Guide to Types of High-Voltage Bushings for Pad-Mounted Transformers

Are you uncertain about which high-voltage bushing your pad-mounted transformer requires? Let our guide to pad-mounted transformer HV bushings enlighten you on the various types and their applications.

What are transformer bushings?

Transformer bushings serve as insulating devices that lead the transformer coil leads outside of the oil tank. Not only do they insulate the tank from the leads, but they also secure the leads in place. These bushings facilitate the flow of current in and out of the transformer through connected cables.

Types of Pad Mounted Transformer HV Bushings

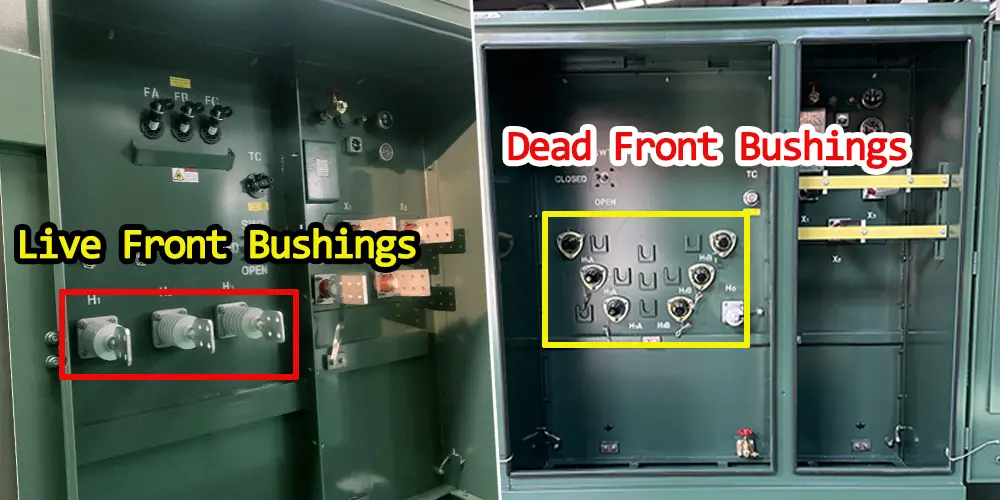

Pad mounted transformers come in two primary types: dead front and live front. Each type corresponds to different high voltage bushing designs, as outlined below:

You may enjoy: The Ultimate Guide to Dead Front Transformers

Dead Front Bushing

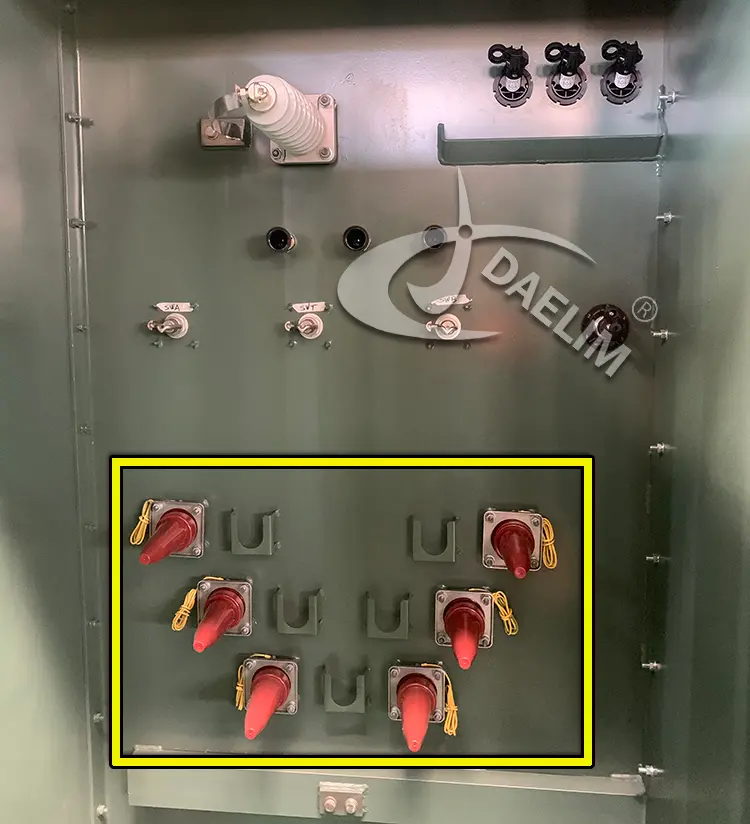

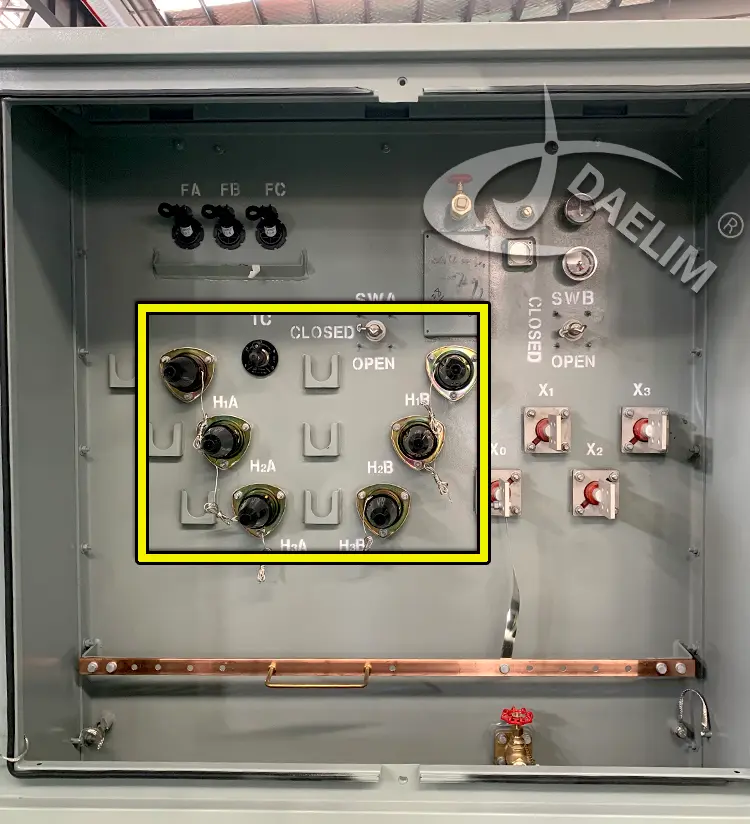

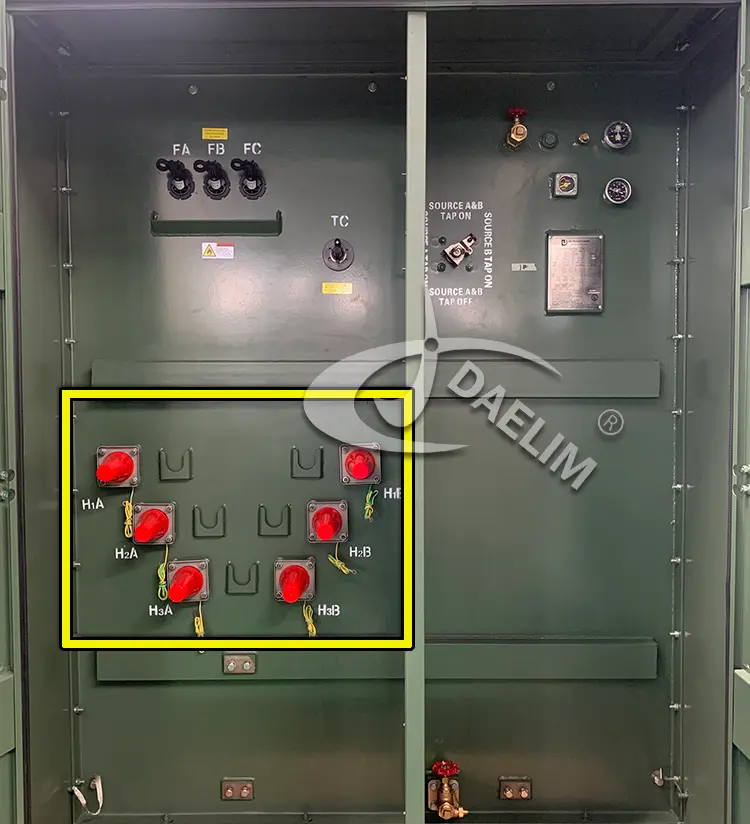

Dead front bushings feature conductors fully enclosed within insulating materials such as epoxy, EPDM, or nylon resin. There are two main types: separate and integrated. Dead front bushings must be externally replaceable, and the inside terminal connections should be externally removable through the connector's opening in the transformer tank or accessible through a handhole to permit removal and replacement.

