8+FAQ About Pad Mounted Transformers

Pad mount transformers, ranging from 15kVA to 10000kVA, are specialized outdoor units prominently visible to the public or located near residential and commercial areas. Available in both single-phase and three-phase configurations, these transformers feature robust, tamper-proof designs with hinged doors, high and low-pressure compartments, and often include baffled vents. Equipped with fuses and on-load tap-changers, they ensure dependable power distribution in urban environments. Installed at ground level for easy accessibility, these transformers play a crucial role in facilitating efficient electricity supply to nearby households, commercial buildings, and industrial facilities. Their strategic placement supports seamless integration into urban infrastructure, ensuring reliable and uninterrupted power distribution.

Daelim Transformer specializes in manufacturing pad mounted transformers that comply with the IEEE/CSA Std standards. With extensive export experience, Daelim has supplied transformers to the North American market. They can provide UL and cUL certification as well as sales records for reference.

Send Inquiry NowYou can assure that Daelim’s pad mounted transformers are rigorously tested and inspected to guarantee that they meet international standards and specifications.

Pad Mounted Transformer In Stock For Blockchain

Daelim Transformer has been involved in hundreds of blockchain projects and is highly knowledgeable about the technology and requirements of transformer systems for blockchain. We maintain a stock of pad-mounted transformers specifically tailored for blockchain, ensuring immediate availability without delays. The following table provides detailed inventory information on our transformers. For further inquiries, please feel free to contact us.

| Primary Voltage | Secondary voltage | Rating | Connection type | Standard | QTY |

| 34.5kV | 415V | 2550kVA | Dyn1 | IEEE Std C57.12.34 | 13 |

| 34.5kV | 480V | 2550kVA | Dyn1 | IEEE Std C57.12.34 | 6 |

| 13.8kV | 415V | 3000kVA | Dyn1 | IEEE Std C57.12.34 | 2 |

| 13.2kV | 480V | 2550kVA | Dyn1 | IEEE Std C57.12.34 | 6 |

| 24.94kV | 415V | 2550kVA | Dyn1 | IEEE Std C57.12.34 | 18 |

| 24.94kV | 480V | 2550kVA | Dyn1 | IEEE Std C57.12.34 | 7 |

| 12.47kV | 415V | 2550kVA | Dyn1 | IEEE Std C57.12.34 | 12 |

| 12.47kV | 480V | 300kVA | YNyn0 | IEEE Std C57.12.34 | 4 |

| 12.47kV | 480V | 500kVA | YNyn0 | IEEE Std C57.12.34 | 4 |

| 12.47kV | 480V | 750kVA | YNyn0 | IEEE Std C57.12.34 | 4 |

| 12.47kV | 480V | 1000kVA | YNyn0 | IEEE Std C57.12.34 | 4 |

| 12.47kV | 480V | 1500kVA | YNyn0 | IEEE Std C57.12.34 | 4 |

| 12.47/24.94 kV | 480V | 750kVA | YNyn0 | IEEE Std C57.12.34 | 3 |

| 12.47/24.94 kV | 480V | 1000kVA | YNyn0 | IEEE Std C57.12.34 | 3 |

How Do Pad Mounted Transformers Function in Power System?

The primary purpose of a pad mounted transformer is to reduce the high power supply from the electrical distribution system to an acceptable level suitable for local use.

The principal cable links to the high-voltage distribution networks, while the subsidiary wires transport lower-voltage electricity to the regional transmission network.These transformers application in residential neighborhoods, commercial developments, and industrial parks.

Pad mounted transformers are typically protected by strong enclosures made of stainless steel or carbon steel. These sturdy housings are specifically designed to safeguard the transformers, ensuring their safety and security. They act as a protective shield, shielding the internal components from external elements and potential harm. This robust construction enhances the reliability and durability of the transformers, enabling them to function efficiently in different environments while prioritizing the safety of the surrounding areas.

For allowed access and defense against unauthorized entry, their doors are frequently locked.

