Find the Best 250 kVA Transformer Price

A 250 kVA Transformer is an electrical transformer used to boost or reduce the voltage of electrical power sources. It is used extensively in commercial and industrial environments to transfer electricity from one circuit to another.

A 250 kVA power transformer is a capacity of 250 Kilovolt-amperes and is specifically designed to deal with high electrical demands. Finding the most competitive 250 kVA transformer price is crucial as it will help lower the total costs of a project or the expense of running the facility.

Daelim is a professional transformer supplier that can provide various types of 250 kVA transformers. UL, cUL, CSA, and other product certifications ensure that the 250kVA transformer you buy has the highest quality and the best price. Transformers with high performance and long service life maximize your economic benefits. Therefore, if you need a transformer, you can Choose Daelim without hesitation.

A quality transformer for a reasonable cost can offer an efficient and reliable electrical energy transfer, while a less-than-quality transformer that is priced at a lower price might not perform as effectively and will require replacing more often, which could lead to increased costs over the long term. In addition, determining the most affordable price will also help ensure that the budget of the project isn't exceeded and allows more money to be used for other crucial components of the work.

What factors influence the price of a 250 kVA transformer?

The cost of raw materials used in the manufacturing of transformers, such as copper and aluminum, can greatly impact the final price of a 250 kVA transformer. The cost of these materials can fluctuate due to various factors, such as changes in supply and demand, changes in the global market, and natural disasters.

The cost of labor also plays a significant role in the final price of a transformer. This includes the cost of the workers who manufacture the transformer, as well as the cost of engineers and designers who develop the transformer's specifications and design. The cost of labor can vary depending on the location of the manufacturing plant and the local cost of living.

The demand for transformers, particularly for 250 kVA transformers, can greatly affect their price. If there is a high demand for transformers, manufacturers may increase their prices to take advantage of the market conditions. In the two or three years since the outbreak of the COVID-19, due to insufficient production capacity, the supply of transformers was in short supply, resulting in a lot of price increases.On the other hand, if demand is low, manufacturers may reduce their prices to remain competitive.

The reputation of the manufacturer can also impact the price of a 250 kVA transformer. Brands with a strong reputation for producing high-quality transformers may be able to charge a premium for their products.For example, ABB, Siemens, Schneider, Eaton, GE, etc., the price will be relatively high. On the other hand, brands with a lesser-known reputation may need to reduce their prices to compete with more established brands in the market.

Learn more about 250 kVA transformer

What are the main parameters of the 250 kVA 3 phase transformer?

The main parameters of a 250 kVA three-phase transformer typically include:

Rated capacity: 250 kVA

Primary voltage: Usually ranges between 6.6 kV to 33 kV (but can vary)

Secondary voltage: Commonly 415V, 440V, or 480V for low-voltage distribution

Phase: Three-phase

Winding material: Copper or aluminum

Insulation class: Varies depending on the specific design (e.g., Class A, B, F, or H)

Frequency: 50 Hz or 60 Hz

Cooling method: Natural or forced air cooling (dry-type) or natural or forced oil cooling (oil-immersed)

Impedance: Depends on the specific design, but typically in the range of 4% to 6%

Short-circuit withstand capability and temperature rise limits: Defined by the applicable standards (e.g., IEC or IEEE)

Learn more about transformer impedance

How should factories set and deploy parameters when producing and designing transformers?

Determine application requirements

Understand the specific application, including voltage levels, load types, environmental conditions, and safety regulations. This information is crucial to define the required transformer parameters.

Design the core and windings

Select the core material (e.g., CRGO silicon steel or amorphous metal) and winding material (copper or aluminum) based on efficiency, weight, and cost considerations. Design the core and windings to meet the required voltage and power ratings while minimizing losses.

Cooling system design

Determine the appropriate cooling method (natural or forced air cooling for dry-type transformers, or natural or forced oil cooling for oil-immersed transformers) based on the application's thermal requirements and temperature limits.

Select the appropriate insulation materials and insulation class based on the transformer's voltage levels, temperature rise limits, and environmental conditions.

Impedance and short-circuit withstand capability

Design the transformer to meet the required impedance values and short-circuit withstand capability. This may involve selecting appropriate winding arrangements, conductor sizes, and bracing structures.

Incorporate protective devices

Depending on the application, it may be necessary to include protective devices such as current transformers, surge arresters, or temperature sensors to ensure safe and reliable operation.

Comply with relevant standards

Ensure that the transformer design complies with relevant standards, such as IEC (International Electrotechnical Commission), IEEE (Institute of Electrical and Electronics Engineers), CSA(The Canadian Standards Association) or other national or regional standards. Compliance with these standards ensures the transformer's safety, performance, and reliability.

