The Ultimate Guide to 1500kVA Transformer

If you're planning to search for a 1500 kVA transformer price, you need to inform the supplier with some basic information about your specific needs. Daelim is a professional transformer manufacturer, and the overseas experienced transformer engineer team can customize any type of 1500kVA transformer. If you encounter problems with transformer technology, you can contact Daelim at any time. Daelim's technical team will give you a satisfactory solution.

In this guide, we will discuss where you can locate a 1500 kVA transformer price with its corresponding weight and amps. We will also take a look at the 1600 kVA transformer price.

Contact Daelim TransformerWhat is a 1500kva transformer?

A 1500kva transformer usually refers to apparent power (transformer capacity) of 1500kva. Usually, its active power is 1200kw. Mostly used in power distribution systems, 1500 kVA distribution transformers can directly supply power to end-users. The high voltage of the transformer generally does not exceed 35kv.

Learn more: Surplus 15000 kVA transformer for sale!

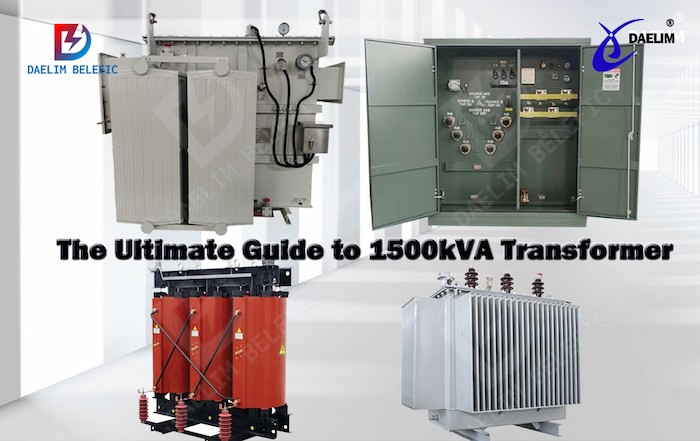

Types of 1500kva transformer

1500kva pad mounted transformer

1500kva pad mounted transformer integrates load switch, backup fuse, and other components inside its fuel tank. This design ensures compactness, corrosion resistance, and dust-proofing, making it easy to install and maintain. Typically mounted on cement platforms, it finds extensive applications in residential areas, shopping malls, industries, and crypto mining farms.

The 1500 kVA pad mounted transformer is available in dead front and live front types, offering both radial feed and loop feed configurations. You can select the appropriate type based on your specific requirements.

Learn more about Pad Mounted Transformer

1500kVA substation transformer

1500kVA substation transformer is widely used in North America and Australia. These transformers feature radiators on both sides and a detachable terminal box. High voltage for substation transformers generally does not exceed 44 kV, with capacities reaching up to 15 MVA.

Daelim Transformer is renowned for exporting substation transformers to North America and Australia in significant quantities. These transformers are designed with environmental protection in mind, utilizing eco-friendly vegetable oils. Daelim offers a wide range of capacities, including1500 kVA, 1000 kVA, 2500 kVA, 3000 kVA, 5000 kVA, 5 MVA, 7.5 MVA, 10 MVA, and 20 MVA transformers.

One of the key advantages of Daelim transformers is their short production cycle, ensuring efficient manufacturing processes. The company maintains high-quality standards, producing reliable and durable transformers. Additionally, Daelim focuses on fast transportation, enabling timely delivery of their transformers to customers. Overall, Daelim's substation transformers are designed to meet the specific requirements of the North American and Australian markets, offering efficient and sustainable power distribution solutions.

More detail about Substation Transformer

1500kVA dry type transformer

The iron core and winding of the 1500kva dry-type transformer are not immersed in insulating oil. The cooling medium is air, and the main insulating material is epoxy resin. It has the characteristics of fireproof, explosion-proof, moisture-proof, environmental protection, and safety. Widely used in local lighting, high-rise buildings, airports, docks, and other places. The 1500kva transformer can only be installed indoors, and the insulation grade of the dry transformer can be A, E, B, F, and H according to your requirements, and the shell can be customized for the dry transformer.

1500kva oil filled transformer

The 1500 kVA oil filled transformer is typically used in transmission and distribution lines. Its voltage regulating switch can be loaded or unloaded. This type of transformer is highly cost-effective, with over 70% of the power grid utilizing oil-filled transformers. They are designed for outdoor installation only.

