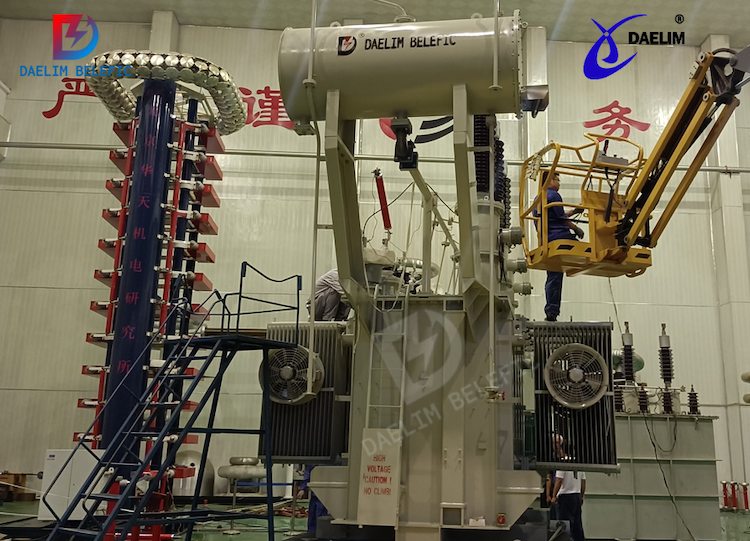

Electrical Transformer Site Acceptance Testing

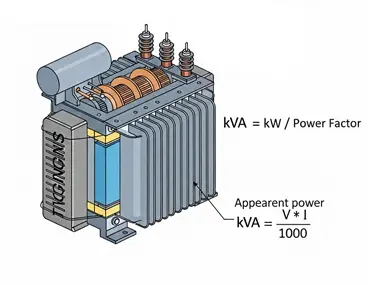

Electrical transformers are a very crucial electrical device in our existing Electricity Distribution system. These Transformers regulate electricity for devices that are much more sensitive to any fluctuation in electricity than the Transformers themselves.

So any mistake made during the Electric transformer design, development, transportation, and installation can lead to serious issues and damage on the electrical load attached to the Transformer. To avoid this a process called site acceptance testing is done on the Electrical Transformer.

This article is about understanding what Site acceptance testing SAT and why this specific site acceptance testing is necessary to perform and what types of test does this acceptance testing involve.

Contact Daelim TransformerWhat is Site Acceptance Testing?

Site acceptance testing definition is that, it is a series of tests that is done to ensure that the Transformer has been designed, developed, transported, installed, and operationalized correctly and it will operate according to the manufacturer specification and the project requirement.

When is Site Acceptance Testing Performed?

The site acceptance testing of Electrical Transformer is conducted after the Electrical Transformer has been installed on the site but it has not been operationalized and being operated on its full load.

The site acceptance testing SAT is a part of Transformer commissioning phase or it can be a part of project handover process where the electrical transformer manufacturing company or service providing company install the Electrical Transformer and then hand it over to the owner or operation team that will look after the operations of the Electrical Transformer.

This site acceptance testing is only done once when a new transformer is installed on any site. It is also performed partially when the Transformer undergoes a major repair or upgrade ensuring that any change made in the Transformer during the repair or upgradation is as per the operation requirement.

Why Site Acceptance Testing is Necessary?

This testing plays a very crucial role in confirming that the Transformer will remain reliable and safe and will not have any premature failure that can result in a costly downtime and can be a safety hazard for the attached load. Following are the four main reasons why the site accepted testing of the electrical transformer is performed for each and every new Electrical Transformer installation.

1. Verification of Factory Test Results Post Installation

Although each and every electrical transformer is designed and developed to satisfy a specific set of requirements and during manufacturing the manufacturing shows that each part is being manufactured and assembled as per the requirement and international standards.

However the entire Electrical Transformer is not delivered in a free assemble form for you to install. A lot of parts are delivered separately and they are installed on the site on the main Transformer body during the installation phase.

