Comprehensive Guide to Pad-Mounted Transformers

The pad-mounted transformer is a prevalent and widely used type of distribution transformer in the Americas. Operating on the principle of electromagnetic induction, it adjusts voltage levels effectively. In this guide, we explore its structure, accessories, design standards, and application scenarios.

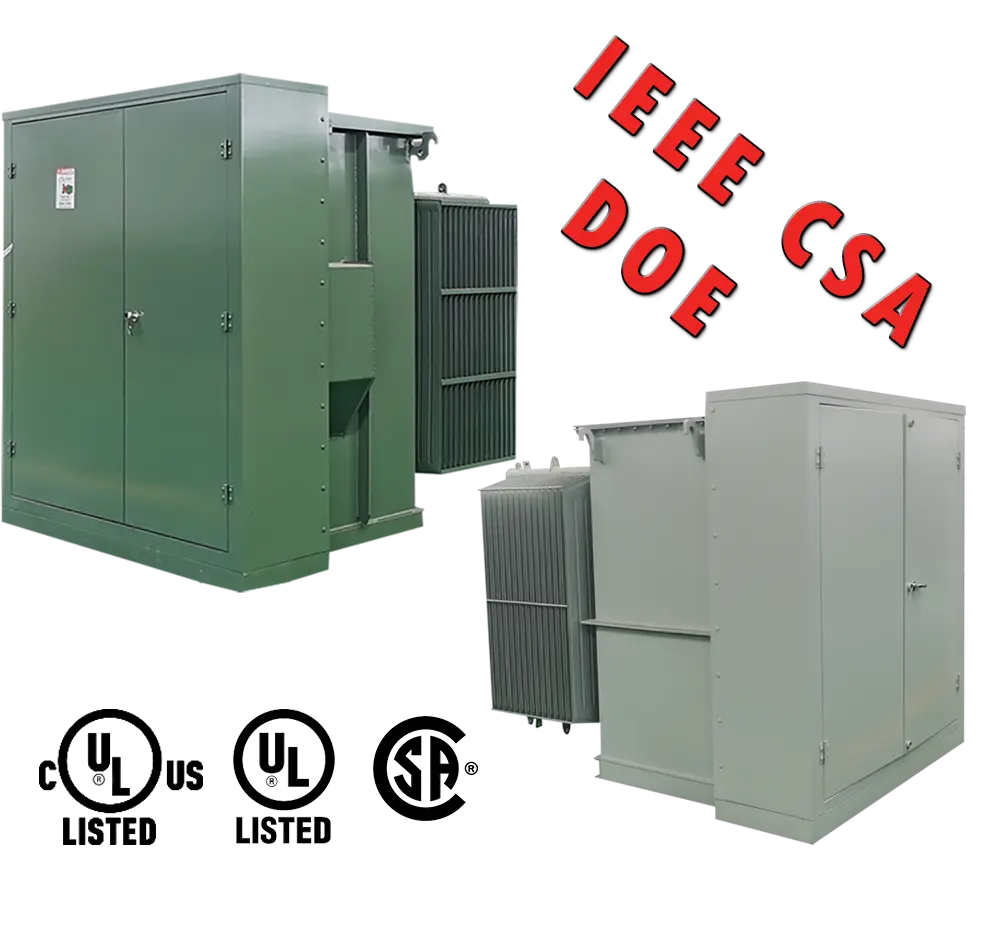

Daelim Transformer is a professional manufacturer and supplier of pad-mounted transformers, UL-certified up to 44 kV, ensuring reliability for diverse applications. We annually export thousands of units to the Americas. Large quantities are In stock for immediate shipment, with custom lead times of 4-8 weeks. Whether for renewable energy, industrial, or commercial projects, our transformers deliver tailored power solutions. Partner with Daelim for unmatched quality, reliability, and performance to meet your transformer needs.

Structure of Pad-Mounted Transformers

The pad-mounted transformer boasts a robust structural design comprising two fundamental compartments: the cable entrance compartment and the oil tank. These compartments house vital components essential for ensuring the transformer's functionality, security, and operational efficiency.