Reading more about Pad Mounted Transformer

What Is The Importance Of Pad Mounted Transformers In Power Distribution?

Pad mounted transformers are a critical component in power distribution systems. They reduce the risk of power outages caused by external factors such as weather, wildlife, and accidents.

To improve power quality, pad mounted transformers manage the degree of voltage. They keep the output voltage equal in order to adequately take into account possible shifts in voltage in the underlying transmission system. This reduces the risk of equipment damage and promotes the functionality of electrical products by guaranteeing the electrical voltage delivered to consumers stays within authorized values.

They also make sure that power is highly supplied to end-users regularly and dependably by scaling down the voltage and distributing it at the proper levels. They are technically designed to be durable and can withstand harsh environmental conditions, making them a cost-effective solution for power distribution systems. It would be difficult to match the voltage needs of various end users without pad mounted transformers.

What Are The Types Of Pad Mounted Transformers?

Despite their wide range in size, capacity, and design, pad-mounted transformers typically fall under the following categories.

Cooper Pad Mounted Transformer Type

The cooper pad mounted transformer has copper winding elements. Copper is an excellent conductor of electricity, meaning that it can efficiently transfer electrical energy with minimal power losses. This results in a more efficient electrical system that can reduce energy costs and improve overall performance.

In addition to that, copper windings have low resistance, which means that they can efficiently transfer electrical energy without losing much energy to heat.

Residential Pad Mounted Transformer Type

Residential pad mounted transformers transform high level electricity from distribution cables to a reduced power suitable for consumption at domestic residences. They have been developed specifically for use in residential environments. They tend to be situated next to housing developments, condominium developments, or solitary homes.

They are frequently housed in weatherproof cages that are mainly placed on concrete ledges that are level with the ground. These shelters protect the transformer against the elements while also protecting the security of the residents.

Overall, they help in ensuring that residences receive the proper voltage levels required for powering lighting, appliances, and other electrical devices inside residential buildings.

Learn more about Residential Transformer

Single Phase Pad Mounted Transformer Type

In homes and small-scale businesses, single-phase pad mounted transformer is frequently used. Compared to three-phase pad-mounted transformers, they are typically smaller and have lesser power capabilities. This includes during peak demand periods, without suffering any damage or decreasing its lifespan. This allows utilities to operate the transformers at 109% or higher of the rated load, which can save both space and weight.

What Can You Find Inside A Pad Mounted Transformer?

Inside a pad mounted transformer, you'll typically find parts like the core, windings, insulation, bushings, cooling system, and the transformer body.

Core: The pad mounted transformer's core is highly made of laminated sheets of magnetic material, such as silicon steel.

It provides a path for the magnetic flux and helps to transfer electrical energy from one circuit to another.

Windings: Pad mounted transformers frequently use both copper and aluminum as conductive materials, and each has advantages and things to keep in mind.

Insulation: Insulation is generally used to separate the windings and the core to prevent electrical arcing and short circuits. The insulation includes a variety of materials, such as paper, enamel, or resin.

Bushings: A pad mounted transformer's bushing creates an electrical connection between the interior components and the outer high-voltage or low-voltage electrical system.

Bushings provide a mechanism to safely move electrical current and voltage into or out of the transformer in addition to providing electrical insulation and mechanical support.

Tap Changers: Tap changers provide the ability to modify the transformer's output voltage to compensate for the input voltage or to meet specific load requirements.

Tap changers inside a pad mounted transformer can be manually operated, allowing for flexibility in voltage regulation.