Some examples of relevant transformer standards include:

IEC 60076 series

Covers power transformers, including general requirements, temperature rise limits, short-circuit withstand capabilities, and test procedures.

Learn more about IEC 60076

IEEE C57.12 series

Addresses various aspects of transformers, including general requirements, temperature rise limits, impedance, and testing methods.

Read more about IEEE C57 standard

CSA C series

It is mainly Canada’s specific standards for power transformers, 3-phase pad-mounted transformers, single-phase pad-mounted transformers, live front pad-mounted transformers, dry type transformers, and other transformers' efficiency values, electrical properties, mechanical properties, and test requirements. By incorporating protective devices and adhering to the relevant standards in the design and production process, manufacturers can ensure that the transformers they produce are safe, reliable, and efficient for their intended applications.

Related Article

CSA C227.3 For Single Phase Pad Mounted Distribution Transformer

Pad Mounted Transformer CSA C227.4 National Standard of Canada

Three Phase Live Front Pad Mounted Transformers Under CSA C227.5

CSA C802 For Minimum Efficiency Values For Power Transformers

CSA C88 Standard For Power Transformers

What is the 250 kVA transformer specification?

Here are the different types of 250 kVA transformer specification:

Single Phase Pad Mounted Transformer

Rated capacity: 250 kVA

Primary voltage: 27600/16000V(249400Y1440V,34500V,14400V,199200V,ect.)

Secondary voltage: Commonly 240/120V, 240/480V

Phase: Single Phase

Winding material: Copper or aluminum

Insulation class: BIL30-150

Frequency: 50 Hz or 60 Hz

Cooling method: ONAN,KNAN

Impedance: 2% to 4%

More detail about 250 kVA single phase pad mounted transformer

250 kVA Dry Type Transformer

Rated capacity: 250 kVA

Primary voltage: Usually ranges between 6.6 kV to 33 kV (but can vary)

Secondary voltage: Commonly 415V, 440V, or 480V for low-voltage distribution

Phase: Three-phase

Winding material: Copper or aluminum

Insulation class: F, H, or higher (depending on the specific design)

Frequency: 50 Hz or 60 Hz

Cooling method: Air-cooled, with natural (AN) or forced (AF) cooling

Impedance: Depends on the specific design, but typically in the range of 4% to 6%

Read more about Dry Transformer

250 kVA Oil Immersed Transformer

Rated capacity: 250 kVA

Primary voltage: Usually ranges between 6.6 kV to 33 kV (but can vary)

Secondary voltage: Commonly 415V, 440V, or 480V for low-voltage distribution

Phase: Three-phase

Winding material: Copper or aluminum

Frequency: 50 Hz or 60 Hz

Cooling method: Oil-immersed, with natural (ONAN) or forced (ONAF) cooling

Impedance: Depends on the specific design, but typically in the range of 4% to 6%

Read detail about Oil Immersed Transformer

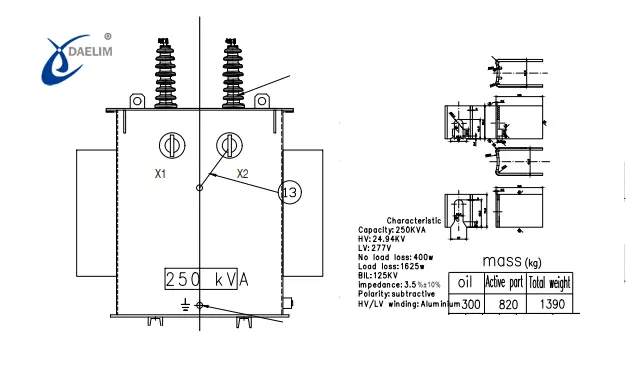

250 kVA Pole Mounted Transformer

Rated capacity: 250 kVA

Primary voltage: Usually ranges between 6.6 kV to 33 kV (but can vary)

Secondary voltage: Commonly 415V, 440V, or 480V for low-voltage distribution

Phase: Single-phase or three-phase

Winding material: Copper or aluminum

Frequency: 50 Hz or 60 Hz

Cooling method: Oil-immersed, with natural (ONAN) or forced (ONAF) cooling

Impedance: Depends on the specific design, but typically in the range of 4% to 6%

Keep reading: Single Phase Pole Mounted Transformer

Please note that these are general specifications, and the specific values can vary depending on the manufacturer, design, and customization options. It's essential to consult with the manufacturer or supplier to ensure the transformer meets your needs and requirements.