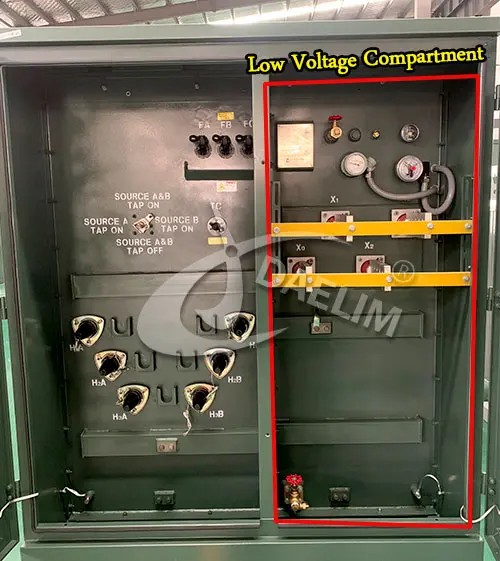

The cable entrance compartment, meticulously divided into high and low-voltage sections, serves as the primary interface for power input and output. Engineered with precision, this compartment is fortified against tampering and theft, safeguarding the transformer's integrity. Within this enclosure, various components are strategically arranged to facilitate seamless power distribution and transmission.

Learn more about Pad Mounted Transformer

High Voltage Compartment

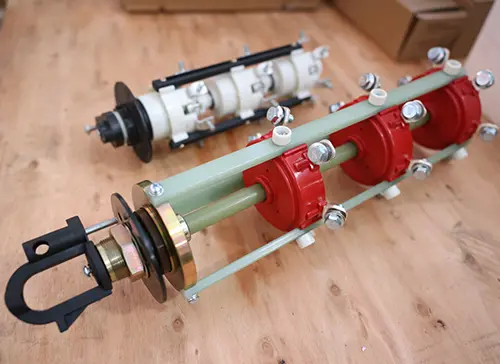

This section houses critical elements such as bushings, tap changers, fuses, and load break switches, essential for ensuring uninterrupted power transmission and distribution. It serves as the nerve center of the transformer's high-voltage operations, enabling efficient power management.

Low Voltage Compartment

Equipped with an array of gauges, terminals, and essential indicators, the low-voltage compartment plays a pivotal role in monitoring and facilitating connectivity. This compartment optimizes operational efficiency by providing real-time insights and facilitating seamless integration into the electrical system.

Oil Tank

The oil tank serves as the central reservoir for indispensable transformer components, including the iron core, coils, and insulating oil. These components play a crucial role in regulating voltage levels and facilitating electromagnetic induction, which forms the cornerstone of the transformer's functionality. The robust construction of the oil tank ensures the safeguarding and longevity of these critical elements, thereby enhancing the transformer's overall performance and reliability.

Pad Mounted Transformer Parts

The tap changer in a pad mounted transformer enables adjustments to the transformer's output voltage to accommodate varying load conditions. Typically featuring a panel-mounted cage switch design, tap changers offer multiple positions, allowing for precise voltage regulation. Daelim Transformer can customize tap changers with different speed and position options to meet specific operational requirements.

Spade-type LV terminals serve as the interface between the transformer and external low voltage circuits. Crafted from corrosion-resistant materials, these terminals ensure reliable and durable connections, compatible with both copper and aluminum conductors. With their robust construction and secure fastening mechanisms, LV terminals guarantee stable electrical conductivity, essential for efficient power distribution.

Various gauges and instruments are integrated into pad-mounted transformers to monitor critical operating parameters and ensure optimal performance. These gauges include vacuum pressure gauges, oil level gauges, pressure relief devices, and temperature indicators. Equipped with alarm functions, these gauges provide real-time monitoring and early warning of potential issues, enabling proactive maintenance and minimizing the risk of equipment failure.

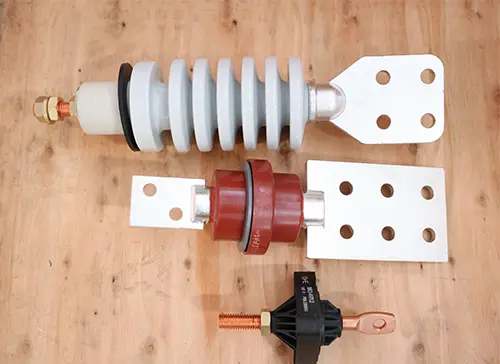

HV bushings play a pivotal role in facilitating the transfer of high voltage electricity from the transformer to external circuits. Available in dead front and live front variants, these bushings are meticulously designed to ensure insulation and safety. Dead front bushings, fully insulated, are typically used in dead front pad mounted transformers, providing comprehensive protection against electrical hazards. On the other hand, live front bushings, partially exposed, are commonly employed in live front pad mounted transformers, offering a balance between safety and accessibility.