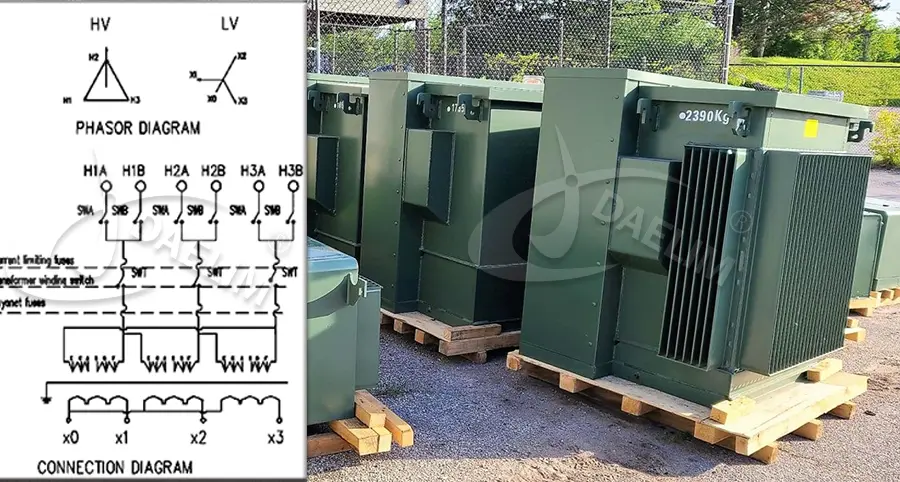

How Electricity Flows Through Pad Mounted Transformer Diagram?

A pad-mounted transformer diagram illustrates the various components and their arrangement within a transformer. It provides a visual representation of how the transformer works and helps in understanding its functioning.

Here's an explanation of the functioning, basic operation, electrical connections, and cooling system of a pad-mounted transformer:

Related Article

Ultimate Guide To Power Transformer Diagrams

Goals and Objectives Of Pad Mounted Transformer

The major goal of pad-mounted transformers is to achieve an efficient circulation of electricity. By doing this, they enable smooth electric power transfer from the power system for end consumers, such as homeowners, business customers, and industry users.

The secondary wirings, which are mainly connected to the pad mounted transformer's lower voltage side, experience a voltage as a result of this magnetic field. On the secondary side, the induced voltage becomes available and is appropriate for local distribution. To power various appliances and gadgets, the lower voltage electricity is subsequently connected to the electrical distribution system or directly to the local electrical loads.

As a matter of fact, it enables the conversion of electrical power and its transmission to residences, commercial buildings, and other end users.

Basic Operation

The electrical transfer of energy is the main focus of a pad mounted transformer diagram. The transformer's core and windings ensure efficient energy transfer while maintaining electrical isolation between the primary and secondary circuits.

Electrical Connections

A pad-mounted transformer diagram has electrical connections, known as bushings, that allow for the safe and efficient transfer of electrical energy. These bushings are typically made of porcelain or polymer materials and provide the necessary insulation and electrical conductivity for reliable power transmission.

Cooling System

Liquid cooling involves circulating a coolant, such as mineral oil, synthetic esters oil, and vegetable oil, to absorb and dissipate heat more efficiently. The cooling system ensures that the pad-mounted transformer diagram operates within safe temperature limits, maintaining its performance and longevity.

Get it now: Three Phase Live Front Pad Mounted Transformers Under CSA C227.5

What Are The Advantages Of Pad Mounted Transformers?

Some of the advantages of pad mounted transformers include reduced installation costs, lower maintenance requirements, improved aesthetics, increased safety, and flexibility in space utilization. These benefits make them a preferred choice in various applications, including residential, commercial, and industrial settings.

Lesser Construction Expenditures

Since they are technically placed on a concrete pad at ground level, they eliminate the need for expensive and time-consuming overhead structures, such as poles and associated wiring. This can result in significant cost savings during the installation process, especially in areas with challenging terrain or where underground electrical infrastructure is usually preferred.

Reduced Maintenance Needs

Compared to overhead transformers, home pad mounted transformers often require less maintenance. They are highly designed with durable materials and sealed enclosures that protect the internal components from environmental elements such as moisture, dust, and temperature fluctuations.

This reduces the risk of corrosion, insulation degradation, and other issues that may require frequent maintenance or repairs.

