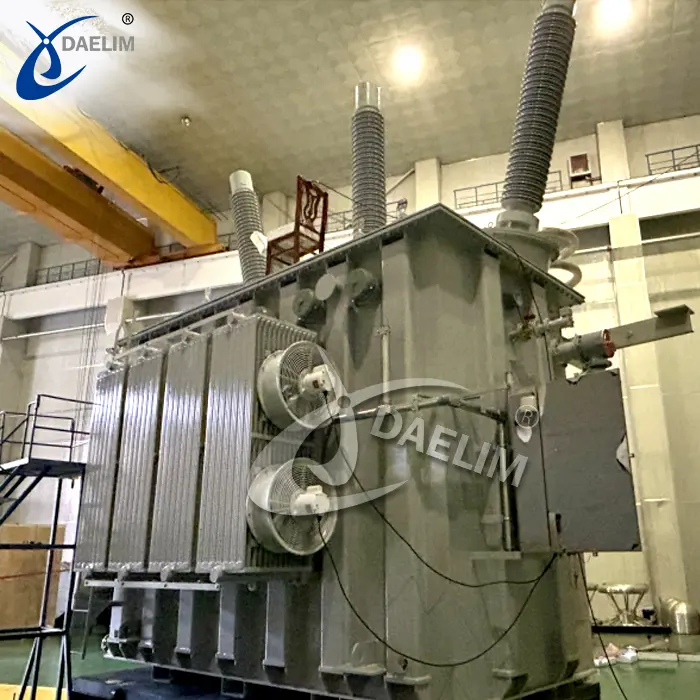

High Voltage Transformers

The high voltage transformers are really huge and they are used for either very heavy industries or in the power generation or National grids. These transformers do not have any small or medium size application either; they are not designed and developed to deliver any normal electrical voltage that we see around us.

These transformers are designed and developed for industries like Steel mills, large chemical plants, the national grid station, Electricity Distribution centres and for power plants that generate electricity. In some applications these large or High Voltage transformers are also used in substations or utility stations of electricity.

A typical industrial Transformer voltage range for high voltage Transformer lies in any of the following voltages

- 69 kV

- 115 kV

- 230 kV

- 345 kV

- 500 kV

Get it free: High Voltage vs Medium Voltage Transformer

Industry Specific Transformer Voltage Requirements

Manufacturing Industry

We consider metal manufacturing industries where there are CNC machines or Robotics setups and large motors and conveyor systems that are designed and developed to process large metal pieces and metal sheets.

Then the common industrial Transformer that might be needed for such an application needs to have a voltage of at least 480 volts to operate CNC machines like CNC turning centre and CNC machining centres. These machines or very sensitive to voltage fluctuation show the Transformer should need to have proper voltage regulation and be able to provide a steady 480 Volts to the machine.

In case that manufacturing industry has large conveyor belts that have multiple high power electrical Motors to move the conveyor belt then the industry might be needing industrial Transformer voltage of 600 volts or more.

Service Industry (Commercial Buildings, Hospitals)

If we look into the services industry where there are different types of professional services being delivered like we have our HVAC systems we have a building with multiple Elevators we have very large hospitals that have high voltage equipment like extreme machines CT Scan machines.

Voltage requirement of these types of services industry is very wide. Each service industry needs very different types or very different categories of electrical voltage and their power requirements are very different.

An HVAC system can be operated on either 120 V, or 220 V. Even in applications where there are very large HVAC systems the system might need 480 volts to operate effectively. Similarly the large or sensitive medical devices that might need a three phase electrical supply with the voltage rating of 480 volts they might be needing single phase electricity of a standard 120 volts for 220 volts.

Data Centers and Blockchain Facilities

One of the most rapidly growing industries is the industry of data centres and blockchain facilities. These facilities consist of very sensitive yet powerful computer systems that operate continuously to handle intensive computational workloads and complex digital processing tasks.

One of the most rapidly growing industries is the industry of data centres and blockchain facilities. These facilities consist of very sensitive yet powerful computer systems that operate continuously to handle intensive computational workloads and complex digital processing tasks.

Voltage requirements of these data centres and blockchain facilities are not that much; they usually operate on either 220 or 480 volts but the quality and the efficiency of the electricity distribution system needs to be very high because these computers are very sensitive to any type of voltage fluctuation. You need to consider the redundancy, efficiency, and compact Transformer design for these data centres.