Load break switches offer manual control over grid connections, allowing operators to safely and efficiently connect or disconnect the transformer from external circuits. Available in two-position and four-position variants, these switches provide flexibility in operational configurations, enabling seamless integration with distribution networks. Whether isolating the transformer for maintenance or reconfiguring the electrical layout, load break switches enhance operational efficiency and safety, minimizing downtime and optimizing system performance.

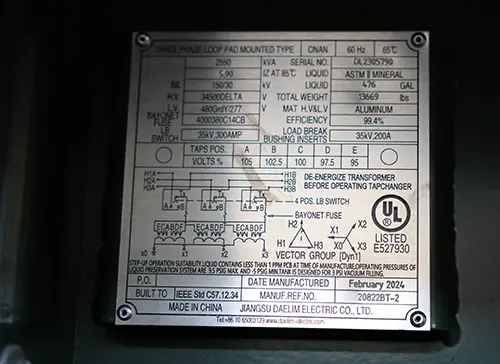

Each pad-mounted transformer features a stainless steel nameplate located within the low voltage compartment. This nameplate contains essential information about the transformer, including its model number, serial number, rated capacity, voltage ratings, and manufacturing date. Serving as a comprehensive reference for maintenance and identification purposes, the nameplate ensures clear documentation of the transformer's specifications and history.

Pad-mounted transformers utilize insulating fluid, either mineral oil or vegetable oil, to dissipate heat generated during operation and enhance insulation performance. This fluid surrounds the core and coils, providing efficient heat transfer and improving the transformer's overall lifespan. With options for both mineral and vegetable oil, Daelim Transformer offers transformers tailored to meet diverse environmental and operational needs.

At the heart of every pad mounted transformer lies the core and coils assembly, constituting the fundamental components responsible for voltage transformation. The iron core, meticulously constructed to minimize energy losses, provides a magnetic pathway for the flux generated by the coils. Wrapped around the core, the coils—fabricated from high-conductivity materials such as aluminum or copper—facilitate the induction process, converting electrical energy from one voltage level to another. By altering the turns ratio between the primary and secondary coils, pad mounted transformers enable precise control over output voltages, catering to diverse operational requirements.

Integral to the protection of pad mounted transformers and associated equipment, fuses serve as critical safety devices, safeguarding against overcurrent and overheating conditions. Typically employing a double fuse protection system, pad mounted transformers utilize bayonet fuses, ISO links, and current-limiting fuse technologies to ensure reliable and robust protection mechanisms. In the event of excessive current flow or elevated temperatures, the fuse elements melt, interrupting the circuit and preventing damage to the transformer components. This proactive approach to electrical safety enhances system reliability and longevity, mitigating the risk of equipment failure and operational disruptions.

Other Accessories

In addition to the core components mentioned above, pad-mounted transformers are equipped with a variety of accessories that enhance their functionality, safety, and ease of installation. These accessories play a vital role in optimizing the transformer's performance and ensuring its seamless integration into the electrical system.

Ground Pad and Strap: Ground pads and straps are essential components that provide a secure ground connection for the transformer. They help dissipate excess electrical energy and reduce the risk of electrical hazards, ensuring safe operation.

Ground pads and straps are essential components that provide a secure ground connection for the transformer. They help dissipate excess electrical energy and reduce the risk of electrical hazards, ensuring safe operation.

Parking Stand: Parking stands are utilized to support and secure medium voltage cables with elbow connectors, providing stability and organization within the transformer setup.

Low Voltage Bushing Support: Low voltage bushing holders enhance the connection and stability of low voltage terminals, promoting reliable electrical connections and minimizing the risk of disconnection or damage during operation.

Drip Tray: The drip tray serves as a protective measure to prevent transformer oil from dripping onto other accessories or the ground during maintenance procedures, minimizing potential hazards and environmental pollution.

SILL (Suitable for Skidding, Rolling): SILL systems are designed to facilitate the movement of the transformer, providing compatibility for skidding and rolling operations as needed for installation or relocation purposes.