Improved Aesthetics

Cooper pad mounted transformer are typically designed with aesthetics in mind. They are often installed in urban or residential areas where the visual impact of traditional overhead transformers and associated wiring may be undesirable.

Therefore, pad mounted transformers are technically enclosed in aesthetically pleasing enclosures, which blend more seamlessly with the surroundings.

Enclosures for Protection

Pad-mounted transformers are technically housed in waterproof casings made of durable materials. The structures protect from environmental dangers like UV radiation, rain, and snow. By restricting unauthorized entry and reducing the chance of unintended contact with live components, they also improve public and utility employee safety.

In addition to that, these transformers are highly protected from unintentional contact and unlawful access by robust, tamper-resistant enclosures.

Compatibility

Because they can be attached to overhead or subsurface lines for distribution, they provide compatibility in access to the wider electrical distribution structure. This flexibility allows for better utilization of available space and provides options for future expansion or rearrangement of electrical infrastructure.

You may enjoy: Pad Mounted Transformer CSA C227.4 National Standard of Canada

How Do I Get The Pad Transformer Ready For Installation?

It is important to note that the specific steps and requirements for preparing a pad transformer for installation may vary. It will all be depending on local regulations, transformer specifications, and other factors.

Step 1. Site Preparation

Make sure the transformer pad has a good foundation. You should provide a stable and flat surface that should consist of concrete or any other appropriate material.

Ensure that the site meets the necessary electrical and safety requirements. Clear the area of any obstacles, debris, or vegetation that may interfere with the installation or access to the pad mounted transformers.

Step 2. Concrete Pad Construction

The construction of a concrete platform for the installation of pad mounted transformers is generally known as concrete pad construction. Then, identify and mark the positions of any subsurface utilities that are already in place, such as communication, water, and gas lines.

Step 3. Electrical Connections:

Coordinate with the utility company or electrical contractor to arrange for electrical connections to the pad mounted transformers. This may involve trenching or laying underground cables to connect the transformer to the electrical grid or power source.

Step 4. Obtain Permits and Approvals

Consult with your local authority to see if any permissions are necessary for the installation of the pad mounted transformer. Ensure compliance with all applicable regulations and codes.

Step 5. Transformer Delivery and Inspection

Arrange for the delivery of the pad mounted transformer to the installation site. Verify that all necessary components, accessories, and documentation are included.

Step 6. Lift and Positioning

Once the transformer is correctly positioned, securely anchor it to the concrete pad using approved methods, such as bolts or anchors. Next is to install the necessary warnings, high voltage indicators, and emergency contact information in the vicinity of the pad mounted transformer.

Step 7. Documentation and Record-Keeping

Maintain accurate records of the installation process, including any permits, inspections, and test results. Keep detailed documentation for future reference and compliance purposes.

Get free: Step-by-Step Guideline On Installing A Transformer

Are Pad Mounted Transformers Safe To The Community?

Yes, pad-mounted transformers are technically designed to be safe for the community when installed and maintained properly. They undergo rigorous testing and adhere to safety standards to ensure their reliable and secure operation. This design minimizes the risk of accidental contact with live electrical parts, making them safer for the community.

Public education on electrical safety, such as staying away from transformer enclosures and reporting any suspicious activities, can further enhance community safety.

Related Products

Related Article

2000 kVA Pad Mounted Transformers for Canadian Utility

Daelim Transformer is pleased to announce its contribution to a utility project in Toronto, Canada, involving the supply of two units 2000 kVA pad mounted transformers. These transformers are integral to enhancing the power infrastructure in the region. The project demands adherence to CSA standards, with a stringent delivery deadline of 10 weeks to meet the urgent needs of the client.

CSA C227.3 For Single Phase Pad Mounted Distribution Transformer

What we have here are the Canadian Standards Association standards. This will include the CSA-C227.3 guidelines for single-phase pad-mounted distribution transformers.

