Kirk Key Interlock | A Complete Guide for Pad Mounted Transformers

The pad mounted electrical transformers are one of the most common types of Electric Transformer and it is one of the most widely used Electrical Transformers in residential and industrial areas. These transformers are known for their compact design that enables them to be installed in an enclosure.

As these electrical transformers are quite sensitive and powerful electrical devices at the same time and with their installation being done in residential areas, safety is one of the main concerns of utility companies. This requires them to take measures necessary to ensure the safety of the electrical equipment and the people living around these Electrical Transformers.

Contact Daelim TransformerOne of the methods used to secure sensitive parts of pad mounted Electrical Transformers is to use a lock that can prevent any type of unauthorised access to the Electrical Transformer and their sensitive yet powerful internal parts.

Now you can protect and lock your pad mounted Electrical Transformer using a special type of lock called Kirk Key Interlock. This article will be all about this Kirk Key Interlock system and how this lock is used to protect the pad mounted transformers installed on poles in residential areas.

What Is a Kirk Key Interlock?

In order to make you understand about the Kirk Key Interlock, we need to explain about the interlock, then the key interlock and then about the Kirk Key Interlock system.

The interlock can be seen as a function that works to combine the state of two mechanisms or two different functions to become mutually dependent on each other. That is, the two different functions that are not related to each other will now be related and they will only function if a certain condition is fulfilled.

The key interlock is one of the interlock types where a key works as the main and only tie between the interlock mechanisms. When you put in the key in the interlock, it will signal the equipment attached with the interlock to perform a certain function and as soon as the key is released or removed from the interlock, this will signal a requirement to perform another specific task.

The Kirk Key Interlock is a key type interlock that is designed and manufactured by a company called Kirk, so basically it's the Kirk Key Interlock company.

So, the Kirk Key Interlock system is a special type of mechanical locking system that is designed to enforce sequential control in security or locking systems. The primary function of this interlock is to mechanically lock and unlock a certain piece of equipment like transformers on which this interlock is installed.

How Kirk Key Interlock Works

The principle behind the Kirk Key Interlock is to have a sequential access control of equipment on which this type of interlock is installed. Depending upon the type of the interlock, there can be a pure mechanical mechanism to do this sequential access control, or there can be a combination of electrical and mechanical mechanisms to deliver the sequential access control.

In key interlocks, the lock uses a mechanical key to ensure that one operation cannot occur until another operation has been safely completed.

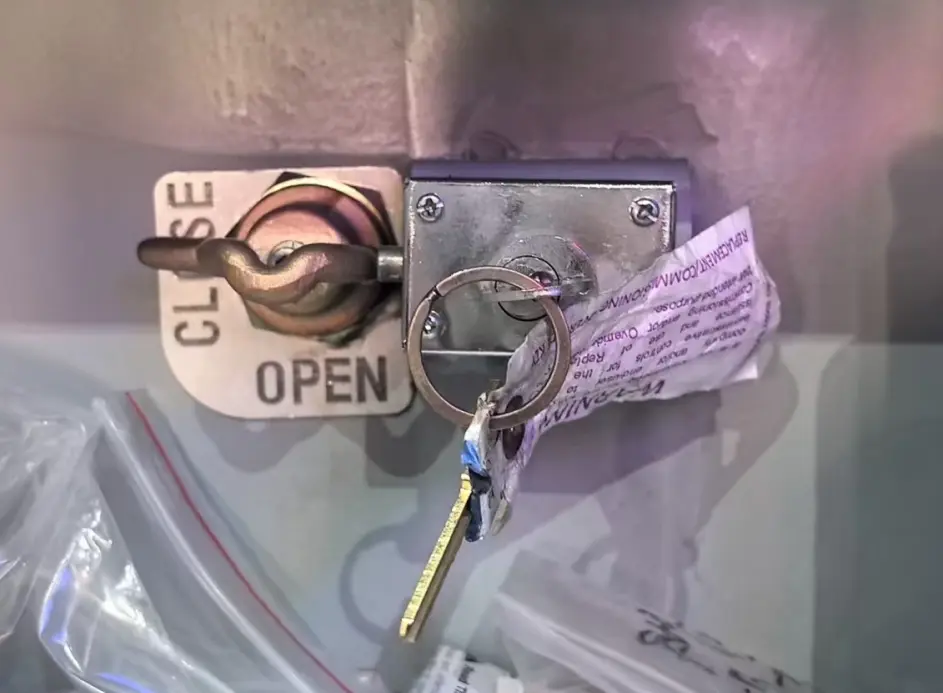

In case of pad mounted Electrical Transformers, these Kirk Key Interlocks are used to ensure that the Electrical Transformer is only accessed when it is fully safe to access and touch any part of the Electrical Transformer.

