Comprehensive Guide on ANSI Transformer Standards

Electrical transformers are such an important part of our current electricity distribution system that each aspect of these electric Transformers needs to be standardized, so that their efficiency, reliability and safety can be ensured.

American National Standard Institute (ANSI) is one of the bodies of the United states of America that issued instructions about each aspect of electrical transformers called ANSI transformer standards. We will go through each aspect of this transformer standards to have a complete and comprehensive understanding of them.

Contact Daelim TransformerPurpose and Scope of ANSI Transformer Standards

The main purpose of ANSI Transformer standards is to have a benchmark for Electric Transformers that will be installed and used in the United States of America. There are four main points that comprehend the purpose and scope of ANSI standards for Electrical Transformer.

The main purpose of ANSI Transformer standards is to have a benchmark for Electric Transformers that will be installed and used in the United States of America. There are four main points that comprehend the purpose and scope of ANSI standards for Electrical Transformer.

Standardizing Transformer Design, Performance, and Testing

The first and the main purpose and scope of ANSI Transformer standards is to develop a bench mark and provide guidance about the acceptable Transformer design, needed performance and compulsory testing.

This specific ansi electrical standards works as a benchmark for Electrical Transformer design that will instruct the designer about limitations under which he has to design the Transformer. These limitations include the material usage, the construction of the Electrical Transformer and what kind of electrical properties that the design needs to ensure.

These standards make sure that different Electrical Transformers that are designed and developed by different transformer manufacturing companies have uniform properties and performance when installed in the United States of America and other countries that follow this ANSI standard.

You may enjoy: Key Principles of High Voltage Transformer Design

Ensuring Transformer Safety, Reliability, and Efficiency

Another purpose and scope of ANSI Transformer standards is to ensure that each transformer design and developed by different manufacturing companies is safe, reliable and is highly efficient as per the requirement of the government of United States of America or any other government that follows this specific standard.

The ansi safety standards will issue guidelines and instructions and the number of safety features for the design aspects that the Transformer needs to have to ensure that it will remain safe during its entire useful life. Similarly the ansi standards for transformers will issue guidance and instruction that the working of the transformer is highly efficient and it remains a reliable source of electricity regulation during its entire useful life.

Get it free: Complete Introduction of Energy Efficient Transformers

Compatibility with Power Systems and Electrical Networks

Another highly important purpose of having or issuing the ANSI Transformer standard is to make sure that the Transformer remains compatible with the power system and electrical network throughout the United States of America and all other reasons that follow these standards.

The ansi electrical standards will ensure that each and every Transformer manufactured under this standard has a working mechanism or design that is acceptable to the national electrical grade of the United State of America and it integrates seamlessly with the electricity distribution system throughout the United States America, irrespective of where the Transformer was designed and developed.

Compliance with National and International Electrical Codes

Another important scope of the ANSI standard for Electrical Transformer is to ensure that the Transformers that are designed and developed under these standards satisfy the national and international electrical standards of all types or standards of any region that follow these ansi standards for transformers. This will make sure that the Electrical Transformer will meet all the legal and the operational requirements of different industries around the globe without any need of custom instructions over custom design to satisfy the requirement.

Key Guidelines Provided by ANSI Transformer Standards

Transformer Design Standards

When we talk about the guidelines that ANSI Transf

ormer standard issues in respect to the Transformer design then we are talking about each and every expert of the Electrical Transformer design including the material used and the operating conditions under which each part will work.

Core Materials and Winding Requirements

During the designing stage of the Electrical Transformer the designer can select any configuration and design for the Transformer winding and the Transformer Core. However the designer is forced to follow the guidelines and instructions provided by the ANSI standards about the Transformer core material and the winding material.

These ANSI electrical standards limit the designer to design the Transformer winding and the core keeping in mind the electrical and physical properties of Specific material for the Transformer winding and Core.

In this regard the ANSI C57.12.01 is the specific code which the ANSI Transformer standard provides to the designer to guide him about the use of silicon steel and amorphous metal cores to improve efficiency and reduce losses.

Keep reading: Ultimate Guide To IEEE C57 Standard

Insulation and Cooling System Guidelines

Similar to the material selection of the core and winding section the designer needs to select the proper material for insulation of the transformer core and winding. Designer needs to perform proper calculations depending upon the transformer size and power capacity and then consult the ANSI Transformer standard so that he can specify this Pacific class of insulation material.

Similar to the material selection of the core and winding section the designer needs to select the proper material for insulation of the transformer core and winding. Designer needs to perform proper calculations depending upon the transformer size and power capacity and then consult the ANSI Transformer standard so that he can specify this Pacific class of insulation material.

The ANSI standard issues specific guidelines in ANSI C57.12.00 According to which the designer needs to select a specific class of insulation material he can either select class A B F and H type insulation materials and it highly depends on the Transformer cooling system. As we know that there are several cooling methods for Electrical Transformers including both natural and forced convections of oil and air.

So the Transformer designer needs to consider two different things at the same time, depending on the Transformer size and Power capacity he needs to simultaneously decide the Transformer cooling method and suitables insulation material for the Transformer. The guidelines issued by the ANSI standards help the designer by first providing the instructions on which cooling method to select depending on the Transformer size and then suggesting a suitable class of insulation material based on the transformer cooling method.