How much is the 250 kVA transformer load capacity?

The capacity of load for the transformer is measured by its rating power, which is the power level that it can handle in continuous operation without exceeding the temperature limit. For a transformer with a capacity of 250 kVA, regardless of type (oil-immersed dry, oil-immersed, or cast resin), the rated power or load capacity mainly depends on the efficiency value of the transformer, and the higher the efficiency value, the greater the load capacity. If you need your 250kVA load to be the largest, you need to ask the supplier to raise the efficiency value.

You may enjoy: Pad Mounted Transformer

What factors will affect the actual load capacity of the 250 kVA transformer?

Ambient temperature

Transformers are designed to operate within a specific ambient temperature range. If the ambient temperature is higher than the rated range, the 250 kva transformer load capacity may decrease because it can't dissipate heat as efficiently. In contrast, if the ambient temperature is lower, the transformer may be able to handle a slightly higher load.

Load type

The type of load connected to the transformer can influence 250 kVA transformer load capacity. For instance, loads with high inrush currents or harmonics, such as motors or electronic equipment, can affect the transformer's performance and reduce its effective load capacity.

Overloading conditions

While transformers can handle short-term overloading conditions, continuous overloading can reduce the transformer's lifespan, increase the risk of failure, and decrease its overall load capacity. It's essential to ensure that transformers are not subjected to overloading beyond their design specifications.

Maintenance

Proper maintenance, including regular inspections and timely replacement of worn components, can help maintain the transformer's load capacity. Neglecting maintenance can result in reduced performance and decreased load capacity.

In summary, in a specific application, various factors will affect the actual load capacity of the 250kVA transformer.

What is the 250 kVA transformer weight?

The 250 kVA transformer weight may depend on the model of the transformer, the design, and the materials that are used. Here's a rough estimate of the weight for different types of 250 kVA transformers:

Single phase pad mounted transformers: 1,000-1,300 kg

Singe phase pole mounted transformers: Approximately 1,200 to 1,500 kg

Oil-immersed transformers: Approximately 1,500 to 3,000 kg (3,300 to 6,600 lbs)

Dry-type transformers: Approximately 1,200 to 2,500 kg (2,640 to 5,500 lbs)

Please note that these weights are approximate and can vary significantly depending on the specific design and features of the transformer. It's essential to consult the manufacturer or supplier for the exact weight of a particular model.

Try for free: The Ultimate FAQs Guide To 225 kVA Transformer

Several factors can influence the 250 kVA transformer weight

Material for the core

The nature and quantity of the core material, like Cold-rolled grain-oriented (CRGO) silicon steel, or amorphous metal will affect the mass that the transformer. Higher-quality core materials may be lighter but provide better performance and efficiency.

Material for winding

The selection of winding materials like aluminum or copper may also affect the power of the transformer. Copper windings are generally heavier than aluminum windings, but they offer better performance due to their higher electrical conductivity.

Cooling method

The cooling method used in the transformer can impact its weight. Oil-immersed transformers are generally heavier than dry-type transformers due to the additional weight of the insulating oil and the larger tank required to contain it.

Learn more: The ultimate guide to ONAN transformers

Enclosure

The type and material of the enclosure or housing can affect the weight of the transformer. For example, pad-mounted transformers often have a robust, tamper-resistant enclosure, which can add to the overall weight.

Accessories

Additional components and accessories, such as cooling fans, radiators, or tap changers, can also contribute to the weight of the transformer. Always consult with the manufacturer or supplier to ensure the transformer meets your specific needs and requirements.

300kVA Transformer Price

Like 250kva transformers, there are many types of 300kva transformers. Different types, manufacturing processes, design standards, materials, brands, etc., will have relatively large differences in price. Listed below are some approximate prices of Daelim’s 300kva transformers for reference only.

300kVA pad mounted transformer:8500-13000$;

300kVA substation transformer:8000-12000$;

300kVA pole mounted transformer:1900-3000$;

300kVA cast resin dry transformer:3500-6000$

Therefore, for the detailed 300kVA transformer price, you need to consult a professional transformer supplier after confirming the technical parameters, requirements and other details.

You may enjoy on:3 Phase Pad Mounted Transformer

Are there also different types of oil-immersed transformers? Please expand in detail and tell me what are the weights.