The dead front bushing on the pad-mounted transformer must meet the dimensional and electrical requirements of IEEE 386.

Contact Daelim TransformerSeparable Insulated High-Voltage Bushings

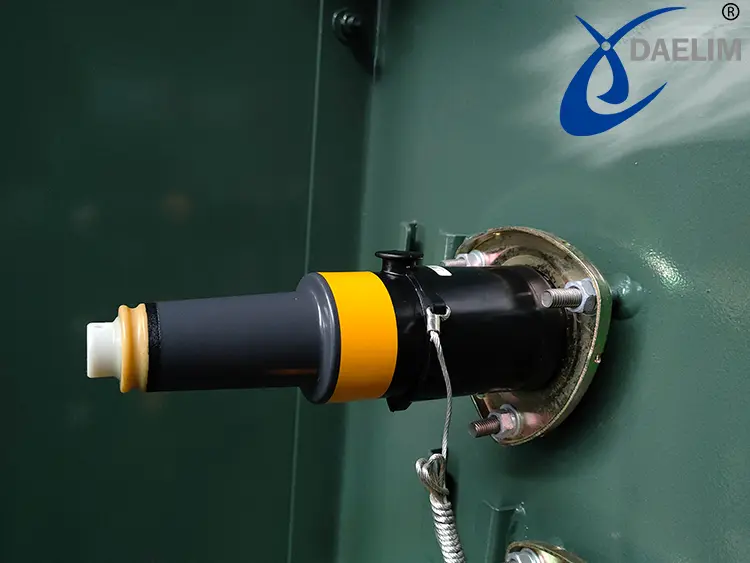

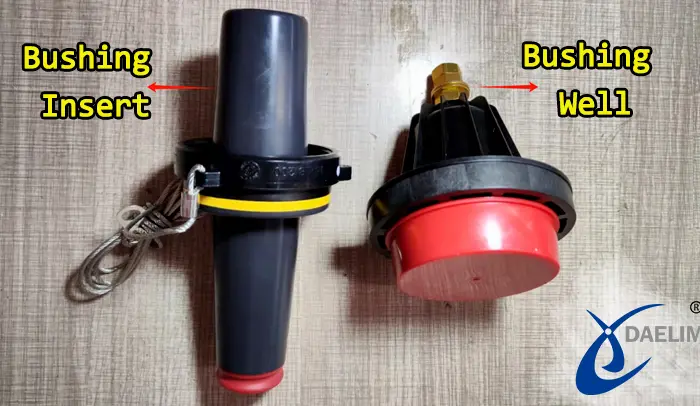

Typically rated at 200 amps, split bushings consist of a two-piece assembly with a bushing well serving as the interface to the transformer tank. The bushing insert plugs into the well, forming a secure connection. A fully insulated rubber elbow connector is used for cable connection, allowing for load break operations. Voltage levels are 15 kV, 25 kV, and 35 kV. Separable 200 A insulated high-voltage bushings designed for operation after the pad-mounted transformer is in place must be located so that they can be operated with hot-line tools.

Integral Insulated High-Voltage Bushing

Often rated at 600 amps, integral bushings, also known as T-body connectors, feature a bolt on one end for securing the elbow connector. This ensures a solid connection that cannot be disconnected while power is supplied to the transformer. Voltage levels, such as 15/25 kV and 35 kV, are distinguished by size. The insulated connection minimizes the risk of arc flash when opening the transformer cabinet, enhancing safety during maintenance.

Send Inquiry Now Both integral and separable dead front bushings offer a significant advantage: when opening the pad-mounted transformer's cabinet, the risk of arc flash is substantially reduced due to their fully insulated connection. Consequently, termination is achieved differently compared to using a mechanical lug or crimp plug. Instead, an elbow is utilized to terminate the cable, which is then plugged into the dead front bushing. To disconnect the load on the pad-mounted transformer, a hot rod is used to withdraw the elbow connector. This method enhances safety during maintenance operations, minimizing the potential for hazardous arc flash incidents.

Both integral and separable dead front bushings offer a significant advantage: when opening the pad-mounted transformer's cabinet, the risk of arc flash is substantially reduced due to their fully insulated connection. Consequently, termination is achieved differently compared to using a mechanical lug or crimp plug. Instead, an elbow is utilized to terminate the cable, which is then plugged into the dead front bushing. To disconnect the load on the pad-mounted transformer, a hot rod is used to withdraw the elbow connector. This method enhances safety during maintenance operations, minimizing the potential for hazardous arc flash incidents.