So after assembling all necessary parts of the Electrical Transformer it is important to ensure that all parts Work together properly and as per the client requirements. So one of the reasons why site acceptance tests are performed is to ensure that all tests performed in the factory were correct and the working of the Electrical Transformer after assembly of all its necessary parts is as per the requirement and international standards.

2. Confirming Proper Transportation, Handling, and Installation

Some of the electrical Transformers might travel hundreds of kilometres from their origin of manufacturing to the place of installation and some of the large power transformers are always delivered in parts that are assembled on site. Other than this based on the application and the installation site requirement, there might be some specific steps you need to follow during the installation of the transformer.

So after transportation and installation of the Electrical Transformer on the specific site several tests are performed on the Electrical Transformer to show that the Transformer has not received any type of damage during transportation and has been handled properly. Tests also ensure that the installation requirements and Standards associated with the installation of specific Electrical Transformer has been met fully.

These tests ensure that all those properties and functions of Electrical Transformer that were tested in the factory against which the Transformer design still hold valid and Transformer will perform as per the manufacturer claim.

You may enjoy: A Complete Guide on Transformer FAT Test

3. Ensuring Compliance with Technical Specifications and Contractual Requirements

It totally depends on the type of contract or the requirement of the application but there are certain scenarios in which there are some specific contractual requirements that need you to perform a specific test on the Transformer after its installation and before operationalisation. This most of the time happens when the transformer is either a main power transformer that receives electricity from the power generating plant or it is a transformer that regulates electricity for specific industries in which once the machinery is started it is very difficult to stop and restart the process.

Site acceptance tests might also be performed as per part of any International or national standards or reasonable rules and regulation associated with the installation of Electrical Transformer. These tests will ensure that the entire work done during the transportation assembly and installation of the Electrical Transformer is done as per the regional rules and international laws.

Get it free: A Comprehensive Guide to Transformer Specifications

4. Detecting Damage, Improper Assembly, or Installation Issues

Even though there is no specific requirement from the application against which the transformer is being used, there is no such regional rule or International standard that forces you to perform any site acceptance test. Still it is important to perform a number of tests on the Electrical Transformer after installation to ensure that there is no loose connection or any other parameter for external factors that will either cause short circuit or disruption in the transformer working in the very near future.

In specific scenarios where a transformer is installed in remote sites. It is important to inspect Transformer after install for any type of damage on the external Parts for any other issue with the Transformer. Issues like oil leak or damage bushing, incorrect connection or incomplete grounding or any other issue that happen after the team leaves the site will cause a lot of waste of time and waste of resources as the team has to visit the remote site again and do the inspection and correction process.

Who Performs the Site Acceptance Testing?

The site acceptance testing of Electrical Transformer is a dedicated task and needs specific skills and a certain level of knowledge to perform as per international standards. Any person who ever is assigned this site acceptance testing SAT task needs to have proper education and skills or should have a certain type of degree or certificate to perform this work properly.

The site acceptance testing of Electrical Transformer is a dedicated task and needs specific skills and a certain level of knowledge to perform as per international standards. Any person who ever is assigned this site acceptance testing SAT task needs to have proper education and skills or should have a certain type of degree or certificate to perform this work properly.

Electrical Engineer

One such person can be an electrical engineer who will be responsible for verifying that all electrical systems are connected properly safely and in compliance with the design's specific action of the Electrical Transformer.

Electrical engineer can be assigned with the task of;

- Checking that all circuit and electrical systems are as per the wire diagram provided by the manufacturer.

- Perform specific insulation resistance test on the Transformer winding insulation and other insulations and also perform continuity test on the Transformers to ensure that integrity of the transformer winding and other electrical parts is as per the manufacturer claim.

- Verify that the Transformer power distribution and control system connections and working is as per the calculations made during the design of the Electrical Transformer

- The electrical engineer can also be assigned with the task of troubleshooting if any unexpected issue arises or there is an Unexpected behaviour of any part of the Electrical Transformer.