You may enjoy: What is Transformer Cooling and How is it done?

Load Handling Capacity and Voltage Ratings

The ANSI standards also specify the operating conditions under which the specific type, size, and power capacity of a transformer can operate. During the designing stage the Electrical Transformer designer needs to consider each and every scenario including the operating load, the maximum load, the minimum load, and the load fluctuation.

Similarly the voltage and current ratings including the minimum and the maximum electrical voltage and electrical current that the Transformer needs to provide. The Transformer designer also needs to consider the overloading condition on the Transformer and need to design the Transformer in a manner that it can handle a specific range of overloading in case of any fault or electrical surge.

The ANSI C57.12.90 provides detail of operating conditions including the range of overloading or voltage fluctuation for which the Transformer needs to be designed. Standard mentions a range of overloading or the voltage fluctuation based on the Transformer type, its size and its Power capacity.

Testing and Maintenance Standards

After selection of material and manufacturing of Transformer the Transformer testing and Developing the maintenance procedures is the most important task. The ANSI standard also has proper documentation to perform all types of Transformer testing and do the proper maintenance of the transformer throughout its useful life.

Reading more: How to test a power transformer?

Factory and Field Testing Requirements

After the manufacturing of an Electrical Transformer there are a number of tests that you need to perform on your Electrical Transformer when it is still inside the factory and there are certain tests that you need to perform in the field before the transformer is optionalised.

The ANSI C57.12.91 Provides detailed guidance and information on several tests that you need to perform on an Electrical Transformer. These tests include the dielectric test and the short circuit as the temperature rise test that needs to be performed before the transformer is deployed. The standard provides you with all the necessary information on how to perform these tests, how to read the outcome, what should the outcome be and how to keep the record of the test.

Periodic Maintenance and Inspection Guidelines

After the Transformer has passed or type of testing and field safety procedures it is now operationalised and needs periodic maintenance and proper inspection throughout its useful life in order to deliver safe and reliable performance. The ANSI also provides proper guidance and instructions on how to do the proper inspection and what are the requirements of periodic maintenance of Electrical Transformer.

The ANSI C57.140 provides proper guidance and documentation about inspection and testing of all types and sizes of electrical Transformers. Standard provides guidance on how to perform specific inspection or how to perform the complete periodic maintenance.

The standard also pinpoints the type of inspections and periodic maintenance of specific parts like the insulation resistance of both dry and wet type transformers and oil quality test of oil type transformers.

ANSI Safety Standards for Handling and Servicing Transformers

Due to their Complex design and sensitive parts the Electrical Transformer needs very careful handling and proper servicing care during all types of maintenance. There are different types of handling requirements of different types of Transformers as similarly there are different types of maintenance needed for different types and sizes of Transformers.

The ansi safety standards ANSI C57.12.50 provides very comprehensive and detailed instruction on how to handle each type of Electrical Transformer. This also includes specific handling procedures of different parts and also includes the Assembly of different types of parts onto the main Transformer body.

This ANSI safety standards also covers the safe handling and installation of Electrical Transformer on the installation site. This standard also deliver's a very comprehensive instructions on how to perform maintenance with proper care and how workers can keep themselves safe and how to protect equipment during scheduled maintenance.

ANSI Electrical Standards for Grid Stability

Our current Electricity Distribution mechanism has several types of Electrical Transformer connected with each other and they are responsible for receiving electricity from the electricity generating power plants to the consumers. With this there is a need for standards that guide and provide necessary instruction about the connectivity and connection stability.

The ANSI C57.12.80 Standard provides necessary guidance and instructions to show that the connection made between the Transformer and the electricity distribution system are a perfect match and there is no face miss match between the Electrical Transformer and the electricity distribution system. Standard also guides you about the type of connection needed in how to make a stable connection so that the grid can offer stability in Electricity Distribution.

Performance and Efficiency Standards

Transformer efficiency is the measure of its output and the different types of losses associated with transformer working and similarly the performance is associated with the different types of noises and other environmental factors associated with electrical Transformers.

Transformer efficiency is the measure of its output and the different types of losses associated with transformer working and similarly the performance is associated with the different types of noises and other environmental factors associated with electrical Transformers.

In order to ensure that all transformers installed in the United States of America have the same efficiency and performance, the ANSI C57.12.92 standard issues a minimum efficiency level for all types of Electrical Transformer. It provides details on the performance criteria and what should be the minimum efficiency of each type size and power capacity and what should be done to reduce the energy wastage from the Transformer and from the entire Electricity distribution system.

The ANSI C57.12.00 offers guidance for defining the power factor production for Electrical Transformer and also provides information on the transformer losses like Copper losses and core losses. Similarly the ANSI C57.12.90 specifies the different types of noises that are associated with electrical transformers. The standard help designer ensures that the transformer that he designed comply with the environment standards of the United State of America and any other region of the world that follows the ANSI standards.