Supply of 37.5 kVA Single Phase Pad Mounted Transformers for Canadian Utility

Today, we are excited to introduce a project undertaken by Daelim Transformer aimed at supplying transformers to a Canadian utility. This project involves the delivery of 80 units of 37.5 kVA single-phase pad mounted transformers, specially designed to meet the utility's requirements. With a high voltage (HV) rating of 24940GRDY/14400 V and a low voltage (LV) rating of 240/120 V, these transformers are vital components in the utility's infrastructure.

1750 kVA Pad Mounted Transformer for the Dominica Market

Today, we're excited to present a transformer project tailored for the Dominican market. Our 1750 kVA pad mounted transformer is designed to meet the specific requirements of our clients in Dominica. This step-down transformer boasts a primary voltage of 13.8 kV and a secondary voltage of 480Grdy/277V, adhering to the IEEE C57.12.34 standard. With its robust features and reliable performance, this transformer is set to enhance the power distribution infrastructure in Dominica.

2 MVA Pad Mounted Transformer for Utility

Behold the backbone of Canada's utility infrastructure—the 2MVA pad mounted transformer. With a primary voltage of 4160Grdy/2400V and a secondary voltage of 800GrdY/461V, this transformer stands as a testament to efficiency and reliability in power distribution. Crafted in strict accordance with CSA standards and CAN/CSA802.1 energy efficiency guidelines, it embodies the pinnacle of engineering excellence.

2600 kVA Pad Mounted Transformer For Blockchain In Kansas

This morning, I received the on-site photos of the pad-mounted transformers from the customer, and I was overwhelmed with excitement and joy. These pad-mounted transformers are installed at a 20MW blockchain site in Kansas, USA. A total of 5 sets of 2600 kVA pad-mounted transformers, all UL-listed, are being deployed at this site. Currently, 3 sets have already been installed onsite and are scheduled to be powered on imminently.

Daelim Transformer Custom 1500 kVA Pad Mounted Transformer for Canada

As a professional pad mounted transformer manufacturer & supplier, Daelim Transformer is committed to meeting standards such as ANSI/IEEE, CSA, DOE, and NEMA, offering customized solutions. Here, we present a case of a 1500 kVA pad mounted transformer tailored for the Canadian market.

1000 kVA Pad Mounted Transformers For Jamaica Market

In October 2023, Daelim Transformer successfully manufactured two units of 6 kV 1000 kVA pad mounted transformers, meeting 100% compliance with IEEE C57.12.34 and IEEE 693-2005 standards. These transformers, one step up and the other step down, were tailored for a valued customer in Jamaica. Let's delve into the details of this exceptional project.

Single Phase Pad Mounted Transformer For USA Utility

Introducing a utility transformer project tailored for the USA, located in Virginia. This utility initiative requires 215 units of single-phase pad-mounted transformers, all UL listed, including 175 units of 25 kVA and 40 units of 50 kVA. The end user's project timeline is 90 days. Adherence to IEEE standards is imperative for single-phase transformers. Additionally, the design of transformer components and markings must be customized to meet project specifications.

Pad Mounted Transformer for BESS System 4.0 MVA in Riverside County, California

Today, Daelim Transformer is proud to introduce a pad-mounted transformer for a 4.0 MVA Battery Energy Storage System (BESS) project located in Riverside County, California. The transformer is meticulously crafted to comply with the specifications outlined in the California Electrical Code Article 450.

2550 kVA Pad Mounted Transformer For Data Center in Mexico, Missouri

Today, we're excited to showcase Daelim Transformer's involvement in a project supplying four 2550 kVA pad mounted transformers tailored for a data center located in Mexico, Missouri. Data centers, known for their substantial power demands, require reliable solutions to ensure seamless operation during peak electricity usage.

2600 kVA Pad Mounted Transformer for Blcokchain

Daelim Transformer successfully provided three customized 2600 kVA pad mounted transformers to power a state-of-the-art blockchain facility in Texas, USA. Our transformers were meticulously designed to meet the unique demands of the mining operation, ensuring seamless power distribution with unwavering reliability and efficiency.