Electrical Technician

The side acceptance testing team will also include and electrical technician who will be responsible for number of task including;

- Assembling all parts of the Electrical Transformer and making all connections ensures that all parts and connections are assembled and made as per the manufacturer guidelines and international standards.

- He will also be responsible for performing any type of calibration of the equipment that is done on site during the installation phase.

- He will also be responsible for performing all types of Diagnostic tests and validation of the payment performance of the installation has been completed and before fully operationalisation of the Electrical Transformer

- He is also responsible for insurance at the installation of all the parts matches the design and the warranty conditions provided by the manufacturer

- He will also provide any other technical support and the training of the team which will hand over Electrical Transformer for operations.

Third Part Test Agencies

In a specific case where a client hires any third party agency or the local government rule and regulation involve any agency to perform several tests for transformer site acceptance testing. The agency will independently perform tests to ensure that transformer installation is as per standards. Agency might perform

- Vibration test to ensure that the transformer installation is as per the international standards and there is now considerable harmful vibration in the structure and Transformer itself.

- Insulation resistance continuity and other electrical related tests to ensure that the installation and connection of the transformer are done as per international standards.

- The agency might also be responsible for issuing certification to the Transformer installing company in certifying that the system and the Transformer installation meet the regulatory safety and functional requirements.

- The agency will provide a detailed report of all the tests conducted on the Transformer and the installation site to the client and Transformer service provider company.

Types of Tests Conducted During Site Acceptance Testing

The test you perform on the Electrical Transformer during the site acceptance testing depends on the nature of the project and requirements by the clients or the regional laws. The following is a detailed list of tests that are performed during the site accepted testing.

Visual and Mechanical Inspection

The most basic test performed on the Transformer after installation is the visual inspection and mechanical inspection test. The test is done to ensure that all parts of the Electrical Transformer are in their best condition and there is no visible sign of any damage or wear and wear. Mechanical inspection is about the installation platform and it involved inspecting the structure, Nuts and bolts involved installation of the transformer. It also involves the inspection of assembly of the transformer parts that are assembled using mechanical methods of nut, bolt, rivets or any other method of assembly.

Learn more about Transformer Inspection

Insulation Resistance Test

Is one of the most important tests performed on the Electrical Transformer after the installation process completes. The insulation resistance test is about checking the resistance between the Transformer winding and the ground connection. This is done to ensure that there is no insulation breakdown between the Transformer winding in any other part of the transformer.

Winding Resistance Measurement

To the insulation resistance test the winding resistance test is done to ensure that the Transformer winding itself is not short circuit and in proper working condition. If there is any type of short circuit between the winding or if there is any poor electrical connection in the winding section of the transformer then this winding resistance test will help you identify and locate that problem.

Turns Ratio Test (TTR)

The turns ratio test is done in order to ensure that the final turn ratio obtained at the winding of the transformer after installation is the same as that of the turn ratio mentioned in the name plate of the transformer by the manufacturer. The turn ratio test is also done in order to ensure the Transformer winding working efficiency and detecting anomalies or tap changer faults.

Dielectric (HiPot) Test

This does involve checking the electrical transformer working without actually operationalization of the transformer. To perform these tests a high voltage is applied to the Transformer insulation system is inspected to confirm that there is no short circuit in the Electrical Transformer and the entire setup of the newly installed transformer is working properly.

Vector Group Verification

The vector group verification test is done during the site acceptance testing to confirm the phase displacement and the connection group of the Electrical Transformer. This is done to ensure that the compatibility of these things is as per the system design and there is no mismatch between what was documented and what is actually present in the current Electrical Transformer connection.

Functional and Protection System Checks

At the end the functional and protection system check is done to ensure that all parts that are connected to the Transformer will show the proper Transformer functionality and the protection of the electrical system or working properly. All types of safety devices like release cooling fans and Buchholz relays in oil-filled transformers are inspected to ensure full operationalization.