Fans: Fans are activated to assist in dissipating heat generated during transformer operation, ensuring optimal temperature regulation and preventing overheating.

Rigid Barrier between H.V & L.V: The rigid barrier between the high and low voltage chambers acts as a physical divider, preventing any contact or interference between the two voltage levels. This enhances safety and reduces the risk of electrical accidents or failures.

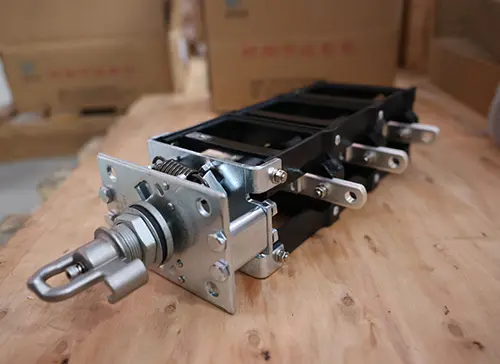

Jacking Mechanism: The jacking mechanism provides lifting support for the transformer during installation or maintenance tasks, ensuring precise positioning and alignment for smooth and efficient operation.

These accessories, when combined with the core components of the transformer, significantly enhance its reliability, safety, and operating efficiency, making it a valuable asset across various electrical applications.

Reading more about Pad Mounted Accessories

Design and Production Standards

Pad-mounted transformers are meticulously designed and manufactured to adhere to stringent industry standards, ensuring optimal performance, safety, and reliability. The design and production processes are governed by a comprehensive set of regulations and guidelines established by prominent regulatory bodies and standards organizations. Below are the key standards and considerations that shape the design and production of pad-mounted transformers:

IEEE Standards

The Institute of Electrical and Electronics Engineers (IEEE) sets forth standards specific to pad-mounted transformers, encompassing various aspects such as design, construction, testing, and performance requirements. IEEE standards provide comprehensive guidelines for transformer manufacturers to ensure consistency, interoperability, and compliance with industry best practices.

You may enjoy: Ultimate Guide To IEEE C57 Standard

CSA Standards

The Canadian Standards Association (CSA) develops standards and specifications for electrical equipment, including pad mounted transformers, to ensure safety, reliability, and environmental sustainability. CSA standards cover a wide range of parameters, including electrical ratings, insulation levels, temperature rise limits, and protection mechanisms.

Learn more: Pad Mounted Transformer CSA C227.4 National Standard of Canada

DOE Efficiency

The U.S. Department of Energy (DOE) imposes regulations and efficiency standards on distribution transformers to promote energy conservation and reduce environmental impact. Pad-mounted transformers must comply with DOE regulations governing energy efficiency, performance metrics, and labeling requirements to ensure optimal energy utilization and minimize operational costs.

Learn more about Transformer Efficiency

NEMA Standard

The National Electrical Manufacturers Association (NEMA) publishes guidelines and recommendations for the design, manufacturing, and installation of electrical equipment, including pad-mounted transformers. NEMA standards address factors such as materials selection, insulation systems, enclosure design, and environmental protection to enhance the reliability and longevity of transformers.

Environmental Considerations

Pad-mounted transformers are designed with environmental considerations in mind, employing eco-friendly materials, insulating fluids, and manufacturing processes to minimize environmental impact. Manufacturers adhere to regulations governing the use and disposal of hazardous substances, such as PCBs, and strive to implement sustainable practices throughout the product lifecycle.

Quality Assurance

Stringent quality assurance measures are implemented throughout the design and production processes to ensure the integrity and performance of pad mounted transformers. Manufacturers employ advanced testing procedures, including dielectric tests, insulation resistance tests, temperature rise tests, and short-circuit tests, to validate the functionality and safety of transformers before they are deployed in the field.

Customization Options

While adhering to standardized design and production protocols, transformer manufacturers offer customization options to meet specific customer requirements and application scenarios. Customization options may include voltage ratings, capacity ratings, enclosure materials, insulation systems, and accessories to accommodate diverse operational needs and environmental conditions.

Try for free: 3 Phase Pad Mounted Transformer

Certifications and Compliance

Pad-mounted transformers undergo rigorous testing and certification processes to demonstrate compliance with industry standards and regulatory requirements. Manufacturers obtain certifications such as UL (Underwriters Laboratories) and CSA (Canadian Standards Association) certification to validate the safety, reliability, and performance of their products, instilling confidence in customers and regulatory authorities alike.