Common Industrial Transformer Sizes and Ratings

Following is a common industrial transformer ratings list.

| Industry | Typical Transformer Voltage & transformer sizes kVA |

| Manufacturing (General) | 480V / 600V with 75 kVA to 500 kVA |

| Precision Manufacturing (CNC, Robotics) | 240V / 480V with 150 kVA to 750 kVA |

| Commercial Buildings | 208V / 480V with 75 kVA to 300 kVA |

| Hospitals & Medical Facilities | 208V / 480V with 150 kVA to 500 kVA (with isolation) |

| Data Centers | 13.8 kV primary to 480V secondary with 500 to 2500 kVA |

| Blockchain | 13.8 kV / 34.5 kV with 1000 kVA to 3000 kVA |

| Large Industrial Plants | 4.16 kV / 13.8 kV with 750 kVA to 5000 kVA |

| Mining Operations | 13.8 kV / 34.5 kV with 1000 kVA to 5000 kVA |

| Power Generation Facilities | 69 kV / 115 kV with 10,000 kVA and above |

| Utility Substations | 69 kV / 230 kV with 10,000 kVA to 100,000+ kVA |

| Institutional Campuses | 4160V / 13.8 kV with 500 kVA to 1500 kVA |

| HVAC Systems (Commercial/Industrial) | 277V / 480V with 75 kVA to 300 kVA |

Conclusion

Industrial Transformer voltage selection and Transformer sizing is one of the most important and crucial tasks during the Transformers selection for a specific industry or application. There are several different factors that are considered during this selection stage as the Transformer voltage is important to ensure the operations stability, ensure effectiveness and equipment safety. By knowing the exact voltage requirement of the specific industrial equipment for machinery you can select a transformer that has the required voltage delivery capabilities to run the requirement with safety.

Follow Up

We have delivered you a guide to common industrial Transformer voltage to enable you to understand how different industries and applications need Transformers with specific voltage output. We at Daelim Transformer offer electrical Transformers of all types, sizes and of different voltage outputs. All transformers are designed and developed to the highest standard and our products can satisfy all types of national and International standards.

If you have any questions related to industrial Transformer and industrial Transformer voltage range then you can contact us and our team of experts will lead you through the process of Transformers selection.

Related Products

Related Article

13.8 kV 10.5 MVA Substation Transformer for Ecuador

A customer from Ecuador contacted Daelim Transformer for a 10.5MVA substation transformer (13.8kV high voltage, 2.4kV low voltage). Daelim Transformer provided a customized solution, conducted virtual factory tours, ensured rigorous quality control via video inspections, and offered post-delivery online training and ongoing support, fostering a successful partnership.

1500 kVA Transformer for Australian Mining Project

Introduce the 1500 kVA transformer tailored for Australian mining projects. The transformer operates in a three-phase configuration, with a total of four units deployed. Notably, its primary voltage stands at 11kV, while the secondary voltage is 1kV. Characterized by its compact size, emphasis on safety, and unwavering reliability, this transformer is meticulously designed and manufactured to meet the stringent requirements outlined in AS 60076 and AS efficiency value standards.Let's delve into the key features and specifications of this essential solution.

2 MVA Pad Mounted Transformer for Utility

Behold the backbone of Canada's utility infrastructure—the 2MVA pad mounted transformer. With a primary voltage of 4160Grdy/2400V and a secondary voltage of 800GrdY/461V, this transformer stands as a testament to efficiency and reliability in power distribution. Crafted in strict accordance with CSA standards and CAN/CSA802.1 energy efficiency guidelines, it embodies the pinnacle of engineering excellence.

2600 kVA Pad Mounted Transformer For Blockchain In Kansas

This morning, I received the on-site photos of the pad-mounted transformers from the customer, and I was overwhelmed with excitement and joy. These pad-mounted transformers are installed at a 20MW blockchain site in Kansas, USA. A total of 5 sets of 2600 kVA pad-mounted transformers, all UL-listed, are being deployed at this site. Currently, 3 sets have already been installed onsite and are scheduled to be powered on imminently.

Pad Mounted Transformer For High Voltage Substation

FWS commissioned Daelim Transformer to design and manufacture a new high voltage substation for the Richardson International Canola Crush facility expansion in Yorkton, SK. The project required two specially designed top-in pad-mounted transformers, one 2 MVA and one 5 MVA. Unable to meet the delivery deadline, local North American suppliers led FWS to choose Daelim Transformer for their capacity and quality. The transformers were successfully produced and delivered within 16 weeks and are now operating safely.

69 kV Power Transformer for Substation in Pennsylvania

Daelim recently completed the design, supply, and installation of a custom 69 kV transformer for a substation in Pennsylvania. This high-efficiency, three-phase transformer is engineered for reliability, scalability, and long-term performance, ensuring a stable power supply to the substation. Key features include low load losses, minimal maintenance, high insulation levels, and flexible cooling options. The solution enhances grid stability, supports future expansion, and minimizes energy consumption, reinforcing Daelim’s commitment to quality and innovation in power systems.