Read more: How much do you know about oil-immersed distribution transformers?

What are the factors affecting 1500 kVA transformer price?

Several factors influence the cost and price of a 1500kVA transformer. Here are three main considerations:

Core Material of the Transformer

The core material significantly impacts the transformer's price. Currently, the primary materials for 1500kVA transformers include two types of cores: conventional grain-oriented silicon steel and customer-specified amorphous alloy cores. Amorphous alloy cores are more expensive but offer lower losses compared to conventional silicon steel cores. Lower losses translate to long-term savings on electricity bills, making them preferable when budget allows. However, silicon steel cores remain popular due to their cost-effectiveness, durability, and compliance with international standards. Silicon steel sheets are categorized into hot-rolled and cold-rolled types, with cold-rolled sheets preferred in transformer production due to lower iron losses and reduced production costs.

Try for free: What influences a high voltage transformer price?

Winding Material of the Transformer

Transformer windings are typically made of either copper or aluminum. The choice depends on engineering requirements; however, aluminum windings are commonly used due to their economic advantage. Copper windings offer better electrical conductivity and higher recyclable value, which is beneficial in terms of environmental sustainability and material recovery.

Special Loss Requirements of the Transformer

Transformer losses, comprising copper losses (on-load losses due to coil resistance) and iron losses (idle losses due to core material properties), are critical cost factors. Lower losses improve transformer efficiency and reduce energy consumption for end-users. Specifications from standards such as IEC, IEEE, and others define permissible loss values, influencing transformer design and cost. Meeting stringent loss requirements increases manufacturing costs but enhances overall transformer performance and energy efficiency.

More Resouce

Transformer Efficiency: The Ultimate FAQs Guide

These factors illustrate how technical specifications, material choices, and efficiency requirements contribute to the pricing of 1500kVA transformers.

What is the weight of a 1500 kVA transformer?

The following is a list of the weights of 1500 kVA transformers for reference only. Due to different technical requirements and designs, there will be significant differences. If you want to know the exact value, please contact Daelim Transformer.

- 1500kva pad mounted transformer weight is about 5800kg.

- 1500kva substation transformer weight is about 6600kg

- 1500kva dry type transformer weight is about 5000kg.

- 1500kva oil filled transformer weight is about 4000kg.

1500 kVA Transformer Dimensions

1500kva pad mounted transformer dimension

| High | Depth | Width |

| 2210mm | 1470mm | 2150mm |

1500kva substation transformer dimension

| High | Depth | Width |

| 1800mm | 870mm | 1880mm |

1500kva dry type transformer dimension

| High | Depth | Length |

| 2000mm | 900mm | 1600mm |

1500kva oil filled transformer dimension

| High | Depth | Length |

| 1860mm | 860mm | 1960mm |

1500 KVA transformer specification

1500kva pad mounted transformer specification

| No-load loss(w) | On-load loss(w) | Impedance |

| 1640 | 14500 | 4.50% |

1500kva substation transformer specification

| Standard Primary Voltage Ratings | ||

| 2400 | 7200 | 13800 |

| 4160 | 12000 | 23000 |

| 4800 | 12470 | 34500 |

| 6900 | 13200 | Other |

Try for free: Subsation Transformer Ultimate Guide, You Need To Know

1500kva dry type transformer specification

| No-load loss(w) | On-load loss(w) | Impedance |

| 2580 | 12800 | 6.00% |

1500kva oil immersed transformer specification

| No-load loss(w) | On-load loss(w) | Impedance |

| 1580 | 14000 | 4.50% |

What Is The Standard 1500 kVA Transformer Price?

The price of a 1500 kVA transformer starts at $9,800 and can go up to $23,000, depending on the manufacturer. Prices vary significantly between regions and suppliers, with well-known brands commanding higher prices due to their reputation.

At Daelim Transformer, our 1500 kVA transformers are priced between $13,600 and $19,800. They meet ANSI, IEEE, CSA, AS, IEC, and EN standards, ensuring technical excellence in design and manufacturing. Contact Daelim Transformer now to get the transformer price.

How Do I Buy A 1500 kVA Transformer?

First, you figure out how many kVA the transformer needs based on how much power it needs to handle.