To understand how this happens, let’s take an example here where these Kirk Key Interlocks are installed on the load break switches of the Electrical Transformer.

You want to access the Electrical Transformer internal parts or the Electrical Transformer control panel to perform a certain task or to perform a regular inspection. Now, the Electrical Transformer is enclosed inside an enclosure for safety purposes. It is also important to ensure that the Electrical Transformer is not energized and is not receiving electricity while the worker is performing the routine inspection or a certain task on its control panel.

Now to ensure the safety of the Electrical Transformer and the safety of the worker, the enclosure is locked using an interlock that is also connected with the load break switch of the Electrical Transformer.

Now when the worker inserts the key in the interlock and rotates the key to unlock the lock of the enclosure, the interlock based on the mechanism it has, either pure mechanical or a combination of mechanical and electrical mechanism switches off the load break switch and cuts off electricity supply to the Electrical Transformer. This ensures that it is not energized and it will not reenergize until the key is returned back with the door of the enclosure closed.

So the interlock mechanism has ensured that the internal control panel and parts of the Electrical Transformer cannot be accessed by any unauthorised person, as only the authorised person will have the key of the locker. It also ensures that the authorised person cannot access the Electrical Transformer internal parts or control panel without first cutting off the supply to the transformer. So the interlock has ensured the security and safety of the electrical equipment by introducing an interlock between two different mechanisms.

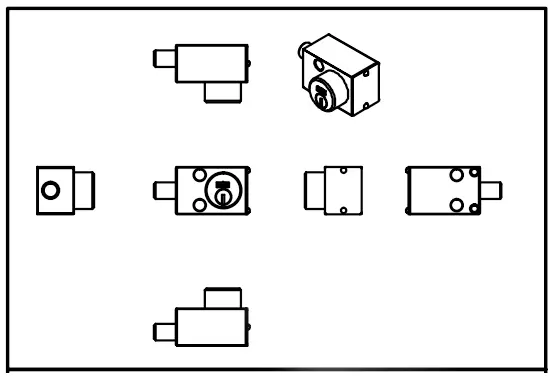

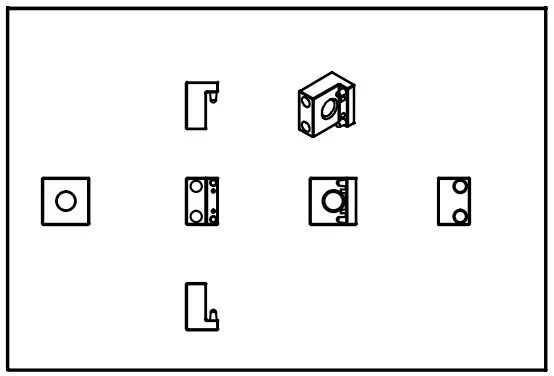

Components of a Kirk Key Interlock System

Kirk Key Interlocks are simple devices and are rarely designed inefficiently; they perform an important and crucial task with minimal parts. It mostly depends on the design that any particular manufacturing company develops. However, there are some common parts that almost all Kirk Key Interlocks have.

Key Interlock Units

The main part of the Kirk Key Interlock is the interlock unit that contains the locking mechanism and features to get mounted on the equipment. The main unit also has the mechanism to hold and release the key based on the condition or process of the operation. It is mostly made from high quality steel alloys and in some cases, other materials like aluminium or extra strong materials like titanium can also be used.