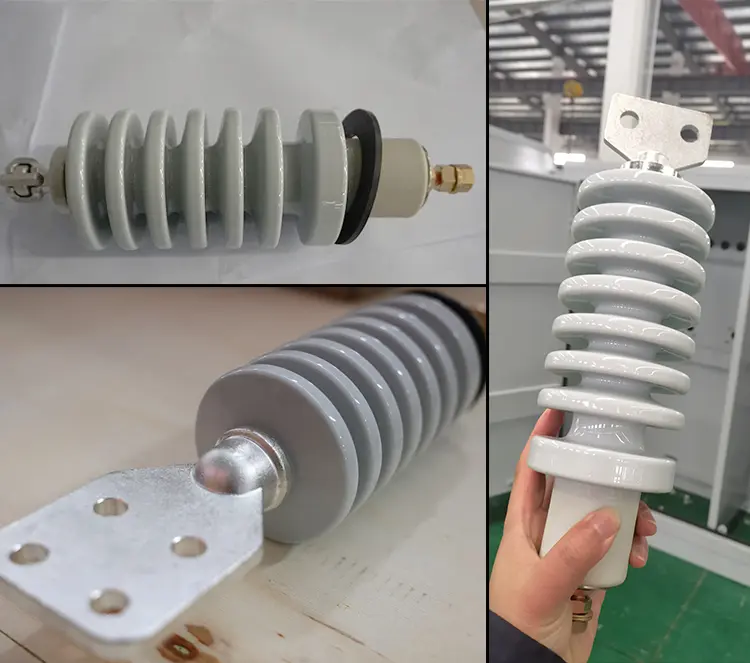

Live Front Bushing

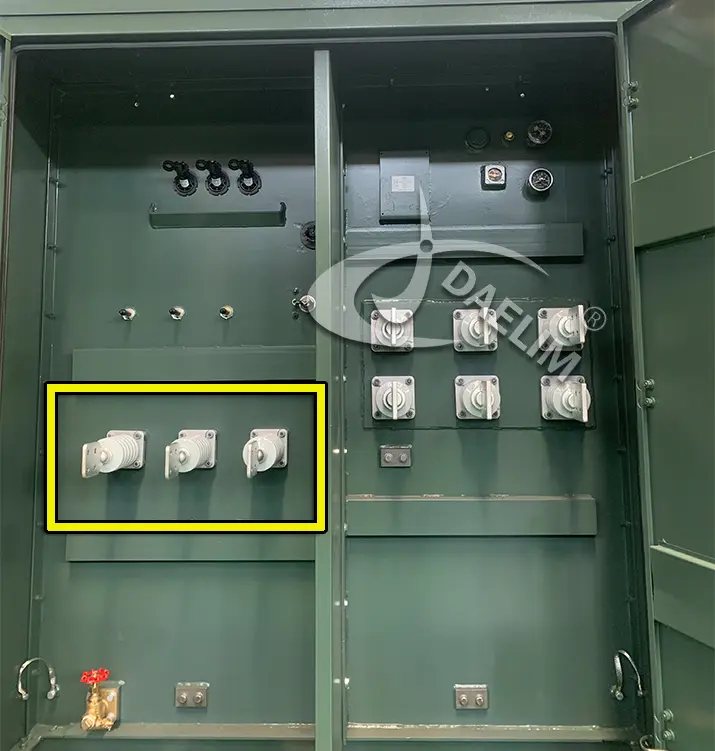

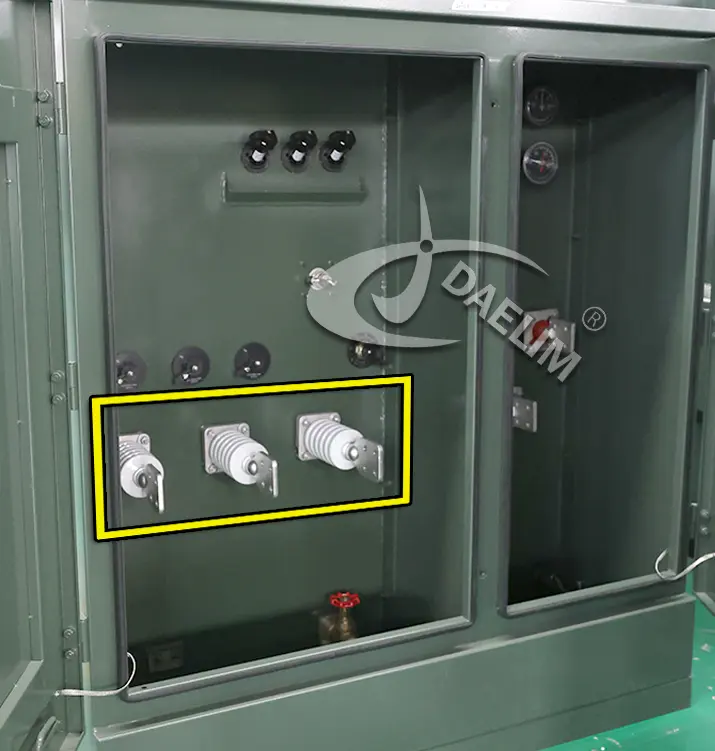

Live front bushings comprise porcelain spade bushings with exposed conductor connectors at the top. Bushings have either tin-plated copper alloy clamp-type connectors or four-hole and three-hole spade terminal, both arranged for a vertical take-off. For 34.5kV and below pad-mounted transformers, the clamp connectors accommodate No. 6 AWG solid to 250 kemil stranded conductors. The holes in the spade terminal are on the same plane, with a typical diameter of 14.3 ± 0.8 mm and a center-to-center distance of 44.5 ± 0.8 mm. Installed on the high-voltage side of live front pad-mounted transformers, cable termination is achieved using mechanical lugs or clamp plugs, providing a secure connection. Live front bushings are available in voltage ratings of 15 kV, 25 kV, 34 kV, and 44 kV.

Send Inquiry NowLearn more about Live Front Transformer

The choice between dead front and live front bushings depends on factors such as current requirements and cable connection methods. Live front bushings, with their larger creep distance and robust anti-fouling properties, excel in harsh operating environments.

For comprehensive guidance on selecting the ideal high voltage bushing for your pad mounted transformer, trust Daelim Transformer's expertise. Contact us today to discuss your specific requirements of pad mounted transformer and benefit from our industry-leading solutions.

Related Products

Related Article

Daelim Transformer Custom 1500 kVA Pad Mounted Transformer for Canada

As a professional pad mounted transformer manufacturer & supplier, Daelim Transformer is committed to meeting standards such as ANSI/IEEE, CSA, DOE, and NEMA, offering customized solutions. Here, we present a case of a 1500 kVA pad mounted transformer tailored for the Canadian market.

1000 kVA Pad Mounted Transformers For Jamaica Market