By adhering to these design and production standards, transformer manufacturers ensure that pad-mounted transformers meet the highest quality and performance benchmarks, delivering reliable and efficient power distribution solutions for a wide range of applications.

Applications

Pad-mounted transformers are widespread applications across a diverse range of sectors, each benefiting from their reliability, efficiency, and adaptability. Here are some key application scenarios where pad-mounted transformers play a crucial role.

In the rapidly expanding blockchain sector, pad-mounted transformers are essential for powering mining equipment, such as ASIC miners and cooling systems. They provide the high-quality electrical power required for efficient and reliable mining operations, contributing to the success of blockchain ventures.

Data Center

Data centers require robust and reliable electrical infrastructure to support their critical operations. Pad-mounted transformers play a key role in providing backup power and ensuring uninterrupted operation of servers, networking equipment, and cooling systems, helping to maintain data center reliability and uptime.

Battery Energy Storage Systems (BESS)

In battery energy storage system (BESS) applications, pad-mounted transformers play a crucial role in linking battery storage systems to the grid. They actively regulate voltage levels, optimize power flow, and ensure the seamless storage and distribution of energy. Their presence is essential for bolstering grid stability and reliability.

Renewable Energy

Pad-mounted transformers are essential components in renewable energy projects, such as wind farms and solar installations. They facilitate the transmission of electricity generated from renewable sources to the grid, enabling the integration of clean energy into the power system.

Oil and Gas Operations

Pad-mounted transformers are deployed in oil and gas facilities to power various equipment and processes, including pumps, compressors, and drilling rigs. They provide reliable and safe electrical power distribution in challenging environments, such as remote oil fields and offshore platforms.

Utility Grids

Pad-mounted transformers form an integral part of utility distribution networks, serving as primary distribution points for delivering electricity to enduser.

They help regulate voltage levels, manage load demand, and ensure reliable power supply across the grid.

Industrial Facilities

Industrial plants and manufacturing facilities rely on pad-mounted transformers to supply power for machinery, lighting, and other operational needs. These transformers ensure uninterrupted power supply, supporting continuous production processes and maximizing operational efficiency.

Commercial Establishments

Pad-mounted transformers are commonly used in commercial buildings, retail centers, and office complexes to deliver power for lighting, HVAC systems, elevators, and other electrical loads. They help meet the diverse energy needs of commercial establishments while ensuring safety and efficiency.

Agricultural Farms

In agricultural, pad-mounted transformers are utilized to power irrigation systems, livestock facilities, and other equipment. They support agricultural operations by providing reliable electrical power for various farming activities, contributing to increased productivity and efficiency.

In conclusion, pad-mounted transformers play a vital role in facilitating electricity distribution across a wide range of applications, from renewable energy projects to industrial facilities and commercial establishments. Their versatility, reliability, and efficiency make them indispensable components of modern infrastructure, driving progress and innovation in the electrification landscape.

Advantages of Daelim Transformer

High Quality: Daelim Transformer is known for producing high-quality transformers that meet stringent industry standards, ensuring reliable performance and longevity.

Fast Delivery Times: They pride themselves on their quick turnaround times, ensuring that customers receive their transformers promptly to meet project deadlines.

Certifications: Daelim Transformer with UL/CUL certified, demonstrating compliance with rigorous safety and performance standards.

Extensive Experience: With extensive international project experience, Daelim Transformer has a deep understanding of various customer needs and specifications, allowing them to provide tailored solutions.

Customization: They offer customization options to meet specific project requirements, providing flexibility and ensuring optimal performance in diverse applications.

Professional Team: Their team consists of skilled professionals with rich project experience who can provide expert guidance and support throughout the transformer procurement process.

Wide Range of Transformers: Daelim Transformer offers a wide range of transformer products, including blockchain-specific transformers, to cater to various industries and applications.

Overall, Daelim Transformer combines quality, expertise, and flexibility to deliver reliable transformer solutions tailored to meet the needs of.

Contact Daelim Transformer Now Get Solutions

Pad Mounted Transformer Projects

Check more of Daelim Transformer's Projects

Related Products

Related Article

2550 kVA Pad Mounted Transformer For Data Center in Mexico, Missouri

Today, we're excited to showcase Daelim Transformer's involvement in a project supplying four 2550 kVA pad mounted transformers tailored for a data center located in Mexico, Missouri. Data centers, known for their substantial power demands, require reliable solutions to ensure seamless operation during peak electricity usage.