Lock Cylinders

Lock cylinder is the main part of the interlock that is operated or moved when we rotate the key in the interlock. It is only present in pure mechanical type interlocks, as there is a pure mechanical mechanism that enables linear movement of the cylinder when the operator gives rotational motion to the key of the locker. The lock cylinder is a simple cylindrical part made from steel and it is the part that performs the locking and unlocking function.

Trap Keys

In the interlock system, the key used to operate the system is not a normal key, for the mechanism that works with the key is not of the regular lock type mechanism. The key is specially called a trap key, as it is designed in a unique way to work with the mechanism of the interlock and can get stuck or remain trapped in the lock until certain conditions like unlocking of the load are done.

Mounting Brackets and Hardware

The interlock also needs a strong and reliable mechanism kirk key interlock installation on the equipment on which it is being used. To ensure that, high quality and heavy duty metal mounting brackets and other hardware like high strength bolts are used to safely and securely mount the interlock on the equipment of interest.

Why Use Kirk Key Interlocks in Pad Mounted Transformers?

There are a number of reasons why the Electrical Transformer design and development companies should use the Kirk Key Interlock in all pad mounted Electrical Transformers.

Enhanced Personnel Safety

These interlocks are specifically designed and well built to ensure the personal safety of the technician or maintenance worker who will be working on the Electrical Transformer during scheduled maintenance or during the inspection of the transformer. The interlock ensures that the door or panel of the Electrical Transformer is not opened before the main load breaker is turned off, which cuts off the supply of electricity to the Electrical Transformer and the transformer does not remain energized until the breaker is turned on again.

Avoids Accidental Energization

The interlock is specifically designed for load break switches on pad mounted transformers to ensure that once the load breaker is turned off and the transformer is deenergized, it remains turned off and does not get accidentally energized by any means. Because this can be proven very harmful and life threatening for the technician or worker working on the Electrical Transformer.

Regulatory Compliance

These interlocks are not only required by companies or by the workers to ensure their safety or the safety of the electrical equipment, these interlocks are now mandatory for all types of international standards that ensure that equipment installed in residential or industrial areas is safe for the residents, workers and technicians that work on those installations. Installing these interlocks ensures that your Electrical Transformer complies with international standards such as OSHA, NFPA 70E and other international standards.

Operational Audit Trails

Key based interlocks rely on metallic keys for operation, so these can be supervised and tracked to determine which worker or technician accessed which machine and during which date and time. This will seriously help in operational audit trails when audits of the Electrical Transformer inspections are made.

Comparison of Kirk Key vs Other Interlock Systems

The Kirk Key Interlock system is one of the most widely used interlock system for all types of pad mounted Transformers. and their are very clear reason why this particular pure mechanical type interlock system is that widely used in Electrical Transformer industry as compared to the other types including electromagnetic and pure electronics based interlockers.

| Feature | Mechanical (Kirk Key) | Electromechanical | Electronic |

| Fail Safe Design | yes | No (needs power) | No need continuous electric power |

| Cost Effective | yes | Moderate | Expensive |

| Maintenance | Low | Moderate | High |

| Complexity | Low | Medium | High |

| Installation | Easy | Moderate | Requires expertise |

Choosing the Right Kirk Key Interlock

As these Kirk Key Interlocks are of different types and can be used in different ways depending upon the application for which they are being used, choosing the right Kirk Key Interlock is important to get the best out of these devices. There are five important considerations that you should keep in mind while selecting or choosing the Kirk Key Interlock for your specific application.

Number of Access Points

The first thing you need to consider is the number of access points that you need to secure. You need to count the number of doors, switches, breakers, or panels that need to be connected using an interlock. More access points mean that you need a multi step interlock sequence to fully secure your electrical equipment.

Operating Environment (Indoor/Outdoor)

You also need to consider the operating environment in which the Kirk Key Interlock will be working. If you have an outdoor application, then you need a Kirk Key Interlock that has a weatherproof rating and excellent corrosion resistance and sealing to stop the penetration of water into the interlock. You might need a NEMA rated or stainless steel enclosure for such an application.

Safety Workflow Requirements

You need to consider the workflow requirement of your specific application and what sequence will be required to ensure 100% safety of the equipment and the personnel using it. You should know the exact sequence of operations that should be followed meaning you need to know which device should be opened first and which should remain locked during the operation. This will help you understand whether a standard interlock system will work for you or if you need a custom made interlock.