Related Resources:

Electrical Transformer Protection Knowledge Guide

Transformer Protection Devices

Transformer Overcurrent Protection

Temperature Protection and Maintenance for Transformers

Differential Protection of UHV Transformer

Tools and Equipment Used

Other than the general purpose that are used during the transportation loading unloading and installing of Electrical Transformer there are some special purpose tools specifically designed and used to perform site acceptance tests on the Electrical Transformer.

Following is the list of tools that are specifically used to perform site acceptance test on Electrical Transformer

- Megger insulation tester

- Transformer turn ratio meter

- Micro ohm meter

- HiPot tester

- Tan Delta analyzer

- Infrared thermography equipment

Standards and Guidelines for Transformer SAT

Might be different standards and guidelines for the installation of different types of Electrical Transformer in different parts of the world. However there are three most widely used and common standards that are used during the site acceptance test of Electrical Transformer.

IEEE Std C57.152

The IEEE Std C57.152 delivers guidelines about the Diagnostic test methods to assess the Transformer Health during field testing.

Reading more about IEEE C57 Std

IEC 60076 series

The IEC 60076 series completes a series of standards that define the site acceptance testing procedures, how to perform each and every test, the site acceptance testing checklist and the performer's requirement for power transformer.

NETA ATS

The NETA ATS specifies the standard on site acceptance testing protocol to ensure safety and reliability of the electrical equipment during the testing and installation of the Electrical Transformer.

Conclusion

Site acceptance test of Electrical Transformer is done to ensure that the Transformer is delivered at the side and the installation process of the transformer is done as per the international standards and plans made by the manufacturer or service providing company. If there is any mishandling or damage done during the transportation or installation of the Electrical Transformer then these tests can point out that error or mistake and you can correct those mistakes before fully operationalizing the Transformer. There are about 8 different tests that you can perform during the site acceptance test and you need a complete team of Electrical engineers, electrical technicians or third party Agencies to complete the testing and certification of the proper installation of the Electrical Transformer.

Follow Up

Installing an Electrical Transformer is really a challenging job as most of the transformers are transported on site where they need to be assembled and installed before fully operationalizing. We at Daelim Transformer, offer complete services of design, development, transportation, installation, and after sale service of the electrical transformer. Each of our transformers is designed, developed, transported, installed and tested on site following all international standards like IEC, ANSI, IEEE and others.

Related Products

Related Article

How to test a power transformer?

Power transformers need to undergo rigorous testing before they leave the factory and are installed to ensure that the transformers can operate safely and efficiently.

Canada 69kV Power Transformer Testing

After a meticulous 16-week production process, we are pleased to commence the factory testing phase for the transformer. At Daelim Transformers, we adhere to the highest industry standards, conducting comprehensive tests to ensure the utmost quality and performance of our products. Each project undergoes rigorous testing in accordance with the relevant standards set by IEEE and CSA.

How To Test a Transformer?

The purpose of the transformer test is to check whether the performance of the transformer meets the requirements of relevant regulations and technical standards. Whether there are defects or fault characteristics to determine whether it can be put into service after leaving the factory or after repair.

A Complete Guide on Transformer FAT Test

Transformer FAT (Factory Acceptance Test) ensures that transformers meet design specifications and international standards for safe, reliable, and efficient operation. It includes inspections and electrical tests like resistance, insulation, and voltage tests. Performed by the manufacturer, client, and sometimes third-party, FAT helps prevent failures, reduce maintenance costs, and ensure long-term reliability.

Transformer Calculation Table

Electric transformers are crucial for stepping voltage up or down in power distribution. Proper transformer calculations, considering consumer requirements and international design standards, are essential for accurate voltage regulation. Understanding transformer specifications, formulas, and sizing methods is key. The article provides examples and a calculation table to guide readers through the transformer design and selection process effectively.

How Much is a Transformer

Electrical transformers are essential for safe, reliable electricity in residential, industrial, and utility systems. Buyers must understand pricing, which depends on transformer type, application, and specifications. Proper budgeting requires knowing cost-driving factors, including design, capacity, and usage requirements, to ensure the right transformer is purchased for specific industrial, utility, or infrastructure needs.