2000 kVA Pad Mounted Transformers for Canadian Utility

Daelim Transformer is pleased to announce its contribution to a utility project in Toronto, Canada, involving the supply of two units 2000 kVA pad mounted transformers. These transformers are integral to enhancing the power infrastructure in the region. The project demands adherence to CSA standards, with a stringent delivery deadline of 10 weeks to meet the urgent needs of the client.

Supply of 37.5 kVA Single Phase Pad Mounted Transformers for Canadian Utility

Today, we are excited to introduce a project undertaken by Daelim Transformer aimed at supplying transformers to a Canadian utility. This project involves the delivery of 80 units of 37.5 kVA single-phase pad mounted transformers, specially designed to meet the utility's requirements. With a high voltage (HV) rating of 24940GRDY/14400 V and a low voltage (LV) rating of 240/120 V, these transformers are vital components in the utility's infrastructure.

1750 kVA Pad Mounted Transformer for the Dominica Market

Today, we're excited to present a transformer project tailored for the Dominican market. Our 1750 kVA pad mounted transformer is designed to meet the specific requirements of our clients in Dominica. This step-down transformer boasts a primary voltage of 13.8 kV and a secondary voltage of 480Grdy/277V, adhering to the IEEE C57.12.34 standard. With its robust features and reliable performance, this transformer is set to enhance the power distribution infrastructure in Dominica.

2600 kVA Pad Mounted Transformer for Blcokchain

Daelim Transformer successfully provided three customized 2600 kVA pad mounted transformers to power a state-of-the-art blockchain facility in Texas, USA. Our transformers were meticulously designed to meet the unique demands of the mining operation, ensuring seamless power distribution with unwavering reliability and efficiency.

2 MVA Pad Mounted Transformer for Utility

Behold the backbone of Canada's utility infrastructure—the 2MVA pad mounted transformer. With a primary voltage of 4160Grdy/2400V and a secondary voltage of 800GrdY/461V, this transformer stands as a testament to efficiency and reliability in power distribution. Crafted in strict accordance with CSA standards and CAN/CSA802.1 energy efficiency guidelines, it embodies the pinnacle of engineering excellence.

14.4kV and 35kV Pad Mounted Transformer, Honduras

We exported 300kva, 750kva, 1500kva and 2500kva radial and loop feed transformers to Honduras this year. There were totally 24 units and we will update the pictures after installation.

Pad Mounted Transformer Project Cases

3750kVA Primary 13.8kV, Secondary:0.415kV Loop-feed Pad-mounted Transformer, 12 sets for US market;

Daelim Transformer Custom 1500 kVA Pad Mounted Transformer for Canada

As a professional pad mounted transformer manufacturer & supplier, Daelim Transformer is committed to meeting standards such as ANSI/IEEE, CSA, DOE, and NEMA, offering customized solutions. Here, we present a case of a 1500 kVA pad mounted transformer tailored for the Canadian market.

1000 kVA Pad Mounted Transformers For Jamaica Market

In October 2023, Daelim Transformer successfully manufactured two units of 6 kV 1000 kVA pad mounted transformers, meeting 100% compliance with IEEE C57.12.34 and IEEE 693-2005 standards. These transformers, one step up and the other step down, were tailored for a valued customer in Jamaica. Let's delve into the details of this exceptional project.

Single Phase Pad Mounted Transformer For USA Utility

Introducing a utility transformer project tailored for the USA, located in Virginia. This utility initiative requires 215 units of single-phase pad-mounted transformers, all UL listed, including 175 units of 25 kVA and 40 units of 50 kVA. The end user's project timeline is 90 days. Adherence to IEEE standards is imperative for single-phase transformers. Additionally, the design of transformer components and markings must be customized to meet project specifications.

Pad Mounted Transformer for BESS System 4.0 MVA in Riverside County, California

Today, Daelim Transformer is proud to introduce a pad-mounted transformer for a 4.0 MVA Battery Energy Storage System (BESS) project located in Riverside County, California. The transformer is meticulously crafted to comply with the specifications outlined in the California Electrical Code Article 450.