After that, you decide on the transformer's technical specs and guaranteed technical details.

In this case, you'll be needing a 1500 kVA transformer. You need to determine the 1500 kVA pad mounted transformer price at this stage.

Most important is to find a middle ground on the transformer's power losses.

The higher the power losses, the lower the initial cost of the equipment, but the higher the operating costs and the more maintenance it will need.

Then, look at the rating of your transformer to figure out what kinds of protection it will need.

Clear up your technical specs first, and then choose your manufacturer based on those specifications. Get quotes and negotiate well to get the best deal.

What Are Factors To Consider Before Buying A 1500 kVA Transformer?

When purchasing a 1500 kVA transformer, several key factors should be carefully considered:

Maximum Loading: Ensure the transformer's 1500 kVA rating can handle anticipated overloads without compromising performance.

Type: Decide between core or shell type, oil or dry type, single-phase or three-phase, and whether it will be pad-mounted or installed in a small substation.

Ambient Temperature: Consider if the transformer is designed to operate effectively under the highest temperatures typical for your region to maximize its lifespan.

Service Life: Evaluate the expected longevity of the transformer, with an average lifespan typically around 25 years.

Losses: Assess the transformer's efficiency to minimize operational costs and extend its lifespan.

Environmental Factors: Consider environmental conditions such as altitude, corrosion resistance, seismic requirements, which impact technical design and cost.

Weight: Factor in the transformer's weight, as it influences transportation costs and profitability for contractors and distributors.

Quality: Prioritize high-quality transformers over the lowest cost options for better long-term economic performance.

Amps: Verify the transformer's amp rating to ensure compatibility with your power supply's current requirements.

Voltage/BIL Requirements: Specify the required minimum and maximum voltages and understand the Basic Impulse Level (BIL) requirements for surge protection.

Phase Spacing/Clearance Requirements: Ensure sufficient electrical clearances between phase bushings as per design specifications.

Winding Requirements: Determine if a delta or wye configuration is preferable and if a grounded wye or tertiary winding is necessary.

Type of Insulation: Choose between dry-type or oil-immersed transformers based on application and insulation requirements.

Testing Requirements: Verify compliance with standardized testing procedures outlined in IEEE C57, including any additional testing requirements.

Shipping Logistics: Plan for transportation needs, including location and method of delivery.

Other Requirements: Include verified test results, final design drawings, instruction manuals, and any onsite support needed from the manufacturer.

Other Accessories: Specify details on bushing material, surge arrestors, winding material, and any necessary alarms or monitoring devices.

Why Are 1500 kVA Transformers Price So Expensive?

1500 kVA transformers command high prices primarily due to escalating costs of essential raw materials such as copper, core materials, iron, transformer oil, and insulating materials. These materials constitute a significant portion of the transformer's total cost. Additionally, factors like experienced engineering expertise and inventory management during the manufacturing process contribute to the overall expense.

The price is further driven up by the use of rare earth metals, essential for energy storage batteries, which are also employed in transformer components.

Copper, especially, plays a crucial role as it determines the transformer's cost due to its conductivity and current-carrying capacity. The amount of copper used directly influences the selling price of the transformer. Moreover, the insulation quality of copper wires allows for fewer turns, reducing the overall material required but increasing cost efficiency.

Manufacturing transformers involves meticulous processes to ensure safety and reliability. Handcrafted coils by skilled engineers ensure high quality but add to production costs due to the care and attention required in their construction.

Studies indicate that nearly 75% of the transformer manufacturing cost is attributed to the limited availability and volatile pricing of steel, copper, and oil. Copper shortages and increasing demand further exacerbate the cost pressures on transformer production.

1500 kVA Transformer Supplier

Daelim is the place to go if you're looking for high-quality 1500 kVA transformer.

When searching for power transformers, it is important to find a recognized manufacturer such as Daelim Transformer.

With us, you know you will receive a high-quality, trustworthy product.

Daelim offers the best total value to its customers by striking a good balance between initial and recurring expenditures.

Currently, Daelim is the leading power transformer manufacturer in China.

1500kVA ]transformers are highly constructed using cutting-edge equipment, premium materials, and innovative methods.

To ensure our power transformers last for years without needing frequent maintenance, we pay close attention to every step of the manufacturing process.