Yes, there are different types of oil-immersed transformers based on their design, application, and installation method. Here's an overview of some common types of oil-immersed transformers, along with their approximate weights for a 250 kVA capacity:

Pole-mounted transformers:

Designed for installation on utility poles

Typically used in residential or rural areas

Commonly feature single-phase or three-phase configurations

Approximate weight: 1,200 to 1,800 kg (2,640 to 3,970 lbs)

Ground-mounted or pad-mounted transformers:

Installed at ground level, usually on a concrete pad

Used in suburban, commercial, or industrial areas

Typically three-phase units

May have tamper-resistant enclosures for safety and security

Approximate weight: 2,000 to 3,000 kg (4,410 to 6,610 lbs)

Substation transformers:

Designed for installation within electrical substations

Used to regulate voltage levels in distribution networks

Can be single-phase or three-phase units

May feature on-load or off-load tap changers for voltage adjustment

Approximate weight: 2,500 to 3,500 kg (5,510 to 7,720 lbs)

Hermetically sealed transformers:

Feature a completely sealed tank, preventing contact between insulating oil and the external environment

Minimize the risk of oil leaks and reduce maintenance requirements

Suitable for various applications, including industrial and commercial settings

Approximate weight: 1,800 to 2,800 kg (3,970 to 6,170 lbs)

Please note that these weights are approximate and can vary significantly depending on the specific design, materials, and features of the transformer. Some factors that influence the weight include core material, winding material, cooling method, and additional components or accessories.

Always consult with the manufacturer or supplier to ensure the transformer meets your specific needs and requirements.

What working conditions are required to operate a 250 kVA transformer?

To ensure the safe and efficient operation of a 250 kVA transformer, it's essential to maintain suitable working conditions. Here are some common working conditions required for the proper operation of a 250 kVA transformer:

Ambient temperature

Transformers are designed to operate within a specific temperature range, typically between -25°C (-13°F) and 40°C (104°F). Ensure that the ambient temperature remains within this range to avoid overheating and reduced performance.

Altitude

Transformers are designed to operate efficiently at certain altitude levels. Generally, they are rated for altitudes up to 1,000 meters (3,281 feet) above sea level. Operation at higher altitudes may require derating or special designs to compensate for reduced cooling efficiency and insulation performance.

Ventilation

Adequate ventilation is crucial for proper cooling of the transformer, especially for dry-type transformers. Ensure that there is sufficient airflow around the transformer to allow heat dissipation and prevent overheating.

Humidity

High humidity can cause condensation, leading to insulation degradation and reduced performance. Maintain a relative humidity level below 90% to prevent moisture-related issues.

Cleanliness

Keep the transformer and its surroundings clean, and free from dust, dirt, and debris. Accumulation of dirt and dust can cause overheating, reduced insulation performance, and increased risk of failure.

Protection from contaminants

Protect the transformer from contaminants such as corrosive gases, chemicals, and salt spray that may cause corrosion and damage to the transformer components.

Stable foundation

Install the transformer on a stable, level, and vibration-free foundation to prevent mechanical stress, movement, or misalignment during operation.

Electrical loading

Ensure that the transformer operates within its rated capacity and avoids continuous overloading, which can cause excessive heating, reduced lifespan, and increased risk of failure.

Proper grounding

Make sure the transformer is properly grounded to protect it from electrical faults and ensure the safety of personnel and equipment.

Regular maintenance

Perform regular maintenance, including inspections, cleaning, and replacement of worn components, to ensure the transformer operates safely and efficiently.

By maintaining suitable working conditions and following the manufacturer's guidelines, you can ensure the safe and efficient operation of a 250 kVA transformer.

Get The 250 kVA Transformer Price

Daelim can provide you with the 250 kVA single phase transformer, pole mounted transformer, pad mounted transformer, substaton transformer, and dry transformer. Contact Daelim to get the latest quotation.

Related Products

Related Article

Ultimate Guide To Transformer Sizes and Ratings

Transformers come in a wide range of sizes and ratings, and the specific requirements of the application will determine the appropriate size and rating for a particular transformer. It is important to choose a transformer that is specifically designed and rated for the required voltage, current, power, frequency, and temperature levels.

Everything You Need To Know With 250 kVA Transformer

Daelim is UL/cUL transformer manufacturer who has been product with ANSI/IEEE,CSA, AS/NZS, GOST, EN standards.The 250 kVA Transformer produced by Daelim can fully meet the DOE efficiency value.Daelim’s 250kVA three -phase transformers and single -phase transformers have been exported to the United States, Canada, Australia, Guyana, Mexico, Panama and other countries.

A Complete Access To 315 kVA Transformer

This post will teach you everything you need about the 315 kVA transformer. If you're in the market for a 315kVA transformer, use this guide to identify its features and specifications.