Regulatory Compliance

Another factor that you need to consider during the selection of the interlock is the concerned regulatory compliance based on regional laws or international standards. You need to ensure that the interlock you select for your specific application satisfies the requirements of OSHA, IEEE, NEC and any other local safety standards.

Standard vs Custom Solutions

You also need to consider whether your application can work with a standard Kirk Key Interlock or if you need a custom designed solution. Standard interlocks are cost effective and require minimal input for installation and operation, while custom solutions are more efficient and reliable for sensitive applications.

Conclusion

The Kirk Key Interlocks are an important part of pad mounted Electrical Transformers as these interlocks ensure that the Electrical Transformer is safe from any type of unauthorized access and also ensure that, when accessed, it remains safe for both the transformer and the worker working on it. These interlocks work by connecting the functionality of two different features or advanced parts and ensure that the lock is only opened when a specific sequence of operation is properly followed.

We have delivered to you a very detailed explanation of how these devices work to ensure the safety of electrical equipment like transformers and the operators working on them. There are five different factors that you should keep in mind during the selection of an interlock for your specific application.

Follow Up

Daelim transformer offers pad-mounted electrical transformers of all types, sizes and power capacities with standard Kirk Key Interlocks or custom made key interlocks based on customer requirements. Our team of engineers has over a decade of experience in designing and developing electrical transformers based on the unique needs of clients.

Our engineers ensure that our transformers satisfy international safety and electrical operation standards like those of OSHA, IEEE, ASME, NEC and others.

If you have any questions related to pad mounted transformers with standard or custom Kirk Key Interlock features, contact us and we will help you get the best solution for your unique needs.

Related Products

Related Article

2600 kVA Pad Mounted Transformer for Blcokchain

Daelim Transformer successfully provided three customized 2600 kVA pad mounted transformers to power a state-of-the-art blockchain facility in Texas, USA. Our transformers were meticulously designed to meet the unique demands of the mining operation, ensuring seamless power distribution with unwavering reliability and efficiency.

2 MVA Pad Mounted Transformer for Utility

Behold the backbone of Canada's utility infrastructure—the 2MVA pad mounted transformer. With a primary voltage of 4160Grdy/2400V and a secondary voltage of 800GrdY/461V, this transformer stands as a testament to efficiency and reliability in power distribution. Crafted in strict accordance with CSA standards and CAN/CSA802.1 energy efficiency guidelines, it embodies the pinnacle of engineering excellence.

Comprehensive Guide to Pad-Mounted Transformers

The pad-mounted transformer is a prevalent and widely used type of distribution transformer in the Americas. Its operating principle is akin to other transformer types, utilizing the principle of electromagnetic induction to either decrease or amplify the voltage level. Below, we will delve into the structure, accessories, design and production standards, and application scenarios of the pad-mounted transformer.

Guide to Pad Mounted Transformer Fuse

This article will delve into pad-mounted transformer fuses, exploring what fuses are and how they function. We will discuss the types of fuses required for pad-mounted transformers and guide on selecting the appropriate fuse for your specific needs. Furthermore, readers will gain insights into the functions and advantages of fuses used in pad-mounted transformers.

2600 kVA Pad Mounted Transformer For Blockchain In Kansas

This morning, I received the on-site photos of the pad-mounted transformers from the customer, and I was overwhelmed with excitement and joy. These pad-mounted transformers are installed at a 20MW blockchain site in Kansas, USA. A total of 5 sets of 2600 kVA pad-mounted transformers, all UL-listed, are being deployed at this site. Currently, 3 sets have already been installed onsite and are scheduled to be powered on imminently.

Guide to Types of High-Voltage Bushings for Pad-Mounted Transformers

Are you uncertain about which high-voltage bushing your pad-mounted transformer requires? Let our guide to pad-mounted transformer HV bushings enlighten you on the various types and their applications. Pad mounted transformers come in two primary types: dead front and live front. Each type corresponds to different high voltage bushing designs: dead front bushing and live front bushing.