In October 2023, Daelim Transformer successfully manufactured two units of 6 kV 1000 kVA pad mounted transformers, meeting 100% compliance with IEEE C57.12.34 and IEEE 693-2005 standards. These transformers, one step up and the other step down, were tailored for a valued customer in Jamaica. Let's delve into the details of this exceptional project.

Single Phase Pad Mounted Transformer For USA Utility

Introducing a utility transformer project tailored for the USA, located in Virginia. This utility initiative requires 215 units of single-phase pad-mounted transformers, all UL listed, including 175 units of 25 kVA and 40 units of 50 kVA. The end user's project timeline is 90 days. Adherence to IEEE standards is imperative for single-phase transformers. Additionally, the design of transformer components and markings must be customized to meet project specifications.

Pad Mounted Transformer for BESS System 4.0 MVA in Riverside County, California

Today, Daelim Transformer is proud to introduce a pad-mounted transformer for a 4.0 MVA Battery Energy Storage System (BESS) project located in Riverside County, California. The transformer is meticulously crafted to comply with the specifications outlined in the California Electrical Code Article 450.

2550 kVA Pad Mounted Transformer For Data Center in Mexico, Missouri

Today, we're excited to showcase Daelim Transformer's involvement in a project supplying four 2550 kVA pad mounted transformers tailored for a data center located in Mexico, Missouri. Data centers, known for their substantial power demands, require reliable solutions to ensure seamless operation during peak electricity usage.

2600 kVA Pad Mounted Transformer For Crypto Mine In Kansas

This morning, I received the on-site photos of the pad-mounted transformers from the customer, and I was overwhelmed with excitement and joy. These pad-mounted transformers are installed at a 20MW crypto mining site in Kansas, USA. A total of 5 sets of 2600 kVA pad-mounted transformers, all UL-listed, are being deployed at this site. Currently, 3 sets have already been installed onsite and are scheduled to be powered on imminently.