Conclusion

ANSI Standards are very important for Electrical Transformer in order to show that each and every Electrical Transformer that is being installed in the United States of America and any other region of the world that follows the standard has uniform performance, efficiency, reliability and safety. The ANSI Transformer standards provide necessary guidance and instructions on the Transformer design, manufacturing, performance, maintenance, safety, reliability and efficiency.

Follow Up

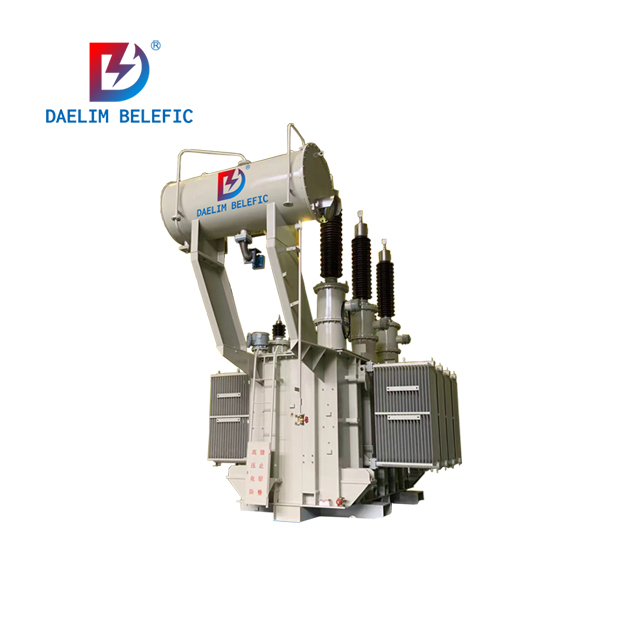

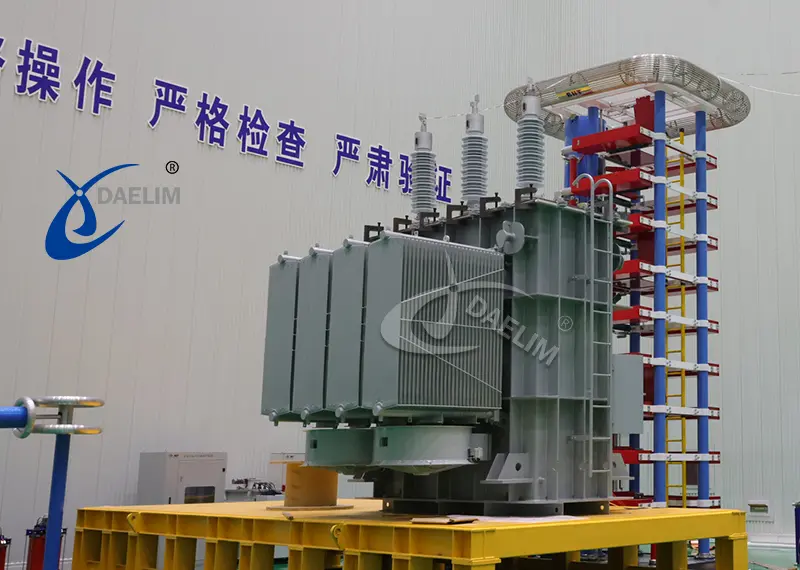

ANSI transformer standards were developed to make sure that all transformers that are designed and developed under these standards have uniformity in their output and they can offer stability in our electricity distribution system. We at Daelim Transformer offer transformers of all types, sizes, and power capacity that can satisfy ANSI and any other electrical transformer standard.

If you have any questions about ANSI transformer standards, Contact Us.

Related Products

Related Article

Pad Mounted Transformer CSA C227.4 National Standard of Canada

As a transformer buyer and manufacturer, you should be familiar with the local transformer design requirements and standards. This article tells the Canadian country's transformer standard CSA C227.4, the pad-mounted transformer below 3000kva.

Ultimate Guide To IEEE C57 Standard

Daelim is a professional IEEE standard transformer supplier and manufacturer. Various types of IEEE standard transformers can be provided, such as pad-mounted transformers, oil-immersed transformers, single phase pole mounted transformers, dry transformers, and power transformers.

CSA C802 For Minimum Efficiency Values For Power Transformers

The Canadian Standards Association has issued and produced CSA C802 as a national standard and policy for the country. This policy explicitly shows the performance and efficacy levels of power transformers rated from 501 to 10000 kVA.

The Ultimate Guide To IEC 60076 Standard

Daelim is IEC, ANSI/IEEE, AS, CSA, and UL transformer manufacturer who has been exported to countries around the world. The transformers supplied by Daelim fully meet and exceed the requirements of the IEC 60076 standard.

CSA C227.3 For Single Phase Pad Mounted Distribution Transformer

What we have here are the Canadian Standards Association standards. This will include the CSA-C227.3 guidelines for single-phase pad-mounted distribution transformers.

Complete Introduction of Energy Efficient Transformers

his article provides a comprehensive overview of energy efficient transformers, explaining their importance, working principles, efficiency factors, and key differences from standard transformers. It also covers materials, manufacturing techniques, selection criteria, regulatory standards, and future trends such as superconducting cores and IoT integration in power distribution systems.